Solid-state sodium battery patent explorations driving new possibilities

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Background and Objectives

Solid-state sodium batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development of these batteries can be traced back to the early 2000s, when researchers began exploring sodium as a more abundant and cost-effective alternative to lithium. The technological trajectory has accelerated notably in the past decade, with substantial breakthroughs in electrolyte materials and interface engineering.

The evolution of solid-state sodium battery technology has been driven by several key factors, including the increasing demand for sustainable energy storage solutions, concerns about lithium resource scarcity, and the need for safer battery technologies. Sodium, being the sixth most abundant element in the Earth's crust, offers a compelling alternative to lithium, which faces potential supply constraints as global battery production scales up.

Patent activity in this field has shown exponential growth since 2015, with a particular focus on novel solid electrolyte compositions, cathode materials compatible with sodium-ion intercalation, and manufacturing processes that enable commercial viability. The innovation landscape spans academic institutions, established battery manufacturers, and emerging startups, creating a diverse ecosystem of technological approaches.

The primary technical objectives for solid-state sodium battery development include achieving energy densities comparable to lithium-ion batteries (>250 Wh/kg), extending cycle life beyond 1,000 cycles, improving rate capability for fast charging applications, and ensuring operational safety across a wide temperature range. Additionally, researchers aim to develop manufacturing processes that can be integrated into existing battery production infrastructure with minimal modification.

Recent advancements in ceramic and polymer-based solid electrolytes have addressed historical challenges related to sodium ion conductivity at room temperature. Particularly promising are NASICON-type materials (Na Super Ionic CONductor) and sodium-beta-alumina structures, which have demonstrated ionic conductivities approaching those of liquid electrolytes while maintaining the safety advantages of solid-state configurations.

The technology roadmap for solid-state sodium batteries anticipates commercial deployment in stationary storage applications by 2025, followed by integration into electric vehicles by 2030. This phased approach acknowledges the different performance requirements across applications and allows for iterative improvement of the technology. The ultimate goal is to establish solid-state sodium batteries as a mainstream energy storage solution that complements rather than directly competes with lithium-based technologies, creating a more diversified and resilient battery ecosystem.

The evolution of solid-state sodium battery technology has been driven by several key factors, including the increasing demand for sustainable energy storage solutions, concerns about lithium resource scarcity, and the need for safer battery technologies. Sodium, being the sixth most abundant element in the Earth's crust, offers a compelling alternative to lithium, which faces potential supply constraints as global battery production scales up.

Patent activity in this field has shown exponential growth since 2015, with a particular focus on novel solid electrolyte compositions, cathode materials compatible with sodium-ion intercalation, and manufacturing processes that enable commercial viability. The innovation landscape spans academic institutions, established battery manufacturers, and emerging startups, creating a diverse ecosystem of technological approaches.

The primary technical objectives for solid-state sodium battery development include achieving energy densities comparable to lithium-ion batteries (>250 Wh/kg), extending cycle life beyond 1,000 cycles, improving rate capability for fast charging applications, and ensuring operational safety across a wide temperature range. Additionally, researchers aim to develop manufacturing processes that can be integrated into existing battery production infrastructure with minimal modification.

Recent advancements in ceramic and polymer-based solid electrolytes have addressed historical challenges related to sodium ion conductivity at room temperature. Particularly promising are NASICON-type materials (Na Super Ionic CONductor) and sodium-beta-alumina structures, which have demonstrated ionic conductivities approaching those of liquid electrolytes while maintaining the safety advantages of solid-state configurations.

The technology roadmap for solid-state sodium batteries anticipates commercial deployment in stationary storage applications by 2025, followed by integration into electric vehicles by 2030. This phased approach acknowledges the different performance requirements across applications and allows for iterative improvement of the technology. The ultimate goal is to establish solid-state sodium batteries as a mainstream energy storage solution that complements rather than directly competes with lithium-based technologies, creating a more diversified and resilient battery ecosystem.

Market Demand Analysis for Sodium Battery Technologies

The global market for sodium battery technologies is experiencing significant growth, driven primarily by the increasing demand for sustainable energy storage solutions. As lithium resources face supply constraints and price volatility, sodium-based alternatives are gaining traction due to sodium's abundant availability—approximately 1000 times more prevalent in the Earth's crust than lithium. This abundance translates to potentially lower raw material costs, positioning sodium batteries as an economically viable alternative for large-scale energy storage applications.

The market demand for solid-state sodium batteries specifically is being shaped by several converging factors. The electric vehicle (EV) sector represents a substantial growth opportunity, with projections indicating that sodium battery technologies could capture up to 20% of the EV battery market by 2030, particularly in regions where cost sensitivity outweighs performance requirements. Commercial vehicles and public transportation fleets are showing particular interest due to the favorable total cost of ownership calculations.

Grid-scale energy storage represents another significant market segment, with utility companies increasingly investing in large-capacity storage solutions to complement renewable energy generation. The intermittent nature of wind and solar power necessitates efficient storage systems, and sodium batteries offer a cost-effective solution for these applications. Market analysis indicates annual growth rates exceeding 25% in this sector through 2028.

Consumer electronics manufacturers are also exploring sodium battery technologies for applications where energy density requirements are less stringent than in EVs. The potential for safer operation—with reduced risk of thermal runaway compared to conventional lithium-ion batteries—presents a compelling value proposition for consumer devices.

Geographically, the market demand shows interesting regional variations. China is emerging as the largest potential market, driven by government initiatives to reduce dependency on imported battery materials and technology. European demand is accelerating due to stringent sustainability regulations and circular economy initiatives that favor sodium's recyclability advantages.

Industry forecasts suggest the global market for sodium battery technologies could reach $12 billion by 2030, representing a compound annual growth rate of approximately 30% from current levels. This growth trajectory is supported by increasing patent activity, with solid-state sodium battery patents showing a 45% year-over-year increase in filing rates since 2018.

The market is further bolstered by favorable regulatory environments in key regions, with policies incentivizing research and commercialization of alternative battery technologies. These include research grants, tax incentives for manufacturing facilities, and inclusion in strategic mineral initiatives that previously focused exclusively on lithium-based technologies.

The market demand for solid-state sodium batteries specifically is being shaped by several converging factors. The electric vehicle (EV) sector represents a substantial growth opportunity, with projections indicating that sodium battery technologies could capture up to 20% of the EV battery market by 2030, particularly in regions where cost sensitivity outweighs performance requirements. Commercial vehicles and public transportation fleets are showing particular interest due to the favorable total cost of ownership calculations.

Grid-scale energy storage represents another significant market segment, with utility companies increasingly investing in large-capacity storage solutions to complement renewable energy generation. The intermittent nature of wind and solar power necessitates efficient storage systems, and sodium batteries offer a cost-effective solution for these applications. Market analysis indicates annual growth rates exceeding 25% in this sector through 2028.

Consumer electronics manufacturers are also exploring sodium battery technologies for applications where energy density requirements are less stringent than in EVs. The potential for safer operation—with reduced risk of thermal runaway compared to conventional lithium-ion batteries—presents a compelling value proposition for consumer devices.

Geographically, the market demand shows interesting regional variations. China is emerging as the largest potential market, driven by government initiatives to reduce dependency on imported battery materials and technology. European demand is accelerating due to stringent sustainability regulations and circular economy initiatives that favor sodium's recyclability advantages.

Industry forecasts suggest the global market for sodium battery technologies could reach $12 billion by 2030, representing a compound annual growth rate of approximately 30% from current levels. This growth trajectory is supported by increasing patent activity, with solid-state sodium battery patents showing a 45% year-over-year increase in filing rates since 2018.

The market is further bolstered by favorable regulatory environments in key regions, with policies incentivizing research and commercialization of alternative battery technologies. These include research grants, tax incentives for manufacturing facilities, and inclusion in strategic mineral initiatives that previously focused exclusively on lithium-based technologies.

Technical Challenges and Global Development Status

Solid-state sodium batteries face significant technical challenges despite their promising potential. The primary obstacle remains the development of suitable solid electrolytes that simultaneously offer high ionic conductivity, excellent mechanical properties, and stable interfaces with electrodes. Current solid electrolytes struggle to achieve room-temperature conductivity comparable to liquid electrolytes, with most materials falling below 10^-3 S/cm at ambient conditions.

Interface stability presents another critical challenge, as solid-state systems experience substantial volume changes during cycling. This leads to contact loss between components and accelerated degradation. The formation of dendrites at the sodium metal/electrolyte interface further compromises safety and cycle life, with researchers still seeking effective mechanical and chemical solutions to mitigate this issue.

Manufacturing scalability remains problematic, as traditional battery production methods require significant modification for solid-state architectures. The precise control needed for thin, uniform electrolyte layers without defects has proven difficult to achieve at industrial scales, limiting commercial viability.

Globally, research and development efforts show distinct regional characteristics. Japan leads in patent filings for solid-state sodium battery technologies, with companies like Toyota, Panasonic, and NGK Insulators making significant investments. Their focus primarily centers on oxide and sulfide-based electrolytes with emphasis on manufacturing processes.

European research institutions demonstrate strength in fundamental materials science, with German and French laboratories pioneering polymer-ceramic composite electrolytes. The European Union's Horizon Europe program has allocated substantial funding specifically for sodium battery technologies as part of its sustainable energy initiatives.

China has rapidly accelerated its research output since 2018, with universities and state-backed enterprises filing increasing numbers of patents focused on low-cost production methods and integration with renewable energy systems. Their approach emphasizes practical applications and cost reduction rather than fundamental breakthroughs.

The United States shows a more distributed innovation landscape, with national laboratories, universities, and startups like Natron Energy and Ambri pursuing diverse technical approaches. Recent Department of Energy initiatives have specifically targeted sodium battery technologies as alternatives to lithium-based systems.

South Korea's battery manufacturers have begun pivoting some research capacity toward solid-state sodium systems, leveraging their extensive experience in lithium battery production to address manufacturing challenges. Their patents frequently address cell design and system integration aspects rather than novel materials.

Interface stability presents another critical challenge, as solid-state systems experience substantial volume changes during cycling. This leads to contact loss between components and accelerated degradation. The formation of dendrites at the sodium metal/electrolyte interface further compromises safety and cycle life, with researchers still seeking effective mechanical and chemical solutions to mitigate this issue.

Manufacturing scalability remains problematic, as traditional battery production methods require significant modification for solid-state architectures. The precise control needed for thin, uniform electrolyte layers without defects has proven difficult to achieve at industrial scales, limiting commercial viability.

Globally, research and development efforts show distinct regional characteristics. Japan leads in patent filings for solid-state sodium battery technologies, with companies like Toyota, Panasonic, and NGK Insulators making significant investments. Their focus primarily centers on oxide and sulfide-based electrolytes with emphasis on manufacturing processes.

European research institutions demonstrate strength in fundamental materials science, with German and French laboratories pioneering polymer-ceramic composite electrolytes. The European Union's Horizon Europe program has allocated substantial funding specifically for sodium battery technologies as part of its sustainable energy initiatives.

China has rapidly accelerated its research output since 2018, with universities and state-backed enterprises filing increasing numbers of patents focused on low-cost production methods and integration with renewable energy systems. Their approach emphasizes practical applications and cost reduction rather than fundamental breakthroughs.

The United States shows a more distributed innovation landscape, with national laboratories, universities, and startups like Natron Energy and Ambri pursuing diverse technical approaches. Recent Department of Energy initiatives have specifically targeted sodium battery technologies as alternatives to lithium-based systems.

South Korea's battery manufacturers have begun pivoting some research capacity toward solid-state sodium systems, leveraging their extensive experience in lithium battery production to address manufacturing challenges. Their patents frequently address cell design and system integration aspects rather than novel materials.

Current Patent Solutions for Solid-State Sodium Batteries

01 Electrode materials for solid-state sodium batteries

Various electrode materials can be used in solid-state sodium batteries to enhance performance. These materials include sodium-based compounds and other materials that facilitate sodium ion transport. The electrode composition significantly affects battery capacity, cycling stability, and energy density. Innovations in electrode materials focus on improving sodium ion conductivity and reducing interfacial resistance.- Solid-state electrolyte compositions for sodium batteries: Solid-state sodium batteries utilize specialized electrolyte compositions that enable sodium ion transport while maintaining structural integrity. These electrolytes typically consist of ceramic materials, polymer matrices, or composite structures that offer high ionic conductivity at operating temperatures. The solid-state design eliminates the need for liquid electrolytes, enhancing safety by reducing risks of leakage and flammability while potentially increasing energy density and battery lifespan.

- Electrode materials and interfaces for sodium solid-state batteries: Advanced electrode materials are critical for solid-state sodium battery performance. These include specially designed cathode materials that accommodate sodium ion insertion/extraction and anode materials with high sodium storage capacity. The electrode-electrolyte interfaces are engineered to minimize resistance and ensure stable cycling. Surface modifications and buffer layers are often employed to improve contact between components and prevent unwanted reactions that could lead to capacity fade or increased impedance.

- Manufacturing processes for solid-state sodium batteries: Specialized manufacturing techniques are employed to produce solid-state sodium batteries with consistent performance. These include dry pressing, tape casting, and various deposition methods to create thin, uniform layers of active materials and electrolytes. The assembly process often requires precise temperature control during sintering to ensure proper interfacial contact between components while maintaining material integrity. Advanced manufacturing approaches focus on scalability and cost-effectiveness for commercial viability.

- Performance enhancement strategies for solid-state sodium batteries: Various strategies are employed to enhance the performance of solid-state sodium batteries. These include doping of electrolyte materials to increase ionic conductivity, nanostructuring of electrode materials to shorten ion diffusion paths, and development of composite materials that combine the advantages of different components. Additional approaches involve pressure application during operation to maintain good interfacial contact and temperature management systems to optimize operating conditions for maximum efficiency and longevity.

- Safety and stability improvements in solid-state sodium battery technology: Solid-state sodium batteries offer inherent safety advantages over liquid electrolyte systems, but further improvements focus on enhancing stability during cycling and extreme conditions. These include development of protective coatings to prevent dendrite formation, implementation of mechanical stress management systems to accommodate volume changes during cycling, and incorporation of thermal management solutions. Advanced designs also address challenges related to ambient temperature operation and long-term stability to ensure reliable performance throughout the battery lifecycle.

02 Solid electrolyte compositions for sodium batteries

Solid electrolytes are crucial components in solid-state sodium batteries, enabling sodium ion transport while preventing short circuits. These electrolytes can be made from various materials including ceramics, polymers, or composite materials. Research focuses on developing electrolytes with high ionic conductivity, good mechanical properties, and stability against sodium metal anodes to improve overall battery performance.Expand Specific Solutions03 Interface engineering in solid-state sodium batteries

Interface engineering addresses the critical challenges at electrode-electrolyte interfaces in solid-state sodium batteries. This includes developing coating materials, buffer layers, and surface modifications to reduce interfacial resistance and improve contact between components. Proper interface design enhances sodium ion transport across boundaries and prevents unwanted side reactions, leading to better cycling stability and longer battery life.Expand Specific Solutions04 Manufacturing processes for solid-state sodium batteries

Advanced manufacturing techniques are essential for producing high-performance solid-state sodium batteries. These processes include specialized methods for material synthesis, electrode preparation, electrolyte formation, and cell assembly. Innovations in manufacturing focus on achieving uniform component distribution, good interfacial contact, and scalable production methods that maintain battery quality while reducing costs.Expand Specific Solutions05 Safety and stability enhancements for sodium batteries

Safety and stability are paramount concerns in solid-state sodium battery development. Innovations in this area include thermal management systems, protective mechanisms against overcharging or short circuits, and materials that resist degradation during cycling. These enhancements aim to prevent thermal runaway, extend battery lifespan, and ensure reliable operation under various environmental conditions, making solid-state sodium batteries viable alternatives to lithium-ion technology.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The solid-state sodium battery market is currently in an early growth phase, characterized by intensive R&D activities and patent explorations across major industry players. Market size remains relatively modest but is projected to expand significantly as this technology addresses limitations of lithium-ion batteries. The competitive landscape features established automotive manufacturers (Honda, Toyota, Samsung) investing heavily alongside specialized battery developers (CATL, LG Energy Solution) and materials companies (TDK, Sumitomo Chemical, Murata). Technical maturity varies, with companies like CATL and Samsung demonstrating more advanced prototypes, while academic-industrial partnerships (University of Houston, JAIST) focus on fundamental challenges. The technology's commercialization timeline remains uncertain as players work to overcome key hurdles in electrolyte stability, interface engineering, and manufacturing scalability.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a distinctive solid-state sodium battery technology focused on automotive applications, utilizing a beta-alumina solid electrolyte (BASE) system. Their approach incorporates a proprietary interface engineering method that creates a stable contact between the sodium metal anode and the ceramic electrolyte through the use of specialized interlayers containing sodium-conducting polymers. Honda's patents reveal an innovative cell architecture that employs a bipolar stacking design, allowing for higher energy density and improved thermal management. Their sodium battery system uses a NaCrO₂ cathode material with optimized particle morphology to enhance sodium diffusion kinetics and structural stability during cycling. Honda has demonstrated prototype cells achieving energy densities of approximately 180-220 Wh/kg with stable performance over 800+ cycles at elevated temperatures (60-90°C). Their manufacturing process utilizes advanced ceramic processing techniques including tape casting and high-temperature sintering to produce thin, dense electrolyte membranes with excellent mechanical properties and minimal defects[8][10].

Strengths: Honda's beta-alumina electrolyte offers exceptional chemical stability against sodium metal and extremely high sodium ion conductivity at elevated temperatures, making it suitable for high-power applications. Their bipolar design enables simplified thermal management and higher volumetric energy density. Weaknesses: The technology requires operation at elevated temperatures (typically above 60°C) for optimal performance, necessitating additional heating systems and thermal management. The ceramic electrolyte faces challenges with mechanical robustness, particularly under vibration and shock conditions typical in automotive applications.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered a solid-state sodium battery technology based on a composite polymer-ceramic electrolyte system. Their approach combines the flexibility of polymer matrices with the high ionic conductivity of ceramic fillers to create a mechanically robust electrolyte with superior sodium ion transport properties. CATL's patents reveal a specialized electrode formulation using hard carbon anodes with optimized porosity and surface area, enabling efficient sodium ion intercalation. The cathode utilizes a proprietary layered oxide structure (Na₂/₃Fe₁/₃Mn₂/₃O₂) that delivers high capacity and excellent cycling stability. Their solid-state cells incorporate a gradient interface design that gradually transitions between electrode and electrolyte components, minimizing interfacial resistance and mechanical stress during cycling. CATL has demonstrated prototype cells achieving energy densities of approximately 160-180 Wh/kg with capacity retention exceeding 80% after 1000 cycles. Their manufacturing process employs solvent-free dry coating techniques that reduce environmental impact while enabling precise control of electrode and electrolyte thickness[4][7].

Strengths: CATL's composite electrolyte approach offers an excellent balance between ionic conductivity and mechanical properties, addressing key challenges in solid-state battery design. Their technology utilizes earth-abundant materials, potentially enabling lower production costs compared to lithium-based alternatives. Weaknesses: The polymer component in the electrolyte may still allow some moisture sensitivity, requiring careful packaging and environmental controls. The energy density remains lower than state-of-the-art lithium-ion batteries, limiting applications in high-energy-density scenarios like long-range electric vehicles.

Critical Patent Analysis and Technical Innovations

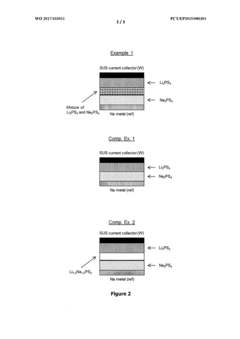

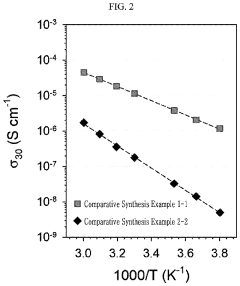

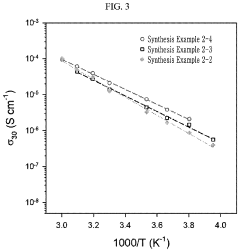

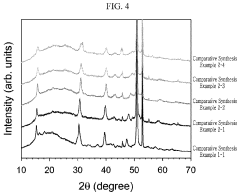

All-solid-state battery using sodium ion intercalation cathode with li/na exchanging layer

PatentWO2017102011A1

Innovation

- An all-solid-state battery configuration is developed with a Li/Na exchanging layer, comprising a physical mixture of sulfide-based sodium-containing and lithium-containing solid electrolyte materials, enhancing ion exchange and increasing battery voltage through a Li/Na hybrid system.

Sodium Halide-based Nanocomposite, Preparing Method Thereof, and Positive Electrode Active Material, Solid Electrolyte, and All-solid-state Battery Comprising the Same

PatentPendingUS20230411616A1

Innovation

- A sodium halide-based nanocomposite is developed, where a nanosized compound is dispersed in a halide compound to enhance ionic conductivity and interfacial stability, forming a glass-ceramic crystal structure that improves the performance of all-solid-state batteries by activating an interfacial conduction phenomenon.

Sustainability and Resource Advantages

Solid-state sodium batteries represent a significant advancement in sustainable energy storage technology, offering numerous environmental and resource advantages over conventional lithium-ion batteries. The sustainability profile of these batteries stems primarily from the abundant nature of sodium resources, which are approximately 1,000 times more plentiful in the Earth's crust than lithium. This abundance translates directly into reduced extraction pressures on limited resources and potentially lower material costs throughout the supply chain.

Patent explorations in this field have increasingly focused on the environmental benefits of sodium-based technologies. Recent patent filings demonstrate innovative approaches to reducing the carbon footprint associated with battery production. These developments include manufacturing processes that require lower temperatures than traditional lithium-ion battery production, resulting in decreased energy consumption during manufacturing and consequently lower greenhouse gas emissions.

The resource geography of sodium presents another compelling sustainability advantage. Unlike lithium, which is concentrated in specific regions such as South America's "Lithium Triangle" and Australia, sodium resources are more evenly distributed globally. This distribution pattern, documented in multiple patent applications for resource extraction methodologies, potentially reduces geopolitical tensions related to critical battery materials and decreases transportation-related emissions in the supply chain.

Patent analyses reveal significant progress in end-of-life considerations for solid-state sodium batteries. Several innovations address recyclability challenges, with novel designs facilitating easier separation of components and recovery of valuable materials. These patents outline processes that could achieve recycling rates exceeding 90% for key components, substantially higher than current lithium-ion recycling capabilities.

Water conservation represents another sustainability dimension highlighted in recent patent filings. Traditional lithium extraction can require up to 500,000 gallons of water per ton of lithium produced, whereas emerging sodium extraction technologies documented in patents require significantly less water input. This advantage becomes particularly critical in water-stressed regions where battery material extraction occurs.

The safety profile of solid-state sodium batteries also contributes to their sustainability credentials. Patents describing non-flammable solid electrolytes eliminate the need for environmentally problematic flame retardants and reduce the risk of thermal runaway events that can release toxic compounds. This improved safety profile translates to reduced environmental impact throughout the battery lifecycle, from manufacturing to disposal or recycling.

Patent explorations in this field have increasingly focused on the environmental benefits of sodium-based technologies. Recent patent filings demonstrate innovative approaches to reducing the carbon footprint associated with battery production. These developments include manufacturing processes that require lower temperatures than traditional lithium-ion battery production, resulting in decreased energy consumption during manufacturing and consequently lower greenhouse gas emissions.

The resource geography of sodium presents another compelling sustainability advantage. Unlike lithium, which is concentrated in specific regions such as South America's "Lithium Triangle" and Australia, sodium resources are more evenly distributed globally. This distribution pattern, documented in multiple patent applications for resource extraction methodologies, potentially reduces geopolitical tensions related to critical battery materials and decreases transportation-related emissions in the supply chain.

Patent analyses reveal significant progress in end-of-life considerations for solid-state sodium batteries. Several innovations address recyclability challenges, with novel designs facilitating easier separation of components and recovery of valuable materials. These patents outline processes that could achieve recycling rates exceeding 90% for key components, substantially higher than current lithium-ion recycling capabilities.

Water conservation represents another sustainability dimension highlighted in recent patent filings. Traditional lithium extraction can require up to 500,000 gallons of water per ton of lithium produced, whereas emerging sodium extraction technologies documented in patents require significantly less water input. This advantage becomes particularly critical in water-stressed regions where battery material extraction occurs.

The safety profile of solid-state sodium batteries also contributes to their sustainability credentials. Patents describing non-flammable solid electrolytes eliminate the need for environmentally problematic flame retardants and reduce the risk of thermal runaway events that can release toxic compounds. This improved safety profile translates to reduced environmental impact throughout the battery lifecycle, from manufacturing to disposal or recycling.

Regulatory Framework and Standardization Progress

The regulatory landscape for solid-state sodium batteries is rapidly evolving as governments worldwide recognize the strategic importance of next-generation energy storage technologies. Currently, most regulatory frameworks governing lithium-ion batteries are being adapted to accommodate sodium-based alternatives, with specialized standards still under development. The International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established working groups specifically focused on creating standardized testing protocols for solid-state sodium batteries, addressing unique safety considerations related to sodium's reactivity and thermal stability characteristics.

In the United States, the Department of Energy has initiated a comprehensive regulatory review process aimed at facilitating the commercialization of sodium battery technologies while ensuring public safety. This includes proposed modifications to transportation regulations under the Pipeline and Hazardous Materials Safety Administration (PHMSA) to accommodate the specific properties of sodium-based energy storage systems. Similarly, the European Union has incorporated solid-state sodium batteries into its Strategic Energy Technology Plan, with the European Committee for Standardization (CEN) developing specialized technical standards.

Japan and South Korea have taken proactive approaches to standardization, with JISC (Japanese Industrial Standards Committee) and KSA (Korean Standards Association) publishing preliminary guidelines for solid-state sodium battery manufacturing and testing. These guidelines emphasize cycle life assessment, thermal runaway prevention, and environmental impact considerations specific to sodium chemistry.

China has integrated solid-state sodium battery development into its national standardization strategy, with the China Electronics Standardization Institute establishing dedicated technical committees to accelerate standards development. Their focus includes performance metrics, safety protocols, and recycling requirements tailored to the unique properties of sodium-based systems.

Industry consortia are playing an increasingly important role in standardization efforts. The Sodium Battery Consortium, comprising leading manufacturers and research institutions, has proposed a unified testing framework that addresses the distinctive characteristics of solid-state sodium technologies. This collaborative approach is helping bridge regulatory gaps while technical standards catch up with innovation pace.

Recycling and end-of-life management represent critical areas for regulatory development, with several jurisdictions now drafting sodium-specific provisions within broader battery recycling frameworks. These emerging regulations aim to address the unique material recovery challenges and environmental considerations associated with sodium battery components, particularly solid electrolytes and sodium metal or sodium-containing anodes.

In the United States, the Department of Energy has initiated a comprehensive regulatory review process aimed at facilitating the commercialization of sodium battery technologies while ensuring public safety. This includes proposed modifications to transportation regulations under the Pipeline and Hazardous Materials Safety Administration (PHMSA) to accommodate the specific properties of sodium-based energy storage systems. Similarly, the European Union has incorporated solid-state sodium batteries into its Strategic Energy Technology Plan, with the European Committee for Standardization (CEN) developing specialized technical standards.

Japan and South Korea have taken proactive approaches to standardization, with JISC (Japanese Industrial Standards Committee) and KSA (Korean Standards Association) publishing preliminary guidelines for solid-state sodium battery manufacturing and testing. These guidelines emphasize cycle life assessment, thermal runaway prevention, and environmental impact considerations specific to sodium chemistry.

China has integrated solid-state sodium battery development into its national standardization strategy, with the China Electronics Standardization Institute establishing dedicated technical committees to accelerate standards development. Their focus includes performance metrics, safety protocols, and recycling requirements tailored to the unique properties of sodium-based systems.

Industry consortia are playing an increasingly important role in standardization efforts. The Sodium Battery Consortium, comprising leading manufacturers and research institutions, has proposed a unified testing framework that addresses the distinctive characteristics of solid-state sodium technologies. This collaborative approach is helping bridge regulatory gaps while technical standards catch up with innovation pace.

Recycling and end-of-life management represent critical areas for regulatory development, with several jurisdictions now drafting sodium-specific provisions within broader battery recycling frameworks. These emerging regulations aim to address the unique material recovery challenges and environmental considerations associated with sodium battery components, particularly solid electrolytes and sodium metal or sodium-containing anodes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!