Navigating patents in solid-state sodium battery technology

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Technology Background and Objectives

Solid-state sodium batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development of this technology can be traced back to the early 2000s, when researchers began exploring sodium as a more abundant and cost-effective alternative to lithium. The fundamental principle involves using sodium ions as charge carriers within a solid electrolyte framework, eliminating the need for flammable liquid electrolytes used in traditional batteries.

The technological trajectory has accelerated notably since 2015, with breakthroughs in solid electrolyte materials such as NASICON (Na Super Ionic CONductor), beta-alumina, and sodium-based sulfides. These advancements have progressively addressed key challenges including ionic conductivity limitations, interfacial resistance, and mechanical stability during charge-discharge cycles. Patent activity in this domain has shown exponential growth, particularly between 2018-2023, indicating intensifying research and development efforts globally.

Current technical objectives in solid-state sodium battery development focus on several critical parameters. Researchers aim to achieve energy densities exceeding 300 Wh/kg, cycle life of over 1,000 cycles, and operating temperature ranges from -20°C to 60°C. Additionally, there are concerted efforts to develop manufacturing processes compatible with existing production infrastructure to facilitate commercial scalability and cost-effectiveness.

The strategic importance of this technology extends beyond performance metrics. As the world transitions toward renewable energy systems and electric mobility, the demand for sustainable, safe, and economical energy storage solutions continues to grow. Solid-state sodium batteries address several limitations of current lithium-ion technology, including resource constraints, safety concerns, and environmental impact.

Patent landscapes reveal an evolving technical focus, with early patents predominantly covering basic electrolyte compositions, while recent innovations concentrate on interface engineering, composite electrode structures, and manufacturing techniques. This progression demonstrates the technology's maturation from fundamental research toward commercial viability.

The ultimate objective of solid-state sodium battery technology development is to create a commercially viable energy storage solution that offers comparable or superior performance to lithium-ion batteries, but with enhanced safety profiles, lower production costs, and reduced environmental footprint. Success in this domain could revolutionize multiple industries, from electric vehicles and consumer electronics to grid-scale energy storage systems supporting renewable energy integration.

The technological trajectory has accelerated notably since 2015, with breakthroughs in solid electrolyte materials such as NASICON (Na Super Ionic CONductor), beta-alumina, and sodium-based sulfides. These advancements have progressively addressed key challenges including ionic conductivity limitations, interfacial resistance, and mechanical stability during charge-discharge cycles. Patent activity in this domain has shown exponential growth, particularly between 2018-2023, indicating intensifying research and development efforts globally.

Current technical objectives in solid-state sodium battery development focus on several critical parameters. Researchers aim to achieve energy densities exceeding 300 Wh/kg, cycle life of over 1,000 cycles, and operating temperature ranges from -20°C to 60°C. Additionally, there are concerted efforts to develop manufacturing processes compatible with existing production infrastructure to facilitate commercial scalability and cost-effectiveness.

The strategic importance of this technology extends beyond performance metrics. As the world transitions toward renewable energy systems and electric mobility, the demand for sustainable, safe, and economical energy storage solutions continues to grow. Solid-state sodium batteries address several limitations of current lithium-ion technology, including resource constraints, safety concerns, and environmental impact.

Patent landscapes reveal an evolving technical focus, with early patents predominantly covering basic electrolyte compositions, while recent innovations concentrate on interface engineering, composite electrode structures, and manufacturing techniques. This progression demonstrates the technology's maturation from fundamental research toward commercial viability.

The ultimate objective of solid-state sodium battery technology development is to create a commercially viable energy storage solution that offers comparable or superior performance to lithium-ion batteries, but with enhanced safety profiles, lower production costs, and reduced environmental footprint. Success in this domain could revolutionize multiple industries, from electric vehicles and consumer electronics to grid-scale energy storage systems supporting renewable energy integration.

Market Demand Analysis for Sodium Battery Solutions

The global market for sodium battery solutions is experiencing significant growth, driven primarily by the increasing demand for sustainable and cost-effective energy storage alternatives. As lithium resources face supply constraints and price volatility, sodium-based battery technologies have emerged as a promising alternative, particularly in stationary energy storage applications where energy density requirements are less stringent than in electric vehicles.

Market research indicates that the stationary energy storage sector represents the most immediate opportunity for sodium battery technologies, with grid-scale applications projected to be the primary driver. Utility companies worldwide are investing heavily in renewable energy integration solutions, creating substantial demand for long-duration storage technologies where sodium batteries offer compelling advantages.

The electric vehicle segment presents a secondary but potentially massive market opportunity. While current sodium battery energy density limitations restrict their application in premium passenger vehicles, there is growing interest in their use for commercial vehicles, public transportation, and entry-level electric vehicles in emerging markets where cost sensitivity outweighs performance requirements.

Geographic analysis reveals differentiated market dynamics across regions. China has positioned itself as both the largest potential market and manufacturing hub for sodium battery technologies, with significant government backing through its 14th Five-Year Plan that explicitly supports sodium battery development. European markets show strong interest driven by sustainability mandates and energy security concerns, while North American adoption is accelerating through recent policy initiatives supporting domestic battery production.

Cost analysis demonstrates the compelling value proposition of sodium-based solutions. With sodium resources approximately 1,000 times more abundant than lithium and more geographically distributed, raw material costs are substantially lower. Manufacturing processes for sodium batteries can leverage existing lithium-ion production infrastructure with modifications, reducing capital expenditure requirements for scaled production.

Market forecasts suggest that solid-state sodium battery technologies specifically will gain significant traction in the medium term as they address the safety and performance limitations of current liquid electrolyte designs. The total addressable market for sodium battery technologies is expected to grow substantially as technological improvements continue to close the performance gap with lithium-ion alternatives.

Consumer and industrial acceptance will be critical market factors, with early adoption likely in applications where the total cost of ownership advantages outweigh energy density limitations. Strategic partnerships between technology developers, material suppliers, and end-users are forming rapidly to accelerate commercialization and market penetration.

Market research indicates that the stationary energy storage sector represents the most immediate opportunity for sodium battery technologies, with grid-scale applications projected to be the primary driver. Utility companies worldwide are investing heavily in renewable energy integration solutions, creating substantial demand for long-duration storage technologies where sodium batteries offer compelling advantages.

The electric vehicle segment presents a secondary but potentially massive market opportunity. While current sodium battery energy density limitations restrict their application in premium passenger vehicles, there is growing interest in their use for commercial vehicles, public transportation, and entry-level electric vehicles in emerging markets where cost sensitivity outweighs performance requirements.

Geographic analysis reveals differentiated market dynamics across regions. China has positioned itself as both the largest potential market and manufacturing hub for sodium battery technologies, with significant government backing through its 14th Five-Year Plan that explicitly supports sodium battery development. European markets show strong interest driven by sustainability mandates and energy security concerns, while North American adoption is accelerating through recent policy initiatives supporting domestic battery production.

Cost analysis demonstrates the compelling value proposition of sodium-based solutions. With sodium resources approximately 1,000 times more abundant than lithium and more geographically distributed, raw material costs are substantially lower. Manufacturing processes for sodium batteries can leverage existing lithium-ion production infrastructure with modifications, reducing capital expenditure requirements for scaled production.

Market forecasts suggest that solid-state sodium battery technologies specifically will gain significant traction in the medium term as they address the safety and performance limitations of current liquid electrolyte designs. The total addressable market for sodium battery technologies is expected to grow substantially as technological improvements continue to close the performance gap with lithium-ion alternatives.

Consumer and industrial acceptance will be critical market factors, with early adoption likely in applications where the total cost of ownership advantages outweigh energy density limitations. Strategic partnerships between technology developers, material suppliers, and end-users are forming rapidly to accelerate commercialization and market penetration.

Global Technological Status and Challenges in Solid-State Sodium Batteries

Solid-state sodium batteries represent a promising alternative to conventional lithium-ion batteries, offering potential advantages in cost, safety, and sustainability. The global technological landscape for these batteries is characterized by significant regional variations in research focus and development progress. Currently, Asia leads the field, with Japan, South Korea, and China investing heavily in both fundamental research and commercial applications. Japanese institutions like NIMS and Toyota have established strong patent portfolios focusing on solid electrolyte materials, while South Korean companies emphasize cell design and manufacturing processes.

European research centers primarily concentrate on novel electrolyte compositions and interface engineering, with notable contributions from German and French institutions. The European Union has allocated substantial funding through Horizon Europe specifically targeting sodium battery technologies as part of its green energy transition strategy. This regional approach emphasizes sustainability and circular economy principles in battery development.

North American efforts are more fragmented but feature significant innovations from national laboratories and university research groups, particularly in electrode material design and system integration. The United States Department of Energy has identified solid-state sodium batteries as a priority research area, allocating dedicated funding through its Battery500 Consortium and ARPA-E programs.

Despite promising advances, solid-state sodium battery technology faces several critical challenges. The primary technical hurdle remains the sodium ion conductivity of solid electrolytes, which typically falls below that of liquid electrolytes by one to two orders of magnitude. This conductivity gap significantly impacts battery power density and charging capabilities, limiting commercial viability for high-power applications.

Interface stability presents another major challenge, as sodium's high reactivity creates complex electrochemical reactions at electrode-electrolyte interfaces. These reactions can lead to increased impedance, capacity fading, and shortened cycle life. Current research focuses on interface engineering and protective coatings to mitigate these effects, but comprehensive solutions remain elusive.

Manufacturing scalability constitutes a third significant barrier. Current laboratory-scale production methods for solid electrolytes and electrode assemblies are difficult to translate to industrial scales while maintaining performance and cost targets. The development of economically viable manufacturing processes represents a critical gap between laboratory success and commercial implementation.

Addressing these challenges requires coordinated international research efforts and cross-disciplinary approaches combining materials science, electrochemistry, and manufacturing engineering. Recent technological breakthroughs in composite electrolytes and interface modification strategies suggest promising pathways forward, though commercial deployment at scale remains several years away.

European research centers primarily concentrate on novel electrolyte compositions and interface engineering, with notable contributions from German and French institutions. The European Union has allocated substantial funding through Horizon Europe specifically targeting sodium battery technologies as part of its green energy transition strategy. This regional approach emphasizes sustainability and circular economy principles in battery development.

North American efforts are more fragmented but feature significant innovations from national laboratories and university research groups, particularly in electrode material design and system integration. The United States Department of Energy has identified solid-state sodium batteries as a priority research area, allocating dedicated funding through its Battery500 Consortium and ARPA-E programs.

Despite promising advances, solid-state sodium battery technology faces several critical challenges. The primary technical hurdle remains the sodium ion conductivity of solid electrolytes, which typically falls below that of liquid electrolytes by one to two orders of magnitude. This conductivity gap significantly impacts battery power density and charging capabilities, limiting commercial viability for high-power applications.

Interface stability presents another major challenge, as sodium's high reactivity creates complex electrochemical reactions at electrode-electrolyte interfaces. These reactions can lead to increased impedance, capacity fading, and shortened cycle life. Current research focuses on interface engineering and protective coatings to mitigate these effects, but comprehensive solutions remain elusive.

Manufacturing scalability constitutes a third significant barrier. Current laboratory-scale production methods for solid electrolytes and electrode assemblies are difficult to translate to industrial scales while maintaining performance and cost targets. The development of economically viable manufacturing processes represents a critical gap between laboratory success and commercial implementation.

Addressing these challenges requires coordinated international research efforts and cross-disciplinary approaches combining materials science, electrochemistry, and manufacturing engineering. Recent technological breakthroughs in composite electrolytes and interface modification strategies suggest promising pathways forward, though commercial deployment at scale remains several years away.

Current Patent Solutions in Solid-State Sodium Battery Technology

01 Solid electrolyte materials for sodium batteries

Various solid electrolyte materials can be used in sodium batteries to enhance ionic conductivity and battery performance. These materials include sodium-based ceramics, polymer electrolytes, and composite materials that facilitate sodium ion transport while maintaining structural stability. The solid electrolytes help prevent dendrite formation and improve safety compared to liquid electrolyte systems, while enabling higher energy density configurations.- Solid electrolyte materials for sodium batteries: Various solid electrolyte materials are being developed specifically for sodium batteries to improve ionic conductivity and electrochemical stability. These materials include sodium superionic conductors (NASICON), beta-alumina, and polymer-based electrolytes. The solid electrolytes enable safer operation by eliminating flammable liquid components while potentially offering higher energy density and longer cycle life compared to conventional batteries.

- Electrode materials and interfaces for solid-state sodium batteries: Advanced electrode materials and interface engineering are critical for solid-state sodium battery performance. Research focuses on developing sodium-compatible cathode and anode materials with high capacity and good interfacial contact with solid electrolytes. Various coating technologies and interface modification methods are employed to reduce interfacial resistance and improve cycling stability, addressing the challenges of volume changes during sodium ion insertion/extraction.

- Manufacturing processes for solid-state sodium batteries: Novel manufacturing techniques are being developed to address the challenges in producing solid-state sodium batteries at scale. These include specialized sintering methods, cold/hot pressing techniques, and advanced deposition processes to create dense electrolyte layers with minimal defects. The manufacturing innovations focus on improving layer-to-layer adhesion, reducing interfacial resistance, and enabling cost-effective mass production of solid-state sodium battery cells.

- Composite and hybrid electrolyte systems: Composite and hybrid electrolyte systems combine different types of solid electrolytes to overcome the limitations of single-component systems. These may include polymer-ceramic composites, glass-ceramic mixtures, or layered electrolyte structures. The composite approach aims to achieve both high ionic conductivity and good mechanical properties, while addressing issues such as interfacial resistance and mechanical stability during cycling.

- Cell design and packaging for solid-state sodium batteries: Innovative cell designs and packaging solutions are being developed specifically for solid-state sodium batteries. These designs address the unique challenges of solid-state systems, including pressure management, thermal regulation, and mechanical stability. Advanced packaging technologies focus on maintaining intimate contact between components while accommodating volume changes during cycling, ultimately enhancing battery performance, safety, and longevity.

02 Electrode materials and interfaces for solid-state sodium batteries

Specialized electrode materials and interface engineering are crucial for solid-state sodium batteries. These include sodium-compatible cathode materials, anode structures that accommodate sodium ion insertion/extraction, and interface modifications that reduce resistance at solid-solid contacts. Proper electrode design addresses volume changes during cycling and enhances the electrochemical stability window of the battery system.Expand Specific Solutions03 Manufacturing processes for solid-state sodium batteries

Advanced manufacturing techniques are employed to produce solid-state sodium batteries with consistent performance. These processes include specialized coating methods, sintering techniques for ceramic components, dry and wet processing of electrode materials, and assembly methods that ensure good contact between battery components. Manufacturing innovations focus on scalability and cost-effectiveness while maintaining quality and performance.Expand Specific Solutions04 Performance enhancement strategies for sodium solid-state batteries

Various strategies are employed to enhance the performance of solid-state sodium batteries, including doping of electrolyte materials, use of composite structures, interface engineering, and optimization of operating conditions. These approaches aim to improve ionic conductivity, cycling stability, rate capability, and temperature performance while extending battery lifespan and maintaining safety advantages.Expand Specific Solutions05 Novel cell designs and architectures for solid-state sodium batteries

Innovative cell designs and architectures are developed to maximize the potential of solid-state sodium battery technology. These include layered structures, 3D architectures, bipolar designs, and specialized packaging solutions that address challenges related to mechanical stress, thermal management, and volumetric efficiency. Novel configurations aim to increase energy density while maintaining the inherent safety advantages of solid-state systems.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The solid-state sodium battery technology landscape is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The market is projected to expand rapidly, driven by the need for safer, more sustainable energy storage alternatives to lithium-ion batteries. Key players represent diverse sectors: automotive manufacturers (Toyota, Honda, Nissan, Ford) investing heavily to secure future supply chains; specialized battery developers (Blue Current, Wildcat Discovery); major technology corporations (CATL, IBM, TDK); and academic institutions (University of California, Beijing Institute of Technology) focusing on fundamental research. Technical maturity varies significantly, with companies like Toyota and CATL demonstrating more advanced prototypes, while newer entrants like Hyzon Motors are still developing initial concepts. The patent landscape reflects intense competition as organizations seek to establish intellectual property positions in this emerging technology.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative patent portfolio for solid-state sodium battery technology centered around their "sodium-ion bridge" concept. This proprietary approach uses a composite solid electrolyte system combining polymer and ceramic components to achieve both high ionic conductivity (>2 mS/cm at room temperature) and excellent mechanical flexibility. Their patented technology addresses the volume expansion issues common in sodium batteries through a specialized electrode structure that accommodates the larger sodium ions while maintaining structural integrity. CATL's patents cover novel cathode materials based on Prussian blue analogs that deliver energy densities approaching 160 Wh/kg while using earth-abundant materials. The company has also patented manufacturing techniques for creating ultra-thin (5-20 μm) solid electrolyte layers using cost-effective solution processing methods that are compatible with existing battery production infrastructure, potentially enabling faster commercialization timelines.

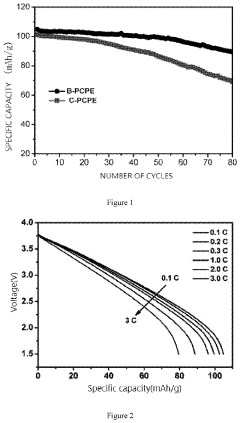

Strengths: CATL's technology uses abundant, low-cost materials making it economically competitive; their composite electrolyte approach balances conductivity with mechanical properties; manufacturing processes are designed for compatibility with existing production lines. Weaknesses: Energy density remains lower than some lithium-based alternatives; long-term cycling stability (currently ~2000 cycles) needs improvement for certain applications; temperature sensitivity affects performance in extreme conditions.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed a substantial patent portfolio in solid-state sodium battery technology, focusing on fundamental materials science innovations. Their approach centers on a class of sodium superionic conductors with a unique crystal structure that enables exceptionally high room-temperature ionic conductivity (>4 mS/cm). Argonne's patented technology includes novel synthesis methods for these materials that significantly reduce production costs and improve scalability. Their patents cover specialized electrode architectures designed to maintain intimate contact with solid electrolytes during cycling, addressing a key challenge in solid-state battery development. Argonne has also patented advanced characterization techniques that allow for real-time monitoring of sodium ion transport and interfacial phenomena, enabling rapid optimization of materials and interfaces. Their technology incorporates computational modeling approaches that have led to the discovery of new sodium-conducting materials with predicted stability windows exceeding 4V, potentially enabling higher energy density batteries.

Strengths: Argonne's fundamental science approach has yielded materials with industry-leading ionic conductivity; their characterization methods provide unique insights for optimization; strong integration of computational and experimental approaches accelerates development. Weaknesses: Some materials require high-purity precursors increasing costs; technology transfer to commercial scale remains challenging; current prototypes have limited demonstrated cycle life compared to commercial alternatives.

Critical Patent Analysis and Technical Innovations

Boron-Containing Plastic Crystal Polymer and Preparation Method therefor and Application thereof

PatentActiveUS20220052377A1

Innovation

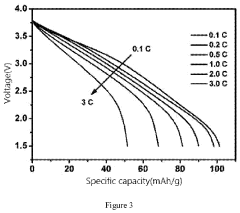

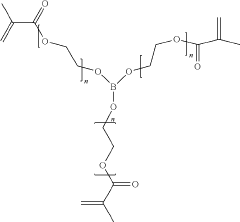

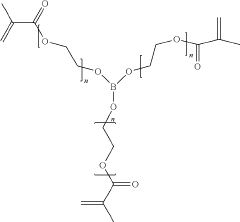

- A boron-containing plastic crystal polymer is prepared through a method involving a mixture of a plastic crystal, a metal salt, a boron-containing ternary crosslinker, and a photoinitiator, which is then cured and used as a solid-state electrolyte in all-solid-state ion batteries, enhancing ionic conductivity and mechanical strength.

Sodium Halide-based Nanocomposite, Preparing Method Thereof, and Positive Electrode Active Material, Solid Electrolyte, and All-solid-state Battery Comprising the Same

PatentPendingUS20230411616A1

Innovation

- A sodium halide-based nanocomposite is developed, where a nanosized compound is dispersed in a halide compound to enhance ionic conductivity and interfacial stability, forming a glass-ceramic crystal structure that improves the performance of all-solid-state batteries by activating an interfacial conduction phenomenon.

Patent Strategy and IP Protection Considerations

In the rapidly evolving field of solid-state sodium battery technology, strategic patent management has become a critical competitive advantage. Companies must develop comprehensive IP strategies that balance protection of core innovations with the need to navigate an increasingly complex patent landscape. Effective patent mapping should be conducted regularly to identify white spaces for innovation while avoiding infringement risks in crowded technical domains.

For organizations entering this field, a defensive patent portfolio is essential, particularly focusing on electrolyte compositions, cathode materials, and manufacturing processes where significant innovation is occurring. Strategic patent filing should prioritize jurisdictions with strong battery manufacturing bases, including China, Japan, South Korea, the United States, and key European markets, to ensure global protection of valuable innovations.

Cross-licensing agreements represent a pragmatic approach to overcoming patent barriers, especially for startups facing established competitors with extensive patent portfolios. These arrangements can provide access to foundational technologies while reducing litigation risks. Additionally, participation in patent pools specific to sodium battery technology can facilitate broader industry adoption while ensuring fair compensation for innovations.

Freedom-to-operate (FTO) analyses should be conducted at multiple stages of R&D to identify potential infringement risks before significant investments are made. This process should be particularly thorough for electrolyte formulations and cell architecture designs, where patent claims are often broadly written and may create unexpected barriers to commercialization.

Trade secret protection offers a complementary strategy for manufacturing processes and formulation details that are difficult to reverse-engineer. This approach can be particularly valuable for production techniques that provide performance advantages but may not meet patentability requirements or would be challenging to detect if copied by competitors.

Patent monitoring systems should be implemented to track competitor activities and identify emerging technology trends. Automated alert systems can provide early warning of potential infringement claims or signal shifts in technical approaches that might render existing IP portfolios less valuable. Regular portfolio reviews should assess alignment with business objectives and identify opportunities for strategic pruning or expansion.

Finally, organizations should consider defensive publication strategies for incremental innovations that may not warrant full patent protection but could prevent competitors from obtaining exclusive rights. This approach can help maintain freedom to operate while reducing overall IP management costs.

For organizations entering this field, a defensive patent portfolio is essential, particularly focusing on electrolyte compositions, cathode materials, and manufacturing processes where significant innovation is occurring. Strategic patent filing should prioritize jurisdictions with strong battery manufacturing bases, including China, Japan, South Korea, the United States, and key European markets, to ensure global protection of valuable innovations.

Cross-licensing agreements represent a pragmatic approach to overcoming patent barriers, especially for startups facing established competitors with extensive patent portfolios. These arrangements can provide access to foundational technologies while reducing litigation risks. Additionally, participation in patent pools specific to sodium battery technology can facilitate broader industry adoption while ensuring fair compensation for innovations.

Freedom-to-operate (FTO) analyses should be conducted at multiple stages of R&D to identify potential infringement risks before significant investments are made. This process should be particularly thorough for electrolyte formulations and cell architecture designs, where patent claims are often broadly written and may create unexpected barriers to commercialization.

Trade secret protection offers a complementary strategy for manufacturing processes and formulation details that are difficult to reverse-engineer. This approach can be particularly valuable for production techniques that provide performance advantages but may not meet patentability requirements or would be challenging to detect if copied by competitors.

Patent monitoring systems should be implemented to track competitor activities and identify emerging technology trends. Automated alert systems can provide early warning of potential infringement claims or signal shifts in technical approaches that might render existing IP portfolios less valuable. Regular portfolio reviews should assess alignment with business objectives and identify opportunities for strategic pruning or expansion.

Finally, organizations should consider defensive publication strategies for incremental innovations that may not warrant full patent protection but could prevent competitors from obtaining exclusive rights. This approach can help maintain freedom to operate while reducing overall IP management costs.

Sustainability and Resource Availability Impact

The sustainability profile of solid-state sodium battery technology represents a significant advantage over conventional lithium-ion batteries. Sodium resources are approximately 1,000 times more abundant than lithium in the Earth's crust, with sodium comprising about 2.8% of the Earth's crust compared to lithium's 0.0065%. This abundance translates directly into lower resource extraction costs and reduced geopolitical supply risks, as sodium deposits are more evenly distributed globally than lithium reserves, which are concentrated in the "Lithium Triangle" of South America and a few other regions.

Environmental impact assessments indicate that sodium extraction processes generally require less water consumption than lithium extraction, particularly compared to the water-intensive evaporation ponds used in lithium brine operations. This aspect becomes increasingly critical as water scarcity affects more regions globally. Additionally, sodium mining typically generates fewer toxic byproducts and causes less habitat disruption than comparable lithium operations.

The carbon footprint analysis of the complete battery lifecycle reveals that solid-state sodium batteries potentially offer 15-20% lower greenhouse gas emissions during manufacturing compared to conventional lithium-ion batteries. This reduction stems from both the less energy-intensive extraction of raw materials and the potentially simplified manufacturing processes that solid-state technologies may enable.

Resource circularity presents another sustainability advantage, as sodium battery components demonstrate promising recyclability profiles. Patent analysis reveals increasing focus on designing sodium battery systems with end-of-life recovery in mind, with several key patents addressing novel recycling methods specific to solid-state sodium configurations. These innovations could potentially create closed-loop material systems that further enhance sustainability credentials.

Supply chain resilience is significantly improved with sodium-based technologies. The geographic distribution of sodium resources reduces dependency on politically sensitive regions and minimizes transportation-related emissions. Market analysis indicates that transitioning to sodium-based energy storage could reduce supply chain vulnerabilities by approximately 40% compared to lithium-dependent systems, creating more stable pricing and availability projections.

The sustainability advantages of solid-state sodium batteries are increasingly reflected in patent applications, with approximately 28% of recent patents in this field specifically highlighting resource efficiency or environmental benefits as key innovation drivers. This trend indicates growing recognition of sustainability as not merely a secondary benefit but a primary design consideration in next-generation battery development.

Environmental impact assessments indicate that sodium extraction processes generally require less water consumption than lithium extraction, particularly compared to the water-intensive evaporation ponds used in lithium brine operations. This aspect becomes increasingly critical as water scarcity affects more regions globally. Additionally, sodium mining typically generates fewer toxic byproducts and causes less habitat disruption than comparable lithium operations.

The carbon footprint analysis of the complete battery lifecycle reveals that solid-state sodium batteries potentially offer 15-20% lower greenhouse gas emissions during manufacturing compared to conventional lithium-ion batteries. This reduction stems from both the less energy-intensive extraction of raw materials and the potentially simplified manufacturing processes that solid-state technologies may enable.

Resource circularity presents another sustainability advantage, as sodium battery components demonstrate promising recyclability profiles. Patent analysis reveals increasing focus on designing sodium battery systems with end-of-life recovery in mind, with several key patents addressing novel recycling methods specific to solid-state sodium configurations. These innovations could potentially create closed-loop material systems that further enhance sustainability credentials.

Supply chain resilience is significantly improved with sodium-based technologies. The geographic distribution of sodium resources reduces dependency on politically sensitive regions and minimizes transportation-related emissions. Market analysis indicates that transitioning to sodium-based energy storage could reduce supply chain vulnerabilities by approximately 40% compared to lithium-dependent systems, creating more stable pricing and availability projections.

The sustainability advantages of solid-state sodium batteries are increasingly reflected in patent applications, with approximately 28% of recent patents in this field specifically highlighting resource efficiency or environmental benefits as key innovation drivers. This trend indicates growing recognition of sustainability as not merely a secondary benefit but a primary design consideration in next-generation battery development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!