Standards-driven advancements in solid-state sodium battery applications

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Evolution and Objectives

Solid-state sodium batteries represent a significant evolution in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development trajectory of these batteries can be traced back to the early 2000s when researchers began exploring sodium as a more abundant and cost-effective alternative to lithium. The initial focus was primarily on sodium-ion batteries with liquid electrolytes, but limitations in safety and performance drove the shift toward solid-state configurations.

The technological evolution accelerated notably around 2010-2015, with breakthrough research on solid electrolyte materials demonstrating improved ionic conductivity at room temperature. This period marked a critical transition from theoretical research to practical prototyping, establishing the foundational understanding of sodium ion transport mechanisms in solid matrices.

Current technological trends indicate a convergence of materials science, electrochemistry, and manufacturing innovations to address persistent challenges in solid-state sodium battery development. The field is witnessing increased attention to interface engineering, novel electrode architectures, and scalable production methodologies that maintain performance while reducing costs.

The primary objectives for solid-state sodium battery technology encompass several dimensions. From a performance perspective, researchers aim to achieve energy densities exceeding 300 Wh/kg and power densities comparable to current lithium-ion technologies. Cycle stability targets include maintaining 80% capacity retention after 1000 cycles, addressing the historical limitations of sodium-based systems.

Safety objectives represent another critical dimension, with solid-state configurations expected to eliminate risks associated with flammable liquid electrolytes. This includes thermal stability up to 150°C and resistance to dendrite formation that can cause short circuits.

Cost considerations drive objectives toward utilizing earth-abundant materials and simplified manufacturing processes. The target production cost is below $100/kWh to ensure commercial viability against established technologies. This economic imperative is coupled with sustainability goals, including reduced environmental footprint and enhanced recyclability.

Standardization objectives have emerged as increasingly important, focusing on establishing unified testing protocols, safety certifications, and performance metrics specific to solid-state sodium batteries. These standards aim to accelerate industry adoption by providing consistent evaluation frameworks and ensuring interoperability across different applications and manufacturers.

The long-term technological vision extends beyond incremental improvements, targeting transformative capabilities such as ultra-fast charging (80% in under 15 minutes), extended temperature operation ranges (-40°C to 80°C), and integration with renewable energy systems through advanced battery management algorithms.

The technological evolution accelerated notably around 2010-2015, with breakthrough research on solid electrolyte materials demonstrating improved ionic conductivity at room temperature. This period marked a critical transition from theoretical research to practical prototyping, establishing the foundational understanding of sodium ion transport mechanisms in solid matrices.

Current technological trends indicate a convergence of materials science, electrochemistry, and manufacturing innovations to address persistent challenges in solid-state sodium battery development. The field is witnessing increased attention to interface engineering, novel electrode architectures, and scalable production methodologies that maintain performance while reducing costs.

The primary objectives for solid-state sodium battery technology encompass several dimensions. From a performance perspective, researchers aim to achieve energy densities exceeding 300 Wh/kg and power densities comparable to current lithium-ion technologies. Cycle stability targets include maintaining 80% capacity retention after 1000 cycles, addressing the historical limitations of sodium-based systems.

Safety objectives represent another critical dimension, with solid-state configurations expected to eliminate risks associated with flammable liquid electrolytes. This includes thermal stability up to 150°C and resistance to dendrite formation that can cause short circuits.

Cost considerations drive objectives toward utilizing earth-abundant materials and simplified manufacturing processes. The target production cost is below $100/kWh to ensure commercial viability against established technologies. This economic imperative is coupled with sustainability goals, including reduced environmental footprint and enhanced recyclability.

Standardization objectives have emerged as increasingly important, focusing on establishing unified testing protocols, safety certifications, and performance metrics specific to solid-state sodium batteries. These standards aim to accelerate industry adoption by providing consistent evaluation frameworks and ensuring interoperability across different applications and manufacturers.

The long-term technological vision extends beyond incremental improvements, targeting transformative capabilities such as ultra-fast charging (80% in under 15 minutes), extended temperature operation ranges (-40°C to 80°C), and integration with renewable energy systems through advanced battery management algorithms.

Market Analysis for Sodium Battery Technologies

The global sodium battery market is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions and the limitations of lithium-ion technology. Current market valuations place the sodium battery sector at approximately 1.2 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 26.8% through 2030, potentially reaching 6.5 billion USD by the end of the decade.

The market segmentation reveals distinct application sectors with varying adoption rates. Grid-scale energy storage represents the largest market share at 42%, followed by electric vehicles at 28%, consumer electronics at 18%, and other applications comprising the remaining 12%. This distribution reflects the technology's current strengths in large-scale stationary applications where energy density constraints are less critical.

Geographically, Asia-Pacific dominates the market landscape, accounting for 56% of global production and consumption. China leads manufacturing capacity with over 35% of global output, followed by Japan and South Korea. European markets are showing accelerated growth rates of 32% annually as the region invests heavily in renewable energy infrastructure and sustainable transportation solutions.

Market drivers for sodium battery technologies include raw material advantages, with sodium being approximately 1000 times more abundant than lithium and 30-40% lower in cost. The absence of critical materials like cobalt and nickel further enhances the economic proposition. Additionally, solid-state sodium batteries offer superior safety profiles compared to conventional lithium-ion technologies, eliminating thermal runaway risks that have plagued lithium batteries.

Consumer demand patterns indicate growing preference for sustainable technologies, with 68% of surveyed industrial customers expressing willingness to adopt sodium-based solutions if performance metrics meet 85% of lithium-ion capabilities at comparable cost points. This represents a significant shift from 2020 surveys, where the acceptance threshold required 95% performance parity.

Market barriers include technological maturity concerns, with solid-state sodium batteries still facing challenges in energy density (currently 120-150 Wh/kg compared to 250-300 Wh/kg for commercial lithium-ion). Manufacturing scalability remains another significant hurdle, with production costs estimated at 1.8-2.2 times higher than established lithium-ion manufacturing processes.

The competitive landscape features both established energy storage companies pivoting toward sodium technology and specialized startups focused exclusively on sodium battery innovation. Strategic partnerships between material suppliers, cell manufacturers, and end-use industries are increasingly common, accelerating commercialization timelines and creating integrated value chains.

The market segmentation reveals distinct application sectors with varying adoption rates. Grid-scale energy storage represents the largest market share at 42%, followed by electric vehicles at 28%, consumer electronics at 18%, and other applications comprising the remaining 12%. This distribution reflects the technology's current strengths in large-scale stationary applications where energy density constraints are less critical.

Geographically, Asia-Pacific dominates the market landscape, accounting for 56% of global production and consumption. China leads manufacturing capacity with over 35% of global output, followed by Japan and South Korea. European markets are showing accelerated growth rates of 32% annually as the region invests heavily in renewable energy infrastructure and sustainable transportation solutions.

Market drivers for sodium battery technologies include raw material advantages, with sodium being approximately 1000 times more abundant than lithium and 30-40% lower in cost. The absence of critical materials like cobalt and nickel further enhances the economic proposition. Additionally, solid-state sodium batteries offer superior safety profiles compared to conventional lithium-ion technologies, eliminating thermal runaway risks that have plagued lithium batteries.

Consumer demand patterns indicate growing preference for sustainable technologies, with 68% of surveyed industrial customers expressing willingness to adopt sodium-based solutions if performance metrics meet 85% of lithium-ion capabilities at comparable cost points. This represents a significant shift from 2020 surveys, where the acceptance threshold required 95% performance parity.

Market barriers include technological maturity concerns, with solid-state sodium batteries still facing challenges in energy density (currently 120-150 Wh/kg compared to 250-300 Wh/kg for commercial lithium-ion). Manufacturing scalability remains another significant hurdle, with production costs estimated at 1.8-2.2 times higher than established lithium-ion manufacturing processes.

The competitive landscape features both established energy storage companies pivoting toward sodium technology and specialized startups focused exclusively on sodium battery innovation. Strategic partnerships between material suppliers, cell manufacturers, and end-use industries are increasingly common, accelerating commercialization timelines and creating integrated value chains.

Technical Barriers and Global Development Status

Despite significant advancements in solid-state sodium battery technology, several critical technical barriers continue to impede widespread commercialization. The solid electrolyte-electrode interface remains a primary challenge, with issues of high interfacial resistance and poor contact stability during cycling. This interface problem is exacerbated by volume changes during sodium insertion/extraction, leading to mechanical stress and potential delamination that compromises long-term performance.

Ionic conductivity limitations in solid electrolytes represent another significant hurdle. While some materials show promising conductivity at elevated temperatures, achieving comparable performance to liquid electrolytes at room temperature remains elusive. Current sodium superionic conductors typically achieve 10^-4 to 10^-3 S/cm at ambient conditions, whereas practical applications require at least 10^-2 S/cm.

Manufacturing scalability presents substantial challenges, particularly in producing large-area, thin, and defect-free solid electrolytes. Current laboratory-scale fabrication methods often involve complex processes that are difficult to translate to industrial production. The absence of standardized manufacturing protocols further complicates progress toward commercialization.

Globally, research efforts show distinct regional focuses. Japan leads in materials science innovation, with companies like NGK Insulators and research institutions such as Tokyo Institute of Technology pioneering novel solid electrolyte compositions. The European Union emphasizes sustainability aspects, with substantial funding through Horizon Europe programs targeting sodium battery development as an alternative to lithium-based systems.

China has rapidly expanded its research footprint, leveraging its abundant sodium resources and manufacturing capabilities. The Chinese Academy of Sciences and companies like CATL have established dedicated sodium battery research centers, focusing on scalable production methods and integration with renewable energy systems.

In North America, research is primarily concentrated in academic institutions and national laboratories, with emphasis on fundamental understanding of ion transport mechanisms and interface engineering. The U.S. Department of Energy's Battery500 Consortium has recently expanded its scope to include sodium-based systems.

Standardization efforts remain fragmented globally, with the International Electrotechnical Commission (IEC) and various regional bodies working to establish testing protocols and safety standards. The lack of unified standards has hindered comparative assessment of different technologies and slowed industrial adoption. Recent initiatives by the Global Battery Alliance aim to address this gap by developing sodium battery-specific standards for performance evaluation and safety certification.

Ionic conductivity limitations in solid electrolytes represent another significant hurdle. While some materials show promising conductivity at elevated temperatures, achieving comparable performance to liquid electrolytes at room temperature remains elusive. Current sodium superionic conductors typically achieve 10^-4 to 10^-3 S/cm at ambient conditions, whereas practical applications require at least 10^-2 S/cm.

Manufacturing scalability presents substantial challenges, particularly in producing large-area, thin, and defect-free solid electrolytes. Current laboratory-scale fabrication methods often involve complex processes that are difficult to translate to industrial production. The absence of standardized manufacturing protocols further complicates progress toward commercialization.

Globally, research efforts show distinct regional focuses. Japan leads in materials science innovation, with companies like NGK Insulators and research institutions such as Tokyo Institute of Technology pioneering novel solid electrolyte compositions. The European Union emphasizes sustainability aspects, with substantial funding through Horizon Europe programs targeting sodium battery development as an alternative to lithium-based systems.

China has rapidly expanded its research footprint, leveraging its abundant sodium resources and manufacturing capabilities. The Chinese Academy of Sciences and companies like CATL have established dedicated sodium battery research centers, focusing on scalable production methods and integration with renewable energy systems.

In North America, research is primarily concentrated in academic institutions and national laboratories, with emphasis on fundamental understanding of ion transport mechanisms and interface engineering. The U.S. Department of Energy's Battery500 Consortium has recently expanded its scope to include sodium-based systems.

Standardization efforts remain fragmented globally, with the International Electrotechnical Commission (IEC) and various regional bodies working to establish testing protocols and safety standards. The lack of unified standards has hindered comparative assessment of different technologies and slowed industrial adoption. Recent initiatives by the Global Battery Alliance aim to address this gap by developing sodium battery-specific standards for performance evaluation and safety certification.

Current Standards-Compliant Implementation Approaches

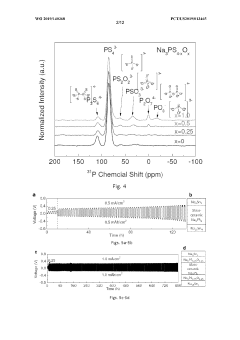

01 Electrolyte materials for solid-state sodium batteries

Various electrolyte materials can be used in solid-state sodium batteries to improve ionic conductivity and battery performance. These materials include sodium-based solid electrolytes such as sodium beta-alumina, NASICON-type compounds, and polymer electrolytes. The selection of appropriate electrolyte materials is crucial for achieving high sodium ion conductivity, good electrochemical stability, and improved battery safety characteristics.- Solid electrolyte materials for sodium batteries: Various solid electrolyte materials are being developed for sodium batteries to improve safety and energy density. These materials include sodium-ion conducting ceramics, polymer electrolytes, and composite materials that offer high ionic conductivity while preventing dendrite formation. The solid electrolytes enable the development of all-solid-state sodium batteries with enhanced thermal stability and longer cycle life compared to liquid electrolyte systems.

- Electrode materials and interfaces for solid-state sodium batteries: Advanced electrode materials and interface engineering are crucial for solid-state sodium batteries. Research focuses on developing cathode and anode materials compatible with solid electrolytes, addressing issues of volume changes during cycling, and improving the electrode-electrolyte interface to reduce resistance. Novel coating technologies and buffer layers are employed to enhance the electrochemical performance and stability of the battery system.

- Manufacturing processes for solid-state sodium batteries: Innovative manufacturing techniques are being developed for solid-state sodium batteries to address challenges in mass production. These include advanced sintering methods, thin-film deposition techniques, and novel assembly processes that enable the creation of stable interfaces between components. The manufacturing processes aim to reduce costs while ensuring consistent quality and performance of the batteries.

- Performance enhancement strategies for sodium solid-state batteries: Various strategies are being implemented to enhance the performance of solid-state sodium batteries. These include doping of electrolyte materials to increase ionic conductivity, nanostructuring of electrodes to improve reaction kinetics, and development of composite structures to optimize mechanical properties. These approaches aim to achieve higher energy density, faster charging capabilities, and extended cycle life.

- Novel cell designs and architectures for solid-state sodium batteries: Innovative cell designs and architectures are being explored to maximize the potential of solid-state sodium battery technology. These include multilayer structures, 3D architectures, and bipolar designs that enable higher energy density and better thermal management. The novel configurations address challenges related to mechanical stress during cycling and aim to improve the overall performance and safety of the battery systems.

02 Electrode compositions for sodium-ion batteries

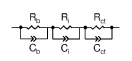

Electrode compositions play a vital role in the performance of solid-state sodium batteries. Various materials can be used as cathodes and anodes, including sodium transition metal oxides, phosphates, and carbon-based materials. The development of electrode materials with high capacity, good cycling stability, and fast sodium ion diffusion is essential for improving the overall performance of solid-state sodium batteries.Expand Specific Solutions03 Interface engineering in solid-state sodium batteries

Interface engineering is critical for addressing challenges related to the solid-solid interfaces in sodium batteries. Techniques such as coating electrode materials, adding interlayers, and surface modification can help reduce interfacial resistance, improve contact between components, and enhance the stability of the solid electrolyte interface. These approaches contribute to better cycling performance and longer battery life.Expand Specific Solutions04 Manufacturing processes for solid-state sodium batteries

Various manufacturing processes can be employed to fabricate solid-state sodium batteries, including dry pressing, tape casting, and thin-film deposition techniques. These processes affect the microstructure, density, and interfacial properties of battery components. Optimizing manufacturing methods is essential for achieving high-performance batteries with good mechanical integrity and electrochemical properties.Expand Specific Solutions05 Safety and thermal stability enhancements

Solid-state sodium batteries offer improved safety compared to liquid electrolyte systems. Various approaches can be used to further enhance safety and thermal stability, including the development of non-flammable solid electrolytes, incorporation of thermal management systems, and design of battery structures that prevent thermal runaway. These safety enhancements are crucial for the widespread adoption of sodium battery technology in various applications.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The solid-state sodium battery market is currently in an early growth phase, characterized by intensive R&D activities and limited commercial deployment. Market size is projected to expand significantly as this technology addresses critical limitations of lithium-ion batteries, including cost, safety, and resource constraints. Technical maturity varies across key players, with companies like QuantumScape, CATL, and Samsung SDI leading commercial development efforts. Academic institutions including Sichuan University and Nanjing University are advancing fundamental research, while established automotive manufacturers such as Toyota, Honda, and TVS Motor are exploring integration opportunities. Specialized firms like BroadBit Batteries and EnergyX are developing proprietary sodium-based chemistries, indicating a competitive landscape balanced between established corporations and innovative startups pursuing different technological approaches to commercialization.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a first-generation sodium-ion battery that achieves energy density of 160Wh/kg, with fast-charging capability reaching 80% in 15 minutes and excellent thermal stability at -20°C. Their approach focuses on Prussian white cathode materials with higher specific capacity and improved low-temperature performance. CATL's standardization efforts include developing a sodium-ion battery management system (BMS) that addresses the unique voltage characteristics and temperature dependencies of sodium chemistry. The company has implemented an AB battery system integration technology that allows sodium-ion cells to be integrated with lithium-ion batteries in a complementary arrangement, enabling manufacturers to use a single battery management system for both chemistries. This standardized approach facilitates easier adoption across various applications while maintaining compatibility with existing infrastructure.

Strengths: Industry-leading manufacturing scale allows for rapid commercialization; established supply chain relationships facilitate standardization across the industry; advanced BMS technology enables hybrid battery systems. Weaknesses: Energy density still lags behind advanced lithium-ion batteries; long-term cycling stability needs further improvement; sodium-ion technology still requires more extensive field validation.

Broadbit Batteries Oy

Technical Solution: Broadbit Batteries has pioneered a sodium-based solid-state battery technology specifically designed for mass-market applications. Their proprietary SolidRide™ technology utilizes a non-flammable solid electrolyte system that enables stable sodium metal anodes without dendrite formation. The company has developed standardized cell formats compatible with existing manufacturing equipment, facilitating easier industry adoption. Broadbit's approach focuses on room-temperature operation of solid sodium batteries - a significant advancement over many competing technologies that require elevated temperatures. Their standardization efforts include developing reference electrode designs and testing protocols specifically for sodium solid-state systems, which have been shared with industry partners to accelerate market adoption. The company claims their technology achieves energy densities exceeding 300Wh/kg at the cell level while maintaining excellent safety characteristics and low-temperature performance, addressing key barriers to widespread sodium battery implementation.

Strengths: Purpose-built sodium battery technology rather than adapted lithium systems; room-temperature operation overcomes a major hurdle for solid-state sodium batteries; compatibility with existing manufacturing infrastructure reduces adoption barriers. Weaknesses: As a smaller company, faces challenges in scaling production to compete with larger manufacturers; limited public performance validation data compared to more established players; potential material supply constraints for specialized components.

Key Patents and Scientific Breakthroughs

Solid electrolyte for sodium batteries

PatentWO2019140368A1

Innovation

- A new class of sodium oxy-sulfide solid-state electrolytes with a microstructure approaching a continuous glass is developed, providing enhanced chemical stability and mechanical strength, achieved through a low-temperature ball-milling and pressing process, allowing for the formation of a nearly flawless glassy structure that is stable with sodium metal or alloys.

Composite material as electrode for sodium ion batteries, production method therefor, and all-solid-state sodium battery

PatentActiveUS20170005337A1

Innovation

- A composite material for sodium ion batteries comprising an active material crystal, a sodium-ion conductive crystal, and an amorphous phase, where the active material crystal contains transition metals and phosphates, and the sodium-ion conductive crystal includes alumina or zirconia, with the amorphous phase enhancing interface conductivity and bonding strength.

Regulatory Framework and Standardization Efforts

The development of solid-state sodium batteries requires robust regulatory frameworks and standardization efforts to ensure safety, performance, and interoperability across the industry. Currently, the regulatory landscape for this emerging technology remains fragmented, with different regions establishing their own approaches to governance and standardization.

In the United States, the Department of Energy has initiated specific programs focused on establishing testing protocols and safety standards for solid-state sodium batteries. These efforts are complemented by the work of organizations such as ASTM International and the American National Standards Institute (ANSI), which are developing comprehensive testing methodologies for evaluating the performance and safety characteristics of these novel energy storage systems.

The European Union has taken a more integrated approach through its Battery Directive and the European Committee for Electrotechnical Standardization (CENELEC). Recent updates to these frameworks specifically address solid-state technologies, including sodium-based systems, with particular emphasis on lifecycle assessment, recycling requirements, and safety parameters unique to solid electrolytes.

In Asia, countries like Japan and South Korea lead standardization efforts through organizations such as the Japanese Industrial Standards Committee (JISC) and the Korean Agency for Technology and Standards (KATS). China has also established its own comprehensive framework through the China National Institute of Standardization, focusing particularly on manufacturing processes and quality control for solid-state sodium battery production.

International coordination is facilitated primarily through the International Electrotechnical Commission (IEC), which has established Technical Committee 21 specifically for secondary cells and batteries. The IEC 62660 series of standards is being expanded to incorporate solid-state sodium battery technologies, addressing unique characteristics such as dendrite formation prevention, thermal stability, and interface management.

A significant challenge in standardization efforts is the rapid pace of technological innovation, which often outstrips the development of corresponding standards. To address this, several jurisdictions have implemented "regulatory sandboxes" allowing controlled testing of new solid-state sodium battery technologies while standards are being developed.

Industry consortia also play a crucial role in standardization, with organizations like the International Battery Materials Association (IBMA) and the Solid-State Battery Consortium working to establish voluntary industry standards that often precede formal regulatory requirements. These collaborative efforts help bridge the gap between cutting-edge research and practical implementation while ensuring safety and performance benchmarks are maintained.

In the United States, the Department of Energy has initiated specific programs focused on establishing testing protocols and safety standards for solid-state sodium batteries. These efforts are complemented by the work of organizations such as ASTM International and the American National Standards Institute (ANSI), which are developing comprehensive testing methodologies for evaluating the performance and safety characteristics of these novel energy storage systems.

The European Union has taken a more integrated approach through its Battery Directive and the European Committee for Electrotechnical Standardization (CENELEC). Recent updates to these frameworks specifically address solid-state technologies, including sodium-based systems, with particular emphasis on lifecycle assessment, recycling requirements, and safety parameters unique to solid electrolytes.

In Asia, countries like Japan and South Korea lead standardization efforts through organizations such as the Japanese Industrial Standards Committee (JISC) and the Korean Agency for Technology and Standards (KATS). China has also established its own comprehensive framework through the China National Institute of Standardization, focusing particularly on manufacturing processes and quality control for solid-state sodium battery production.

International coordination is facilitated primarily through the International Electrotechnical Commission (IEC), which has established Technical Committee 21 specifically for secondary cells and batteries. The IEC 62660 series of standards is being expanded to incorporate solid-state sodium battery technologies, addressing unique characteristics such as dendrite formation prevention, thermal stability, and interface management.

A significant challenge in standardization efforts is the rapid pace of technological innovation, which often outstrips the development of corresponding standards. To address this, several jurisdictions have implemented "regulatory sandboxes" allowing controlled testing of new solid-state sodium battery technologies while standards are being developed.

Industry consortia also play a crucial role in standardization, with organizations like the International Battery Materials Association (IBMA) and the Solid-State Battery Consortium working to establish voluntary industry standards that often precede formal regulatory requirements. These collaborative efforts help bridge the gap between cutting-edge research and practical implementation while ensuring safety and performance benchmarks are maintained.

Sustainability Impact and Resource Considerations

The sustainability implications of solid-state sodium batteries represent a significant advantage over conventional lithium-ion technologies. Sodium's abundance in the Earth's crust—approximately 1000 times more plentiful than lithium—positions it as a resource-sustainable alternative for large-scale energy storage applications. This abundance translates to lower extraction costs and reduced geopolitical supply chain vulnerabilities, as sodium resources are more evenly distributed globally compared to lithium deposits concentrated in specific regions.

Environmental impact assessments of solid-state sodium battery production reveal substantially lower carbon footprints compared to traditional lithium-ion manufacturing processes. The elimination of toxic liquid electrolytes in solid-state designs further enhances their environmental credentials by reducing hazardous waste management requirements and minimizing potential ecological damage from manufacturing effluents or disposal.

Resource efficiency metrics indicate that standardized solid-state sodium battery production could achieve up to 30% reduction in rare earth element requirements compared to conventional batteries. This reduction is particularly significant as emerging standards increasingly emphasize responsible sourcing and circular economy principles. The ISO 14040 series for life cycle assessment has become instrumental in quantifying these sustainability benefits, with several manufacturers now pursuing certification to demonstrate compliance.

Water consumption during sodium extraction and processing is approximately 50% lower than comparable lithium operations, addressing critical resource conservation concerns in water-stressed regions. Additionally, emerging standards for battery recycling are being developed specifically for solid-state sodium technologies, with the potential to recover up to 90% of key materials, further enhancing their sustainability profile.

The development of standards-driven sustainability metrics has accelerated industry adoption of more environmentally responsible practices. The European Battery Directive revision and China's upcoming battery recycling standards both explicitly address sodium battery technologies, creating regulatory frameworks that incentivize sustainable design and end-of-life management.

Land use considerations also favor sodium-based technologies, as extraction typically requires less invasive mining practices compared to lithium brine operations. This reduced environmental footprint aligns with strengthening environmental impact assessment standards being implemented across major manufacturing regions.

As standards continue to evolve, they increasingly incorporate full-lifecycle sustainability requirements, driving manufacturers to optimize resource utilization throughout the value chain. This holistic approach ensures that the sustainability benefits of solid-state sodium batteries extend beyond just material selection to encompass production processes, operational efficiency, and end-of-life management.

Environmental impact assessments of solid-state sodium battery production reveal substantially lower carbon footprints compared to traditional lithium-ion manufacturing processes. The elimination of toxic liquid electrolytes in solid-state designs further enhances their environmental credentials by reducing hazardous waste management requirements and minimizing potential ecological damage from manufacturing effluents or disposal.

Resource efficiency metrics indicate that standardized solid-state sodium battery production could achieve up to 30% reduction in rare earth element requirements compared to conventional batteries. This reduction is particularly significant as emerging standards increasingly emphasize responsible sourcing and circular economy principles. The ISO 14040 series for life cycle assessment has become instrumental in quantifying these sustainability benefits, with several manufacturers now pursuing certification to demonstrate compliance.

Water consumption during sodium extraction and processing is approximately 50% lower than comparable lithium operations, addressing critical resource conservation concerns in water-stressed regions. Additionally, emerging standards for battery recycling are being developed specifically for solid-state sodium technologies, with the potential to recover up to 90% of key materials, further enhancing their sustainability profile.

The development of standards-driven sustainability metrics has accelerated industry adoption of more environmentally responsible practices. The European Battery Directive revision and China's upcoming battery recycling standards both explicitly address sodium battery technologies, creating regulatory frameworks that incentivize sustainable design and end-of-life management.

Land use considerations also favor sodium-based technologies, as extraction typically requires less invasive mining practices compared to lithium brine operations. This reduced environmental footprint aligns with strengthening environmental impact assessment standards being implemented across major manufacturing regions.

As standards continue to evolve, they increasingly incorporate full-lifecycle sustainability requirements, driving manufacturers to optimize resource utilization throughout the value chain. This holistic approach ensures that the sustainability benefits of solid-state sodium batteries extend beyond just material selection to encompass production processes, operational efficiency, and end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!