Effective Ultrafiltration Integration into Closed-Loop Water Systems

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration technology has evolved significantly since its inception in the 1960s, transitioning from laboratory-scale applications to widespread industrial implementation. The fundamental principle involves the separation of particles, macromolecules, and colloids from fluids using semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers. This positioning between microfiltration and nanofiltration in the membrane filtration spectrum has made ultrafiltration particularly valuable for water treatment applications.

The historical trajectory shows a marked acceleration in ultrafiltration development during the 1980s and 1990s, coinciding with advancements in polymer chemistry and membrane manufacturing techniques. These innovations led to more durable membranes with enhanced flux rates and reduced fouling tendencies, addressing earlier limitations that had constrained widespread adoption.

Recent technological trends indicate a shift toward energy-efficient designs, with particular emphasis on reducing the pressure requirements and energy consumption of ultrafiltration systems. Additionally, there has been significant progress in developing anti-fouling membranes through surface modifications and novel material compositions, extending operational lifespans and reducing maintenance requirements.

In closed-loop water systems specifically, ultrafiltration has emerged as a critical technology for achieving water reuse objectives across various industries. The integration challenge lies in optimizing ultrafiltration processes to maintain consistent water quality while minimizing energy consumption and waste generation within the circular water economy paradigm.

The primary technical objectives for ultrafiltration integration into closed-loop systems include: maximizing water recovery rates (targeting >95%); ensuring consistent permeate quality regardless of influent variations; minimizing energy consumption through pressure optimization and efficient hydraulic designs; extending membrane life through advanced cleaning protocols and fouling-resistant materials; and developing intelligent monitoring systems for real-time performance optimization.

Long-term technological goals focus on developing self-cleaning membrane systems, achieving zero liquid discharge capabilities through ultrafiltration-based treatment trains, and creating modular, scalable solutions adaptable to various industrial contexts. These objectives align with broader sustainability imperatives and regulatory trends toward water conservation and contaminant reduction.

The convergence of ultrafiltration with complementary technologies, particularly advanced oxidation processes and biological treatment systems, represents a promising frontier for closed-loop water management. This integration pathway aims to address recalcitrant contaminants while maintaining the energy and operational advantages that make ultrafiltration attractive for sustainable water management solutions.

The historical trajectory shows a marked acceleration in ultrafiltration development during the 1980s and 1990s, coinciding with advancements in polymer chemistry and membrane manufacturing techniques. These innovations led to more durable membranes with enhanced flux rates and reduced fouling tendencies, addressing earlier limitations that had constrained widespread adoption.

Recent technological trends indicate a shift toward energy-efficient designs, with particular emphasis on reducing the pressure requirements and energy consumption of ultrafiltration systems. Additionally, there has been significant progress in developing anti-fouling membranes through surface modifications and novel material compositions, extending operational lifespans and reducing maintenance requirements.

In closed-loop water systems specifically, ultrafiltration has emerged as a critical technology for achieving water reuse objectives across various industries. The integration challenge lies in optimizing ultrafiltration processes to maintain consistent water quality while minimizing energy consumption and waste generation within the circular water economy paradigm.

The primary technical objectives for ultrafiltration integration into closed-loop systems include: maximizing water recovery rates (targeting >95%); ensuring consistent permeate quality regardless of influent variations; minimizing energy consumption through pressure optimization and efficient hydraulic designs; extending membrane life through advanced cleaning protocols and fouling-resistant materials; and developing intelligent monitoring systems for real-time performance optimization.

Long-term technological goals focus on developing self-cleaning membrane systems, achieving zero liquid discharge capabilities through ultrafiltration-based treatment trains, and creating modular, scalable solutions adaptable to various industrial contexts. These objectives align with broader sustainability imperatives and regulatory trends toward water conservation and contaminant reduction.

The convergence of ultrafiltration with complementary technologies, particularly advanced oxidation processes and biological treatment systems, represents a promising frontier for closed-loop water management. This integration pathway aims to address recalcitrant contaminants while maintaining the energy and operational advantages that make ultrafiltration attractive for sustainable water management solutions.

Market Analysis for Closed-Loop Water Treatment Systems

The global market for closed-loop water treatment systems is experiencing robust growth, driven by increasing water scarcity concerns and stringent environmental regulations. Current market valuation stands at approximately $7.8 billion, with projections indicating a compound annual growth rate of 8.3% through 2028. This growth trajectory is particularly pronounced in regions facing severe water stress, including the Middle East, parts of Asia-Pacific, and the southwestern United States.

Industrial sectors represent the largest market segment, accounting for nearly 45% of the total market share. Manufacturing facilities, particularly in semiconductor production, pharmaceuticals, and food processing, demonstrate the highest adoption rates due to their substantial water consumption and quality requirements. The commercial building sector follows closely, showing accelerated growth as green building certifications increasingly prioritize water recycling capabilities.

Municipal applications represent an emerging market with significant growth potential, especially in urban centers experiencing population growth coupled with aging water infrastructure. The agricultural sector, while currently a smaller segment, shows promising expansion opportunities as precision irrigation systems become more sophisticated and integrated with water recycling technologies.

Ultrafiltration technology specifically has captured approximately 28% of the closed-loop water treatment market, competing with reverse osmosis (32%) and various membrane bioreactor systems (24%). The ultrafiltration segment demonstrates the fastest growth rate at 9.7% annually, attributed to its optimal balance of filtration efficiency, energy consumption, and operational costs.

Geographically, North America leads the market with 34% share, followed by Europe (28%) and Asia-Pacific (26%). However, the highest growth rates are observed in developing economies within Southeast Asia and Latin America, where industrialization is accelerating amid limited water resources.

Key market drivers include regulatory pressures mandating water reuse in industrial operations, rising water utility costs (increasing at an average of 5.7% annually in developed markets), and corporate sustainability initiatives. The return on investment period for closed-loop systems has decreased from 7-8 years a decade ago to 3-5 years currently, significantly enhancing market attractiveness.

Customer demand increasingly focuses on system integration capabilities, remote monitoring functionality, and reduced maintenance requirements. Market research indicates that 73% of potential customers rank system reliability and operational simplicity as their primary purchasing considerations, followed by energy efficiency (68%) and initial capital costs (61%).

Industrial sectors represent the largest market segment, accounting for nearly 45% of the total market share. Manufacturing facilities, particularly in semiconductor production, pharmaceuticals, and food processing, demonstrate the highest adoption rates due to their substantial water consumption and quality requirements. The commercial building sector follows closely, showing accelerated growth as green building certifications increasingly prioritize water recycling capabilities.

Municipal applications represent an emerging market with significant growth potential, especially in urban centers experiencing population growth coupled with aging water infrastructure. The agricultural sector, while currently a smaller segment, shows promising expansion opportunities as precision irrigation systems become more sophisticated and integrated with water recycling technologies.

Ultrafiltration technology specifically has captured approximately 28% of the closed-loop water treatment market, competing with reverse osmosis (32%) and various membrane bioreactor systems (24%). The ultrafiltration segment demonstrates the fastest growth rate at 9.7% annually, attributed to its optimal balance of filtration efficiency, energy consumption, and operational costs.

Geographically, North America leads the market with 34% share, followed by Europe (28%) and Asia-Pacific (26%). However, the highest growth rates are observed in developing economies within Southeast Asia and Latin America, where industrialization is accelerating amid limited water resources.

Key market drivers include regulatory pressures mandating water reuse in industrial operations, rising water utility costs (increasing at an average of 5.7% annually in developed markets), and corporate sustainability initiatives. The return on investment period for closed-loop systems has decreased from 7-8 years a decade ago to 3-5 years currently, significantly enhancing market attractiveness.

Customer demand increasingly focuses on system integration capabilities, remote monitoring functionality, and reduced maintenance requirements. Market research indicates that 73% of potential customers rank system reliability and operational simplicity as their primary purchasing considerations, followed by energy efficiency (68%) and initial capital costs (61%).

Current Challenges in Ultrafiltration Integration

Despite significant advancements in ultrafiltration (UF) technology, integrating these systems effectively into closed-loop water systems presents several persistent challenges. Membrane fouling remains the primary obstacle, occurring when particulates, colloids, organic matter, and biological growth accumulate on membrane surfaces. This phenomenon significantly reduces filtration efficiency, increases energy consumption, and shortens membrane lifespan, ultimately elevating operational costs.

Pressure management across UF systems poses another substantial challenge. Maintaining optimal transmembrane pressure is critical for efficient operation, yet pressure fluctuations in closed-loop systems can compromise membrane integrity and filtration performance. These fluctuations often result from varying water quality inputs or downstream demand changes, creating complex control requirements.

Energy efficiency represents a growing concern as sustainability becomes increasingly important. Current UF integration approaches typically consume significant energy for pumping, backwashing, and chemical cleaning processes. This high energy demand contradicts the sustainability goals that many closed-loop water systems aim to achieve, creating a fundamental tension in system design.

Chemical compatibility issues further complicate integration efforts. The chemicals used in pretreatment or cleaning regimens must be compatible with both the UF membranes and other components in the closed-loop system. Inappropriate chemical selection can lead to membrane degradation, reduced system lifespan, or contamination of the treated water stream.

Real-time monitoring and control systems present technical limitations that hinder optimal UF performance. Current sensor technologies often lack the precision needed to detect early-stage fouling or subtle changes in water quality parameters. This monitoring gap prevents proactive maintenance and optimization of filtration parameters, leading to suboptimal performance.

Space constraints frequently challenge implementation in existing facilities. Retrofitting UF systems into established water treatment infrastructures requires compact designs that can function effectively within limited spaces without compromising performance or maintenance accessibility.

System scalability presents difficulties when water demand fluctuates. Many current UF integration approaches lack the flexibility to efficiently scale operations up or down in response to changing water volumes, resulting in either underutilization of capacity or insufficient treatment during peak demands.

Finally, achieving consistent water quality across varying input conditions remains challenging. Closed-loop systems often experience significant variations in contaminant profiles, temperature, and pH, all of which can affect UF performance and compromise the reliability of water quality outputs.

Pressure management across UF systems poses another substantial challenge. Maintaining optimal transmembrane pressure is critical for efficient operation, yet pressure fluctuations in closed-loop systems can compromise membrane integrity and filtration performance. These fluctuations often result from varying water quality inputs or downstream demand changes, creating complex control requirements.

Energy efficiency represents a growing concern as sustainability becomes increasingly important. Current UF integration approaches typically consume significant energy for pumping, backwashing, and chemical cleaning processes. This high energy demand contradicts the sustainability goals that many closed-loop water systems aim to achieve, creating a fundamental tension in system design.

Chemical compatibility issues further complicate integration efforts. The chemicals used in pretreatment or cleaning regimens must be compatible with both the UF membranes and other components in the closed-loop system. Inappropriate chemical selection can lead to membrane degradation, reduced system lifespan, or contamination of the treated water stream.

Real-time monitoring and control systems present technical limitations that hinder optimal UF performance. Current sensor technologies often lack the precision needed to detect early-stage fouling or subtle changes in water quality parameters. This monitoring gap prevents proactive maintenance and optimization of filtration parameters, leading to suboptimal performance.

Space constraints frequently challenge implementation in existing facilities. Retrofitting UF systems into established water treatment infrastructures requires compact designs that can function effectively within limited spaces without compromising performance or maintenance accessibility.

System scalability presents difficulties when water demand fluctuates. Many current UF integration approaches lack the flexibility to efficiently scale operations up or down in response to changing water volumes, resulting in either underutilization of capacity or insufficient treatment during peak demands.

Finally, achieving consistent water quality across varying input conditions remains challenging. Closed-loop systems often experience significant variations in contaminant profiles, temperature, and pH, all of which can affect UF performance and compromise the reliability of water quality outputs.

Current Integration Approaches for Ultrafiltration Systems

01 Membrane design and materials for ultrafiltration

The effectiveness of ultrafiltration systems largely depends on the design and materials of the membranes used. Advanced membrane materials such as polymeric composites and ceramic materials can significantly improve filtration efficiency, reduce fouling, and extend membrane life. Innovations in membrane structure, including pore size distribution, surface morphology, and hydrophilicity, contribute to enhanced separation performance and throughput in various applications.- Membrane design and materials for ultrafiltration: The effectiveness of ultrafiltration systems largely depends on membrane design and material selection. Advanced membrane materials such as polymeric composites, ceramic membranes, and modified surfaces can significantly improve filtration efficiency, reduce fouling, and extend operational lifespan. Innovations in membrane structure, including pore size distribution, surface charge, and hydrophilicity, directly impact separation performance and energy consumption in ultrafiltration processes.

- Fouling prevention and membrane cleaning techniques: Membrane fouling is a critical challenge affecting ultrafiltration effectiveness. Various approaches have been developed to prevent fouling and maintain filtration efficiency, including backwashing protocols, chemical cleaning methods, and hydrodynamic techniques like air scouring. Implementation of optimized cleaning regimes and anti-fouling strategies can significantly extend membrane life and maintain consistent filtration performance over time.

- Process optimization and control systems: Advanced control systems and process optimization techniques play a crucial role in maximizing ultrafiltration effectiveness. Real-time monitoring of parameters such as transmembrane pressure, flux, and permeate quality allows for dynamic adjustment of operating conditions. Automated control systems that incorporate machine learning algorithms can optimize filtration cycles, energy consumption, and cleaning intervals, resulting in improved overall system performance and reduced operational costs.

- Application-specific ultrafiltration configurations: Ultrafiltration effectiveness varies significantly across different applications, necessitating specialized system configurations. Industry-specific designs for water treatment, food processing, pharmaceutical manufacturing, and industrial wastewater treatment incorporate tailored membrane modules, flow patterns, and pre-treatment steps. These customized configurations address unique challenges such as specific contaminant profiles, required throughput, and quality standards relevant to each application domain.

- Integration with complementary treatment technologies: The effectiveness of ultrafiltration can be enhanced through integration with complementary treatment technologies. Hybrid systems combining ultrafiltration with processes such as coagulation, adsorption, biological treatment, or other membrane technologies (like reverse osmosis or nanofiltration) can achieve superior separation performance. These integrated approaches leverage the strengths of multiple technologies to overcome limitations of standalone ultrafiltration, particularly for complex feed streams containing diverse contaminants.

02 Process optimization techniques for ultrafiltration

Various process optimization techniques can enhance ultrafiltration effectiveness. These include cross-flow velocity adjustment, transmembrane pressure control, backwashing protocols, and feed pretreatment methods. Optimizing operational parameters such as temperature, pH, and flux rates can significantly improve filtration efficiency, reduce energy consumption, and extend the service life of ultrafiltration systems while maintaining high-quality filtrate production.Expand Specific Solutions03 Anti-fouling strategies in ultrafiltration systems

Fouling is a major challenge affecting ultrafiltration effectiveness. Advanced anti-fouling strategies include surface modifications of membranes, incorporation of antimicrobial agents, implementation of air scouring techniques, and development of self-cleaning membrane systems. These approaches help maintain consistent filtration performance, reduce cleaning frequency, minimize operational downtime, and extend the overall lifespan of ultrafiltration systems.Expand Specific Solutions04 Monitoring and control systems for ultrafiltration

Advanced monitoring and control systems play a crucial role in maintaining ultrafiltration effectiveness. Real-time sensors for measuring parameters such as turbidity, pressure differential, and flow rates allow for automated adjustments to operational conditions. Integrated control systems with predictive maintenance capabilities can detect early signs of performance degradation, optimize cleaning cycles, and ensure consistent filtration quality across varying feed conditions.Expand Specific Solutions05 Hybrid and integrated ultrafiltration technologies

Combining ultrafiltration with other separation technologies creates hybrid systems with enhanced effectiveness. Integration with processes such as coagulation, adsorption, biological treatment, or other membrane technologies (like nanofiltration or reverse osmosis) can significantly improve overall filtration performance. These hybrid approaches enable more comprehensive contaminant removal, address a wider range of pollutants, and optimize energy efficiency in water and wastewater treatment applications.Expand Specific Solutions

Leading Companies in Advanced Water Treatment Solutions

The ultrafiltration integration into closed-loop water systems market is currently in a growth phase, with increasing adoption across industrial and municipal sectors. The global market size is estimated to be expanding at a CAGR of 6-8%, driven by water scarcity concerns and stringent environmental regulations. Technologically, the field shows varying maturity levels, with companies like Siemens AG, Kurita Water Industries, and WILO SE leading with advanced commercial solutions. Research institutions such as Hohai University and Kumamoto University are advancing fundamental research, while specialized players like Nomura Micro Science and WaterSurplus focus on niche applications. The competitive landscape features a mix of established industrial conglomerates (Dow, Infineon), water treatment specialists, and emerging technology providers developing more efficient, compact, and energy-saving ultrafiltration systems for sustainable water management.

Research Center For Eco-Environmental Sciences

Technical Solution: The Research Center for Eco-Environmental Sciences has developed an innovative ultrafiltration integration approach for closed-loop water systems focused on sustainability and energy efficiency. Their solution employs composite ceramic-polymeric membranes with hierarchical pore structures that provide superior fouling resistance while maintaining high flux rates. The system incorporates their patented Oscillating Membrane Filtration (OMF) technology that creates controlled vibrations in the membrane module, disrupting the boundary layer and reducing fouling without requiring frequent backwashing. Their closed-loop implementation achieves water recovery rates of 96-98% through the integration of concentrate treatment using advanced oxidation processes. The center's approach features a biomimetic membrane cleaning system inspired by natural water filtration processes, using enzymatic cleaners that specifically target organic foulants without damaging membrane materials. Their solution also includes a decentralized control architecture that allows for autonomous operation of individual filtration modules while maintaining system-wide optimization. The design incorporates energy recovery devices that capture hydraulic energy from the concentrate stream, reducing overall energy consumption by up to 40% compared to conventional ultrafiltration systems.

Strengths: The center's ultrafiltration technology offers exceptional energy efficiency through their innovative membrane design and energy recovery systems. Their biomimetic cleaning approach significantly extends membrane life while reducing chemical usage. Weaknesses: The composite membrane technology has higher initial costs than conventional polymeric membranes. The system's advanced control architecture requires specialized programming knowledge for modifications and troubleshooting.

Kurita Water Industries Ltd.

Technical Solution: Kurita has developed an advanced ultrafiltration (UF) integration system for closed-loop water systems that combines membrane technology with their proprietary chemical treatment approach. Their solution employs hollow fiber UF membranes with pore sizes of 0.01-0.02 microns, capable of removing suspended solids, bacteria, and certain viruses. The system incorporates automatic membrane cleaning protocols using both forward and backward flushing techniques, alongside chemical cleaning cycles that utilize Kurita's specialized membrane-safe cleaning agents. Their closed-loop design achieves water recovery rates exceeding 95%, significantly reducing wastewater discharge. Kurita's approach also features real-time monitoring through their "S.sensing" technology that tracks membrane performance, water quality parameters, and system efficiency metrics to optimize operation and predict maintenance needs. The integration includes pre-treatment systems customized to specific water sources and post-treatment options for achieving precise water quality requirements.

Strengths: Kurita's solution offers exceptional water recovery rates and reduced chemical consumption through their proprietary cleaning formulations. Their integrated monitoring system provides predictive maintenance capabilities, reducing downtime. Weaknesses: The initial capital investment is relatively high, and the system requires specialized technical expertise for optimal operation and maintenance. The membrane replacement costs can be significant over the system's lifecycle.

Key Technical Innovations in Membrane Technology

Process for water treatment in a closed circuit with a reactor

PatentInactiveEP0847374A1

Innovation

- A method involving pre-cleaning of waste water to reduce solids content and pH, followed by oxidation with atmospheric oxygen and a catalyst, then filtration using membrane or nanofilters to achieve a closed-loop system with reduced organic components and minimal fresh water usage.

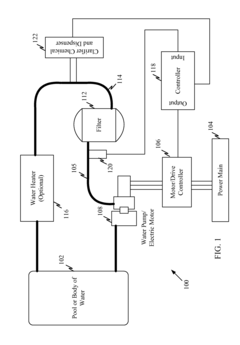

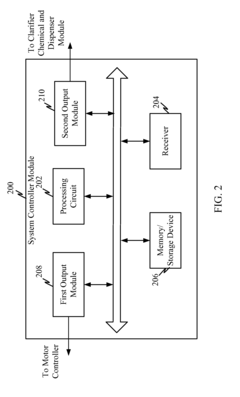

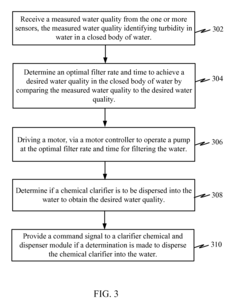

Systems and methods for reducing electric power by optimizing water turbidity, suspended solids, circulation and filtration in pools, spas, water features, and other closed bodies of water

PatentInactiveUS20110253638A1

Innovation

- A closed-loop circulation/filtration system that uses turbidity and suspended solids sensors to dynamically adjust the filtration rate and time based on real-time water clarity, optimizing energy use and water quality by controlling the pump's speed and operation through a system controller.

Energy Efficiency Considerations in Ultrafiltration Systems

Energy consumption represents a significant operational cost in ultrafiltration (UF) systems integrated into closed-loop water treatment processes. The primary energy demand stems from pumping requirements to overcome transmembrane pressure (TMP), which typically ranges from 0.5 to 5 bar depending on membrane configuration and fouling conditions. Recent advancements in energy-efficient UF systems have demonstrated potential reductions of 20-30% in overall energy consumption compared to conventional designs.

Membrane fouling directly correlates with increased energy requirements, as the progressive accumulation of contaminants necessitates higher operating pressures to maintain desired flux rates. Studies indicate that optimized backwashing and chemical cleaning protocols can reduce energy consumption by 15-25% through effective fouling management, thereby extending membrane lifespan and maintaining operational efficiency.

Variable frequency drives (VFDs) have emerged as a critical component in energy-efficient UF systems, allowing for dynamic adjustment of pump speeds based on actual filtration demands. Implementation of VFDs in closed-loop water systems has demonstrated energy savings of 30-50% compared to fixed-speed pump operations, particularly in applications with fluctuating flow requirements.

Pressure recovery devices, including pressure exchangers and energy recovery turbines, represent another significant advancement in UF energy efficiency. These technologies can recover 25-40% of the hydraulic energy that would otherwise be lost in concentrate streams, making them particularly valuable in high-pressure UF applications within industrial closed-loop systems.

System configuration optimization presents substantial energy-saving opportunities. Parallel membrane arrangements with intelligent flow distribution have shown 10-15% greater energy efficiency compared to series configurations in large-scale applications. Additionally, strategic placement of UF modules within the closed-loop system to leverage existing hydraulic gradients can reduce pumping requirements by 5-10%.

Advanced control systems utilizing machine learning algorithms for real-time optimization have demonstrated promising results in pilot studies, achieving energy reductions of 15-20% through predictive maintenance and adaptive operation. These systems continuously adjust operational parameters based on feed water quality, membrane condition, and production requirements.

Temperature management also plays a crucial role in UF energy efficiency, as water viscosity significantly impacts filtration resistance. Research indicates that maintaining optimal operating temperatures through waste heat recovery or seasonal operational adjustments can improve energy efficiency by 8-12% in closed-loop systems where temperature control is feasible.

Membrane fouling directly correlates with increased energy requirements, as the progressive accumulation of contaminants necessitates higher operating pressures to maintain desired flux rates. Studies indicate that optimized backwashing and chemical cleaning protocols can reduce energy consumption by 15-25% through effective fouling management, thereby extending membrane lifespan and maintaining operational efficiency.

Variable frequency drives (VFDs) have emerged as a critical component in energy-efficient UF systems, allowing for dynamic adjustment of pump speeds based on actual filtration demands. Implementation of VFDs in closed-loop water systems has demonstrated energy savings of 30-50% compared to fixed-speed pump operations, particularly in applications with fluctuating flow requirements.

Pressure recovery devices, including pressure exchangers and energy recovery turbines, represent another significant advancement in UF energy efficiency. These technologies can recover 25-40% of the hydraulic energy that would otherwise be lost in concentrate streams, making them particularly valuable in high-pressure UF applications within industrial closed-loop systems.

System configuration optimization presents substantial energy-saving opportunities. Parallel membrane arrangements with intelligent flow distribution have shown 10-15% greater energy efficiency compared to series configurations in large-scale applications. Additionally, strategic placement of UF modules within the closed-loop system to leverage existing hydraulic gradients can reduce pumping requirements by 5-10%.

Advanced control systems utilizing machine learning algorithms for real-time optimization have demonstrated promising results in pilot studies, achieving energy reductions of 15-20% through predictive maintenance and adaptive operation. These systems continuously adjust operational parameters based on feed water quality, membrane condition, and production requirements.

Temperature management also plays a crucial role in UF energy efficiency, as water viscosity significantly impacts filtration resistance. Research indicates that maintaining optimal operating temperatures through waste heat recovery or seasonal operational adjustments can improve energy efficiency by 8-12% in closed-loop systems where temperature control is feasible.

Environmental Impact and Sustainability Assessment

The integration of ultrafiltration technology into closed-loop water systems represents a significant advancement in sustainable water management practices. When evaluating the environmental impact and sustainability of these systems, it is essential to consider both direct and indirect effects across multiple ecological dimensions.

Ultrafiltration systems substantially reduce the need for freshwater extraction from natural sources, directly alleviating pressure on increasingly stressed water resources. Quantitative assessments indicate that properly designed closed-loop ultrafiltration systems can achieve water reuse rates of 75-90%, significantly reducing the water footprint of industrial operations and urban water systems.

Energy consumption remains a critical consideration in the environmental profile of ultrafiltration systems. While membrane-based filtration requires energy input, particularly for maintaining optimal transmembrane pressure, closed-loop configurations offer opportunities for energy recovery and optimization. Recent technological innovations have reduced the energy intensity of ultrafiltration processes by approximately 30% over the past decade, with further improvements anticipated through enhanced membrane materials and system design.

The chemical footprint of ultrafiltration systems must be carefully evaluated. Membrane cleaning processes typically require chemical agents that, if improperly managed, could introduce environmental contaminants. However, closed-loop designs enable precise control and recovery of these chemicals, minimizing discharge to the environment. Advanced cleaning protocols utilizing biodegradable agents have demonstrated reduced environmental impact while maintaining system performance.

Waste stream management represents another crucial environmental consideration. Concentrated reject streams from ultrafiltration processes contain elevated levels of contaminants that require appropriate handling. Innovative approaches to valorizing these waste streams, such as resource recovery and beneficial reuse applications, are emerging as promising strategies to transform waste management challenges into circular economy opportunities.

Life cycle assessment (LCA) studies of integrated ultrafiltration systems reveal favorable environmental profiles compared to conventional water treatment approaches. These systems typically demonstrate reduced carbon footprints, decreased chemical usage, and lower overall environmental impact scores across multiple categories including eutrophication potential, ecotoxicity, and resource depletion.

The resilience benefits of ultrafiltration in closed-loop systems extend beyond operational advantages to include climate adaptation capabilities. By reducing dependence on climate-vulnerable water sources and enabling localized water management, these systems contribute to community and industrial resilience in the face of increasing climate uncertainty and water scarcity events.

Ultrafiltration systems substantially reduce the need for freshwater extraction from natural sources, directly alleviating pressure on increasingly stressed water resources. Quantitative assessments indicate that properly designed closed-loop ultrafiltration systems can achieve water reuse rates of 75-90%, significantly reducing the water footprint of industrial operations and urban water systems.

Energy consumption remains a critical consideration in the environmental profile of ultrafiltration systems. While membrane-based filtration requires energy input, particularly for maintaining optimal transmembrane pressure, closed-loop configurations offer opportunities for energy recovery and optimization. Recent technological innovations have reduced the energy intensity of ultrafiltration processes by approximately 30% over the past decade, with further improvements anticipated through enhanced membrane materials and system design.

The chemical footprint of ultrafiltration systems must be carefully evaluated. Membrane cleaning processes typically require chemical agents that, if improperly managed, could introduce environmental contaminants. However, closed-loop designs enable precise control and recovery of these chemicals, minimizing discharge to the environment. Advanced cleaning protocols utilizing biodegradable agents have demonstrated reduced environmental impact while maintaining system performance.

Waste stream management represents another crucial environmental consideration. Concentrated reject streams from ultrafiltration processes contain elevated levels of contaminants that require appropriate handling. Innovative approaches to valorizing these waste streams, such as resource recovery and beneficial reuse applications, are emerging as promising strategies to transform waste management challenges into circular economy opportunities.

Life cycle assessment (LCA) studies of integrated ultrafiltration systems reveal favorable environmental profiles compared to conventional water treatment approaches. These systems typically demonstrate reduced carbon footprints, decreased chemical usage, and lower overall environmental impact scores across multiple categories including eutrophication potential, ecotoxicity, and resource depletion.

The resilience benefits of ultrafiltration in closed-loop systems extend beyond operational advantages to include climate adaptation capabilities. By reducing dependence on climate-vulnerable water sources and enabling localized water management, these systems contribute to community and industrial resilience in the face of increasing climate uncertainty and water scarcity events.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!