Direct Lithium Extraction vs Solar Evaporation: Efficiency Analysis

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Technologies Background and Objectives

Lithium extraction technologies have evolved significantly over the past century, with two primary methodologies dominating the industry: traditional solar evaporation and the emerging direct lithium extraction (DLE) techniques. Solar evaporation, established in the 1950s, has been the cornerstone of lithium production from brine resources, particularly in the "Lithium Triangle" of South America. This process relies on natural evaporation of lithium-rich brines in large ponds over 12-24 months, resulting in lithium concentrations suitable for further processing.

The technological landscape began shifting in the early 2000s with increased research into more efficient extraction methods, driven by growing demand from the rechargeable battery sector. This demand acceleration, particularly from electric vehicle manufacturers, has highlighted the limitations of traditional extraction methods in terms of production speed, water consumption, and environmental impact.

Direct Lithium Extraction technologies represent the next generation of extraction methodologies, encompassing various approaches including adsorption, ion exchange, solvent extraction, and membrane processes. These technologies aim to reduce extraction time from months to hours while improving recovery rates from the typical 40-50% of solar evaporation to potentially over 90%.

The evolution of lithium extraction technologies reflects broader industry trends toward sustainability, efficiency, and scalability. As global lithium demand projections indicate a potential supply gap of 0.5-1.7 million tonnes by 2030, technological innovation in extraction processes has become critical to meeting market needs.

The primary objectives of current technological development include reducing water consumption (solar evaporation requires approximately 500,000 gallons per tonne of lithium), minimizing environmental footprint, increasing lithium recovery rates, and enabling extraction from lower-grade resources previously considered uneconomical.

Another significant goal is geographical diversification of lithium production. Currently, approximately 75% of global lithium resources are concentrated in the Lithium Triangle (Argentina, Bolivia, and Chile), creating supply chain vulnerabilities. Advanced extraction technologies could potentially unlock lithium resources in regions with less favorable conditions for solar evaporation, including North America and Europe.

The technological trajectory suggests a hybrid future where both traditional and advanced extraction methods coexist, with DLE technologies gradually gaining market share as they mature and demonstrate commercial viability at scale. This transition represents not merely an incremental improvement but a fundamental paradigm shift in how critical battery materials are sourced and processed.

The technological landscape began shifting in the early 2000s with increased research into more efficient extraction methods, driven by growing demand from the rechargeable battery sector. This demand acceleration, particularly from electric vehicle manufacturers, has highlighted the limitations of traditional extraction methods in terms of production speed, water consumption, and environmental impact.

Direct Lithium Extraction technologies represent the next generation of extraction methodologies, encompassing various approaches including adsorption, ion exchange, solvent extraction, and membrane processes. These technologies aim to reduce extraction time from months to hours while improving recovery rates from the typical 40-50% of solar evaporation to potentially over 90%.

The evolution of lithium extraction technologies reflects broader industry trends toward sustainability, efficiency, and scalability. As global lithium demand projections indicate a potential supply gap of 0.5-1.7 million tonnes by 2030, technological innovation in extraction processes has become critical to meeting market needs.

The primary objectives of current technological development include reducing water consumption (solar evaporation requires approximately 500,000 gallons per tonne of lithium), minimizing environmental footprint, increasing lithium recovery rates, and enabling extraction from lower-grade resources previously considered uneconomical.

Another significant goal is geographical diversification of lithium production. Currently, approximately 75% of global lithium resources are concentrated in the Lithium Triangle (Argentina, Bolivia, and Chile), creating supply chain vulnerabilities. Advanced extraction technologies could potentially unlock lithium resources in regions with less favorable conditions for solar evaporation, including North America and Europe.

The technological trajectory suggests a hybrid future where both traditional and advanced extraction methods coexist, with DLE technologies gradually gaining market share as they mature and demonstrate commercial viability at scale. This transition represents not merely an incremental improvement but a fundamental paradigm shift in how critical battery materials are sourced and processed.

Global Market Demand for Lithium Resources

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium has surged from approximately 200,000 metric tons of lithium carbonate equivalent (LCE) in 2016 to over 500,000 metric tons in 2022, with projections indicating a potential demand of 1.5 million metric tons by 2030.

This exponential growth trajectory is fundamentally reshaping the lithium extraction industry, creating urgent pressure to develop more efficient extraction technologies beyond traditional solar evaporation methods. The automotive sector represents the largest demand segment, accounting for roughly 80% of lithium consumption, primarily for battery production. Energy storage systems constitute the second-largest market segment at approximately 15%, with consumer electronics and other applications comprising the remainder.

Geographically, demand distribution has shifted significantly. While China remains the dominant consumer, accounting for approximately 40% of global lithium demand due to its massive battery manufacturing capacity, European demand has grown substantially following aggressive EV adoption policies. North American demand is accelerating rapidly as domestic battery production capacity expands in response to policy incentives and supply chain security concerns.

The price volatility in lithium markets further underscores the critical nature of extraction efficiency improvements. Lithium carbonate prices have fluctuated dramatically, reaching peaks of $80,000 per ton in 2022 before moderating. This volatility has intensified interest in Direct Lithium Extraction (DLE) technologies that can potentially stabilize supply chains through faster, more predictable production cycles compared to traditional solar evaporation.

Industry analysts project that the lithium supply gap could reach 700,000 metric tons by 2030 if extraction capacity does not significantly expand. This shortfall represents a critical challenge for the clean energy transition, potentially constraining EV production targets and grid-scale energy storage deployment. The supply-demand imbalance has catalyzed unprecedented investment in lithium extraction technologies, with venture capital funding for DLE startups exceeding $1 billion in 2022 alone.

The quality requirements for lithium are also evolving, with battery manufacturers demanding increasingly pure lithium products with consistent specifications. This trend favors extraction methods that can deliver higher purity outputs with less variability than traditional solar evaporation, which is subject to weather conditions and other environmental factors.

This exponential growth trajectory is fundamentally reshaping the lithium extraction industry, creating urgent pressure to develop more efficient extraction technologies beyond traditional solar evaporation methods. The automotive sector represents the largest demand segment, accounting for roughly 80% of lithium consumption, primarily for battery production. Energy storage systems constitute the second-largest market segment at approximately 15%, with consumer electronics and other applications comprising the remainder.

Geographically, demand distribution has shifted significantly. While China remains the dominant consumer, accounting for approximately 40% of global lithium demand due to its massive battery manufacturing capacity, European demand has grown substantially following aggressive EV adoption policies. North American demand is accelerating rapidly as domestic battery production capacity expands in response to policy incentives and supply chain security concerns.

The price volatility in lithium markets further underscores the critical nature of extraction efficiency improvements. Lithium carbonate prices have fluctuated dramatically, reaching peaks of $80,000 per ton in 2022 before moderating. This volatility has intensified interest in Direct Lithium Extraction (DLE) technologies that can potentially stabilize supply chains through faster, more predictable production cycles compared to traditional solar evaporation.

Industry analysts project that the lithium supply gap could reach 700,000 metric tons by 2030 if extraction capacity does not significantly expand. This shortfall represents a critical challenge for the clean energy transition, potentially constraining EV production targets and grid-scale energy storage deployment. The supply-demand imbalance has catalyzed unprecedented investment in lithium extraction technologies, with venture capital funding for DLE startups exceeding $1 billion in 2022 alone.

The quality requirements for lithium are also evolving, with battery manufacturers demanding increasingly pure lithium products with consistent specifications. This trend favors extraction methods that can deliver higher purity outputs with less variability than traditional solar evaporation, which is subject to weather conditions and other environmental factors.

DLE and Solar Evaporation: Current Status and Challenges

The global lithium extraction landscape is currently dominated by two primary methodologies: traditional solar evaporation and emerging Direct Lithium Extraction (DLE) technologies. Solar evaporation, accounting for approximately 60% of global production, remains the established method particularly in the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), where favorable climatic conditions support this approach.

Solar evaporation faces significant challenges despite its widespread adoption. The process requires extensive land use (typically 2,000 hectares per operation), consumes substantial water resources (500,000 gallons per ton of lithium), and operates on extended production timelines (12-24 months from brine extraction to lithium carbonate). These inefficiencies are increasingly problematic as global lithium demand accelerates, projected to reach 1.5 million metric tons of lithium carbonate equivalent (LCE) by 2030.

Environmental concerns present additional challenges for solar evaporation, including disruption of local ecosystems, alteration of water tables, and potential contamination of freshwater resources. These issues have intensified regulatory scrutiny and community opposition in key production regions, particularly in Chile's Atacama Desert where indigenous communities have raised concerns about water rights.

DLE technologies represent the emerging alternative, with over 60 distinct technological approaches currently under development globally. These technologies promise significant improvements: reduced land footprint (80-90% smaller than evaporation ponds), dramatically shortened production timelines (hours to days rather than months), and improved recovery rates (potentially exceeding 90% compared to 50% for solar evaporation).

Despite these advantages, DLE faces its own set of challenges. High energy requirements remain a significant barrier, with most DLE processes consuming 5-15 times more energy than solar evaporation. Water usage efficiency varies widely across different DLE technologies, with some requiring substantial freshwater for processing. Additionally, the selective extraction of lithium from complex brine chemistries continues to present technical difficulties.

The geographical distribution of lithium extraction technologies shows interesting patterns. While solar evaporation dominates in South America, DLE development is concentrated in North America, Europe, and East Asia. China has made significant investments in both approaches, securing its position as the leading processor of lithium globally regardless of extraction method.

Commercial scalability remains the primary challenge for DLE technologies. While numerous pilot projects have demonstrated technical feasibility, only a handful have achieved commercial-scale operations. The capital expenditure requirements for DLE facilities, though potentially lower per unit of production than solar evaporation, represent a significant barrier to widespread adoption in an industry traditionally resistant to technological disruption.

Solar evaporation faces significant challenges despite its widespread adoption. The process requires extensive land use (typically 2,000 hectares per operation), consumes substantial water resources (500,000 gallons per ton of lithium), and operates on extended production timelines (12-24 months from brine extraction to lithium carbonate). These inefficiencies are increasingly problematic as global lithium demand accelerates, projected to reach 1.5 million metric tons of lithium carbonate equivalent (LCE) by 2030.

Environmental concerns present additional challenges for solar evaporation, including disruption of local ecosystems, alteration of water tables, and potential contamination of freshwater resources. These issues have intensified regulatory scrutiny and community opposition in key production regions, particularly in Chile's Atacama Desert where indigenous communities have raised concerns about water rights.

DLE technologies represent the emerging alternative, with over 60 distinct technological approaches currently under development globally. These technologies promise significant improvements: reduced land footprint (80-90% smaller than evaporation ponds), dramatically shortened production timelines (hours to days rather than months), and improved recovery rates (potentially exceeding 90% compared to 50% for solar evaporation).

Despite these advantages, DLE faces its own set of challenges. High energy requirements remain a significant barrier, with most DLE processes consuming 5-15 times more energy than solar evaporation. Water usage efficiency varies widely across different DLE technologies, with some requiring substantial freshwater for processing. Additionally, the selective extraction of lithium from complex brine chemistries continues to present technical difficulties.

The geographical distribution of lithium extraction technologies shows interesting patterns. While solar evaporation dominates in South America, DLE development is concentrated in North America, Europe, and East Asia. China has made significant investments in both approaches, securing its position as the leading processor of lithium globally regardless of extraction method.

Commercial scalability remains the primary challenge for DLE technologies. While numerous pilot projects have demonstrated technical feasibility, only a handful have achieved commercial-scale operations. The capital expenditure requirements for DLE facilities, though potentially lower per unit of production than solar evaporation, represent a significant barrier to widespread adoption in an industry traditionally resistant to technological disruption.

Comparative Analysis of DLE and Solar Evaporation Techniques

01 Direct Lithium Extraction (DLE) Technologies

Direct Lithium Extraction technologies offer more efficient alternatives to traditional evaporation methods. These technologies typically use selective adsorption, ion exchange resins, or membranes to extract lithium directly from brines. DLE methods can significantly reduce processing time from months to days or hours, while achieving higher lithium recovery rates. These processes are generally less dependent on climate conditions and require smaller land footprints compared to solar evaporation.- Direct Lithium Extraction (DLE) Technologies: Direct Lithium Extraction technologies offer more efficient alternatives to traditional evaporation methods. These technologies typically use selective adsorption, ion exchange resins, or membrane processes to extract lithium directly from brines. DLE methods can significantly reduce processing time from months to days or hours, while also improving lithium recovery rates. These technologies generally require less land area and water consumption compared to solar evaporation methods, making them more environmentally sustainable.

- Solar Evaporation Efficiency Improvements: Traditional solar evaporation methods for lithium extraction have been enhanced through various technological improvements. These include optimized pond designs, advanced monitoring systems, and improved brine circulation techniques. Enhanced evaporation systems may incorporate additional heating elements or reflective surfaces to accelerate the natural evaporation process. While still requiring significant land area and time, these improvements have increased lithium recovery rates and reduced overall processing time compared to conventional solar evaporation methods.

- Hybrid Extraction Systems: Hybrid lithium extraction systems combine elements of both solar evaporation and direct extraction technologies to maximize efficiency. These systems typically use solar evaporation for initial concentration of brines, followed by direct extraction methods for final lithium recovery. This approach leverages the low operational costs of solar evaporation while addressing its time inefficiencies through selective extraction technologies. Hybrid systems can achieve higher recovery rates while reducing water consumption and environmental impact compared to traditional methods.

- Energy Efficiency in Lithium Extraction: Energy consumption is a critical factor in determining the overall efficiency of lithium extraction methods. While solar evaporation relies primarily on natural energy sources, it requires extensive land use and has low recovery rates. Direct extraction methods typically have higher energy requirements but significantly improved recovery rates and processing times. Recent innovations focus on reducing energy consumption in DLE through improved materials, optimized process designs, and integration of renewable energy sources to power extraction operations.

- Environmental Impact and Sustainability Metrics: The efficiency of lithium extraction methods is increasingly measured not only by recovery rates but also by environmental sustainability metrics. These include water consumption, land use, chemical usage, and carbon footprint. Direct Lithium Extraction typically offers advantages in water conservation and land use compared to solar evaporation. Advanced extraction technologies incorporate closed-loop water systems, reduced chemical consumption, and minimized waste generation to improve overall sustainability while maintaining high lithium recovery efficiency.

02 Solar Evaporation Methods and Efficiency

Solar evaporation is a traditional method for lithium extraction that relies on natural sunlight to evaporate water from brine solutions in large ponds, concentrating the lithium content. While this method has low operational costs, it typically has lower efficiency with recovery rates of 30-50%, requires large land areas, and is highly dependent on climate conditions. The process can take 12-18 months to complete a production cycle, making it significantly slower than newer DLE technologies.Expand Specific Solutions03 Hybrid Extraction Systems

Hybrid lithium extraction systems combine elements of both solar evaporation and direct extraction technologies to optimize efficiency and reduce environmental impact. These systems typically use pre-concentration via solar evaporation followed by direct extraction methods, or employ energy-efficient technologies to accelerate the evaporation process. Hybrid approaches can achieve higher recovery rates than traditional solar evaporation while maintaining lower energy consumption than some DLE methods.Expand Specific Solutions04 Environmental Impact and Sustainability Considerations

The environmental impact of lithium extraction methods varies significantly between technologies. Solar evaporation requires extensive land use and substantial water consumption, while some DLE technologies offer reduced water usage and smaller physical footprints. Advanced extraction methods are being developed to minimize freshwater consumption, reduce chemical usage, and enable the recycling of process water. Sustainable approaches also focus on reducing carbon emissions associated with the extraction process through renewable energy integration.Expand Specific Solutions05 Efficiency Enhancements and Technological Innovations

Recent technological innovations have significantly improved the efficiency of lithium extraction processes. These include advanced membrane technologies, selective sorbents with higher lithium selectivity, electrochemical systems, and process optimization through AI and automation. Innovations focus on increasing lithium recovery rates, reducing processing time, minimizing reagent consumption, and enabling extraction from lower-grade resources. Some newer technologies can achieve recovery rates above 90% while reducing water and energy requirements.Expand Specific Solutions

Key Industry Players in Lithium Extraction Market

Direct Lithium Extraction (DLE) technology is disrupting the traditional solar evaporation method in the lithium extraction market, which is currently in a growth phase with increasing demand from battery manufacturers. The global lithium market is projected to expand significantly, driven by electric vehicle adoption and renewable energy storage needs. DLE technologies offer higher efficiency, reduced water consumption, and faster extraction times compared to traditional methods. Companies like Energy Exploration Technologies, International Battery Metals, and Schlumberger are leading DLE innovation, while established players such as POSCO Holdings and Saudi Aramco are investing heavily in this space. Academic institutions including The University of Manchester and Xi'an Jiaotong University are advancing research in this field. The technology is approaching commercial maturity with several pilot plants operational, though widespread adoption faces economic and technical challenges.

Energy Exploration Technologies, Inc.

Technical Solution: Energy Exploration Technologies (EnergyX) has developed a proprietary Direct Lithium Extraction (DLE) technology called LiTAS™ (Lithium Ion Transport and Separation). This platform utilizes advanced membrane technology and metal-organic frameworks (MOFs) to selectively extract lithium ions from brine solutions. The LiTAS™ system employs a solid-state electrolyte membrane that allows for highly selective lithium ion transport while blocking other elements. EnergyX's approach can extract lithium directly from brine resources with reported efficiency rates of over 90% in 24-48 hours, compared to traditional evaporation methods that take 18-24 months and recover only 30-40% of available lithium. The technology operates as a continuous flow system that can process brines regardless of weather conditions or geographical limitations, significantly reducing water consumption by up to 90% compared to evaporation ponds.

Strengths: High lithium recovery rates (>90%), dramatically reduced processing time, minimal water consumption, and ability to operate in various climatic conditions. The technology is also modular and scalable, allowing for flexible deployment. Weaknesses: Requires significant initial capital investment, has limited commercial-scale implementation history, and may face challenges with membrane fouling in high-impurity brines.

International Battery Metals Ltd.

Technical Solution: International Battery Metals (IBAT) has engineered an advanced modular Direct Lithium Extraction (DLE) technology that utilizes selective absorption materials to extract lithium from various brine sources. Their patented system employs a proprietary selective absorption process that can extract lithium chloride from brines with minimal pre-treatment requirements. IBAT's technology features a mobile, modular plant design that can be deployed rapidly and scaled according to resource requirements. The system operates as a closed-loop process that returns over 98% of the processed brine back to its source, minimizing environmental impact. According to company reports, their DLE technology can achieve lithium recovery rates of approximately 90% while reducing water consumption by over 90% compared to traditional evaporation methods. The process can extract lithium in hours rather than months, with the ability to produce battery-grade lithium chloride directly at the brine source location.

Strengths: Highly mobile and modular design allows for rapid deployment and scalability; near-complete brine return to source (>98%) minimizes environmental footprint; high lithium recovery rates with minimal water loss; and significantly accelerated extraction timeframe. Weaknesses: Technology is still being proven at commercial scale; may have higher operational costs than traditional methods; and performance may vary depending on specific brine chemistry and impurity profiles.

Critical Patents and Innovations in Lithium Extraction

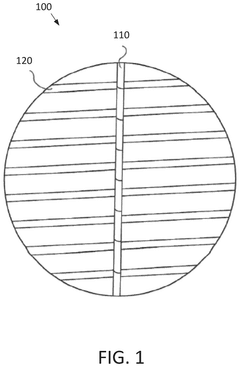

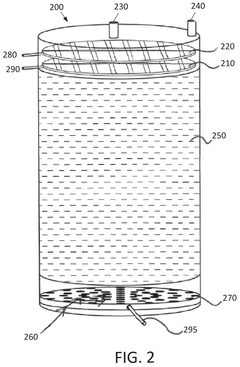

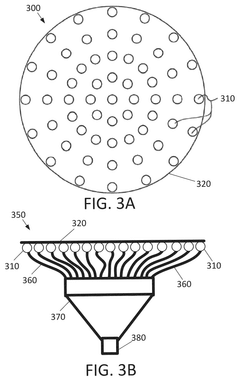

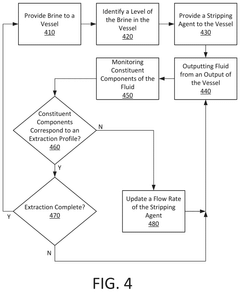

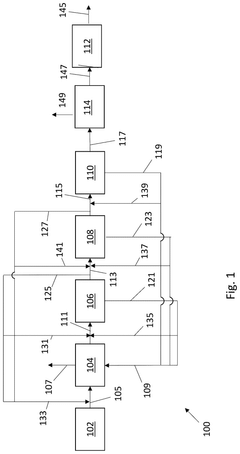

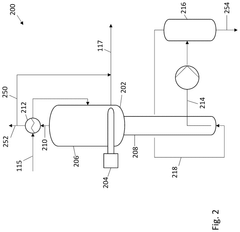

Ion extraction column for brine

PatentPendingUS20250092490A1

Innovation

- A method and apparatus for direct lithium extraction (DLE) using a porous media bed with a uniform extractant material that absorbs target ions like lithium, followed by a stripping solution to separate and regenerate the extractant, maintaining a sharp interface between brine and stripping solution to maximize extraction efficiency.

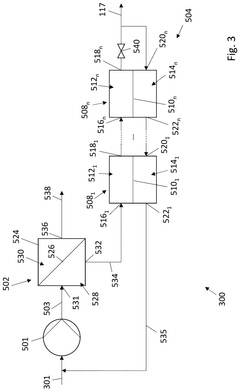

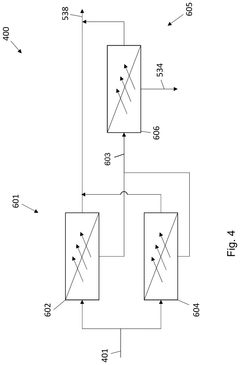

Method of recovering lithium from a lithium source

PatentPendingUS20250177923A1

Innovation

- The method involves direct lithium extraction using techniques such as electrochemical separation, solvent extraction, ion withdrawal, or membrane separation, followed by purification, concentration, and removal of monovalent impurities to yield a purified lithium concentrate.

Environmental Impact Assessment of Extraction Methods

The environmental footprint of lithium extraction methods represents a critical factor in evaluating their overall sustainability and long-term viability. Solar evaporation, the traditional method employed for decades, creates significant environmental challenges despite its simplicity. These operations typically consume between 500,000 to 2 million gallons of water per ton of lithium produced, exacerbating water scarcity in already arid regions like Chile's Atacama Desert, Argentina's Salar de Olaroz, and Bolivia's Salar de Uyuni.

Solar evaporation also disrupts local ecosystems through the construction of extensive evaporation pond networks that fragment habitats and alter natural hydrological systems. The process creates imbalances in local water tables, potentially affecting surrounding communities and indigenous populations who depend on these water resources for agriculture and daily consumption.

In contrast, Direct Lithium Extraction (DLE) technologies demonstrate substantially reduced environmental impacts across several key metrics. Water consumption in DLE systems can be reduced by 50-90% compared to traditional methods, with some advanced systems achieving closed-loop water recycling that returns up to 90% of process water back to source aquifers. This represents a transformative improvement in regions where water conservation is paramount.

Land disturbance metrics similarly favor DLE approaches, which typically require 50-75% less surface area than equivalent solar evaporation operations. This reduced footprint minimizes habitat disruption and preserves natural landscapes. Additionally, DLE facilities can be designed with significantly smaller physical footprints, often occupying less than 10% of the land area required by traditional evaporation pond systems.

Carbon emissions analyses reveal that while both methods contribute to greenhouse gas production, DLE technologies offer pathways to lower overall emissions through integration with renewable energy sources and more efficient processing cycles. Several pilot DLE projects have demonstrated carbon footprint reductions of 30-60% compared to conventional methods when powered by renewable energy sources.

Chemical usage presents a more complex environmental tradeoff. DLE methods typically employ selective adsorbents, ion exchange resins, or specialized membranes that require periodic regeneration with chemical solutions. While these chemicals introduce potential contamination risks, advanced DLE systems incorporate sophisticated containment and treatment protocols that minimize discharge risks.

Recovery timelines also favor DLE approaches, as disturbed ecosystems from solar evaporation operations may require decades for natural rehabilitation, whereas DLE facilities can be decommissioned with substantially less long-term environmental impact and faster ecosystem recovery potential.

Solar evaporation also disrupts local ecosystems through the construction of extensive evaporation pond networks that fragment habitats and alter natural hydrological systems. The process creates imbalances in local water tables, potentially affecting surrounding communities and indigenous populations who depend on these water resources for agriculture and daily consumption.

In contrast, Direct Lithium Extraction (DLE) technologies demonstrate substantially reduced environmental impacts across several key metrics. Water consumption in DLE systems can be reduced by 50-90% compared to traditional methods, with some advanced systems achieving closed-loop water recycling that returns up to 90% of process water back to source aquifers. This represents a transformative improvement in regions where water conservation is paramount.

Land disturbance metrics similarly favor DLE approaches, which typically require 50-75% less surface area than equivalent solar evaporation operations. This reduced footprint minimizes habitat disruption and preserves natural landscapes. Additionally, DLE facilities can be designed with significantly smaller physical footprints, often occupying less than 10% of the land area required by traditional evaporation pond systems.

Carbon emissions analyses reveal that while both methods contribute to greenhouse gas production, DLE technologies offer pathways to lower overall emissions through integration with renewable energy sources and more efficient processing cycles. Several pilot DLE projects have demonstrated carbon footprint reductions of 30-60% compared to conventional methods when powered by renewable energy sources.

Chemical usage presents a more complex environmental tradeoff. DLE methods typically employ selective adsorbents, ion exchange resins, or specialized membranes that require periodic regeneration with chemical solutions. While these chemicals introduce potential contamination risks, advanced DLE systems incorporate sophisticated containment and treatment protocols that minimize discharge risks.

Recovery timelines also favor DLE approaches, as disturbed ecosystems from solar evaporation operations may require decades for natural rehabilitation, whereas DLE facilities can be decommissioned with substantially less long-term environmental impact and faster ecosystem recovery potential.

Economic Viability and ROI Analysis

The economic analysis of Direct Lithium Extraction (DLE) versus traditional Solar Evaporation reveals significant differences in capital expenditure, operational costs, and return on investment profiles. Initial investment for DLE technologies typically ranges from $20-30 million for small to medium-scale operations, compared to $15-25 million for equivalent solar evaporation facilities. However, this higher upfront cost for DLE is offset by substantially reduced production timeframes.

Solar evaporation operations generally require 18-24 months to achieve first production, with full capacity reached only after 3-5 years. In contrast, DLE facilities can begin production within 6-12 months and reach full capacity within 18 months. This acceleration translates to earlier revenue generation, significantly improving project NPV calculations by an estimated 15-25% when comparing equivalent production capacities.

Operational expenditure analysis demonstrates that while DLE requires higher energy inputs (approximately 2-4 kWh per kilogram of lithium produced), it achieves lower water consumption (averaging 5-10 cubic meters per ton versus 500-1,000 cubic meters for evaporation). Labor costs tend to be 10-15% higher for DLE due to the technical expertise required, but land acquisition and preparation costs are substantially lower, requiring only 10-20% of the land area needed for evaporation ponds.

Recovery rates represent perhaps the most compelling economic advantage for DLE, achieving 80-95% lithium recovery compared to 40-50% for traditional methods. This efficiency differential dramatically improves resource utilization economics, particularly as lithium prices remain elevated in global markets.

ROI calculations indicate that DLE projects typically achieve payback periods of 3-5 years versus 5-8 years for solar evaporation, assuming current lithium carbonate prices of $15,000-25,000 per ton. Sensitivity analysis reveals that DLE economics become increasingly favorable as lithium prices rise, with the breakeven advantage occurring at approximately $12,000 per ton under current technology parameters.

Environmental compliance costs further enhance DLE's economic profile, as regulatory requirements for water usage and land disturbance continue to strengthen globally. These factors typically add 5-10% to operational costs for solar evaporation projects but remain minimal for DLE operations due to their smaller physical footprint and reduced environmental impact.

The scalability economics also favor DLE, with modular expansion capabilities allowing for incremental capacity increases that can be matched to market demand with lower financial risk compared to the large-scale infrastructure commitments required for expanding evaporation operations.

Solar evaporation operations generally require 18-24 months to achieve first production, with full capacity reached only after 3-5 years. In contrast, DLE facilities can begin production within 6-12 months and reach full capacity within 18 months. This acceleration translates to earlier revenue generation, significantly improving project NPV calculations by an estimated 15-25% when comparing equivalent production capacities.

Operational expenditure analysis demonstrates that while DLE requires higher energy inputs (approximately 2-4 kWh per kilogram of lithium produced), it achieves lower water consumption (averaging 5-10 cubic meters per ton versus 500-1,000 cubic meters for evaporation). Labor costs tend to be 10-15% higher for DLE due to the technical expertise required, but land acquisition and preparation costs are substantially lower, requiring only 10-20% of the land area needed for evaporation ponds.

Recovery rates represent perhaps the most compelling economic advantage for DLE, achieving 80-95% lithium recovery compared to 40-50% for traditional methods. This efficiency differential dramatically improves resource utilization economics, particularly as lithium prices remain elevated in global markets.

ROI calculations indicate that DLE projects typically achieve payback periods of 3-5 years versus 5-8 years for solar evaporation, assuming current lithium carbonate prices of $15,000-25,000 per ton. Sensitivity analysis reveals that DLE economics become increasingly favorable as lithium prices rise, with the breakeven advantage occurring at approximately $12,000 per ton under current technology parameters.

Environmental compliance costs further enhance DLE's economic profile, as regulatory requirements for water usage and land disturbance continue to strengthen globally. These factors typically add 5-10% to operational costs for solar evaporation projects but remain minimal for DLE operations due to their smaller physical footprint and reduced environmental impact.

The scalability economics also favor DLE, with modular expansion capabilities allowing for incremental capacity increases that can be matched to market demand with lower financial risk compared to the large-scale infrastructure commitments required for expanding evaporation operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!