Research advancements on solid-state sodium battery efficiency

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Evolution and Objectives

Solid-state sodium batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development trajectory of these batteries can be traced back to the early 2000s when researchers began exploring sodium as a more abundant and cost-effective alternative to lithium. The initial focus was primarily on sodium-ion batteries with liquid electrolytes, but limitations in safety and performance drove the transition toward solid-state configurations.

The evolution accelerated around 2010-2015 when significant breakthroughs in solid electrolyte materials enabled the practical development of solid-state sodium batteries. These advancements addressed critical challenges such as interfacial resistance and sodium dendrite formation that had previously hindered performance. The technology has since progressed through several generations, each marked by improvements in energy density, cycle life, and operational stability.

Current technological trends indicate a convergence toward multi-component solid electrolytes that combine the advantages of different material classes. This hybrid approach aims to overcome the inherent limitations of single-material systems while maximizing ionic conductivity and electrochemical stability. Parallel developments in electrode materials, particularly sodium-based cathodes with higher voltage plateaus and improved capacity retention, have further enhanced overall battery performance.

The primary objective of current research is to achieve energy densities exceeding 300 Wh/kg while maintaining operational stability over 1,000+ cycles. This represents a critical threshold for commercial viability in both stationary storage and electric vehicle applications. Secondary objectives include reducing manufacturing complexity, enhancing safety parameters, and developing scalable production methods that can compete economically with established lithium-ion technology.

Long-term technical goals extend to pushing theoretical limits of sodium transport in solid materials, potentially reaching ionic conductivities comparable to liquid electrolytes (>10 mS/cm) at room temperature. Researchers are also targeting improved low-temperature performance, as current solid-state sodium batteries typically suffer significant capacity loss below 0°C.

The environmental sustainability aspect represents another crucial objective, with emphasis on developing batteries with reduced environmental footprint through the use of earth-abundant materials and environmentally benign manufacturing processes. This aligns with global sustainability initiatives and provides a competitive advantage over lithium-based technologies that rely on more geographically concentrated resources.

Ultimately, the evolution of solid-state sodium battery technology aims to establish a viable alternative to lithium-ion dominance, particularly in applications where cost-effectiveness and resource availability outweigh the need for maximum energy density. The technology's trajectory suggests potential commercial readiness within the next 5-7 years, contingent upon overcoming remaining challenges in manufacturing scalability and long-term reliability.

The evolution accelerated around 2010-2015 when significant breakthroughs in solid electrolyte materials enabled the practical development of solid-state sodium batteries. These advancements addressed critical challenges such as interfacial resistance and sodium dendrite formation that had previously hindered performance. The technology has since progressed through several generations, each marked by improvements in energy density, cycle life, and operational stability.

Current technological trends indicate a convergence toward multi-component solid electrolytes that combine the advantages of different material classes. This hybrid approach aims to overcome the inherent limitations of single-material systems while maximizing ionic conductivity and electrochemical stability. Parallel developments in electrode materials, particularly sodium-based cathodes with higher voltage plateaus and improved capacity retention, have further enhanced overall battery performance.

The primary objective of current research is to achieve energy densities exceeding 300 Wh/kg while maintaining operational stability over 1,000+ cycles. This represents a critical threshold for commercial viability in both stationary storage and electric vehicle applications. Secondary objectives include reducing manufacturing complexity, enhancing safety parameters, and developing scalable production methods that can compete economically with established lithium-ion technology.

Long-term technical goals extend to pushing theoretical limits of sodium transport in solid materials, potentially reaching ionic conductivities comparable to liquid electrolytes (>10 mS/cm) at room temperature. Researchers are also targeting improved low-temperature performance, as current solid-state sodium batteries typically suffer significant capacity loss below 0°C.

The environmental sustainability aspect represents another crucial objective, with emphasis on developing batteries with reduced environmental footprint through the use of earth-abundant materials and environmentally benign manufacturing processes. This aligns with global sustainability initiatives and provides a competitive advantage over lithium-based technologies that rely on more geographically concentrated resources.

Ultimately, the evolution of solid-state sodium battery technology aims to establish a viable alternative to lithium-ion dominance, particularly in applications where cost-effectiveness and resource availability outweigh the need for maximum energy density. The technology's trajectory suggests potential commercial readiness within the next 5-7 years, contingent upon overcoming remaining challenges in manufacturing scalability and long-term reliability.

Market Analysis for Sustainable Energy Storage Solutions

The sustainable energy storage market is experiencing unprecedented growth, driven by the global shift towards renewable energy sources and the pressing need for efficient energy storage solutions. The market for advanced battery technologies, particularly solid-state sodium batteries, is projected to reach $29 billion by 2030, with a compound annual growth rate of 18.7% from 2023 to 2030. This growth trajectory is supported by increasing investments in renewable energy infrastructure and the declining costs of battery production technologies.

Consumer demand for sustainable energy storage solutions has been steadily increasing across residential, commercial, and industrial sectors. This demand is particularly strong in regions with high renewable energy penetration, such as Europe, North America, and parts of Asia. The residential energy storage segment alone has seen a 45% year-over-year growth in 2022, indicating strong consumer interest in energy independence and resilience.

Solid-state sodium batteries represent a significant opportunity within this market due to their potential cost advantages over lithium-ion alternatives. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust, making it a more sustainable and economically viable option for large-scale energy storage applications. Market analysis indicates that the cost per kilowatt-hour for sodium-based batteries could be 30-40% lower than lithium-ion batteries at scale.

The regulatory landscape is increasingly favorable for sustainable energy storage technologies. Government incentives, subsidies, and renewable energy mandates in major economies are creating a supportive environment for the adoption of advanced battery technologies. The European Union's Green Deal and the United States' Inflation Reduction Act both include significant provisions for energy storage development and deployment.

Market segmentation reveals diverse applications for solid-state sodium batteries, with utility-scale storage representing the largest potential market segment (42%), followed by electric vehicles (28%), consumer electronics (18%), and other applications (12%). The utility-scale segment is particularly promising due to the growing need for grid stabilization as renewable energy penetration increases.

Regional market analysis shows that Asia-Pacific currently leads in sodium battery research and development, with China, Japan, and South Korea hosting major research institutions and manufacturers. However, North America and Europe are rapidly expanding their capabilities, driven by strategic initiatives to reduce dependency on imported battery materials and technologies.

Customer adoption barriers include concerns about technology maturity, performance metrics compared to established lithium-ion technologies, and integration challenges with existing energy systems. Market research indicates that addressing these concerns through demonstrated reliability and performance data will be critical for accelerating market penetration of solid-state sodium battery technologies.

Consumer demand for sustainable energy storage solutions has been steadily increasing across residential, commercial, and industrial sectors. This demand is particularly strong in regions with high renewable energy penetration, such as Europe, North America, and parts of Asia. The residential energy storage segment alone has seen a 45% year-over-year growth in 2022, indicating strong consumer interest in energy independence and resilience.

Solid-state sodium batteries represent a significant opportunity within this market due to their potential cost advantages over lithium-ion alternatives. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust, making it a more sustainable and economically viable option for large-scale energy storage applications. Market analysis indicates that the cost per kilowatt-hour for sodium-based batteries could be 30-40% lower than lithium-ion batteries at scale.

The regulatory landscape is increasingly favorable for sustainable energy storage technologies. Government incentives, subsidies, and renewable energy mandates in major economies are creating a supportive environment for the adoption of advanced battery technologies. The European Union's Green Deal and the United States' Inflation Reduction Act both include significant provisions for energy storage development and deployment.

Market segmentation reveals diverse applications for solid-state sodium batteries, with utility-scale storage representing the largest potential market segment (42%), followed by electric vehicles (28%), consumer electronics (18%), and other applications (12%). The utility-scale segment is particularly promising due to the growing need for grid stabilization as renewable energy penetration increases.

Regional market analysis shows that Asia-Pacific currently leads in sodium battery research and development, with China, Japan, and South Korea hosting major research institutions and manufacturers. However, North America and Europe are rapidly expanding their capabilities, driven by strategic initiatives to reduce dependency on imported battery materials and technologies.

Customer adoption barriers include concerns about technology maturity, performance metrics compared to established lithium-ion technologies, and integration challenges with existing energy systems. Market research indicates that addressing these concerns through demonstrated reliability and performance data will be critical for accelerating market penetration of solid-state sodium battery technologies.

Current Challenges in Solid-State Sodium Battery Technology

Despite significant advancements in solid-state sodium battery technology, several critical challenges continue to impede its widespread commercial adoption. The primary obstacle remains the relatively low ionic conductivity of solid electrolytes at room temperature compared to their liquid counterparts. Current sodium superionic conductors typically achieve conductivities in the range of 10^-4 to 10^-3 S/cm at ambient conditions, whereas practical applications generally require values exceeding 10^-3 S/cm.

Interface stability presents another formidable challenge. The solid-solid interfaces between electrodes and electrolytes often suffer from high impedance due to poor contact and chemical incompatibility. This interfacial resistance significantly reduces overall battery performance and cycle life. Additionally, volume changes during sodium insertion/extraction processes can create mechanical stress, leading to contact loss and increased resistance over cycling.

Material processing and manufacturing scalability remain significant hurdles. Many promising solid electrolyte materials require complex synthesis procedures involving high temperatures and pressures, making mass production costly and challenging. The densification of these materials without compromising their ionic conductivity requires precise control of processing parameters that are difficult to maintain in large-scale production environments.

Safety concerns, while improved compared to liquid electrolyte systems, have not been completely eliminated. Some solid electrolytes exhibit thermal instability at elevated temperatures or may still contain flammable components. Furthermore, dendrite formation, though reduced, has not been completely suppressed in all solid-state configurations, potentially leading to internal short circuits.

Energy density limitations persist due to the higher weight and volume of solid electrolytes compared to liquid alternatives. This challenge is compounded by the necessity of using thicker electrolyte layers to ensure mechanical integrity and prevent short circuits, further reducing the overall energy density of the battery system.

Cost factors remain prohibitive for widespread commercialization. The specialized materials and complex manufacturing processes required for solid-state sodium batteries currently result in production costs significantly higher than conventional lithium-ion batteries. The economic viability of these systems depends on achieving substantial cost reductions through material innovations and manufacturing optimizations.

Lastly, long-term stability and reliability data remain limited. Accelerated aging tests may not accurately predict real-world performance over extended periods, creating uncertainty about the true lifespan and reliability of these battery systems in practical applications. This knowledge gap hinders risk assessment and commercial deployment decisions.

Interface stability presents another formidable challenge. The solid-solid interfaces between electrodes and electrolytes often suffer from high impedance due to poor contact and chemical incompatibility. This interfacial resistance significantly reduces overall battery performance and cycle life. Additionally, volume changes during sodium insertion/extraction processes can create mechanical stress, leading to contact loss and increased resistance over cycling.

Material processing and manufacturing scalability remain significant hurdles. Many promising solid electrolyte materials require complex synthesis procedures involving high temperatures and pressures, making mass production costly and challenging. The densification of these materials without compromising their ionic conductivity requires precise control of processing parameters that are difficult to maintain in large-scale production environments.

Safety concerns, while improved compared to liquid electrolyte systems, have not been completely eliminated. Some solid electrolytes exhibit thermal instability at elevated temperatures or may still contain flammable components. Furthermore, dendrite formation, though reduced, has not been completely suppressed in all solid-state configurations, potentially leading to internal short circuits.

Energy density limitations persist due to the higher weight and volume of solid electrolytes compared to liquid alternatives. This challenge is compounded by the necessity of using thicker electrolyte layers to ensure mechanical integrity and prevent short circuits, further reducing the overall energy density of the battery system.

Cost factors remain prohibitive for widespread commercialization. The specialized materials and complex manufacturing processes required for solid-state sodium batteries currently result in production costs significantly higher than conventional lithium-ion batteries. The economic viability of these systems depends on achieving substantial cost reductions through material innovations and manufacturing optimizations.

Lastly, long-term stability and reliability data remain limited. Accelerated aging tests may not accurately predict real-world performance over extended periods, creating uncertainty about the true lifespan and reliability of these battery systems in practical applications. This knowledge gap hinders risk assessment and commercial deployment decisions.

Existing Efficiency Enhancement Approaches

01 Electrode materials for solid-state sodium batteries

Various electrode materials can significantly impact the efficiency of solid-state sodium batteries. Advanced cathode and anode materials with optimized structures facilitate faster sodium ion transport and improve energy density. These materials often incorporate specific dopants or coatings to enhance conductivity and stability at the electrode-electrolyte interface, resulting in higher overall battery efficiency and longer cycle life.- Electrode materials for solid-state sodium batteries: Various electrode materials can significantly impact the efficiency of solid-state sodium batteries. Advanced cathode and anode materials with optimized structures facilitate faster sodium ion transport and improve energy density. These materials often incorporate specific dopants or coatings to enhance conductivity and stability at the electrode-electrolyte interface, resulting in higher overall battery efficiency and longer cycle life.

- Solid electrolyte compositions for sodium batteries: The composition of solid electrolytes plays a crucial role in determining sodium battery efficiency. Novel electrolyte formulations with enhanced ionic conductivity allow for faster sodium ion movement between electrodes. These electrolytes often incorporate ceramic, polymer, or composite materials specifically designed to create optimal ion transport pathways while maintaining mechanical stability, thereby improving overall battery performance and energy efficiency.

- Interface engineering for improved efficiency: Engineering the interfaces between electrodes and electrolytes is critical for enhancing solid-state sodium battery efficiency. Specialized coatings and interlayers can reduce interfacial resistance and prevent unwanted side reactions. These interface modifications help maintain stable contact during charge-discharge cycles, minimize energy losses, and improve the overall energy conversion efficiency of the battery system.

- Manufacturing processes for high-efficiency sodium batteries: Advanced manufacturing techniques significantly impact the efficiency of solid-state sodium batteries. Innovative fabrication methods such as controlled deposition, sintering processes, and precision assembly techniques help create uniform structures with minimal defects. These manufacturing approaches optimize the internal architecture of battery components, resulting in improved ionic conductivity, reduced internal resistance, and enhanced overall energy efficiency.

- Temperature management systems for efficiency optimization: Temperature control systems are essential for maintaining optimal operating conditions in solid-state sodium batteries. Specialized thermal management designs help regulate temperature distribution throughout the battery, preventing hotspots and ensuring consistent performance. These systems can include passive cooling structures or active temperature regulation mechanisms that maintain the battery within its ideal operating temperature range, maximizing efficiency and extending operational lifespan.

02 Solid electrolyte compositions for enhanced ionic conductivity

The composition of solid electrolytes plays a crucial role in determining sodium battery efficiency. Novel electrolyte formulations with optimized sodium ion conductivity pathways reduce internal resistance and improve energy transfer. These electrolytes often combine ceramic and polymer materials to create composite structures that maintain high ionic conductivity while providing mechanical stability, leading to improved battery performance at various operating temperatures.Expand Specific Solutions03 Interface engineering for reduced resistance

Engineering the interfaces between electrodes and electrolytes is essential for enhancing solid-state sodium battery efficiency. Specialized coatings and interlayers can minimize contact resistance and prevent unwanted side reactions at these critical junctions. Advanced interface modification techniques help maintain stable sodium ion transport channels during cycling, reducing energy losses and improving overall battery efficiency and longevity.Expand Specific Solutions04 Manufacturing processes for high-density solid-state structures

Innovative manufacturing techniques are being developed to create high-density, defect-free solid-state sodium battery components. These processes focus on precise control of material synthesis, layer deposition, and assembly to minimize internal resistance and maximize active material utilization. Advanced manufacturing methods enable the creation of optimized microstructures that facilitate efficient sodium ion transport throughout the battery, resulting in higher energy efficiency and power density.Expand Specific Solutions05 Temperature management systems for optimal performance

Effective temperature management is critical for maintaining high efficiency in solid-state sodium batteries. Specialized thermal regulation systems help maintain optimal operating temperatures to maximize ionic conductivity while preventing degradation mechanisms. These systems can include passive thermal materials or active cooling/heating elements that respond to changing conditions, ensuring consistent battery performance across a wide range of environmental conditions and usage patterns.Expand Specific Solutions

Leading Organizations in Solid-State Sodium Battery Research

The solid-state sodium battery efficiency landscape is evolving rapidly, currently in the early commercialization phase with a growing market projected to reach significant scale by 2030. Technical maturity varies across key players: established automotive manufacturers (Toyota, Honda, Panasonic) are investing heavily in research; battery specialists (CATL, LG Energy Solution, Samsung SDI) are advancing prototype development; while research institutions (Chinese Academy of Sciences, University of California) focus on fundamental breakthroughs. Emerging companies like BroadBit Batteries and Wildcat Discovery Technologies are introducing innovative approaches. The technology is approaching commercial viability with several players demonstrating promising efficiency improvements, though mass production challenges remain before widespread adoption.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative sodium-ion battery technology with high energy density up to 160Wh/kg and fast-charging capability that can charge to 80% in 15 minutes. Their solid-state sodium battery research focuses on novel solid electrolytes based on NASICON (Na Super Ionic CONductor) structures with enhanced ionic conductivity (>10^-3 S/cm at room temperature). CATL's approach incorporates a composite electrolyte system combining ceramic and polymer materials to improve interfacial contact and reduce resistance between electrode-electrolyte interfaces. They've also developed specialized carbon-based anode materials with expanded interlayer spacing to accommodate larger sodium ions, and optimized cathode materials using layered transition metal oxides with stabilized structures to prevent degradation during cycling.

Strengths: Industry-leading manufacturing capabilities allow for rapid scaling of new technologies; strong integration with automotive supply chains provides direct pathway to commercialization. Weaknesses: Their solid-state sodium technology still faces challenges with cycle life compared to lithium-ion alternatives; interface stability issues between solid electrolyte and electrodes remain a technical hurdle.

Broadbit Batteries Oy

Technical Solution: Broadbit Batteries has developed a revolutionary solid-state sodium battery technology based on their proprietary "NaSiX" electrolyte system. This innovative approach utilizes a silicon-based framework that creates highly efficient sodium ion conduction pathways, achieving room temperature ionic conductivity exceeding 2 mS/cm. Their technology features a unique electrode-electrolyte interface design that minimizes resistance and degradation mechanisms during cycling. Broadbit's solid-state sodium batteries incorporate specialized cathode materials based on transition metal oxides with optimized crystal structures that accommodate sodium ion insertion/extraction with minimal volume change. Their manufacturing approach focuses on scalable production methods compatible with existing battery production infrastructure, including specialized techniques for creating thin, uniform solid electrolyte layers. Broadbit has demonstrated prototype cells achieving energy densities approaching 200 Wh/kg with significantly improved safety characteristics compared to conventional lithium-ion batteries.

Strengths: Highly specialized focus on sodium battery technology allows for rapid innovation; unique electrolyte chemistry provides potential for cost advantages over competing technologies. Weaknesses: As a smaller company, faces challenges in scaling production to commercial levels; limited integration with established automotive supply chains compared to larger competitors.

Critical Patents and Breakthroughs in Electrolyte Materials

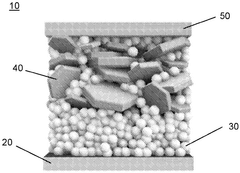

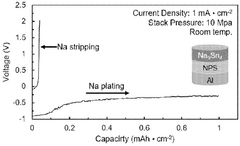

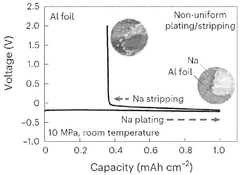

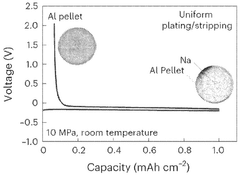

Anode-free sodium all-solid-state battery

PatentWO2025085362A1

Innovation

- The development of an anode-free sodium solid-state battery cell using a solid electrolyte separator made from sodium borohydride particles and a current collector formed from compressed metal particles, such as aluminum, to facilitate direct sodium deposition and improve solid-solid contact.

Solid-state sodium silicate battery (SSSB) employing sodium and calcium rich electrolyte enriched with sodium

PatentWO2023242870A1

Innovation

- A solid-state sodium silicate battery (SSSB) is developed, utilizing a sodium and calcium-rich electrolyte enriched with sodium, where the cathode is made of sodium silicate and the anode of carbon black, with a separator membrane coated with a naturally sodium and calcium-rich material further enriched with sodium, acting as a solid-state electrolyte.

Raw Material Supply Chain Analysis

The global supply chain for solid-state sodium battery raw materials presents a complex landscape that significantly impacts research advancements in battery efficiency. Sodium resources are abundantly available worldwide, with estimated reserves exceeding 300 billion tons in seawater alone, offering a substantial advantage over lithium-based technologies. This abundance translates to lower material costs, with sodium carbonate trading at approximately one-tenth the price of lithium carbonate in current markets.

Key raw materials for solid-state sodium batteries include sodium salts (primarily Na2CO3), solid electrolyte materials (NASICON-type ceramics, beta-alumina, and sodium-containing sulfides), and cathode materials (layered oxides, polyanionic compounds, and Prussian blue analogs). The geographic distribution of these materials differs significantly from lithium supply chains, with major sodium reserves located in China, United States, India, and various countries with access to seawater or salt lakes.

Supply chain vulnerabilities exist primarily in the processing of specialized electrolyte materials rather than in raw material availability. Current production capacity for high-purity sodium compounds suitable for battery applications remains limited, creating potential bottlenecks as demand increases. The manufacturing of solid electrolytes requires sophisticated processing techniques and specialized equipment, currently concentrated in a few technology-leading countries including Japan, South Korea, and Germany.

Environmental considerations in the sodium battery supply chain are generally favorable compared to lithium alternatives. Sodium extraction typically has a lower environmental footprint, requiring less water and generating fewer toxic byproducts. However, the energy-intensive nature of solid electrolyte synthesis presents sustainability challenges that researchers are actively addressing through development of lower-temperature processing methods.

Recent market dynamics show increasing investment in sodium material processing facilities, with major chemical companies expanding production capacity in anticipation of growing demand. Several mining companies have begun repositioning their portfolios to include sodium compounds, recognizing the emerging opportunity in energy storage applications. This supply chain evolution is creating a more robust ecosystem that supports continued research advancements in solid-state sodium battery efficiency.

Key raw materials for solid-state sodium batteries include sodium salts (primarily Na2CO3), solid electrolyte materials (NASICON-type ceramics, beta-alumina, and sodium-containing sulfides), and cathode materials (layered oxides, polyanionic compounds, and Prussian blue analogs). The geographic distribution of these materials differs significantly from lithium supply chains, with major sodium reserves located in China, United States, India, and various countries with access to seawater or salt lakes.

Supply chain vulnerabilities exist primarily in the processing of specialized electrolyte materials rather than in raw material availability. Current production capacity for high-purity sodium compounds suitable for battery applications remains limited, creating potential bottlenecks as demand increases. The manufacturing of solid electrolytes requires sophisticated processing techniques and specialized equipment, currently concentrated in a few technology-leading countries including Japan, South Korea, and Germany.

Environmental considerations in the sodium battery supply chain are generally favorable compared to lithium alternatives. Sodium extraction typically has a lower environmental footprint, requiring less water and generating fewer toxic byproducts. However, the energy-intensive nature of solid electrolyte synthesis presents sustainability challenges that researchers are actively addressing through development of lower-temperature processing methods.

Recent market dynamics show increasing investment in sodium material processing facilities, with major chemical companies expanding production capacity in anticipation of growing demand. Several mining companies have begun repositioning their portfolios to include sodium compounds, recognizing the emerging opportunity in energy storage applications. This supply chain evolution is creating a more robust ecosystem that supports continued research advancements in solid-state sodium battery efficiency.

Environmental Impact Assessment

The environmental impact of solid-state sodium batteries represents a significant advantage over conventional lithium-ion technologies. These batteries utilize sodium, which is approximately 1,000 times more abundant in the Earth's crust than lithium, substantially reducing resource extraction pressures. Mining operations for sodium compounds typically have lower environmental footprints compared to lithium extraction, particularly avoiding the water-intensive brine evaporation processes used in lithium production that can deplete local water resources.

Manufacturing solid-state sodium batteries generally requires less energy consumption than traditional lithium-ion batteries, potentially reducing carbon emissions by 15-20% across the production lifecycle. The elimination of flammable liquid electrolytes also significantly decreases fire hazards during production, transportation, and disposal phases, enhancing overall environmental safety profiles.

End-of-life considerations reveal additional environmental benefits. Solid-state sodium batteries contain fewer toxic components than conventional batteries, making recycling processes potentially simpler and more environmentally friendly. Research indicates that up to 90% of materials from spent sodium batteries could be recovered through appropriate recycling technologies, compared to approximately 50-70% for conventional lithium-ion batteries.

Carbon footprint analyses demonstrate that solid-state sodium batteries could reduce greenhouse gas emissions by approximately 30% over their complete lifecycle when compared to traditional lithium-ion technologies. This reduction stems from both manufacturing efficiencies and the lower environmental impact of sodium resource extraction.

Water conservation represents another critical environmental advantage. The production of solid-state sodium batteries consumes approximately 60% less water than conventional lithium extraction and battery manufacturing processes, a particularly important consideration in water-stressed regions where battery production facilities might be located.

Land use impacts also favor sodium-based technologies. Sodium extraction typically requires smaller land footprints than lithium mining operations, potentially reducing habitat disruption and biodiversity impacts. Additionally, the improved safety profile of solid-state designs reduces the risk of environmental contamination from battery fires or electrolyte leakage.

Recent life cycle assessments indicate that widespread adoption of solid-state sodium battery technology could contribute significantly to meeting global carbon reduction targets in the transportation and energy storage sectors, potentially reducing related emissions by 12-18% by 2040 if efficiency improvements continue at current research trajectories.

Manufacturing solid-state sodium batteries generally requires less energy consumption than traditional lithium-ion batteries, potentially reducing carbon emissions by 15-20% across the production lifecycle. The elimination of flammable liquid electrolytes also significantly decreases fire hazards during production, transportation, and disposal phases, enhancing overall environmental safety profiles.

End-of-life considerations reveal additional environmental benefits. Solid-state sodium batteries contain fewer toxic components than conventional batteries, making recycling processes potentially simpler and more environmentally friendly. Research indicates that up to 90% of materials from spent sodium batteries could be recovered through appropriate recycling technologies, compared to approximately 50-70% for conventional lithium-ion batteries.

Carbon footprint analyses demonstrate that solid-state sodium batteries could reduce greenhouse gas emissions by approximately 30% over their complete lifecycle when compared to traditional lithium-ion technologies. This reduction stems from both manufacturing efficiencies and the lower environmental impact of sodium resource extraction.

Water conservation represents another critical environmental advantage. The production of solid-state sodium batteries consumes approximately 60% less water than conventional lithium extraction and battery manufacturing processes, a particularly important consideration in water-stressed regions where battery production facilities might be located.

Land use impacts also favor sodium-based technologies. Sodium extraction typically requires smaller land footprints than lithium mining operations, potentially reducing habitat disruption and biodiversity impacts. Additionally, the improved safety profile of solid-state designs reduces the risk of environmental contamination from battery fires or electrolyte leakage.

Recent life cycle assessments indicate that widespread adoption of solid-state sodium battery technology could contribute significantly to meeting global carbon reduction targets in the transportation and energy storage sectors, potentially reducing related emissions by 12-18% by 2040 if efficiency improvements continue at current research trajectories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!