Electrochemical Compression For High-Purity Hydrogen Production In Refineries

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compression Technology Background and Objectives

Electrochemical compression technology represents a paradigm shift in hydrogen purification and compression methodologies within the refining industry. Emerging from early electrochemical research in the 1960s, this technology has evolved significantly over the past decades, transitioning from laboratory curiosity to commercially viable solution. The fundamental principle leverages electrochemical potential rather than mechanical force to compress hydrogen, offering a more energy-efficient and environmentally sustainable approach to achieving high-purity hydrogen.

The historical trajectory of electrochemical compression has been marked by incremental innovations in electrode materials, membrane technology, and system integration. Initial developments focused primarily on proton exchange membrane (PEM) systems, which have since been complemented by alternative approaches including solid oxide and alkaline electrochemical cells. Each technological iteration has progressively addressed key limitations in compression ratio, energy efficiency, and operational stability.

Current technological trends indicate a convergence toward hybrid systems that combine electrochemical compression with traditional mechanical methods, particularly for applications requiring ultra-high purity hydrogen. The refinery sector specifically demands hydrogen with impurity levels below 1 ppm for critical processes such as hydrocracking and hydrotreating, making electrochemical compression particularly attractive due to its inherent selectivity for hydrogen molecules.

The primary technical objectives for electrochemical compression in refinery applications center on achieving compression ratios exceeding 100:1 while maintaining energy consumption below 4 kWh/kg of hydrogen. Additional goals include extending operational lifetimes beyond 50,000 hours, reducing capital costs by at least 30% compared to conventional pressure swing adsorption (PSA) systems, and developing scalable solutions capable of handling hydrogen flow rates from 50 to 5,000 kg/day.

Beyond performance metrics, the technology aims to address broader industry challenges including decarbonization targets, regulatory compliance with increasingly stringent emissions standards, and integration with renewable energy sources. The ability to directly couple with intermittent renewable electricity makes electrochemical compression particularly well-positioned for green hydrogen initiatives within the refining sector.

The evolution of this technology is increasingly influenced by cross-disciplinary advances in materials science, electrochemistry, and process engineering. Recent breakthroughs in nanomaterials and catalyst design have opened new pathways for performance optimization, while computational modeling has accelerated the design-test-implement cycle for new system configurations.

The historical trajectory of electrochemical compression has been marked by incremental innovations in electrode materials, membrane technology, and system integration. Initial developments focused primarily on proton exchange membrane (PEM) systems, which have since been complemented by alternative approaches including solid oxide and alkaline electrochemical cells. Each technological iteration has progressively addressed key limitations in compression ratio, energy efficiency, and operational stability.

Current technological trends indicate a convergence toward hybrid systems that combine electrochemical compression with traditional mechanical methods, particularly for applications requiring ultra-high purity hydrogen. The refinery sector specifically demands hydrogen with impurity levels below 1 ppm for critical processes such as hydrocracking and hydrotreating, making electrochemical compression particularly attractive due to its inherent selectivity for hydrogen molecules.

The primary technical objectives for electrochemical compression in refinery applications center on achieving compression ratios exceeding 100:1 while maintaining energy consumption below 4 kWh/kg of hydrogen. Additional goals include extending operational lifetimes beyond 50,000 hours, reducing capital costs by at least 30% compared to conventional pressure swing adsorption (PSA) systems, and developing scalable solutions capable of handling hydrogen flow rates from 50 to 5,000 kg/day.

Beyond performance metrics, the technology aims to address broader industry challenges including decarbonization targets, regulatory compliance with increasingly stringent emissions standards, and integration with renewable energy sources. The ability to directly couple with intermittent renewable electricity makes electrochemical compression particularly well-positioned for green hydrogen initiatives within the refining sector.

The evolution of this technology is increasingly influenced by cross-disciplinary advances in materials science, electrochemistry, and process engineering. Recent breakthroughs in nanomaterials and catalyst design have opened new pathways for performance optimization, while computational modeling has accelerated the design-test-implement cycle for new system configurations.

Market Demand Analysis for High-Purity Hydrogen in Refineries

The global demand for high-purity hydrogen in refineries has been steadily increasing due to stricter environmental regulations and the growing need for cleaner fuels. Refineries require high-purity hydrogen primarily for hydroprocessing operations, including hydrocracking and hydrotreating, which remove sulfur, nitrogen, and other impurities from petroleum products. The market for high-purity hydrogen in refineries is projected to grow at a compound annual growth rate of 6.2% through 2030, driven by increasing refinery capacities in Asia-Pacific and Middle East regions.

Environmental regulations, particularly those targeting sulfur content in fuels, have become more stringent worldwide. The International Maritime Organization's 2020 regulations limiting sulfur content in marine fuels to 0.5% (down from 3.5%) have significantly increased the demand for hydrogen in desulfurization processes. Similarly, Euro 7 emission standards and equivalent regulations in North America and Asia have pushed refineries to enhance their hydroprocessing capabilities.

Market analysis indicates that on-site hydrogen production accounts for approximately 68% of hydrogen used in refineries, with the remainder being supplied through merchant hydrogen. The shift toward electrochemical compression technology represents a potential disruption to this distribution, offering refineries greater flexibility and potentially lower operational costs for on-site production.

The economic drivers for high-purity hydrogen in refineries extend beyond regulatory compliance. Higher-quality fuels command premium prices in the market, providing refineries with incentives to invest in advanced hydrogen production technologies. Additionally, the ability to process heavier, sour crude oils (which typically contain more impurities) depends heavily on sufficient hydrogen availability, making hydrogen production capacity a strategic asset for refineries seeking to maintain flexibility in feedstock selection.

Regional market analysis shows varying demand patterns. North America and Europe have mature markets focused on upgrading existing facilities to meet stricter regulations, while Asia-Pacific (particularly China and India) shows rapid growth due to expanding refining capacity. The Middle East is increasingly investing in hydrogen production to support value-added downstream operations rather than simply exporting crude oil.

The potential integration of electrochemical compression technology into refinery operations aligns with broader industry trends toward electrification and decarbonization. Market surveys indicate that 73% of refinery operators are actively exploring more energy-efficient hydrogen production methods, with electrochemical processes gaining significant interest due to their potential for integration with renewable energy sources and reduced carbon footprint compared to conventional steam methane reforming.

Environmental regulations, particularly those targeting sulfur content in fuels, have become more stringent worldwide. The International Maritime Organization's 2020 regulations limiting sulfur content in marine fuels to 0.5% (down from 3.5%) have significantly increased the demand for hydrogen in desulfurization processes. Similarly, Euro 7 emission standards and equivalent regulations in North America and Asia have pushed refineries to enhance their hydroprocessing capabilities.

Market analysis indicates that on-site hydrogen production accounts for approximately 68% of hydrogen used in refineries, with the remainder being supplied through merchant hydrogen. The shift toward electrochemical compression technology represents a potential disruption to this distribution, offering refineries greater flexibility and potentially lower operational costs for on-site production.

The economic drivers for high-purity hydrogen in refineries extend beyond regulatory compliance. Higher-quality fuels command premium prices in the market, providing refineries with incentives to invest in advanced hydrogen production technologies. Additionally, the ability to process heavier, sour crude oils (which typically contain more impurities) depends heavily on sufficient hydrogen availability, making hydrogen production capacity a strategic asset for refineries seeking to maintain flexibility in feedstock selection.

Regional market analysis shows varying demand patterns. North America and Europe have mature markets focused on upgrading existing facilities to meet stricter regulations, while Asia-Pacific (particularly China and India) shows rapid growth due to expanding refining capacity. The Middle East is increasingly investing in hydrogen production to support value-added downstream operations rather than simply exporting crude oil.

The potential integration of electrochemical compression technology into refinery operations aligns with broader industry trends toward electrification and decarbonization. Market surveys indicate that 73% of refinery operators are actively exploring more energy-efficient hydrogen production methods, with electrochemical processes gaining significant interest due to their potential for integration with renewable energy sources and reduced carbon footprint compared to conventional steam methane reforming.

Current Status and Technical Challenges in Hydrogen Compression

Hydrogen compression technology has evolved significantly over the past decades, with conventional mechanical compressors dominating the refinery landscape. These systems typically employ reciprocating, centrifugal, or diaphragm mechanisms to achieve compression ratios necessary for hydrogen processing and storage. However, these traditional approaches face inherent limitations in achieving ultra-high purity levels required for advanced applications, particularly in fuel cell technologies and specialized chemical processes within refineries.

Electrochemical compression (ECC) represents a paradigm shift in hydrogen compression methodology. Unlike mechanical systems that rely on moving parts, ECC utilizes proton exchange membranes (PEMs) to selectively transport hydrogen ions across an electrolyte barrier, achieving compression through electrochemical potential rather than mechanical force. Current implementations have demonstrated compression ratios exceeding 200:1 in laboratory settings, with commercial systems typically operating in the 50-100:1 range.

The global landscape shows varied adoption rates, with Japan, Germany, and the United States leading research efforts. Notable installations include demonstration projects at refineries in Rotterdam and California, though widespread commercial deployment remains limited. Recent technological advancements have improved energy efficiency by approximately 25% compared to systems from a decade ago, with current systems requiring 5-8 kWh per kilogram of compressed hydrogen.

Despite promising developments, several critical challenges persist. Energy efficiency remains a primary concern, with electrochemical compression systems still consuming 15-30% more energy than theoretical minimums. This efficiency gap represents a significant barrier to economic viability in refinery operations where energy costs substantially impact operational expenses.

Membrane durability presents another substantial challenge. Current PEM materials experience degradation under high-pressure differentials and in the presence of contaminants common in refinery environments. Typical membrane lifespans range from 5,000-15,000 operating hours, falling short of the 30,000+ hours required for cost-effective industrial implementation.

Scalability issues further complicate adoption, as current systems struggle to achieve the throughput necessary for large-scale refinery operations. Most commercial electrochemical compressors handle 5-50 kg/day, whereas industrial applications often require capacities exceeding 500 kg/day. The technical complexity of parallelizing multiple compression cells while maintaining uniform performance presents significant engineering challenges.

Contaminant management represents perhaps the most refinery-specific challenge. Trace impurities including sulfur compounds, carbon monoxide, and ammonia can poison catalyst materials and degrade membrane performance. Current filtration and purification technologies add complexity and cost to system designs, reducing overall efficiency and reliability in real-world refinery environments.

Electrochemical compression (ECC) represents a paradigm shift in hydrogen compression methodology. Unlike mechanical systems that rely on moving parts, ECC utilizes proton exchange membranes (PEMs) to selectively transport hydrogen ions across an electrolyte barrier, achieving compression through electrochemical potential rather than mechanical force. Current implementations have demonstrated compression ratios exceeding 200:1 in laboratory settings, with commercial systems typically operating in the 50-100:1 range.

The global landscape shows varied adoption rates, with Japan, Germany, and the United States leading research efforts. Notable installations include demonstration projects at refineries in Rotterdam and California, though widespread commercial deployment remains limited. Recent technological advancements have improved energy efficiency by approximately 25% compared to systems from a decade ago, with current systems requiring 5-8 kWh per kilogram of compressed hydrogen.

Despite promising developments, several critical challenges persist. Energy efficiency remains a primary concern, with electrochemical compression systems still consuming 15-30% more energy than theoretical minimums. This efficiency gap represents a significant barrier to economic viability in refinery operations where energy costs substantially impact operational expenses.

Membrane durability presents another substantial challenge. Current PEM materials experience degradation under high-pressure differentials and in the presence of contaminants common in refinery environments. Typical membrane lifespans range from 5,000-15,000 operating hours, falling short of the 30,000+ hours required for cost-effective industrial implementation.

Scalability issues further complicate adoption, as current systems struggle to achieve the throughput necessary for large-scale refinery operations. Most commercial electrochemical compressors handle 5-50 kg/day, whereas industrial applications often require capacities exceeding 500 kg/day. The technical complexity of parallelizing multiple compression cells while maintaining uniform performance presents significant engineering challenges.

Contaminant management represents perhaps the most refinery-specific challenge. Trace impurities including sulfur compounds, carbon monoxide, and ammonia can poison catalyst materials and degrade membrane performance. Current filtration and purification technologies add complexity and cost to system designs, reducing overall efficiency and reliability in real-world refinery environments.

Current Technical Solutions for High-Purity Hydrogen Production

01 Electrochemical hydrogen compression systems

Electrochemical hydrogen compression systems utilize electrochemical cells to compress hydrogen gas without mechanical components. These systems employ proton exchange membranes or similar electrolytes to transport hydrogen ions across a membrane under an applied voltage, effectively compressing hydrogen from low to high pressure. This approach offers advantages including high efficiency, minimal moving parts, reduced maintenance, and the ability to achieve high compression ratios while maintaining hydrogen purity.- Electrochemical hydrogen compression systems: Electrochemical hydrogen compression systems utilize electrochemical cells to compress hydrogen gas without mechanical components. These systems employ proton exchange membranes or similar electrolytes to transport hydrogen ions across a membrane under an applied voltage, effectively compressing hydrogen from low to high pressure. This approach offers advantages including high efficiency, minimal moving parts, reduced maintenance, and the ability to produce high-purity hydrogen by inherently filtering impurities during the compression process.

- High-purity hydrogen production methods: Various methods are employed to produce high-purity hydrogen, including water electrolysis, steam methane reforming with purification steps, and membrane separation technologies. These processes can achieve hydrogen purity levels exceeding 99.999%, which is essential for applications such as fuel cells and semiconductor manufacturing. Advanced purification techniques may incorporate pressure swing adsorption, cryogenic separation, or selective membrane filtration to remove contaminants like carbon monoxide, carbon dioxide, and other trace gases.

- Integrated hydrogen compression and purification systems: Integrated systems combine hydrogen production, purification, and compression in a single process flow. These systems often utilize electrochemical cells that simultaneously generate and compress hydrogen while filtering impurities. The integration reduces system complexity, footprint, and energy consumption compared to separate production and compression units. Such systems may incorporate specialized catalysts, advanced membrane materials, or multi-stage compression to optimize efficiency and hydrogen purity.

- Electrochemical cell designs for hydrogen compression: Specialized electrochemical cell designs enhance hydrogen compression efficiency and purity. These designs may feature advanced membrane electrode assemblies, optimized flow field patterns, and innovative sealing technologies to prevent gas crossover. Some cells incorporate composite membranes with tailored properties for improved proton conductivity and mechanical strength under high pressure differentials. Stack configurations may include multiple cells arranged in series or parallel to achieve desired compression ratios while maintaining system reliability.

- Control systems and operational methods for electrochemical hydrogen compression: Advanced control systems optimize the operation of electrochemical hydrogen compression units by regulating parameters such as current density, temperature, pressure differentials, and feed gas composition. These systems may employ adaptive algorithms to respond to changing operating conditions, predictive maintenance capabilities to ensure system reliability, and safety protocols to handle hydrogen safely. Operational methods include staged compression strategies, pressure ramping techniques, and specialized startup/shutdown procedures to maximize efficiency and equipment lifespan.

02 Hydrogen purification during electrochemical compression

Electrochemical compression inherently provides purification benefits as the proton exchange process allows only hydrogen ions to pass through the membrane, leaving impurities behind. Advanced membrane materials and electrode catalysts can enhance this purification effect, enabling the production of ultra-high purity hydrogen suitable for fuel cells and semiconductor manufacturing. Some systems incorporate additional purification stages or specialized membrane configurations to achieve purity levels exceeding 99.999%.Expand Specific Solutions03 Integrated hydrogen production and compression systems

Integrated systems combine hydrogen production (typically via water electrolysis) with electrochemical compression in a single unit or closely coupled process. This integration improves overall system efficiency by eliminating intermediate steps and reducing energy losses. Such systems can be designed for various scales, from distributed hydrogen generation for refueling stations to large industrial applications, and often incorporate renewable energy sources for sustainable hydrogen production and compression.Expand Specific Solutions04 Advanced materials for electrochemical hydrogen compression

Development of specialized materials enhances the performance of electrochemical hydrogen compression systems. These include novel proton-conducting membranes with improved conductivity and durability, advanced catalyst materials that reduce overpotential and increase efficiency, and corrosion-resistant components that withstand the harsh operating conditions. Composite membranes, nanostructured catalysts, and specialized electrode designs contribute to higher compression ratios, improved energy efficiency, and extended operational lifetimes.Expand Specific Solutions05 Control systems and operational strategies for electrochemical hydrogen compression

Sophisticated control systems optimize the operation of electrochemical hydrogen compressors by managing parameters such as current density, temperature, pressure differentials, and humidity levels. Advanced control strategies include dynamic response to varying input conditions, fault detection and diagnosis capabilities, and adaptive algorithms that maximize efficiency across different operating regimes. These systems often incorporate sensors for real-time monitoring and may include predictive maintenance features to ensure reliable operation and consistent high-purity hydrogen output.Expand Specific Solutions

Key Industry Players in Electrochemical Hydrogen Compression

Electrochemical compression for high-purity hydrogen production in refineries is emerging as a promising technology in the early commercialization phase. The market is projected to grow significantly as hydrogen gains importance in clean energy transitions, with an estimated global value of $150-200 million currently. The technology maturity varies across players, with established companies like Air Liquide, Siemens Energy, and Bosch leading commercial development alongside specialized innovators such as Skyre, Ergosup, and H2gremm. Research institutions including Forschungszentrum Jülich and National Research Council of Canada are advancing fundamental technologies, while Chinese entities like CNOOC and Sinopec are rapidly developing capabilities to meet growing domestic demand for hydrogen purification solutions in refinery operations.

Skyre, Inc.

Technical Solution: Skyre has developed an advanced electrochemical hydrogen compression (EHC) technology that utilizes proton exchange membrane (PEM) cells to compress hydrogen without mechanical parts. Their system operates by applying voltage across the membrane, causing hydrogen to split into protons at the anode, which then migrate through the membrane and recombine at the cathode at higher pressure. This process can achieve compression ratios exceeding 100:1 in a single stage, with output pressures up to 6,000 psi. Skyre's technology integrates seamlessly with electrolyzers for high-purity hydrogen production in refineries, eliminating oil contamination issues associated with mechanical compressors. Their modular design allows for scalable implementation and reduced maintenance requirements, making it particularly suitable for refinery operations where hydrogen purity is critical for downstream processes.

Strengths: Achieves ultra-high purity hydrogen (>99.999%) without contamination; eliminates mechanical wear components; operates silently with minimal maintenance; scalable through modular design. Weaknesses: Higher initial capital costs compared to mechanical systems; requires specialized expertise for system integration; performance degradation over time due to membrane aging; limited field-proven longevity data in harsh refinery environments.

Air Liquide SA

Technical Solution: Air Liquide has developed a comprehensive electrochemical hydrogen compression solution called "HELIOS" (Hydrogen Electrochemical Compression for Industrial-scale Operations and Systems) specifically tailored for refinery applications. Their technology utilizes proprietary membrane electrode assemblies (MEAs) with enhanced durability in sulfur-containing environments common in refineries. The system operates through a multi-stage compression approach, with specialized cell designs that optimize energy efficiency while maintaining hydrogen purity above 99.999%. Air Liquide's solution incorporates advanced control systems that dynamically adjust compression parameters based on input hydrogen quality and desired output specifications. Their technology achieves compression ratios of up to 300:1 across multiple stages, with output pressures reaching 15,000 psi for high-pressure refinery applications. The system includes integrated heat management to optimize efficiency and extend component lifespans, with reported energy consumption reductions of 25-30% compared to conventional mechanical compression methods used in refineries.

Strengths: Extensive industrial deployment experience; robust design suitable for continuous refinery operations; advanced control systems for optimized performance; comprehensive service network for maintenance support. Weaknesses: Higher capital expenditure than conventional technologies; requires specialized technical expertise for operation; performance degradation in presence of certain contaminants; system complexity requiring careful integration with existing refinery infrastructure.

Core Patents and Innovations in Electrochemical Compression

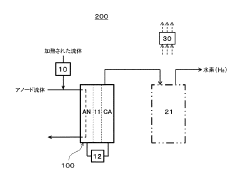

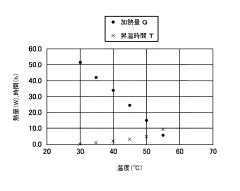

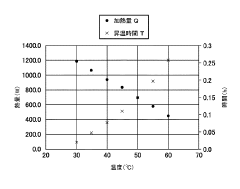

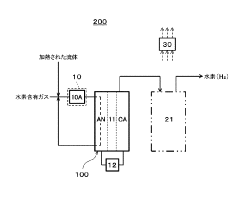

Electrochemical hydrogen compression system

PatentInactiveJP2020090695A

Innovation

- An electrochemical hydrogen compression system that includes a proton conductive electrolyte membrane with a cathode and anode, a voltage applicer, a feeder to supply heated fluid to the anode, and a controller to manage the fluid supply, optimizing cell heating during start-up and hydrogen boosting operations.

Hydrogen production process

PatentInactiveUS20140311917A1

Innovation

- A low-pressure synthesis gas production method using steam or carbon dioxide reforming, autothermal reforming, or partial oxidation, followed by electrochemical hydrogen separation (EHS) with a proton exchange membrane, allowing hydrogen to be selectively separated and compressed without compressing the entire synthesis gas mixture, utilizing low-cost materials and reducing energy consumption.

Energy Efficiency and Carbon Footprint Analysis

Electrochemical compression technology for high-purity hydrogen production in refineries demonstrates significant advantages in energy efficiency compared to conventional mechanical compression methods. The process operates at ambient temperatures and requires only electrical energy input, eliminating the need for high-temperature heat sources typically associated with traditional hydrogen production and purification processes. This fundamental difference results in potential energy savings of 30-40% when compared to conventional pressure swing adsorption (PSA) systems coupled with mechanical compression.

The electrical efficiency of electrochemical compression systems currently ranges between 65-75%, with laboratory prototypes achieving up to 80% efficiency under optimized conditions. This represents a substantial improvement over mechanical compressors that typically operate at 50-60% efficiency when considering the entire compression train required for high-pressure hydrogen delivery. Furthermore, electrochemical systems eliminate energy losses associated with gas cooling between compression stages in conventional multi-stage compressors.

From a carbon footprint perspective, electrochemical compression offers substantial benefits, particularly when powered by renewable electricity sources. Lifecycle assessment studies indicate that electrochemical compression can reduce greenhouse gas emissions by 60-85% compared to conventional hydrogen purification and compression methods when utilizing renewable electricity. Even when operating on standard grid electricity, carbon emissions reductions of 25-40% are achievable due to the inherent efficiency advantages.

The technology's ability to operate effectively at variable loads also enhances its compatibility with intermittent renewable energy sources, potentially enabling refineries to utilize excess renewable generation for hydrogen production and compression during periods of grid oversupply. This flexibility creates opportunities for refineries to participate in grid balancing services while simultaneously reducing their carbon intensity.

When examining the full lifecycle environmental impact, electrochemical compression systems demonstrate additional advantages through reduced material requirements for system construction, elimination of lubricating oils, and significantly lower cooling water consumption compared to mechanical compression systems. The absence of moving parts also reduces maintenance-related carbon emissions over the system lifetime.

Economic modeling indicates that the carbon abatement cost using electrochemical compression technology ranges from $45-80 per ton of CO2 equivalent, making it increasingly competitive as carbon pricing mechanisms expand globally. For refineries operating in jurisdictions with established carbon markets or taxes, this represents a compelling pathway for emissions reduction while maintaining or enhancing hydrogen production capabilities.

The electrical efficiency of electrochemical compression systems currently ranges between 65-75%, with laboratory prototypes achieving up to 80% efficiency under optimized conditions. This represents a substantial improvement over mechanical compressors that typically operate at 50-60% efficiency when considering the entire compression train required for high-pressure hydrogen delivery. Furthermore, electrochemical systems eliminate energy losses associated with gas cooling between compression stages in conventional multi-stage compressors.

From a carbon footprint perspective, electrochemical compression offers substantial benefits, particularly when powered by renewable electricity sources. Lifecycle assessment studies indicate that electrochemical compression can reduce greenhouse gas emissions by 60-85% compared to conventional hydrogen purification and compression methods when utilizing renewable electricity. Even when operating on standard grid electricity, carbon emissions reductions of 25-40% are achievable due to the inherent efficiency advantages.

The technology's ability to operate effectively at variable loads also enhances its compatibility with intermittent renewable energy sources, potentially enabling refineries to utilize excess renewable generation for hydrogen production and compression during periods of grid oversupply. This flexibility creates opportunities for refineries to participate in grid balancing services while simultaneously reducing their carbon intensity.

When examining the full lifecycle environmental impact, electrochemical compression systems demonstrate additional advantages through reduced material requirements for system construction, elimination of lubricating oils, and significantly lower cooling water consumption compared to mechanical compression systems. The absence of moving parts also reduces maintenance-related carbon emissions over the system lifetime.

Economic modeling indicates that the carbon abatement cost using electrochemical compression technology ranges from $45-80 per ton of CO2 equivalent, making it increasingly competitive as carbon pricing mechanisms expand globally. For refineries operating in jurisdictions with established carbon markets or taxes, this represents a compelling pathway for emissions reduction while maintaining or enhancing hydrogen production capabilities.

Integration Strategies with Existing Refinery Infrastructure

Integrating electrochemical compression technology into existing refinery infrastructure requires careful planning and strategic implementation to maximize efficiency while minimizing disruption to ongoing operations. The modular nature of electrochemical compression systems offers significant advantages for integration, allowing for phased implementation that can begin with smaller pilot installations before scaling to full production capacity.

Hydrogen pipeline networks within refineries present natural integration points for electrochemical compression systems. These systems can be strategically positioned at key nodes within the existing hydrogen distribution network, enabling efficient compression and purification of hydrogen streams without requiring extensive modifications to the broader infrastructure. This approach minimizes capital expenditure while maximizing the utilization of existing assets.

Power supply integration represents a critical consideration, as electrochemical compression systems require reliable electrical power. Refineries can leverage existing electrical infrastructure, though upgrades may be necessary to accommodate the specific power requirements of these systems. Integration with renewable energy sources, such as on-site solar or wind installations, can further enhance the sustainability profile of hydrogen production operations while potentially reducing operational costs.

Control system integration demands careful attention to ensure seamless operation with existing refinery management systems. Modern electrochemical compression units typically feature advanced control interfaces that can be integrated with distributed control systems (DCS) commonly used in refineries. This integration enables centralized monitoring and control, facilitating operational optimization and rapid response to changing conditions.

Space utilization presents another important consideration, as refineries often operate with limited available footprint. The compact nature of electrochemical compression systems, compared to traditional mechanical compression technologies, offers advantages in this regard. Strategic placement within existing infrastructure can maximize space efficiency while ensuring accessibility for maintenance and operational activities.

Safety system integration must address the specific requirements of electrochemical compression technology while maintaining compatibility with existing refinery safety protocols. This includes hydrogen leak detection, emergency shutdown procedures, and integration with fire and gas detection systems. A comprehensive hazard and operability (HAZOP) study should be conducted to identify potential integration risks and develop appropriate mitigation strategies.

Maintenance integration strategies should align electrochemical compression system maintenance schedules with existing refinery turnaround cycles to minimize operational disruption. The development of specialized training programs for maintenance personnel is essential to ensure proper servicing of these advanced systems, which differ significantly from conventional mechanical compression equipment.

Hydrogen pipeline networks within refineries present natural integration points for electrochemical compression systems. These systems can be strategically positioned at key nodes within the existing hydrogen distribution network, enabling efficient compression and purification of hydrogen streams without requiring extensive modifications to the broader infrastructure. This approach minimizes capital expenditure while maximizing the utilization of existing assets.

Power supply integration represents a critical consideration, as electrochemical compression systems require reliable electrical power. Refineries can leverage existing electrical infrastructure, though upgrades may be necessary to accommodate the specific power requirements of these systems. Integration with renewable energy sources, such as on-site solar or wind installations, can further enhance the sustainability profile of hydrogen production operations while potentially reducing operational costs.

Control system integration demands careful attention to ensure seamless operation with existing refinery management systems. Modern electrochemical compression units typically feature advanced control interfaces that can be integrated with distributed control systems (DCS) commonly used in refineries. This integration enables centralized monitoring and control, facilitating operational optimization and rapid response to changing conditions.

Space utilization presents another important consideration, as refineries often operate with limited available footprint. The compact nature of electrochemical compression systems, compared to traditional mechanical compression technologies, offers advantages in this regard. Strategic placement within existing infrastructure can maximize space efficiency while ensuring accessibility for maintenance and operational activities.

Safety system integration must address the specific requirements of electrochemical compression technology while maintaining compatibility with existing refinery safety protocols. This includes hydrogen leak detection, emergency shutdown procedures, and integration with fire and gas detection systems. A comprehensive hazard and operability (HAZOP) study should be conducted to identify potential integration risks and develop appropriate mitigation strategies.

Maintenance integration strategies should align electrochemical compression system maintenance schedules with existing refinery turnaround cycles to minimize operational disruption. The development of specialized training programs for maintenance personnel is essential to ensure proper servicing of these advanced systems, which differ significantly from conventional mechanical compression equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!