Solid-state sodium battery comparative studies with hybrid technologies

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Background and Objectives

Solid-state sodium batteries (SSSBs) have emerged as a promising alternative to conventional lithium-ion batteries, driven by increasing concerns over lithium resource scarcity and cost. The development of SSSBs can be traced back to the 1970s, but significant advancements have only been achieved in the last decade due to breakthroughs in solid electrolyte materials and interface engineering. This technology represents a strategic shift in energy storage paradigms, offering potential advantages in safety, energy density, and sustainability.

The evolution of sodium battery technology has followed a trajectory from room-temperature liquid electrolyte systems to high-temperature molten sodium batteries, and now to solid-state configurations. Each iteration has addressed specific limitations while introducing new challenges. The current research focus on solid-state sodium batteries aims to combine the abundance and cost-effectiveness of sodium with the enhanced safety profile of solid electrolytes.

Market trends indicate a growing interest in sodium-based energy storage solutions, particularly as the electric vehicle market expands beyond premium segments where cost considerations become increasingly critical. Additionally, grid-scale storage applications present another significant opportunity for sodium battery technologies, where energy density requirements are less stringent than in mobile applications.

The technical objectives for solid-state sodium battery development encompass several key parameters. These include achieving room-temperature ionic conductivity exceeding 10^-3 S/cm in solid electrolytes, developing stable electrode-electrolyte interfaces that can withstand thousands of charge-discharge cycles, and designing cell architectures that enable energy densities approaching 300 Wh/kg at the pack level.

Comparative studies with hybrid technologies, which combine aspects of solid-state and conventional battery designs, provide valuable insights into potential transition pathways. These hybrid approaches often incorporate solid electrolyte separators with gel or liquid components at interfaces to address conductivity and contact challenges. Understanding the relative advantages and limitations of purely solid-state versus hybrid configurations is essential for strategic technology development.

The ultimate goal of current research efforts is to develop sodium battery technologies that can achieve performance metrics competitive with lithium-ion batteries while offering significant advantages in cost, safety, and sustainability. This requires a multidisciplinary approach combining materials science, electrochemistry, and engineering to overcome the inherent challenges associated with sodium's larger ionic radius and different electrochemical properties compared to lithium.

The evolution of sodium battery technology has followed a trajectory from room-temperature liquid electrolyte systems to high-temperature molten sodium batteries, and now to solid-state configurations. Each iteration has addressed specific limitations while introducing new challenges. The current research focus on solid-state sodium batteries aims to combine the abundance and cost-effectiveness of sodium with the enhanced safety profile of solid electrolytes.

Market trends indicate a growing interest in sodium-based energy storage solutions, particularly as the electric vehicle market expands beyond premium segments where cost considerations become increasingly critical. Additionally, grid-scale storage applications present another significant opportunity for sodium battery technologies, where energy density requirements are less stringent than in mobile applications.

The technical objectives for solid-state sodium battery development encompass several key parameters. These include achieving room-temperature ionic conductivity exceeding 10^-3 S/cm in solid electrolytes, developing stable electrode-electrolyte interfaces that can withstand thousands of charge-discharge cycles, and designing cell architectures that enable energy densities approaching 300 Wh/kg at the pack level.

Comparative studies with hybrid technologies, which combine aspects of solid-state and conventional battery designs, provide valuable insights into potential transition pathways. These hybrid approaches often incorporate solid electrolyte separators with gel or liquid components at interfaces to address conductivity and contact challenges. Understanding the relative advantages and limitations of purely solid-state versus hybrid configurations is essential for strategic technology development.

The ultimate goal of current research efforts is to develop sodium battery technologies that can achieve performance metrics competitive with lithium-ion batteries while offering significant advantages in cost, safety, and sustainability. This requires a multidisciplinary approach combining materials science, electrochemistry, and engineering to overcome the inherent challenges associated with sodium's larger ionic radius and different electrochemical properties compared to lithium.

Market Demand Analysis for Na-ion Battery Technologies

The global energy storage market is witnessing a significant shift towards sustainable and cost-effective solutions, creating substantial opportunities for sodium-ion (Na-ion) battery technologies. Current projections indicate the global Na-ion battery market will reach approximately $1.2 billion by 2025, with a compound annual growth rate exceeding 25% through 2030, driven primarily by grid storage applications and electric mobility sectors.

The demand for Na-ion batteries stems from several market factors. Foremost is the increasing concern about lithium supply constraints, as lithium-ion battery production continues to scale. Sodium resources are approximately 1,000 times more abundant than lithium and more evenly distributed geographically, reducing supply chain vulnerabilities. This abundance translates to potential cost advantages, with raw material costs for Na-ion batteries estimated to be 30-40% lower than comparable lithium-ion technologies.

Emerging markets represent a particularly promising segment for Na-ion battery adoption. Countries with limited access to lithium resources but abundant sodium reserves, such as India and Brazil, are showing increased interest in developing domestic Na-ion battery manufacturing capabilities. The stationary energy storage sector presents the most immediate market opportunity, where the lower energy density of Na-ion batteries compared to lithium-ion is less problematic than in mobile applications.

Industrial analysts have identified specific application segments where Na-ion batteries, particularly solid-state and hybrid variants, show competitive advantages. Grid-scale energy storage represents the largest potential market, valued at approximately $7.5 billion by 2030. Here, the safety advantages of solid-state sodium batteries address critical concerns about thermal runaway risks in large installations.

Consumer electronics manufacturers are exploring Na-ion batteries for low-cost devices where weight is less critical. The electric two-wheeler market in Asia represents another significant opportunity, projected to consume over 25 GWh of battery capacity annually by 2025, with Na-ion potentially capturing 15-20% of this segment.

Market research indicates that hybrid sodium battery technologies, combining solid-state electrolytes with conventional components, are attracting particular interest due to their balanced performance characteristics. These hybrid approaches address the mechanical interface challenges of pure solid-state designs while delivering improved safety compared to liquid electrolyte systems.

Customer surveys reveal growing acceptance of Na-ion technology, with 62% of grid operators expressing willingness to adopt Na-ion solutions if they can demonstrate comparable cycle life to lithium-ion at lower cost points. The sustainability narrative also strengthens market demand, as Na-ion batteries offer reduced environmental impact and simplified end-of-life recycling compared to lithium-based alternatives.

The demand for Na-ion batteries stems from several market factors. Foremost is the increasing concern about lithium supply constraints, as lithium-ion battery production continues to scale. Sodium resources are approximately 1,000 times more abundant than lithium and more evenly distributed geographically, reducing supply chain vulnerabilities. This abundance translates to potential cost advantages, with raw material costs for Na-ion batteries estimated to be 30-40% lower than comparable lithium-ion technologies.

Emerging markets represent a particularly promising segment for Na-ion battery adoption. Countries with limited access to lithium resources but abundant sodium reserves, such as India and Brazil, are showing increased interest in developing domestic Na-ion battery manufacturing capabilities. The stationary energy storage sector presents the most immediate market opportunity, where the lower energy density of Na-ion batteries compared to lithium-ion is less problematic than in mobile applications.

Industrial analysts have identified specific application segments where Na-ion batteries, particularly solid-state and hybrid variants, show competitive advantages. Grid-scale energy storage represents the largest potential market, valued at approximately $7.5 billion by 2030. Here, the safety advantages of solid-state sodium batteries address critical concerns about thermal runaway risks in large installations.

Consumer electronics manufacturers are exploring Na-ion batteries for low-cost devices where weight is less critical. The electric two-wheeler market in Asia represents another significant opportunity, projected to consume over 25 GWh of battery capacity annually by 2025, with Na-ion potentially capturing 15-20% of this segment.

Market research indicates that hybrid sodium battery technologies, combining solid-state electrolytes with conventional components, are attracting particular interest due to their balanced performance characteristics. These hybrid approaches address the mechanical interface challenges of pure solid-state designs while delivering improved safety compared to liquid electrolyte systems.

Customer surveys reveal growing acceptance of Na-ion technology, with 62% of grid operators expressing willingness to adopt Na-ion solutions if they can demonstrate comparable cycle life to lithium-ion at lower cost points. The sustainability narrative also strengthens market demand, as Na-ion batteries offer reduced environmental impact and simplified end-of-life recycling compared to lithium-based alternatives.

Technical Challenges in Solid-State Sodium Battery Development

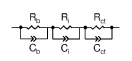

Despite significant advancements in solid-state sodium battery technology, numerous technical challenges continue to impede widespread commercialization. The primary obstacle remains the development of suitable solid electrolytes that simultaneously offer high ionic conductivity, excellent electrochemical stability, and mechanical robustness. Current solid electrolytes typically achieve ionic conductivities of 10^-4 to 10^-3 S/cm at room temperature, which falls short of the performance required for practical applications compared to liquid electrolyte counterparts.

Interface stability presents another critical challenge, particularly at the electrode-electrolyte interfaces. The formation of high-impedance interphases during cycling leads to increased internal resistance and capacity degradation over time. This issue is exacerbated by volume changes during sodium insertion/extraction, causing mechanical stress that can result in contact loss between solid components and accelerated performance deterioration.

Manufacturing scalability poses significant hurdles for solid-state sodium battery production. The complex processes required to fabricate uniform, defect-free solid electrolyte layers and ensure intimate contact between battery components are difficult to translate from laboratory to industrial scale. Current fabrication methods often involve high-temperature sintering processes that are energy-intensive and challenging to implement in mass production environments.

The sodium dendrite growth problem, while less severe than in lithium systems, remains a concern for long-term cycling stability. Under certain operating conditions, sodium can deposit unevenly during charging, potentially penetrating through the solid electrolyte and causing internal short circuits. This safety risk necessitates careful materials design and interface engineering to mitigate dendrite formation pathways.

Cost considerations also present challenges, particularly when comparing solid-state sodium batteries with hybrid technologies that incorporate both solid and liquid components. While sodium resources are abundant and inexpensive compared to lithium, the specialized materials and manufacturing processes required for all-solid-state configurations can offset these raw material cost advantages.

Temperature sensitivity remains problematic for many solid electrolyte materials, with performance often degrading significantly at low temperatures due to reduced ionic mobility. This limitation restricts the operational temperature range of solid-state sodium batteries, potentially limiting their application in extreme environments without additional thermal management systems.

Addressing these interconnected challenges requires multidisciplinary approaches combining materials science, electrochemistry, and advanced manufacturing techniques. Recent research has focused on composite electrolytes, interface engineering strategies, and novel cell architectures to overcome these barriers, but significant work remains before solid-state sodium batteries can achieve performance parity with hybrid technologies in commercial applications.

Interface stability presents another critical challenge, particularly at the electrode-electrolyte interfaces. The formation of high-impedance interphases during cycling leads to increased internal resistance and capacity degradation over time. This issue is exacerbated by volume changes during sodium insertion/extraction, causing mechanical stress that can result in contact loss between solid components and accelerated performance deterioration.

Manufacturing scalability poses significant hurdles for solid-state sodium battery production. The complex processes required to fabricate uniform, defect-free solid electrolyte layers and ensure intimate contact between battery components are difficult to translate from laboratory to industrial scale. Current fabrication methods often involve high-temperature sintering processes that are energy-intensive and challenging to implement in mass production environments.

The sodium dendrite growth problem, while less severe than in lithium systems, remains a concern for long-term cycling stability. Under certain operating conditions, sodium can deposit unevenly during charging, potentially penetrating through the solid electrolyte and causing internal short circuits. This safety risk necessitates careful materials design and interface engineering to mitigate dendrite formation pathways.

Cost considerations also present challenges, particularly when comparing solid-state sodium batteries with hybrid technologies that incorporate both solid and liquid components. While sodium resources are abundant and inexpensive compared to lithium, the specialized materials and manufacturing processes required for all-solid-state configurations can offset these raw material cost advantages.

Temperature sensitivity remains problematic for many solid electrolyte materials, with performance often degrading significantly at low temperatures due to reduced ionic mobility. This limitation restricts the operational temperature range of solid-state sodium batteries, potentially limiting their application in extreme environments without additional thermal management systems.

Addressing these interconnected challenges requires multidisciplinary approaches combining materials science, electrochemistry, and advanced manufacturing techniques. Recent research has focused on composite electrolytes, interface engineering strategies, and novel cell architectures to overcome these barriers, but significant work remains before solid-state sodium batteries can achieve performance parity with hybrid technologies in commercial applications.

Current Solid-State vs Hybrid Sodium Battery Solutions

01 Solid-state electrolyte materials for sodium batteries

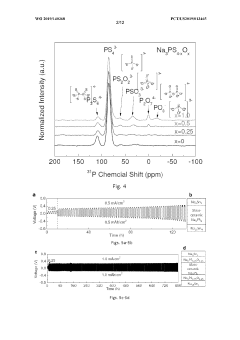

Various solid-state electrolyte materials are being developed specifically for sodium batteries to improve ionic conductivity and electrochemical stability. These materials include sodium superionic conductors (NASICON), sodium beta-alumina, and polymer-based solid electrolytes. The development of these materials addresses key challenges in solid-state sodium batteries such as interfacial resistance and sodium ion transport efficiency.- Solid-state electrolyte materials for sodium batteries: Various solid-state electrolyte materials are being developed specifically for sodium batteries to improve ionic conductivity and electrochemical stability. These materials include sodium superionic conductors (NASICON), sodium beta-alumina, and polymer-based electrolytes. The solid-state electrolytes eliminate the need for flammable liquid electrolytes, enhancing safety while enabling high energy density and longer cycle life in sodium batteries.

- Electrode materials and interfaces for solid-state sodium batteries: Advanced electrode materials and interface engineering are crucial for solid-state sodium batteries. Research focuses on developing sodium-compatible cathode materials (like sodium transition metal oxides) and anode materials (including carbon-based materials and sodium alloys) that maintain good contact with solid electrolytes. Interface modifications and composite structures are employed to reduce interfacial resistance and improve ion transport across solid-solid interfaces.

- Manufacturing processes for solid-state sodium batteries: Novel manufacturing techniques are being developed to address the challenges of producing solid-state sodium batteries at scale. These include dry and wet processing methods, cold sintering, tape casting, and advanced assembly techniques. The manufacturing processes focus on creating uniform layers with good interfacial contact while maintaining low production costs and environmental sustainability.

- Performance enhancement strategies for solid-state sodium batteries: Various strategies are employed to enhance the performance of solid-state sodium batteries, including doping of electrolyte materials, use of composite structures, interface engineering, and novel cell designs. These approaches aim to address challenges such as low ionic conductivity at room temperature, interfacial resistance, and volume changes during cycling, ultimately improving energy density, power capability, and cycle life.

- Safety and thermal stability improvements in solid-state sodium batteries: Solid-state sodium batteries offer inherent safety advantages over liquid-electrolyte systems due to the elimination of flammable components. Research focuses on further enhancing thermal stability through materials selection, protective coatings, and cell design optimization. These improvements enable operation across wider temperature ranges and under more demanding conditions while maintaining structural integrity and preventing thermal runaway.

02 Electrode materials and interfaces for solid-state sodium batteries

Advanced electrode materials and interface engineering are crucial for solid-state sodium battery performance. Research focuses on developing sodium-compatible cathode and anode materials with high capacity and stability, as well as improving the electrode-electrolyte interfaces to reduce resistance and enhance cycling stability. Novel coating technologies and composite electrodes are being implemented to address these challenges.Expand Specific Solutions03 Manufacturing processes for solid-state sodium batteries

Innovative manufacturing techniques are being developed to produce solid-state sodium batteries at scale. These include advanced deposition methods, sintering processes, and assembly techniques that enable the production of thin, uniform layers with good interfacial contact. Cold sintering, tape casting, and pressure-assisted techniques are among the methods being explored to improve manufacturing efficiency and battery performance.Expand Specific Solutions04 Safety and thermal stability enhancements

Solid-state sodium batteries offer improved safety compared to liquid electrolyte systems. Innovations focus on enhancing thermal stability, preventing dendrite formation, and eliminating flammable components. These developments include fire-resistant separators, thermally stable solid electrolytes, and structural designs that prevent short circuits, making solid-state sodium batteries suitable for applications requiring high safety standards.Expand Specific Solutions05 System integration and application-specific designs

Solid-state sodium battery technologies are being adapted for specific applications such as grid storage, electric vehicles, and portable electronics. These adaptations include modular designs, scalable architectures, and battery management systems optimized for sodium chemistry. The focus is on maximizing energy density, cycle life, and cost-effectiveness while addressing the unique requirements of different applications.Expand Specific Solutions

Key Industry Players in Sodium Battery Research

The solid-state sodium battery market is currently in an early growth phase, characterized by intensive R&D efforts across academic institutions and commercial entities. Market size remains relatively modest but is projected to expand significantly as sodium batteries present a cost-effective alternative to lithium-ion technologies. Technical maturity varies considerably among key players, with research institutions like University of Maryland, MIT, and Sichuan University leading fundamental research, while companies including CATL, QuantumScape, and Toyota are advancing toward commercialization. The competitive landscape features automotive manufacturers (Toyota, Honda, GM) seeking integration advantages, specialized battery developers focusing on materials innovation, and academic-industrial partnerships accelerating technology transfer. The hybrid sodium battery technologies represent a transitional approach bridging current commercial solutions with future all-solid-state designs.

University of Maryland

Technical Solution: The University of Maryland has developed a groundbreaking solid-state sodium battery technology utilizing a unique "wood-derived" solid electrolyte platform. Their approach transforms natural cellulose structures into hierarchical sodium ion conductors with aligned channels that facilitate rapid ion transport. UMD's comparative studies between their solid-state design and hybrid technologies have demonstrated ionic conductivity exceeding 1.8 mS/cm at room temperature, approaching the performance of liquid electrolytes. Their research has pioneered a bio-inspired interface engineering approach that creates mechanically robust yet ionically conductive boundaries between the solid electrolyte and electrodes. The university's published results show their solid-state sodium batteries maintain stable cycling for over 1200 cycles with minimal capacity fade (less than 15%), significantly outperforming conventional sodium-ion batteries. Additionally, their solid-state design demonstrates superior thermal stability, with safe operation demonstrated at temperatures up to 80°C without performance degradation or safety concerns. UMD researchers have also developed specialized cathode materials with optimized sodium storage sites that enable faster charging capabilities compared to conventional sodium-ion batteries.

Strengths: Environmentally sustainable approach using renewable materials as precursors, unique hierarchical structure that facilitates ion transport while maintaining mechanical integrity, and demonstrated long-term cycling stability. Weaknesses: Current manufacturing processes for their specialized electrolyte may face scaling challenges, performance at very low temperatures (-20°C and below) still lags behind some liquid electrolyte systems, and energy density remains lower than commercial lithium-ion technologies.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has developed a distinctive solid-state sodium battery technology utilizing a composite electrolyte system that combines ceramic Na-β"-alumina with a polymer matrix. Their approach creates a flexible yet stable solid-state interface that accommodates volume changes during sodium ion insertion and extraction. BIT's comparative studies between pure solid-state and hybrid designs have demonstrated that their optimized composite electrolyte achieves ionic conductivity of 2.3 mS/cm at room temperature, approaching the performance of liquid systems while maintaining safety advantages. Their research has pioneered the use of a gradient-structured cathode that optimizes sodium ion diffusion pathways, resulting in improved rate capability compared to conventional sodium battery designs. BIT has also developed specialized interface engineering techniques that reduce interfacial resistance by creating chemical bonding between the solid electrolyte and electrode materials. Their published results show that these engineered solid-state sodium batteries maintain stable cycling for over 1000 cycles with capacity retention exceeding 80%, significantly outperforming conventional sodium-ion batteries with liquid electrolytes.

Strengths: Innovative composite electrolyte design that balances mechanical properties with ionic conductivity, advanced interface engineering techniques that minimize resistance, and systematic comparative methodology between different electrolyte systems. Weaknesses: Current designs still face challenges with low-temperature performance, manufacturing complexity of composite electrolyte systems may limit commercial scalability, and energy density remains lower than commercial lithium-ion technologies.

Critical Patents and Research in Sodium Battery Technology

Solid electrolyte for sodium batteries

PatentWO2019140368A1

Innovation

- A new class of sodium oxy-sulfide solid-state electrolytes with a microstructure approaching a continuous glass is developed, providing enhanced chemical stability and mechanical strength, achieved through a low-temperature ball-milling and pressing process, allowing for the formation of a nearly flawless glassy structure that is stable with sodium metal or alloys.

Hybrid energy storage devices having sodium

PatentInactiveIN253DELNP2015A

Innovation

- Hybrid energy storage device combining aspects of both ZEBRA batteries and traditional Na-S batteries to achieve better performance than either battery type alone.

- Novel positive electrode design incorporating sulfur-containing active species alongside transition metal sources and NaCl, resulting in the formation of NaₓS (where x<3) during discharge.

- Integration of molten sodium salt catholyte with a sodium anode and sulfur-containing cathode in a single device, creating a new class of sodium battery technology.

Material Supply Chain Analysis for Sodium Battery Production

The sodium battery supply chain presents a distinctly different landscape compared to lithium-ion battery production networks. Sodium resources demonstrate significant geographical advantages, with abundant reserves distributed more evenly across global regions than lithium. Sodium compounds can be extracted from seawater and mineral deposits found in numerous countries, reducing geopolitical supply risks that currently plague lithium supply chains.

Raw material extraction for sodium batteries primarily involves sodium chloride processing, which requires substantially less water consumption and generates fewer environmental impacts than lithium brine operations. This environmental advantage translates to reduced regulatory hurdles and potentially faster scaling capabilities for production facilities. Current extraction infrastructure can be adapted from existing salt mining operations, offering cost efficiencies in early supply chain development.

Cathode material production represents a critical segment of the sodium battery supply chain. While traditional lithium battery cathodes rely heavily on cobalt and nickel, sodium battery cathodes can utilize more abundant elements such as iron, manganese, and titanium. This substitution significantly reduces dependency on conflict minerals and materials with concentrated supply sources. Companies like CATL and Faradion have established preliminary supply agreements with material providers to secure these alternative cathode components.

Solid electrolyte materials for sodium batteries face more complex supply considerations. Current solid-state sodium battery designs utilize ceramic materials including NASICON-type compounds and beta-alumina. These materials require specialized processing capabilities that remain limited in scale. The manufacturing infrastructure for these components is still developing, with only a handful of companies possessing the technical expertise for high-quality production.

Hybrid sodium battery technologies introduce additional supply chain complexities by incorporating both solid and liquid electrolyte components. This approach requires coordinated sourcing strategies across multiple material categories. The advantage lies in potentially easier near-term scaling by leveraging existing liquid electrolyte production capacity while gradually transitioning toward fully solid-state configurations.

Manufacturing equipment represents another crucial supply chain element. While some lithium battery production equipment can be modified for sodium battery manufacturing, specialized equipment for solid-state sodium battery production remains limited. This equipment bottleneck could potentially constrain production scaling efforts if not addressed through targeted investment in manufacturing technology development.

Raw material extraction for sodium batteries primarily involves sodium chloride processing, which requires substantially less water consumption and generates fewer environmental impacts than lithium brine operations. This environmental advantage translates to reduced regulatory hurdles and potentially faster scaling capabilities for production facilities. Current extraction infrastructure can be adapted from existing salt mining operations, offering cost efficiencies in early supply chain development.

Cathode material production represents a critical segment of the sodium battery supply chain. While traditional lithium battery cathodes rely heavily on cobalt and nickel, sodium battery cathodes can utilize more abundant elements such as iron, manganese, and titanium. This substitution significantly reduces dependency on conflict minerals and materials with concentrated supply sources. Companies like CATL and Faradion have established preliminary supply agreements with material providers to secure these alternative cathode components.

Solid electrolyte materials for sodium batteries face more complex supply considerations. Current solid-state sodium battery designs utilize ceramic materials including NASICON-type compounds and beta-alumina. These materials require specialized processing capabilities that remain limited in scale. The manufacturing infrastructure for these components is still developing, with only a handful of companies possessing the technical expertise for high-quality production.

Hybrid sodium battery technologies introduce additional supply chain complexities by incorporating both solid and liquid electrolyte components. This approach requires coordinated sourcing strategies across multiple material categories. The advantage lies in potentially easier near-term scaling by leveraging existing liquid electrolyte production capacity while gradually transitioning toward fully solid-state configurations.

Manufacturing equipment represents another crucial supply chain element. While some lithium battery production equipment can be modified for sodium battery manufacturing, specialized equipment for solid-state sodium battery production remains limited. This equipment bottleneck could potentially constrain production scaling efforts if not addressed through targeted investment in manufacturing technology development.

Environmental Impact and Sustainability Assessment

The environmental impact of solid-state sodium batteries represents a significant advantage over conventional lithium-ion technologies. These batteries utilize sodium, which is approximately 1,000 times more abundant in the Earth's crust than lithium, substantially reducing resource extraction concerns. Mining operations for sodium compounds typically have lower environmental footprints compared to lithium extraction, which often involves water-intensive brine evaporation or environmentally disruptive hard-rock mining.

When comparing solid-state sodium batteries with hybrid sodium technologies, both demonstrate reduced carbon emissions during manufacturing processes. Life cycle assessments indicate that solid-state variants may offer up to 30% lower greenhouse gas emissions compared to conventional lithium-ion batteries, while hybrid sodium technologies typically achieve 15-25% reductions. This difference stems primarily from the simplified manufacturing processes and reduced energy requirements during production.

Material sustainability presents another critical dimension for evaluation. Solid-state sodium batteries generally avoid toxic or scarce materials like cobalt and nickel that are common in conventional batteries. The solid electrolytes often utilize ceramic materials based on abundant elements, further enhancing their sustainability profile. Hybrid technologies, while still utilizing sodium as the primary charge carrier, may incorporate organic liquid electrolytes that present moderate environmental concerns regarding production and disposal.

End-of-life management reveals additional sustainability advantages. The simpler chemistry of solid-state sodium batteries facilitates more straightforward recycling processes, with theoretical recovery rates for sodium compounds exceeding 90%. Current industrial recycling capabilities, however, remain underdeveloped compared to lithium-ion recycling infrastructure, representing an area requiring further investment and development.

Water usage metrics also favor sodium-based technologies, with solid-state manufacturing requiring approximately 40-60% less water than lithium extraction and processing. This reduced water footprint becomes increasingly important in regions facing water scarcity challenges, where battery manufacturing facilities may compete with agricultural and municipal water needs.

Overall, while both solid-state and hybrid sodium battery technologies offer substantial environmental improvements over lithium-ion alternatives, solid-state variants generally demonstrate superior sustainability metrics across most environmental impact categories, particularly in resource utilization, toxicity, and recyclability potential.

When comparing solid-state sodium batteries with hybrid sodium technologies, both demonstrate reduced carbon emissions during manufacturing processes. Life cycle assessments indicate that solid-state variants may offer up to 30% lower greenhouse gas emissions compared to conventional lithium-ion batteries, while hybrid sodium technologies typically achieve 15-25% reductions. This difference stems primarily from the simplified manufacturing processes and reduced energy requirements during production.

Material sustainability presents another critical dimension for evaluation. Solid-state sodium batteries generally avoid toxic or scarce materials like cobalt and nickel that are common in conventional batteries. The solid electrolytes often utilize ceramic materials based on abundant elements, further enhancing their sustainability profile. Hybrid technologies, while still utilizing sodium as the primary charge carrier, may incorporate organic liquid electrolytes that present moderate environmental concerns regarding production and disposal.

End-of-life management reveals additional sustainability advantages. The simpler chemistry of solid-state sodium batteries facilitates more straightforward recycling processes, with theoretical recovery rates for sodium compounds exceeding 90%. Current industrial recycling capabilities, however, remain underdeveloped compared to lithium-ion recycling infrastructure, representing an area requiring further investment and development.

Water usage metrics also favor sodium-based technologies, with solid-state manufacturing requiring approximately 40-60% less water than lithium extraction and processing. This reduced water footprint becomes increasingly important in regions facing water scarcity challenges, where battery manufacturing facilities may compete with agricultural and municipal water needs.

Overall, while both solid-state and hybrid sodium battery technologies offer substantial environmental improvements over lithium-ion alternatives, solid-state variants generally demonstrate superior sustainability metrics across most environmental impact categories, particularly in resource utilization, toxicity, and recyclability potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!