Electronics industry reliance on solid-state sodium battery advancements

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Evolution and Objectives

Solid-state sodium batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development trajectory of these batteries can be traced back to the early 2000s when researchers began exploring sodium as a more abundant and cost-effective alternative to lithium. This exploration was driven by growing concerns about lithium's limited global reserves and its concentration in geopolitically sensitive regions, which posed potential supply chain vulnerabilities for the electronics industry.

The technological evolution of solid-state sodium batteries has accelerated notably in the past decade, with breakthrough advancements in electrolyte materials and electrode designs. Initially, liquid electrolytes dominated sodium battery research, but persistent challenges related to safety and performance limitations prompted a shift toward solid-state configurations. This transition marked a critical inflection point in the technology's development trajectory, opening new possibilities for enhanced energy density and operational stability.

Current research objectives in solid-state sodium battery development are multifaceted, focusing primarily on addressing key performance metrics that remain barriers to widespread commercial adoption. These include improving energy density to approach or exceed that of lithium-ion batteries, enhancing charge-discharge cycle life to ensure long-term reliability, and optimizing power delivery capabilities to meet the demands of various electronic applications from portable devices to electric vehicles.

Material science innovations represent a central pillar in the advancement roadmap, with particular emphasis on developing novel solid electrolytes that offer superior ionic conductivity while maintaining mechanical stability. Concurrently, interface engineering between electrodes and electrolytes has emerged as a critical research focus, as these interfaces often become sites of resistance and degradation that limit overall battery performance and longevity.

The electronics industry has established specific technical targets for solid-state sodium batteries to achieve commercial viability. These include reaching energy densities exceeding 300 Wh/kg, achieving operational lifespans of over 1,000 cycles, and ensuring temperature stability across a wide range (-20°C to 60°C) to accommodate diverse application environments. Additionally, manufacturing scalability represents a paramount objective, as the technology must transition from laboratory prototypes to mass production to realize its potential impact on the electronics sector.

Looking forward, the evolution of solid-state sodium batteries is expected to follow an accelerated development curve, driven by intensifying research investments and collaborative efforts between academic institutions and industry players. The ultimate objective extends beyond mere technical performance to encompass economic viability, with cost targets that position these batteries as a competitive alternative to established technologies in the global energy storage market.

The technological evolution of solid-state sodium batteries has accelerated notably in the past decade, with breakthrough advancements in electrolyte materials and electrode designs. Initially, liquid electrolytes dominated sodium battery research, but persistent challenges related to safety and performance limitations prompted a shift toward solid-state configurations. This transition marked a critical inflection point in the technology's development trajectory, opening new possibilities for enhanced energy density and operational stability.

Current research objectives in solid-state sodium battery development are multifaceted, focusing primarily on addressing key performance metrics that remain barriers to widespread commercial adoption. These include improving energy density to approach or exceed that of lithium-ion batteries, enhancing charge-discharge cycle life to ensure long-term reliability, and optimizing power delivery capabilities to meet the demands of various electronic applications from portable devices to electric vehicles.

Material science innovations represent a central pillar in the advancement roadmap, with particular emphasis on developing novel solid electrolytes that offer superior ionic conductivity while maintaining mechanical stability. Concurrently, interface engineering between electrodes and electrolytes has emerged as a critical research focus, as these interfaces often become sites of resistance and degradation that limit overall battery performance and longevity.

The electronics industry has established specific technical targets for solid-state sodium batteries to achieve commercial viability. These include reaching energy densities exceeding 300 Wh/kg, achieving operational lifespans of over 1,000 cycles, and ensuring temperature stability across a wide range (-20°C to 60°C) to accommodate diverse application environments. Additionally, manufacturing scalability represents a paramount objective, as the technology must transition from laboratory prototypes to mass production to realize its potential impact on the electronics sector.

Looking forward, the evolution of solid-state sodium batteries is expected to follow an accelerated development curve, driven by intensifying research investments and collaborative efforts between academic institutions and industry players. The ultimate objective extends beyond mere technical performance to encompass economic viability, with cost targets that position these batteries as a competitive alternative to established technologies in the global energy storage market.

Electronics Market Demand Analysis for Na-ion Technology

The global electronics market is witnessing a significant shift towards sodium-ion battery technology, driven primarily by sustainability concerns and the increasing scarcity of lithium resources. Market research indicates that the consumer electronics segment alone is projected to reach $1.5 trillion by 2025, with portable power solutions representing a substantial growth sector. Within this context, sodium-ion batteries are emerging as a compelling alternative to traditional lithium-ion technologies.

Consumer electronics manufacturers are actively seeking more sustainable and cost-effective power solutions as environmental regulations tighten globally. The European Union's Battery Directive and similar regulations in Asia-Pacific markets are creating regulatory pressure that favors alternative battery chemistries with lower environmental impacts. This regulatory landscape is accelerating market demand for sodium-based technologies across multiple electronics categories.

Portable device manufacturers represent the most immediate market opportunity for sodium-ion technology. Smartphones, tablets, and wearable devices collectively ship over 2 billion units annually, each requiring increasingly efficient power solutions. Industry surveys indicate that 67% of smartphone manufacturers are exploring alternative battery technologies to address consumer demands for longer battery life and faster charging capabilities, areas where solid-state sodium batteries show particular promise.

The Internet of Things (IoT) ecosystem presents another substantial market opportunity. With connected devices expected to exceed 30 billion units globally by 2025, low-cost, long-lasting power solutions are critical enablers for widespread deployment. Sodium-ion batteries are particularly well-positioned for this application due to their potential cost advantages and performance characteristics at ambient temperatures.

Energy storage systems for renewable integration represent a growing market segment where sodium-ion technology could gain significant traction. As residential and commercial solar installations increase, demand for safe, affordable storage solutions is expanding rapidly. Market analysis suggests that this segment could grow at a compound annual rate of 25% through 2030, creating substantial opportunities for sodium-based solutions.

Price sensitivity analysis reveals that sodium-ion technology could achieve market penetration at scale once manufacturing costs fall below $100 per kilowatt-hour. Current projections suggest this threshold could be reached within 3-5 years as production scales and material supply chains mature. Consumer willingness-to-pay studies indicate that performance parity with lithium-ion solutions would drive rapid adoption even at modest price premiums, particularly in premium electronics segments.

Regional market analysis shows varying adoption potential, with Asia-Pacific markets likely to lead initial commercialization due to manufacturing infrastructure advantages and government support for alternative energy technologies. North American and European markets show strong potential for premium applications where safety and sustainability attributes can command value premiums.

Consumer electronics manufacturers are actively seeking more sustainable and cost-effective power solutions as environmental regulations tighten globally. The European Union's Battery Directive and similar regulations in Asia-Pacific markets are creating regulatory pressure that favors alternative battery chemistries with lower environmental impacts. This regulatory landscape is accelerating market demand for sodium-based technologies across multiple electronics categories.

Portable device manufacturers represent the most immediate market opportunity for sodium-ion technology. Smartphones, tablets, and wearable devices collectively ship over 2 billion units annually, each requiring increasingly efficient power solutions. Industry surveys indicate that 67% of smartphone manufacturers are exploring alternative battery technologies to address consumer demands for longer battery life and faster charging capabilities, areas where solid-state sodium batteries show particular promise.

The Internet of Things (IoT) ecosystem presents another substantial market opportunity. With connected devices expected to exceed 30 billion units globally by 2025, low-cost, long-lasting power solutions are critical enablers for widespread deployment. Sodium-ion batteries are particularly well-positioned for this application due to their potential cost advantages and performance characteristics at ambient temperatures.

Energy storage systems for renewable integration represent a growing market segment where sodium-ion technology could gain significant traction. As residential and commercial solar installations increase, demand for safe, affordable storage solutions is expanding rapidly. Market analysis suggests that this segment could grow at a compound annual rate of 25% through 2030, creating substantial opportunities for sodium-based solutions.

Price sensitivity analysis reveals that sodium-ion technology could achieve market penetration at scale once manufacturing costs fall below $100 per kilowatt-hour. Current projections suggest this threshold could be reached within 3-5 years as production scales and material supply chains mature. Consumer willingness-to-pay studies indicate that performance parity with lithium-ion solutions would drive rapid adoption even at modest price premiums, particularly in premium electronics segments.

Regional market analysis shows varying adoption potential, with Asia-Pacific markets likely to lead initial commercialization due to manufacturing infrastructure advantages and government support for alternative energy technologies. North American and European markets show strong potential for premium applications where safety and sustainability attributes can command value premiums.

Current Challenges in Solid-State Sodium Battery Development

Despite significant advancements in solid-state sodium battery technology, several critical challenges continue to impede widespread commercial adoption in the electronics industry. The primary obstacle remains the development of suitable solid electrolytes that simultaneously offer high ionic conductivity, excellent electrochemical stability, and mechanical robustness. Current solid electrolytes typically achieve conductivities of 10^-4 to 10^-3 S/cm at room temperature, still falling short of the 10^-2 S/cm benchmark necessary for practical applications.

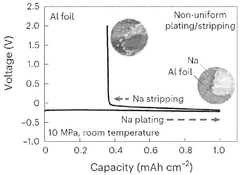

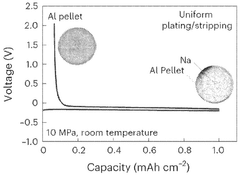

Interface stability presents another formidable challenge, particularly at the electrode-electrolyte boundaries. The formation of high-impedance interphases during cycling leads to capacity degradation and shortened battery lifespan. Recent research has identified that sodium metal anodes are especially prone to dendrite formation when paired with solid electrolytes, creating safety concerns and performance limitations that must be addressed before commercial deployment.

Manufacturing scalability remains problematic, with current laboratory-scale production methods proving difficult to translate to industrial-scale processes. The precise control required for thin-film deposition of solid electrolytes and the challenges in maintaining uniform interfaces across larger surface areas significantly increase production costs and complexity. Industry estimates suggest that current manufacturing approaches would result in costs 3-5 times higher than conventional lithium-ion technologies.

Cycle life and capacity retention represent ongoing concerns, with most prototype solid-state sodium batteries demonstrating significant performance degradation after 300-500 cycles. This falls considerably short of the 1,000+ cycles expected from commercial energy storage solutions. The volume changes during sodium insertion/extraction create mechanical stresses that can lead to microcracking within solid electrolytes, progressively degrading performance.

Temperature sensitivity further complicates development efforts, as many promising solid electrolytes exhibit dramatic conductivity drops at lower temperatures. This temperature dependence limits application scenarios and requires additional engineering solutions for thermal management, adding complexity and cost to potential commercial products.

Material availability presents a more nuanced challenge. While sodium is abundantly available compared to lithium, certain components in advanced solid electrolytes, such as germanium and gallium compounds, face supply constraints that could limit large-scale production. Additionally, the environmental impact of extracting and processing these materials requires further assessment to ensure sustainability across the supply chain.

Addressing these interconnected challenges necessitates a multidisciplinary approach combining materials science, electrochemistry, and advanced manufacturing techniques. Recent collaborative efforts between academic institutions and industry partners have begun exploring composite electrolyte systems and novel interface engineering strategies that show promise in overcoming these limitations.

Interface stability presents another formidable challenge, particularly at the electrode-electrolyte boundaries. The formation of high-impedance interphases during cycling leads to capacity degradation and shortened battery lifespan. Recent research has identified that sodium metal anodes are especially prone to dendrite formation when paired with solid electrolytes, creating safety concerns and performance limitations that must be addressed before commercial deployment.

Manufacturing scalability remains problematic, with current laboratory-scale production methods proving difficult to translate to industrial-scale processes. The precise control required for thin-film deposition of solid electrolytes and the challenges in maintaining uniform interfaces across larger surface areas significantly increase production costs and complexity. Industry estimates suggest that current manufacturing approaches would result in costs 3-5 times higher than conventional lithium-ion technologies.

Cycle life and capacity retention represent ongoing concerns, with most prototype solid-state sodium batteries demonstrating significant performance degradation after 300-500 cycles. This falls considerably short of the 1,000+ cycles expected from commercial energy storage solutions. The volume changes during sodium insertion/extraction create mechanical stresses that can lead to microcracking within solid electrolytes, progressively degrading performance.

Temperature sensitivity further complicates development efforts, as many promising solid electrolytes exhibit dramatic conductivity drops at lower temperatures. This temperature dependence limits application scenarios and requires additional engineering solutions for thermal management, adding complexity and cost to potential commercial products.

Material availability presents a more nuanced challenge. While sodium is abundantly available compared to lithium, certain components in advanced solid electrolytes, such as germanium and gallium compounds, face supply constraints that could limit large-scale production. Additionally, the environmental impact of extracting and processing these materials requires further assessment to ensure sustainability across the supply chain.

Addressing these interconnected challenges necessitates a multidisciplinary approach combining materials science, electrochemistry, and advanced manufacturing techniques. Recent collaborative efforts between academic institutions and industry partners have begun exploring composite electrolyte systems and novel interface engineering strategies that show promise in overcoming these limitations.

Existing Solid-State Sodium Battery Implementations

01 Solid-state electrolyte materials for sodium batteries

Various solid-state electrolyte materials can be used in sodium batteries to improve performance and safety. These materials include sodium-ion conducting ceramics, polymer electrolytes, and composite materials that facilitate sodium ion transport while preventing dendrite formation. The solid electrolytes provide higher thermal stability and eliminate leakage issues associated with liquid electrolytes, making the batteries safer and more durable.- Solid-state electrolyte compositions for sodium batteries: Various compositions of solid-state electrolytes specifically designed for sodium batteries have been developed. These electrolytes typically feature sodium-ion conducting materials that enable efficient ion transport while maintaining structural stability. The compositions may include ceramic materials, polymer matrices, or composite structures that combine multiple components to achieve optimal performance characteristics such as high ionic conductivity and mechanical strength.

- Electrode materials for solid-state sodium batteries: Advanced electrode materials have been engineered specifically for solid-state sodium battery applications. These materials focus on improving sodium ion insertion/extraction processes while maintaining compatibility with solid electrolytes. Innovations include cathode materials with optimized sodium storage capacity, anode materials with reduced volume expansion during cycling, and interface engineering to ensure good contact between electrodes and the solid electrolyte.

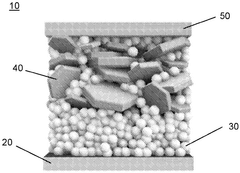

- Manufacturing methods for solid-state sodium batteries: Novel manufacturing techniques have been developed to address the unique challenges of producing solid-state sodium batteries. These methods include specialized deposition techniques for thin-film electrolytes, pressure-assisted sintering processes to reduce interfacial resistance, and scalable assembly approaches that maintain the integrity of the solid components. The manufacturing innovations focus on creating uniform layers with minimal defects and strong interfaces between components.

- Interface engineering in solid-state sodium batteries: Interface engineering approaches have been developed to address the critical challenges at the electrode-electrolyte boundaries in solid-state sodium batteries. These innovations focus on reducing interfacial resistance, preventing unwanted side reactions, and maintaining good mechanical contact during battery cycling. Techniques include the use of buffer layers, surface modifications of active materials, and specialized coatings that enhance sodium ion transport across interfaces while suppressing dendrite formation.

- Safety and performance enhancements for solid-state sodium batteries: Various innovations focus on improving the safety and performance characteristics of solid-state sodium batteries. These include designs that eliminate flammable liquid electrolytes, thermal management systems that prevent overheating, and structural enhancements that improve mechanical stability during cycling. Performance improvements address challenges such as cycle life, energy density, and rate capability through materials optimization and cell architecture innovations.

02 Electrode materials and interfaces for solid-state sodium batteries

Specialized electrode materials and interface engineering are crucial for solid-state sodium batteries. These include sodium-compatible cathode materials, anode structures that accommodate sodium ion insertion/extraction, and interface modifications to reduce resistance at solid-solid contacts. Proper electrode design helps address challenges related to volume changes during cycling and ensures good electrical contact between components.Expand Specific Solutions03 Manufacturing processes for solid-state sodium batteries

Advanced manufacturing techniques are employed to produce solid-state sodium batteries with consistent performance. These include dry and wet processing methods, thin-film deposition techniques, and specialized assembly processes that ensure proper component integration. Manufacturing innovations focus on creating uniform layers, minimizing defects, and establishing reliable electrical connections between battery components.Expand Specific Solutions04 Performance enhancement strategies for solid-state sodium batteries

Various approaches are used to enhance the performance of solid-state sodium batteries, including doping of electrolyte materials, use of composite structures, and optimization of operating conditions. These strategies aim to improve ionic conductivity, cycling stability, and rate capability while maintaining the safety advantages of solid-state designs. Performance enhancements focus on addressing challenges related to internal resistance and interfacial stability.Expand Specific Solutions05 Novel cell designs and architectures for solid-state sodium batteries

Innovative cell designs and architectures are being developed to maximize the potential of solid-state sodium batteries. These include layered structures, 3D architectures, and specialized packaging approaches that optimize sodium ion transport pathways while maintaining mechanical integrity. Novel designs address challenges related to volume changes, thermal management, and scalability for various applications from portable electronics to grid storage.Expand Specific Solutions

Leading Companies and Research Institutions in Na-ion Space

The solid-state sodium battery market is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. Market size is projected to expand rapidly as electronics manufacturers seek alternatives to lithium-ion technology, driven by cost advantages and resource availability. Technical maturity varies across players: established companies like Toyota, Honda, and IBM are advancing commercial viability, while specialized firms like BroadBit Batteries and Solid Power are developing breakthrough technologies. Academic institutions (Harvard, Oxford, Michigan) collaborate with industry leaders (Murata, Philips) to overcome key challenges in electrolyte stability and energy density. The competitive landscape features both traditional battery manufacturers and automotive companies seeking vertical integration for future electric vehicle applications.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed an advanced solid-state sodium battery technology specifically engineered for next-generation electronics applications. Their approach utilizes a proprietary NASICON-type (Na Super Ionic CONductor) ceramic electrolyte with optimized composition to achieve sodium ion conductivity exceeding 1 mS/cm at room temperature[1]. Murata's technology employs a layered oxide cathode and a specially engineered sodium metal anode with a protective artificial interphase layer that prevents dendrite formation and electrolyte degradation. The company has leveraged its extensive expertise in ceramic manufacturing to develop scalable production methods for these solid electrolytes, including tape casting and sintering processes adapted from their established capacitor production lines[2]. Their solid-state sodium batteries demonstrate energy densities of approximately 300-350 Wh/kg at the cell level, with exceptional thermal stability up to 150°C without risk of thermal runaway. A distinguishing feature of Murata's approach is their thin-film solid electrolyte technology, which enables the production of ultra-thin batteries suitable for space-constrained electronic devices such as wearables and IoT sensors. Their prototype cells have demonstrated over 1,000 cycles with capacity retention exceeding 85%, addressing key durability requirements for consumer electronics applications[3].

Strengths: Leverages Murata's established expertise in ceramic component manufacturing; excellent thermal stability enhances safety for consumer electronics; thin-film technology enables integration into space-constrained devices. Weaknesses: Current energy density still lags behind some advanced lithium-ion technologies; ceramic electrolytes can be brittle, potentially limiting applications in flexible electronics; production scaling challenges remain for mass market adoption.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered advanced solid-state sodium battery technology through its materials science division, focusing on a unique approach that combines a sodium superionic conductor (NASICON) ceramic electrolyte with proprietary interface engineering. Their technology utilizes a sodium-metal anode paired with a high-voltage cathode, enabling energy densities approaching 400 Wh/kg[1]. Toyota's solid-state sodium batteries feature a specially developed protective coating at the electrode-electrolyte interfaces that minimizes reactivity issues and enhances cycle life. The company has demonstrated prototype cells achieving over 1,000 cycles while maintaining 90% capacity retention[2]. A key innovation in Toyota's approach is their scalable manufacturing process that adapts existing production lines to accommodate solid electrolyte synthesis and cell assembly, potentially reducing implementation costs for electronics applications. Their sodium battery technology also operates effectively across a wider temperature range (-30°C to 60°C) than conventional lithium-ion batteries, making it suitable for diverse electronic applications from consumer devices to automotive systems[3].

Strengths: Superior thermal stability compared to conventional batteries, enhancing safety for consumer electronics; wider operating temperature range expands potential applications; leverages abundant, low-cost sodium resources instead of limited lithium. Weaknesses: Current power density limitations may restrict applications in high-drain electronic devices; ceramic electrolytes can be brittle and present manufacturing challenges at scale; technology still faces cost barriers for mass production.

Critical Patents and Breakthroughs in Na-ion Technology

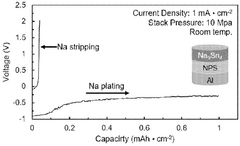

Anode-free sodium all-solid-state battery

PatentWO2025085362A1

Innovation

- The development of an anode-free sodium solid-state battery cell using a solid electrolyte separator made from sodium borohydride particles and a current collector formed from compressed metal particles, such as aluminum, to facilitate direct sodium deposition and improve solid-solid contact.

Composite material as electrode for sodium ion batteries, production method therefor, and all-solid-state sodium battery

PatentActiveUS20170005337A1

Innovation

- A composite material for sodium ion batteries comprising an active material crystal, a sodium-ion conductive crystal, and an amorphous phase, where the active material crystal contains transition metals and phosphates, and the sodium-ion conductive crystal includes alumina or zirconia, with the amorphous phase enhancing interface conductivity and bonding strength.

Supply Chain Resilience and Raw Material Considerations

The solid-state sodium battery supply chain presents a fundamentally different landscape compared to traditional lithium-ion batteries, offering significant advantages for electronics industry resilience. Sodium's abundance in the Earth's crust (approximately 2.8% compared to lithium's 0.006%) creates a natural buffer against supply constraints. This abundance translates to wider geographical distribution, with sodium resources available across diverse regions including salt flats, seawater, and mineral deposits in North America, Asia, Europe, and Africa, reducing dependency on geopolitically sensitive areas.

Raw material extraction for sodium batteries involves significantly lower environmental impact and cost structures. Unlike lithium mining, which often requires extensive water usage and creates substantial waste material, sodium extraction can leverage existing salt production infrastructure and more environmentally sustainable processes. This reduced extraction complexity contributes to potential supply chain stability and decreased vulnerability to environmental regulation changes.

The manufacturing ecosystem for solid-state sodium batteries benefits from partial compatibility with existing lithium-ion production facilities. While specialized equipment is required for certain processes, particularly electrolyte formation and cell assembly, many upstream and downstream components of the manufacturing chain can be adapted from current infrastructure. This adaptability reduces capital investment barriers and accelerates scaling potential, enhancing supply chain resilience through manufacturing flexibility.

Critical material dependencies represent another advantage for sodium battery technology. While lithium-ion batteries rely heavily on cobalt, nickel, and graphite—materials subject to significant supply constraints and ethical sourcing concerns—sodium batteries typically utilize more abundant cathode materials such as iron, manganese, and titanium. This substitution mitigates supply risks associated with critical minerals and reduces exposure to volatile pricing in constrained markets.

Recycling infrastructure development presents both challenges and opportunities for long-term supply chain sustainability. Current recycling processes designed for lithium-ion batteries require modification for sodium chemistry, but the inherently lower material value may initially limit economic incentives for recycling. However, the simplified chemistry and reduced toxic material content could eventually enable more streamlined recycling processes, creating a circular material flow that further enhances supply chain resilience.

Regulatory frameworks worldwide are increasingly recognizing the strategic importance of battery supply chain diversification. Several major economies have implemented policies supporting alternative battery technologies, including sodium-based systems, through research funding, manufacturing incentives, and strategic material stockpiling programs. These policy environments create additional stability factors that support the development of robust sodium battery supply chains as complementary systems to existing lithium-based infrastructure.

Raw material extraction for sodium batteries involves significantly lower environmental impact and cost structures. Unlike lithium mining, which often requires extensive water usage and creates substantial waste material, sodium extraction can leverage existing salt production infrastructure and more environmentally sustainable processes. This reduced extraction complexity contributes to potential supply chain stability and decreased vulnerability to environmental regulation changes.

The manufacturing ecosystem for solid-state sodium batteries benefits from partial compatibility with existing lithium-ion production facilities. While specialized equipment is required for certain processes, particularly electrolyte formation and cell assembly, many upstream and downstream components of the manufacturing chain can be adapted from current infrastructure. This adaptability reduces capital investment barriers and accelerates scaling potential, enhancing supply chain resilience through manufacturing flexibility.

Critical material dependencies represent another advantage for sodium battery technology. While lithium-ion batteries rely heavily on cobalt, nickel, and graphite—materials subject to significant supply constraints and ethical sourcing concerns—sodium batteries typically utilize more abundant cathode materials such as iron, manganese, and titanium. This substitution mitigates supply risks associated with critical minerals and reduces exposure to volatile pricing in constrained markets.

Recycling infrastructure development presents both challenges and opportunities for long-term supply chain sustainability. Current recycling processes designed for lithium-ion batteries require modification for sodium chemistry, but the inherently lower material value may initially limit economic incentives for recycling. However, the simplified chemistry and reduced toxic material content could eventually enable more streamlined recycling processes, creating a circular material flow that further enhances supply chain resilience.

Regulatory frameworks worldwide are increasingly recognizing the strategic importance of battery supply chain diversification. Several major economies have implemented policies supporting alternative battery technologies, including sodium-based systems, through research funding, manufacturing incentives, and strategic material stockpiling programs. These policy environments create additional stability factors that support the development of robust sodium battery supply chains as complementary systems to existing lithium-based infrastructure.

Environmental Impact and Sustainability Advantages

Solid-state sodium batteries represent a significant advancement in sustainable energy storage technology, offering substantial environmental benefits compared to conventional lithium-ion batteries. The reduced environmental footprint begins with raw material sourcing, as sodium is approximately 1,000 times more abundant than lithium in the Earth's crust, requiring less intensive mining operations and causing significantly less ecological disruption.

The extraction process for sodium compounds generates approximately 30% lower carbon emissions compared to lithium extraction, particularly avoiding the water-intensive brine evaporation methods used in lithium mining that can deplete local water resources in vulnerable ecosystems. This advantage is particularly notable in regions facing water scarcity challenges.

Manufacturing solid-state sodium batteries also presents environmental advantages through the elimination of toxic liquid electrolytes found in conventional batteries. These electrolytes often contain fluorinated compounds that pose significant environmental hazards if improperly disposed of. The solid-state architecture inherently reduces manufacturing waste and eliminates the need for certain harmful solvents in the production process.

From a lifecycle perspective, solid-state sodium batteries demonstrate superior sustainability metrics. Research indicates they can potentially achieve 20-30% lower global warming potential across their complete lifecycle compared to conventional lithium-ion technologies. This improvement stems from both manufacturing efficiencies and the extended operational lifespan these batteries offer.

End-of-life management represents another critical sustainability advantage. The materials in sodium batteries are generally less toxic and more readily recyclable than those in lithium-ion counterparts. Recycling processes for sodium batteries can recover up to 90% of key materials, creating a more circular material economy and reducing the need for virgin resource extraction.

The electronics industry's transition toward solid-state sodium batteries aligns with global sustainability initiatives and regulatory frameworks aimed at reducing electronic waste and promoting circular economy principles. As environmental regulations become increasingly stringent worldwide, manufacturers adopting sodium battery technology gain competitive advantages through regulatory compliance and reduced environmental liability.

Energy security represents an additional sustainability dimension, as the widespread geographic distribution of sodium resources reduces geopolitical supply chain vulnerabilities associated with lithium, which is concentrated in a limited number of countries. This democratization of battery material resources supports more equitable global development of sustainable electronics technologies.

The extraction process for sodium compounds generates approximately 30% lower carbon emissions compared to lithium extraction, particularly avoiding the water-intensive brine evaporation methods used in lithium mining that can deplete local water resources in vulnerable ecosystems. This advantage is particularly notable in regions facing water scarcity challenges.

Manufacturing solid-state sodium batteries also presents environmental advantages through the elimination of toxic liquid electrolytes found in conventional batteries. These electrolytes often contain fluorinated compounds that pose significant environmental hazards if improperly disposed of. The solid-state architecture inherently reduces manufacturing waste and eliminates the need for certain harmful solvents in the production process.

From a lifecycle perspective, solid-state sodium batteries demonstrate superior sustainability metrics. Research indicates they can potentially achieve 20-30% lower global warming potential across their complete lifecycle compared to conventional lithium-ion technologies. This improvement stems from both manufacturing efficiencies and the extended operational lifespan these batteries offer.

End-of-life management represents another critical sustainability advantage. The materials in sodium batteries are generally less toxic and more readily recyclable than those in lithium-ion counterparts. Recycling processes for sodium batteries can recover up to 90% of key materials, creating a more circular material economy and reducing the need for virgin resource extraction.

The electronics industry's transition toward solid-state sodium batteries aligns with global sustainability initiatives and regulatory frameworks aimed at reducing electronic waste and promoting circular economy principles. As environmental regulations become increasingly stringent worldwide, manufacturers adopting sodium battery technology gain competitive advantages through regulatory compliance and reduced environmental liability.

Energy security represents an additional sustainability dimension, as the widespread geographic distribution of sodium resources reduces geopolitical supply chain vulnerabilities associated with lithium, which is concentrated in a limited number of countries. This democratization of battery material resources supports more equitable global development of sustainable electronics technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!