Durability Testing of AGM Batteries in High-Vibration Environments

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in battery technology, particularly in applications requiring high performance under demanding conditions. AGM batteries emerged in the 1980s as a response to the limitations of traditional flooded lead-acid batteries, offering improved safety, reliability, and performance.

Initially developed for military aircraft, AGM batteries quickly found applications in various industries due to their unique construction. The key innovation lies in the use of a fiberglass mat separator that absorbs and immobilizes the electrolyte, allowing for a spill-proof and maintenance-free design. This construction also enables higher charge and discharge rates, making AGM batteries particularly suitable for high-vibration environments.

Throughout the 1990s and early 2000s, AGM battery technology continued to evolve, with manufacturers focusing on improving energy density, cycle life, and overall durability. The introduction of thinner plates and more efficient electrode designs allowed for higher power output and faster recharge capabilities. These advancements made AGM batteries increasingly attractive for automotive applications, particularly in start-stop systems and vehicles with high electrical demands.

In the context of high-vibration environments, the evolution of AGM batteries has been particularly noteworthy. Engineers have worked to enhance the internal structure of these batteries, developing more robust plate designs and improved compression techniques to withstand intense vibration without compromising performance. The use of advanced materials in separators and plate grids has further contributed to the batteries' resilience in challenging conditions.

Recent years have seen a focus on optimizing AGM batteries for specific applications, including those involving extreme vibration. This has led to the development of specialized AGM variants designed to meet the rigorous demands of military vehicles, construction equipment, and off-road applications. These batteries often feature reinforced casings, enhanced internal support structures, and vibration-resistant plate designs.

The ongoing evolution of AGM battery technology has also been driven by the need for improved environmental performance. Manufacturers have made significant strides in increasing the recyclability of AGM batteries and reducing their environmental impact. This has included the development of more efficient recycling processes and the use of more environmentally friendly materials in battery construction.

As the demand for reliable energy storage solutions in high-vibration environments continues to grow, the evolution of AGM batteries is likely to accelerate. Future developments may include the integration of smart monitoring systems to provide real-time performance data and predictive maintenance capabilities, further enhancing the reliability and longevity of these batteries in challenging applications.

Initially developed for military aircraft, AGM batteries quickly found applications in various industries due to their unique construction. The key innovation lies in the use of a fiberglass mat separator that absorbs and immobilizes the electrolyte, allowing for a spill-proof and maintenance-free design. This construction also enables higher charge and discharge rates, making AGM batteries particularly suitable for high-vibration environments.

Throughout the 1990s and early 2000s, AGM battery technology continued to evolve, with manufacturers focusing on improving energy density, cycle life, and overall durability. The introduction of thinner plates and more efficient electrode designs allowed for higher power output and faster recharge capabilities. These advancements made AGM batteries increasingly attractive for automotive applications, particularly in start-stop systems and vehicles with high electrical demands.

In the context of high-vibration environments, the evolution of AGM batteries has been particularly noteworthy. Engineers have worked to enhance the internal structure of these batteries, developing more robust plate designs and improved compression techniques to withstand intense vibration without compromising performance. The use of advanced materials in separators and plate grids has further contributed to the batteries' resilience in challenging conditions.

Recent years have seen a focus on optimizing AGM batteries for specific applications, including those involving extreme vibration. This has led to the development of specialized AGM variants designed to meet the rigorous demands of military vehicles, construction equipment, and off-road applications. These batteries often feature reinforced casings, enhanced internal support structures, and vibration-resistant plate designs.

The ongoing evolution of AGM battery technology has also been driven by the need for improved environmental performance. Manufacturers have made significant strides in increasing the recyclability of AGM batteries and reducing their environmental impact. This has included the development of more efficient recycling processes and the use of more environmentally friendly materials in battery construction.

As the demand for reliable energy storage solutions in high-vibration environments continues to grow, the evolution of AGM batteries is likely to accelerate. Future developments may include the integration of smart monitoring systems to provide real-time performance data and predictive maintenance capabilities, further enhancing the reliability and longevity of these batteries in challenging applications.

Market Demand Analysis

The market demand for durable AGM (Absorbent Glass Mat) batteries in high-vibration environments has been steadily increasing across various industries. This growth is primarily driven by the expanding applications in automotive, aerospace, marine, and industrial sectors where equipment is subjected to constant vibration and shock.

In the automotive industry, there is a rising need for robust battery solutions in commercial vehicles, off-road equipment, and performance cars. These vehicles often operate in harsh conditions, requiring batteries that can withstand severe vibrations without compromising performance or lifespan. The global commercial vehicle market, a key driver for this demand, is projected to grow significantly in the coming years, further boosting the need for vibration-resistant AGM batteries.

The aerospace sector presents another substantial market for high-durability AGM batteries. With the increasing number of commercial flights and the growing satellite industry, there is a constant demand for reliable power sources that can endure the extreme vibrations experienced during takeoff, flight, and landing. The space industry, in particular, requires batteries that can withstand the intense vibrations of rocket launches while maintaining optimal performance in zero-gravity environments.

In the marine industry, AGM batteries are becoming increasingly popular due to their ability to withstand the constant motion and vibration of boats and ships. As the global shipping industry continues to expand and recreational boating gains popularity, the demand for durable AGM batteries is expected to rise correspondingly.

The industrial sector, including manufacturing and construction, also contributes significantly to the market demand. Heavy machinery and equipment used in these industries often operate in high-vibration environments, necessitating battery solutions that can maintain reliability under such conditions. The ongoing trend of industrial automation and the adoption of electric forklifts and other material handling equipment further drive the need for vibration-resistant AGM batteries.

Moreover, the growing focus on renewable energy systems, particularly in remote or off-grid locations, has created a new market segment for durable AGM batteries. These batteries are often used in wind turbines and solar panel installations, where they must withstand environmental vibrations while providing consistent power storage and delivery.

The increasing emphasis on sustainability and environmental regulations is also influencing market demand. AGM batteries, known for their sealed design and recyclability, align well with these concerns, making them an attractive option for environmentally conscious consumers and businesses alike.

In conclusion, the market demand for AGM batteries capable of withstanding high-vibration environments is robust and diverse, spanning multiple industries and applications. As technology advances and the need for reliable power sources in challenging conditions grows, this market segment is poised for continued expansion in the foreseeable future.

In the automotive industry, there is a rising need for robust battery solutions in commercial vehicles, off-road equipment, and performance cars. These vehicles often operate in harsh conditions, requiring batteries that can withstand severe vibrations without compromising performance or lifespan. The global commercial vehicle market, a key driver for this demand, is projected to grow significantly in the coming years, further boosting the need for vibration-resistant AGM batteries.

The aerospace sector presents another substantial market for high-durability AGM batteries. With the increasing number of commercial flights and the growing satellite industry, there is a constant demand for reliable power sources that can endure the extreme vibrations experienced during takeoff, flight, and landing. The space industry, in particular, requires batteries that can withstand the intense vibrations of rocket launches while maintaining optimal performance in zero-gravity environments.

In the marine industry, AGM batteries are becoming increasingly popular due to their ability to withstand the constant motion and vibration of boats and ships. As the global shipping industry continues to expand and recreational boating gains popularity, the demand for durable AGM batteries is expected to rise correspondingly.

The industrial sector, including manufacturing and construction, also contributes significantly to the market demand. Heavy machinery and equipment used in these industries often operate in high-vibration environments, necessitating battery solutions that can maintain reliability under such conditions. The ongoing trend of industrial automation and the adoption of electric forklifts and other material handling equipment further drive the need for vibration-resistant AGM batteries.

Moreover, the growing focus on renewable energy systems, particularly in remote or off-grid locations, has created a new market segment for durable AGM batteries. These batteries are often used in wind turbines and solar panel installations, where they must withstand environmental vibrations while providing consistent power storage and delivery.

The increasing emphasis on sustainability and environmental regulations is also influencing market demand. AGM batteries, known for their sealed design and recyclability, align well with these concerns, making them an attractive option for environmentally conscious consumers and businesses alike.

In conclusion, the market demand for AGM batteries capable of withstanding high-vibration environments is robust and diverse, spanning multiple industries and applications. As technology advances and the need for reliable power sources in challenging conditions grows, this market segment is poised for continued expansion in the foreseeable future.

Vibration Challenges

Vibration poses significant challenges for AGM (Absorbent Glass Mat) batteries in high-vibration environments, particularly in automotive, marine, and industrial applications. These challenges stem from the battery's internal structure and the nature of vibration forces, which can lead to various forms of degradation and failure.

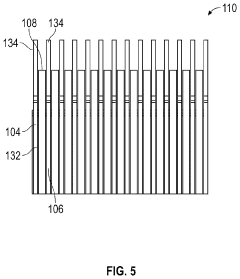

One of the primary concerns is the potential for mechanical damage to the battery's internal components. Constant vibration can cause the glass mat separators to wear down or shift, leading to short circuits between positive and negative plates. This not only reduces the battery's capacity but can also result in premature failure or, in extreme cases, safety hazards.

The electrolyte distribution within AGM batteries is another critical factor affected by vibration. Unlike flooded lead-acid batteries, AGM batteries rely on the glass mat to hold the electrolyte in place. Excessive vibration can disrupt this delicate balance, causing uneven electrolyte distribution and potentially dry areas within the battery. This uneven distribution can lead to localized areas of increased temperature and accelerated degradation of the active material on the plates.

Vibration also impacts the battery's plate structure. The constant movement can cause the active material to shed from the plates, reducing the battery's overall capacity and lifespan. In severe cases, this shedding can accumulate at the bottom of the battery, potentially causing short circuits or blocking electrolyte pathways.

The connection points within the battery, such as inter-cell connectors and terminal posts, are particularly vulnerable to vibration-induced stress. Over time, these connections may loosen or develop micro-fractures, increasing internal resistance and potentially leading to connection failures. This can result in intermittent power supply issues or complete battery failure.

Furthermore, vibration can exacerbate other environmental stressors on AGM batteries. For instance, in applications where temperature fluctuations are common, the combined effect of thermal cycling and vibration can accelerate the breakdown of internal components and seals, potentially leading to electrolyte leakage or ingress of contaminants.

The frequency and amplitude of vibration also play crucial roles in determining the extent of these challenges. Different applications expose batteries to varying vibration profiles, from low-frequency, high-amplitude vibrations in off-road vehicles to high-frequency, low-amplitude vibrations in industrial machinery. Each profile presents unique challenges that must be addressed in the battery design and testing processes.

Addressing these vibration challenges requires a multifaceted approach, including advanced battery design, robust manufacturing processes, and comprehensive testing protocols. Innovations in materials science, such as improved separator technologies and more resilient plate structures, are essential for enhancing AGM battery durability in high-vibration environments.

One of the primary concerns is the potential for mechanical damage to the battery's internal components. Constant vibration can cause the glass mat separators to wear down or shift, leading to short circuits between positive and negative plates. This not only reduces the battery's capacity but can also result in premature failure or, in extreme cases, safety hazards.

The electrolyte distribution within AGM batteries is another critical factor affected by vibration. Unlike flooded lead-acid batteries, AGM batteries rely on the glass mat to hold the electrolyte in place. Excessive vibration can disrupt this delicate balance, causing uneven electrolyte distribution and potentially dry areas within the battery. This uneven distribution can lead to localized areas of increased temperature and accelerated degradation of the active material on the plates.

Vibration also impacts the battery's plate structure. The constant movement can cause the active material to shed from the plates, reducing the battery's overall capacity and lifespan. In severe cases, this shedding can accumulate at the bottom of the battery, potentially causing short circuits or blocking electrolyte pathways.

The connection points within the battery, such as inter-cell connectors and terminal posts, are particularly vulnerable to vibration-induced stress. Over time, these connections may loosen or develop micro-fractures, increasing internal resistance and potentially leading to connection failures. This can result in intermittent power supply issues or complete battery failure.

Furthermore, vibration can exacerbate other environmental stressors on AGM batteries. For instance, in applications where temperature fluctuations are common, the combined effect of thermal cycling and vibration can accelerate the breakdown of internal components and seals, potentially leading to electrolyte leakage or ingress of contaminants.

The frequency and amplitude of vibration also play crucial roles in determining the extent of these challenges. Different applications expose batteries to varying vibration profiles, from low-frequency, high-amplitude vibrations in off-road vehicles to high-frequency, low-amplitude vibrations in industrial machinery. Each profile presents unique challenges that must be addressed in the battery design and testing processes.

Addressing these vibration challenges requires a multifaceted approach, including advanced battery design, robust manufacturing processes, and comprehensive testing protocols. Innovations in materials science, such as improved separator technologies and more resilient plate structures, are essential for enhancing AGM battery durability in high-vibration environments.

Current Solutions

01 Improved electrolyte composition

Enhancing the durability of AGM batteries through advanced electrolyte formulations. These compositions may include additives or modified chemical structures that reduce acid stratification, minimize grid corrosion, and extend the overall lifespan of the battery.- Improved electrode design for AGM batteries: Enhancing the durability of AGM batteries through advanced electrode designs. This includes optimizing the structure, material composition, and manufacturing processes of electrodes to improve their longevity and performance under various operating conditions.

- Electrolyte management systems: Implementing sophisticated electrolyte management systems to maintain optimal electrolyte levels and distribution within AGM batteries. These systems help prevent dry-out, reduce stratification, and ensure consistent performance over the battery's lifespan.

- Thermal management solutions: Developing effective thermal management solutions to regulate battery temperature during operation and charging. This includes innovative cooling systems and heat-resistant materials to prevent thermal runaway and extend battery life in extreme conditions.

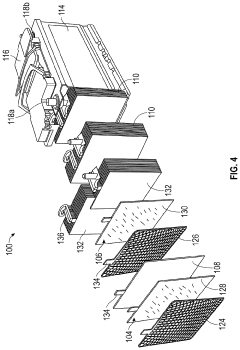

- Advanced separator technology: Utilizing advanced separator materials and designs to improve the overall durability of AGM batteries. These separators enhance acid retention, prevent short circuits, and maintain consistent performance throughout the battery's lifecycle.

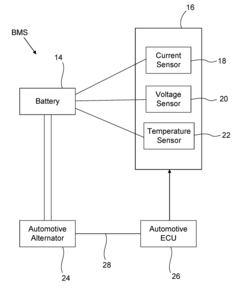

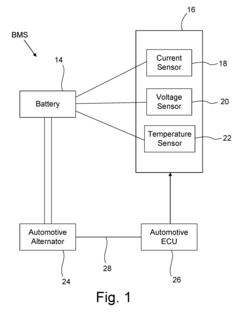

- Smart battery management systems: Integrating intelligent battery management systems that monitor and optimize charging, discharging, and overall battery health. These systems use advanced algorithms and sensors to extend battery life, prevent overcharging, and provide real-time diagnostics.

02 Optimized plate design and materials

Developing innovative plate designs and materials to improve the durability of AGM batteries. This may involve using advanced alloys, optimizing grid structures, or incorporating nano-materials to enhance charge/discharge efficiency and reduce degradation over time.Expand Specific Solutions03 Enhanced separator technology

Implementing advanced separator technologies to improve AGM battery durability. This includes developing high-performance glass fiber mats or composite separators that better retain electrolyte, prevent short circuits, and maintain consistent performance throughout the battery's life cycle.Expand Specific Solutions04 Thermal management systems

Integrating effective thermal management systems to regulate battery temperature and prevent degradation caused by extreme heat or cold. This may involve innovative cooling mechanisms or insulation techniques to maintain optimal operating conditions and extend battery life.Expand Specific Solutions05 Smart charging and monitoring systems

Implementing intelligent charging and monitoring systems to optimize the charging process and prevent overcharging or deep discharging. These systems may use advanced algorithms to adapt charging patterns based on battery condition and usage, thereby extending the overall lifespan of AGM batteries.Expand Specific Solutions

Key Industry Players

The durability testing of AGM batteries in high-vibration environments is a niche but critical area within the broader battery industry. The market is in a growth phase, driven by increasing demand for reliable energy storage in automotive, aerospace, and industrial applications. The global AGM battery market size is projected to expand significantly in the coming years, with a focus on enhancing performance in challenging conditions. Technologically, the field is moderately mature, with ongoing innovations from key players like Fengfan Co., Ltd., LG Energy Solution Ltd., and Contemporary Amperex Technology Co., Ltd. These companies are investing in research and development to improve battery resilience and longevity under extreme vibration, pushing the boundaries of current AGM technology.

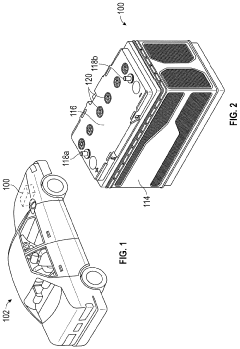

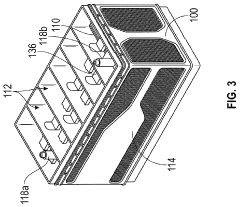

Stryten Energy LLC

Technical Solution: Stryten Energy has developed advanced AGM (Absorbed Glass Mat) batteries specifically designed for high-vibration environments. Their technology incorporates reinforced plate structures and specialized glass mat separators to enhance durability. The company utilizes a proprietary vibration testing protocol that simulates extreme conditions, including those found in heavy-duty vehicles and industrial equipment. Their batteries undergo rigorous testing, including accelerated life cycle tests under various vibration frequencies and amplitudes[1]. Stryten's AGM batteries feature a valve-regulated design that prevents electrolyte leakage and allows for flexible mounting orientations, crucial for applications in high-vibration settings[2].

Strengths: Specialized design for high-vibration environments, comprehensive testing protocols, and flexible mounting options. Weaknesses: Potentially higher cost due to specialized construction and limited data on long-term performance in extreme conditions.

FIAMM Energy Technology SpA

Technical Solution: FIAMM Energy Technology has engineered AGM batteries with enhanced vibration resistance for automotive and industrial applications. Their approach includes a robust internal structure with tightly packed active material and high-compression glass mat separators. FIAMM's durability testing involves multi-axis vibration simulations that replicate real-world conditions experienced in vehicles and machinery. The company has implemented advanced grid alloys and paste formulations to improve the mechanical strength of the plates, reducing the risk of material shedding during prolonged vibration exposure[3]. FIAMM's AGM batteries also feature a sealed design with pressure relief valves to maintain internal pressure and prevent electrolyte loss under severe vibration conditions[4].

Strengths: Multi-axis vibration testing, advanced materials for improved mechanical strength, and sealed design for electrolyte retention. Weaknesses: May have limitations in extreme temperature conditions combined with high vibration.

Innovative Approaches

Negative mass for lead-acid battery electrodes and lead-acid battery including same

PatentActiveUS20210336249A1

Innovation

- The introduction of additives such as fine particle barium sulfate, two organic compounds (oxylignins), and a carbonaceous material to the negative active material in lead-acid battery electrodes, which are pre-mixed to form a blended expander mixture, improving the homogeneity and dispersion of the battery paste and enhancing the battery's cycling performance and water retention.

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

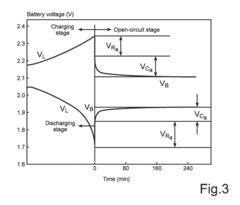

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Environmental Impact

The environmental impact of AGM (Absorbent Glass Mat) battery durability testing in high-vibration environments is a crucial aspect to consider in the development and implementation of these energy storage systems. This analysis focuses on the potential ecological consequences and sustainability concerns associated with such testing procedures.

AGM batteries, while generally considered more environmentally friendly than traditional lead-acid batteries, still pose certain risks during their lifecycle, including the testing phase. The durability testing process in high-vibration environments may lead to increased wear and tear on the battery components, potentially resulting in the release of harmful substances if not properly managed.

One of the primary environmental concerns is the potential leakage of electrolyte solution during vigorous testing. Although AGM batteries are designed to be spill-proof, extreme vibrations may compromise the integrity of the battery casing, leading to small leaks. These leaks, if undetected, can contaminate soil and water sources with sulfuric acid and lead compounds, posing risks to local ecosystems and wildlife.

The testing process itself consumes significant energy, contributing to the overall carbon footprint of battery production and evaluation. High-vibration test equipment often requires substantial power input, which, depending on the energy source, may indirectly contribute to greenhouse gas emissions. Manufacturers and testing facilities should consider implementing renewable energy sources to mitigate this impact.

Waste generation is another environmental factor to consider. Batteries that fail durability tests may need to be disposed of prematurely, increasing the volume of battery waste. Proper recycling and disposal protocols are essential to minimize the environmental impact of these discarded units. Additionally, the frequent replacement of test batteries may lead to increased resource consumption and manufacturing emissions.

The materials used in AGM batteries, particularly lead and plastic components, have their own environmental implications. While lead is highly recyclable, the mining and refining processes associated with its production can have significant ecological impacts. The plastic components, if not properly recycled, contribute to the global plastic waste problem.

On a positive note, improving the durability of AGM batteries through rigorous testing can lead to longer-lasting products, reducing the frequency of battery replacements and, consequently, the overall environmental impact of battery production and disposal. This long-term benefit should be weighed against the short-term environmental costs of the testing process.

To mitigate the environmental impact of durability testing, manufacturers and testing facilities should implement comprehensive waste management systems, utilize energy-efficient testing equipment, and explore ways to simulate high-vibration environments with reduced physical stress on the batteries. Additionally, developing non-destructive testing methods could significantly reduce waste generation while still ensuring battery reliability.

AGM batteries, while generally considered more environmentally friendly than traditional lead-acid batteries, still pose certain risks during their lifecycle, including the testing phase. The durability testing process in high-vibration environments may lead to increased wear and tear on the battery components, potentially resulting in the release of harmful substances if not properly managed.

One of the primary environmental concerns is the potential leakage of electrolyte solution during vigorous testing. Although AGM batteries are designed to be spill-proof, extreme vibrations may compromise the integrity of the battery casing, leading to small leaks. These leaks, if undetected, can contaminate soil and water sources with sulfuric acid and lead compounds, posing risks to local ecosystems and wildlife.

The testing process itself consumes significant energy, contributing to the overall carbon footprint of battery production and evaluation. High-vibration test equipment often requires substantial power input, which, depending on the energy source, may indirectly contribute to greenhouse gas emissions. Manufacturers and testing facilities should consider implementing renewable energy sources to mitigate this impact.

Waste generation is another environmental factor to consider. Batteries that fail durability tests may need to be disposed of prematurely, increasing the volume of battery waste. Proper recycling and disposal protocols are essential to minimize the environmental impact of these discarded units. Additionally, the frequent replacement of test batteries may lead to increased resource consumption and manufacturing emissions.

The materials used in AGM batteries, particularly lead and plastic components, have their own environmental implications. While lead is highly recyclable, the mining and refining processes associated with its production can have significant ecological impacts. The plastic components, if not properly recycled, contribute to the global plastic waste problem.

On a positive note, improving the durability of AGM batteries through rigorous testing can lead to longer-lasting products, reducing the frequency of battery replacements and, consequently, the overall environmental impact of battery production and disposal. This long-term benefit should be weighed against the short-term environmental costs of the testing process.

To mitigate the environmental impact of durability testing, manufacturers and testing facilities should implement comprehensive waste management systems, utilize energy-efficient testing equipment, and explore ways to simulate high-vibration environments with reduced physical stress on the batteries. Additionally, developing non-destructive testing methods could significantly reduce waste generation while still ensuring battery reliability.

Safety Regulations

Safety regulations play a crucial role in the durability testing of AGM batteries in high-vibration environments. These regulations are designed to ensure the safety of both the testing procedures and the end-use applications of the batteries. The primary focus is on preventing potential hazards associated with battery failure, such as electrolyte leakage, short circuits, and thermal runaway.

International standards, such as those set by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), provide guidelines for testing AGM batteries under vibration conditions. These standards typically specify the frequency range, amplitude, and duration of vibration tests, as well as the acceptable performance criteria for batteries during and after testing.

One key aspect of safety regulations is the requirement for proper containment and isolation of batteries during testing. This includes using appropriate fixtures and enclosures to prevent physical damage to the battery and contain any potential leaks or emissions. Additionally, testing facilities must be equipped with adequate ventilation systems to manage any gases that may be released during the testing process.

Regulations also mandate the use of personal protective equipment (PPE) for technicians conducting the tests. This typically includes safety glasses, gloves, and protective clothing to guard against potential chemical exposure or electrical hazards. Furthermore, testing areas must be equipped with appropriate fire suppression systems and emergency shutdown procedures.

Safety regulations often require comprehensive documentation of testing procedures, including risk assessments and safety protocols. This documentation ensures that all personnel involved in the testing process are aware of potential hazards and the necessary precautions to be taken. It also facilitates regulatory compliance and audits.

Specific safety measures for high-vibration environments include monitoring systems to detect any abnormal battery behavior during testing. These systems may include temperature sensors, voltage monitors, and gas detectors to provide early warning of potential failures or safety issues. In some cases, regulations may require remote monitoring and control capabilities to minimize human exposure to potential hazards.

Environmental considerations are also addressed in safety regulations for AGM battery testing. This includes proper disposal procedures for batteries that fail during testing, as well as guidelines for managing any chemical spills or emissions that may occur. Regulations may also specify requirements for the storage and handling of batteries before and after testing to prevent degradation or safety issues.

As technology advances and new battery chemistries emerge, safety regulations for durability testing continue to evolve. Regulatory bodies work closely with industry experts to update standards and guidelines, ensuring that they remain relevant and effective in addressing the latest safety challenges associated with AGM batteries in high-vibration environments.

International standards, such as those set by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), provide guidelines for testing AGM batteries under vibration conditions. These standards typically specify the frequency range, amplitude, and duration of vibration tests, as well as the acceptable performance criteria for batteries during and after testing.

One key aspect of safety regulations is the requirement for proper containment and isolation of batteries during testing. This includes using appropriate fixtures and enclosures to prevent physical damage to the battery and contain any potential leaks or emissions. Additionally, testing facilities must be equipped with adequate ventilation systems to manage any gases that may be released during the testing process.

Regulations also mandate the use of personal protective equipment (PPE) for technicians conducting the tests. This typically includes safety glasses, gloves, and protective clothing to guard against potential chemical exposure or electrical hazards. Furthermore, testing areas must be equipped with appropriate fire suppression systems and emergency shutdown procedures.

Safety regulations often require comprehensive documentation of testing procedures, including risk assessments and safety protocols. This documentation ensures that all personnel involved in the testing process are aware of potential hazards and the necessary precautions to be taken. It also facilitates regulatory compliance and audits.

Specific safety measures for high-vibration environments include monitoring systems to detect any abnormal battery behavior during testing. These systems may include temperature sensors, voltage monitors, and gas detectors to provide early warning of potential failures or safety issues. In some cases, regulations may require remote monitoring and control capabilities to minimize human exposure to potential hazards.

Environmental considerations are also addressed in safety regulations for AGM battery testing. This includes proper disposal procedures for batteries that fail during testing, as well as guidelines for managing any chemical spills or emissions that may occur. Regulations may also specify requirements for the storage and handling of batteries before and after testing to prevent degradation or safety issues.

As technology advances and new battery chemistries emerge, safety regulations for durability testing continue to evolve. Regulatory bodies work closely with industry experts to update standards and guidelines, ensuring that they remain relevant and effective in addressing the latest safety challenges associated with AGM batteries in high-vibration environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!