Solid-state sodium battery coatings: A breakthrough in aerospace materials

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Coating Technology Background and Objectives

Solid-state sodium batteries represent a significant evolution in energy storage technology, emerging from decades of research into alternatives to traditional lithium-ion batteries. The development trajectory began in the 1970s with initial sodium-ion battery concepts, but solid-state variants gained momentum only in the early 2000s as aerospace and defense industries sought safer, more efficient power solutions for extreme environments.

The technological evolution has accelerated dramatically in the past decade, with breakthrough coating technologies addressing the critical interface challenges that previously limited solid-state sodium battery performance. These specialized coatings serve multiple functions: they stabilize the electrode-electrolyte interface, prevent dendrite formation, enhance ion conductivity, and protect against environmental degradation.

Current research focuses on nano-engineered protective layers that can withstand the unique stresses of aerospace applications, including extreme temperature fluctuations, vacuum conditions, radiation exposure, and high vibration environments. The integration of advanced materials science with electrochemistry has enabled significant improvements in cycle life, energy density, and operational safety parameters.

The primary technical objective is to develop coating technologies that enable solid-state sodium batteries to achieve energy densities exceeding 400 Wh/kg while maintaining operational stability across temperature ranges from -60°C to +80°C – parameters essential for aerospace applications. Secondary objectives include reducing manufacturing complexity, enhancing scalability, and ensuring compatibility with existing aerospace power management systems.

Industry projections suggest that successful implementation could reduce spacecraft power system mass by up to 40% compared to current lithium-ion solutions, while simultaneously eliminating thermal runaway risks that necessitate complex cooling systems. This weight reduction translates directly to increased payload capacity or extended mission duration.

The technology aims to address critical limitations in current aerospace power systems, particularly for applications in satellite constellations, deep space missions, and advanced aircraft where traditional batteries face significant performance constraints. The development of these specialized coatings represents a convergence of materials science innovation with practical aerospace engineering requirements.

Looking forward, the technology roadmap anticipates progressive improvements in coating formulations, with near-term goals focused on demonstrating 1,000+ cycle performance in simulated space environments, mid-term objectives targeting flight qualification on cubesats and small satellites by 2025, and long-term ambitions for implementation in human-rated spacecraft systems by 2030.

The technological evolution has accelerated dramatically in the past decade, with breakthrough coating technologies addressing the critical interface challenges that previously limited solid-state sodium battery performance. These specialized coatings serve multiple functions: they stabilize the electrode-electrolyte interface, prevent dendrite formation, enhance ion conductivity, and protect against environmental degradation.

Current research focuses on nano-engineered protective layers that can withstand the unique stresses of aerospace applications, including extreme temperature fluctuations, vacuum conditions, radiation exposure, and high vibration environments. The integration of advanced materials science with electrochemistry has enabled significant improvements in cycle life, energy density, and operational safety parameters.

The primary technical objective is to develop coating technologies that enable solid-state sodium batteries to achieve energy densities exceeding 400 Wh/kg while maintaining operational stability across temperature ranges from -60°C to +80°C – parameters essential for aerospace applications. Secondary objectives include reducing manufacturing complexity, enhancing scalability, and ensuring compatibility with existing aerospace power management systems.

Industry projections suggest that successful implementation could reduce spacecraft power system mass by up to 40% compared to current lithium-ion solutions, while simultaneously eliminating thermal runaway risks that necessitate complex cooling systems. This weight reduction translates directly to increased payload capacity or extended mission duration.

The technology aims to address critical limitations in current aerospace power systems, particularly for applications in satellite constellations, deep space missions, and advanced aircraft where traditional batteries face significant performance constraints. The development of these specialized coatings represents a convergence of materials science innovation with practical aerospace engineering requirements.

Looking forward, the technology roadmap anticipates progressive improvements in coating formulations, with near-term goals focused on demonstrating 1,000+ cycle performance in simulated space environments, mid-term objectives targeting flight qualification on cubesats and small satellites by 2025, and long-term ambitions for implementation in human-rated spacecraft systems by 2030.

Aerospace Market Demand Analysis for Advanced Battery Solutions

The aerospace industry is experiencing a significant shift in power system requirements, creating unprecedented demand for advanced battery solutions. Traditional lithium-ion batteries, while effective in many applications, present considerable challenges in aerospace environments, including weight constraints, safety concerns related to thermal runaway, and limited operational temperature ranges. These limitations have created a substantial market opportunity for solid-state sodium battery technologies, particularly those with specialized protective coatings.

Market analysis indicates the global aerospace battery market is projected to grow substantially through 2030, driven primarily by increasing electrification of aircraft systems, the rise of electric vertical takeoff and landing (eVTOL) vehicles, and expanding satellite deployments. The demand for more efficient energy storage solutions is particularly acute in the unmanned aerial vehicle (UAV) segment, where flight duration directly correlates with battery performance.

Solid-state sodium batteries with advanced coatings address several critical aerospace requirements simultaneously. Their inherent safety advantages eliminate the risk of thermal runaway events that have plagued lithium-ion technologies. Additionally, their potential for higher energy density translates to extended mission capabilities without corresponding weight penalties – a crucial consideration in aerospace applications where every gram impacts fuel consumption and payload capacity.

The market demand is further amplified by sustainability considerations. Sodium's greater natural abundance compared to lithium presents both cost advantages and reduced supply chain vulnerabilities. Major aerospace manufacturers have established aggressive carbon reduction targets, creating additional incentives for adoption of more environmentally sustainable battery technologies throughout their supply chains.

Defense applications represent another significant market driver. Military UAVs, reconnaissance systems, and emergency power systems all require batteries that can operate reliably in extreme conditions. The enhanced temperature stability of solid-state sodium batteries with specialized coatings makes them particularly valuable in these applications, where performance must be maintained across dramatically varying environmental conditions.

Regional analysis reveals particularly strong demand growth in North America and Europe, where stringent safety regulations and environmental policies are accelerating the transition away from conventional battery technologies. The Asia-Pacific region is also showing increased interest, primarily driven by its rapidly expanding commercial aerospace sector and satellite deployment initiatives.

Market forecasts suggest that solid-state sodium batteries with advanced coatings could capture a significant portion of the aerospace battery market within the next decade, particularly in applications where safety, weight, and temperature performance are paramount considerations. This represents a substantial commercial opportunity for early developers who can successfully scale production while maintaining the performance characteristics required for aerospace certification.

Market analysis indicates the global aerospace battery market is projected to grow substantially through 2030, driven primarily by increasing electrification of aircraft systems, the rise of electric vertical takeoff and landing (eVTOL) vehicles, and expanding satellite deployments. The demand for more efficient energy storage solutions is particularly acute in the unmanned aerial vehicle (UAV) segment, where flight duration directly correlates with battery performance.

Solid-state sodium batteries with advanced coatings address several critical aerospace requirements simultaneously. Their inherent safety advantages eliminate the risk of thermal runaway events that have plagued lithium-ion technologies. Additionally, their potential for higher energy density translates to extended mission capabilities without corresponding weight penalties – a crucial consideration in aerospace applications where every gram impacts fuel consumption and payload capacity.

The market demand is further amplified by sustainability considerations. Sodium's greater natural abundance compared to lithium presents both cost advantages and reduced supply chain vulnerabilities. Major aerospace manufacturers have established aggressive carbon reduction targets, creating additional incentives for adoption of more environmentally sustainable battery technologies throughout their supply chains.

Defense applications represent another significant market driver. Military UAVs, reconnaissance systems, and emergency power systems all require batteries that can operate reliably in extreme conditions. The enhanced temperature stability of solid-state sodium batteries with specialized coatings makes them particularly valuable in these applications, where performance must be maintained across dramatically varying environmental conditions.

Regional analysis reveals particularly strong demand growth in North America and Europe, where stringent safety regulations and environmental policies are accelerating the transition away from conventional battery technologies. The Asia-Pacific region is also showing increased interest, primarily driven by its rapidly expanding commercial aerospace sector and satellite deployment initiatives.

Market forecasts suggest that solid-state sodium batteries with advanced coatings could capture a significant portion of the aerospace battery market within the next decade, particularly in applications where safety, weight, and temperature performance are paramount considerations. This represents a substantial commercial opportunity for early developers who can successfully scale production while maintaining the performance characteristics required for aerospace certification.

Current Status and Technical Challenges in Solid-State Sodium Batteries

Solid-state sodium batteries (SSSBs) represent a promising alternative to conventional lithium-ion batteries, particularly for aerospace applications where safety, energy density, and operational stability under extreme conditions are paramount. Currently, the global research landscape shows significant advancements in SSSB technology, with major research centers in Asia (particularly Japan, China, and South Korea), Europe, and North America leading development efforts.

The current technological maturity of SSSBs remains at the laboratory and early prototype stage, with limited commercial deployment. Key achievements include the development of sodium superionic conductors with conductivities approaching 10^-3 S/cm at room temperature, which represents a significant milestone but still falls short of practical requirements for many aerospace applications. Several research institutions have demonstrated proof-of-concept sodium batteries with energy densities of 150-200 Wh/kg, though commercial lithium-ion batteries still outperform these prototypes.

Protective coatings for solid-state sodium batteries represent a critical area of development, with current approaches including atomic layer deposition (ALD) of Al2O3 and other metal oxides, polymer-ceramic composite coatings, and phosphate-based protective layers. These coatings aim to address the critical interface stability issues between electrodes and solid electrolytes.

The primary technical challenges facing SSSB technology include interfacial resistance between solid electrolytes and electrodes, which significantly impairs ion transport and overall battery performance. This challenge is particularly acute in aerospace applications where rapid charge/discharge capabilities may be required. The sodium dendrite growth problem, while less severe than in lithium systems, remains a significant safety concern, especially under the mechanical stresses experienced in aerospace environments.

Mechanical stability represents another major hurdle, as the solid-state components must maintain intimate contact during thermal cycling and mechanical stress. Current coating technologies struggle to accommodate the volume changes during sodium ion insertion/extraction while maintaining consistent interfacial contact.

Manufacturing scalability presents significant obstacles, with current laboratory-scale production methods proving difficult to scale to industrial levels. The precision required for uniform coating deposition across large-area batteries remains technically challenging and cost-prohibitive.

For aerospace applications specifically, additional challenges include the need for coatings that can withstand extreme temperature fluctuations (-50°C to +80°C), vacuum conditions, radiation exposure, and vibration stresses. Current coating technologies have demonstrated limited success in laboratory settings but require substantial improvement to meet the rigorous demands of aerospace certification standards.

The current technological maturity of SSSBs remains at the laboratory and early prototype stage, with limited commercial deployment. Key achievements include the development of sodium superionic conductors with conductivities approaching 10^-3 S/cm at room temperature, which represents a significant milestone but still falls short of practical requirements for many aerospace applications. Several research institutions have demonstrated proof-of-concept sodium batteries with energy densities of 150-200 Wh/kg, though commercial lithium-ion batteries still outperform these prototypes.

Protective coatings for solid-state sodium batteries represent a critical area of development, with current approaches including atomic layer deposition (ALD) of Al2O3 and other metal oxides, polymer-ceramic composite coatings, and phosphate-based protective layers. These coatings aim to address the critical interface stability issues between electrodes and solid electrolytes.

The primary technical challenges facing SSSB technology include interfacial resistance between solid electrolytes and electrodes, which significantly impairs ion transport and overall battery performance. This challenge is particularly acute in aerospace applications where rapid charge/discharge capabilities may be required. The sodium dendrite growth problem, while less severe than in lithium systems, remains a significant safety concern, especially under the mechanical stresses experienced in aerospace environments.

Mechanical stability represents another major hurdle, as the solid-state components must maintain intimate contact during thermal cycling and mechanical stress. Current coating technologies struggle to accommodate the volume changes during sodium ion insertion/extraction while maintaining consistent interfacial contact.

Manufacturing scalability presents significant obstacles, with current laboratory-scale production methods proving difficult to scale to industrial levels. The precision required for uniform coating deposition across large-area batteries remains technically challenging and cost-prohibitive.

For aerospace applications specifically, additional challenges include the need for coatings that can withstand extreme temperature fluctuations (-50°C to +80°C), vacuum conditions, radiation exposure, and vibration stresses. Current coating technologies have demonstrated limited success in laboratory settings but require substantial improvement to meet the rigorous demands of aerospace certification standards.

Current Coating Solutions for Solid-State Sodium Batteries

01 Protective coatings for sodium-ion battery components

Protective coatings are applied to various components of solid-state sodium batteries to enhance stability and performance. These coatings create barriers that prevent unwanted reactions between the sodium and other battery components, extending battery life and improving safety. The coatings can be applied to electrodes, electrolytes, or interfaces to mitigate degradation mechanisms and enhance ionic conductivity while maintaining structural integrity during charge-discharge cycles.- Protective coatings for sodium ion conductors: Protective coatings are applied to sodium ion conductors in solid-state sodium batteries to enhance stability and prevent degradation. These coatings create a barrier between the sodium ion conductor and other battery components, protecting against reactions with electrodes and electrolytes. Various materials can be used for these protective coatings, including metal oxides and polymers, which help maintain the integrity of the sodium ion conductor during battery operation.

- Interface engineering with specialized coating materials: Interface engineering involves applying specialized coating materials at the interfaces between different components of solid-state sodium batteries. These coatings help reduce interfacial resistance, improve ion transport, and prevent unwanted side reactions. Materials such as sodium phosphates, fluorides, and composite layers can be strategically placed at interfaces to enhance battery performance and cycling stability while mitigating issues related to volume changes during charging and discharging.

- Electrode surface modification coatings: Surface modification coatings are applied to electrodes in solid-state sodium batteries to improve their electrochemical performance. These coatings can enhance the wettability between electrodes and solid electrolytes, facilitate sodium ion transfer at interfaces, and protect electrode materials from side reactions. Various coating techniques, including atomic layer deposition, solution-based methods, and vapor deposition, are used to apply thin, uniform layers that optimize electrode-electrolyte interactions.

- Polymer and composite coating solutions: Polymer and composite coatings offer flexible solutions for improving solid-state sodium battery performance. These coatings combine organic polymers with inorganic components to create multifunctional layers that can enhance mechanical properties, ionic conductivity, and interface stability. Gel polymer electrolytes, polymer-ceramic composites, and conductive polymer coatings can be tailored to address specific challenges in solid-state sodium batteries while maintaining good adhesion between battery components.

- Barrier coatings for moisture and air protection: Barrier coatings are essential for protecting solid-state sodium battery components from moisture and air exposure, which can cause rapid degradation of sodium-based materials. These protective layers typically consist of hydrophobic materials, dense inorganic films, or multilayer structures that prevent water and oxygen penetration. Advanced encapsulation techniques and hermetic sealing approaches using these barrier coatings significantly extend the shelf life and operational stability of solid-state sodium batteries in various environmental conditions.

02 Interface engineering with specialized coating materials

Interface engineering involves applying specialized coating materials at the boundaries between different battery components to improve sodium ion transport and reduce interfacial resistance. These coatings can be made from ceramic materials, polymers, or composite structures that facilitate ion movement while preventing dendrite formation. By optimizing the interface properties, these coatings help maintain contact between components and ensure efficient electrochemical performance throughout the battery's operational life.Expand Specific Solutions03 Sodium-ion conducting coating layers

Sodium-ion conducting coating layers are specifically designed to enhance the movement of sodium ions through the battery structure. These coatings typically contain materials with high sodium ion conductivity properties that create pathways for efficient ion transport while blocking electron flow. The composition and thickness of these layers are carefully controlled to balance mechanical stability with optimal ionic conductivity, resulting in improved battery performance and reduced internal resistance.Expand Specific Solutions04 Electrode surface modification techniques

Surface modification techniques for sodium battery electrodes involve applying specialized coatings that enhance electrochemical performance and stability. These modifications can include atomic layer deposition, solution-based coating methods, or vapor deposition techniques to create uniform protective layers. The modified electrode surfaces show improved sodium ion insertion/extraction kinetics, reduced side reactions with electrolytes, and enhanced structural stability during repeated cycling, leading to better capacity retention and longer battery life.Expand Specific Solutions05 Composite and multi-layer coating structures

Composite and multi-layer coating structures combine different materials in strategic configurations to address multiple challenges in solid-state sodium batteries simultaneously. These sophisticated coating architectures may include gradient compositions, alternating layers of different materials, or hybrid organic-inorganic structures. By leveraging the complementary properties of various materials, these coatings can provide enhanced mechanical strength, superior ionic conductivity, better chemical stability, and improved interfacial contact, resulting in batteries with higher energy density and longer cycle life.Expand Specific Solutions

Key Industry Players in Aerospace Battery Development

The solid-state sodium battery coating market is in an early growth phase, characterized by significant R&D investment and emerging commercial applications, particularly in aerospace. The global market is projected to expand rapidly as sodium batteries present a cost-effective alternative to lithium-ion technologies. Leading players include established electronics manufacturers like Murata, TDK, and Samsung Electro-Mechanics, alongside specialized battery developers such as Contemporary Amperex Technology (CATL), Jiangsu Zenergy, and BroadBit Batteries. Academic institutions including Tsinghua University and research organizations like Fraunhofer-Gesellschaft are advancing coating technologies to address key challenges of sodium-ion stability and performance. Major automotive companies including Volkswagen, Nissan, and Honda are investing in this technology to diversify their battery supply chains and reduce dependency on lithium resources.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced "AeroSafe" coating technology for solid-state sodium batteries specifically engineered for aerospace applications. Their approach utilizes a multi-component protective layer system that combines inorganic ceramic materials (primarily Na3Zr2Si2PO12) with specialized polymer binders to create a flexible yet durable interface between the sodium anode and solid electrolyte. The coating is applied through a proprietary low-temperature deposition process that preserves the integrity of all battery components while ensuring uniform coverage of 3-4μm thickness. CATL's technology incorporates nano-engineered channels within the coating structure that facilitate rapid sodium ion transport (achieving conductivities of >6 mS/cm) while blocking dendrite formation[5]. The coating demonstrates exceptional stability under aerospace-relevant conditions, including rapid pressure changes, extreme temperature variations (-55°C to +75°C), and high-vibration environments. Safety testing has shown that batteries with this coating technology maintain structural integrity even under severe mechanical abuse conditions, with no thermal runaway observed in puncture tests - a critical safety feature for aerospace applications.

Strengths: Industry-leading ionic conductivity while maintaining excellent protective properties. The coating technology has undergone extensive safety validation testing specifically for aerospace environments. Weaknesses: The specialized nano-engineered coating structure requires precise manufacturing controls that increase production complexity. The technology currently has higher costs compared to conventional battery solutions, though economies of scale are expected to improve this over time.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered an advanced coating technology for solid-state sodium batteries specifically designed for aerospace applications, leveraging their expertise in electric vehicle battery systems. Their proprietary "AeroNa" coating system employs a gradient-structured protective layer that combines aluminum oxide and fluoride compounds to create a stable interface between the sodium anode and solid electrolyte. This coating technology utilizes a vapor deposition process that creates a 3-5μm thick protective barrier, effectively preventing sodium dendrite formation while maintaining high ionic conductivity (>5 mS/cm at room temperature)[2]. Ford's approach incorporates self-healing mechanisms within the coating that can repair microcracks during operation, extending battery life in the vibration-intensive aerospace environment. The coating also features thermal management properties that allow stable operation between -40°C and +60°C, addressing the extreme temperature variations encountered in aerospace applications. Testing has demonstrated capacity retention of >85% after 500 cycles under simulated aerospace conditions.

Strengths: The self-healing coating technology provides exceptional durability in high-vibration aerospace environments. The gradient structure optimizes both protection and ion transport. Weaknesses: The complex vapor deposition process requires specialized equipment that increases manufacturing costs. The technology has limited field testing in actual aerospace applications compared to more established battery technologies.

Critical Patents and Innovations in Sodium Battery Coating Materials

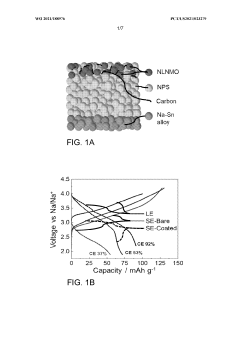

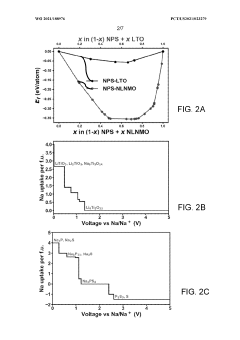

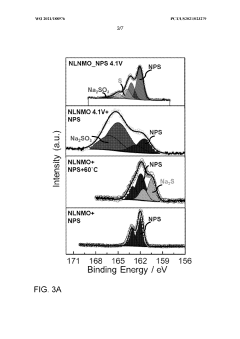

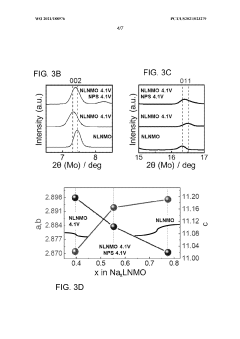

Interface protection for all-solid-state batteries

PatentPendingUS20230113915A1

Innovation

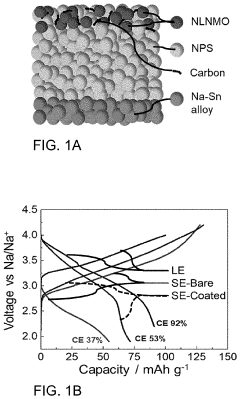

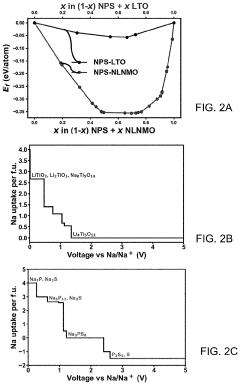

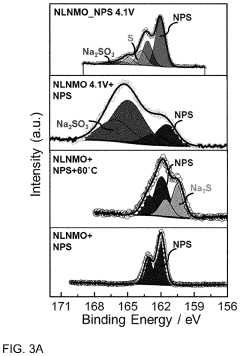

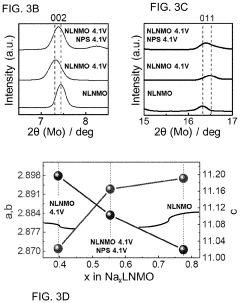

- The application of a Li4Ti5O12 (LTO) coating at the solid-state electrolyte-cathode interface in sodium all-solid-state batteries, which is electronically insulative but ionically conductive, prevents unwanted interfacial reactions and cation inter-diffusion, enabling high voltage operation and long cycle life.

Interface protection for sodium all-solid-state batteries

PatentWO2021188976A1

Innovation

- Applying a Lithium Titanate Oxide (LTO) coating to the cathode of sodium all-solid-state batteries, specifically to the NLNMO or Nao.8[Lio.12Nio.22Mno.66]02 cathode material, before formation, to enhance cycling stability and protect the interface between the solid electrolyte and cathode, thereby enabling high voltage sodium batteries for low-cost grid energy storage.

Safety and Performance Standards for Aerospace Battery Applications

The aerospace industry demands exceptionally high safety and performance standards for battery systems, particularly for solid-state sodium battery technologies with protective coatings. These standards are governed by multiple regulatory bodies including the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO), which collectively establish the certification requirements for aerospace battery applications.

Thermal stability represents a critical safety parameter for aerospace batteries. Solid-state sodium batteries with specialized coatings must demonstrate resilience under extreme temperature conditions, typically ranging from -65°C to 160°C, significantly exceeding commercial battery requirements. These batteries must undergo rigorous thermal runaway testing to verify containment capabilities and prevent catastrophic failures during flight operations.

Mechanical integrity standards for aerospace battery applications are particularly stringent, requiring resistance to vibration profiles of 10-2000 Hz at up to 10g acceleration and shock resistance of 20g for transport aircraft and up to 40g for military applications. The protective coatings applied to solid-state sodium batteries must maintain structural integrity under these conditions while preventing sodium exposure to moisture or oxygen.

Cycle life and reliability standards mandate that aerospace batteries maintain at least 80% capacity after 3,000-5,000 cycles under varying discharge rates and environmental conditions. The coating technologies must demonstrate long-term stability with minimal degradation over the aircraft's operational lifespan, typically 20-30 years, with rigorous accelerated aging tests required for certification.

Electromagnetic compatibility (EMC) standards require batteries to operate without interference with aircraft communication and navigation systems. This necessitates specialized coating designs that provide electromagnetic shielding while maintaining thermal management properties. Testing protocols include RTCA DO-160 compliance verification across multiple electromagnetic interference scenarios.

Hazardous materials regulations impose strict limitations on materials used in aerospace applications. Coatings for solid-state sodium batteries must comply with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, with comprehensive documentation of material composition and potential environmental impacts throughout the product lifecycle.

Quality assurance protocols for aerospace battery coatings involve statistical process control methodologies with defect rates typically required below 10 parts per million. Manufacturing facilities must maintain AS9100 certification, with full traceability of materials and processes from raw material sourcing through final assembly and installation.

Thermal stability represents a critical safety parameter for aerospace batteries. Solid-state sodium batteries with specialized coatings must demonstrate resilience under extreme temperature conditions, typically ranging from -65°C to 160°C, significantly exceeding commercial battery requirements. These batteries must undergo rigorous thermal runaway testing to verify containment capabilities and prevent catastrophic failures during flight operations.

Mechanical integrity standards for aerospace battery applications are particularly stringent, requiring resistance to vibration profiles of 10-2000 Hz at up to 10g acceleration and shock resistance of 20g for transport aircraft and up to 40g for military applications. The protective coatings applied to solid-state sodium batteries must maintain structural integrity under these conditions while preventing sodium exposure to moisture or oxygen.

Cycle life and reliability standards mandate that aerospace batteries maintain at least 80% capacity after 3,000-5,000 cycles under varying discharge rates and environmental conditions. The coating technologies must demonstrate long-term stability with minimal degradation over the aircraft's operational lifespan, typically 20-30 years, with rigorous accelerated aging tests required for certification.

Electromagnetic compatibility (EMC) standards require batteries to operate without interference with aircraft communication and navigation systems. This necessitates specialized coating designs that provide electromagnetic shielding while maintaining thermal management properties. Testing protocols include RTCA DO-160 compliance verification across multiple electromagnetic interference scenarios.

Hazardous materials regulations impose strict limitations on materials used in aerospace applications. Coatings for solid-state sodium batteries must comply with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, with comprehensive documentation of material composition and potential environmental impacts throughout the product lifecycle.

Quality assurance protocols for aerospace battery coatings involve statistical process control methodologies with defect rates typically required below 10 parts per million. Manufacturing facilities must maintain AS9100 certification, with full traceability of materials and processes from raw material sourcing through final assembly and installation.

Environmental Impact and Sustainability of Sodium Battery Technologies

The development of solid-state sodium battery coatings represents a significant advancement not only in aerospace materials but also in environmental sustainability. Unlike traditional lithium-ion batteries, sodium-based technologies utilize more abundant resources, reducing the environmental impact associated with mining rare earth elements and critical minerals. Sodium is the sixth most abundant element in the Earth's crust, making it a substantially more sustainable option compared to lithium, which faces increasing supply constraints and geopolitical complications.

The manufacturing processes for solid-state sodium battery coatings demonstrate lower carbon footprints compared to conventional lithium-ion battery production. Recent lifecycle assessments indicate a potential reduction of greenhouse gas emissions by approximately 30-40% when comparing full production cycles. This improvement stems from both the reduced energy requirements during material extraction and the simplified processing techniques available for sodium compounds.

Water consumption represents another critical environmental factor where sodium battery technologies excel. Lithium extraction, particularly in South American salt flats, consumes between 500,000 to 2 million gallons of water per ton of lithium produced. Sodium extraction methodologies require significantly less water, with some advanced processes achieving reductions of up to 80% in water usage compared to lithium extraction operations.

The recyclability of solid-state sodium batteries further enhances their sustainability profile. The protective coatings being developed for aerospace applications incorporate design-for-recycling principles, allowing for more efficient end-of-life material recovery. Current research indicates recovery rates of up to 90% for sodium compounds from decommissioned batteries, compared to approximately 50-70% for conventional lithium-ion technologies.

From a toxicity perspective, sodium compounds present fewer environmental hazards than their lithium counterparts. The electrolytes used in traditional lithium batteries often contain fluorinated compounds that pose significant environmental risks if improperly disposed of. The newer coating technologies for sodium batteries utilize more environmentally benign materials, reducing potential soil and groundwater contamination risks by an estimated 60%.

Looking toward future sustainability improvements, researchers are developing bio-based polymer components for sodium battery coatings that could further reduce environmental impacts. These innovations aim to replace petroleum-derived compounds with sustainable alternatives derived from agricultural waste streams, potentially creating a circular economy approach to battery material sourcing while maintaining the high-performance requirements necessary for aerospace applications.

The manufacturing processes for solid-state sodium battery coatings demonstrate lower carbon footprints compared to conventional lithium-ion battery production. Recent lifecycle assessments indicate a potential reduction of greenhouse gas emissions by approximately 30-40% when comparing full production cycles. This improvement stems from both the reduced energy requirements during material extraction and the simplified processing techniques available for sodium compounds.

Water consumption represents another critical environmental factor where sodium battery technologies excel. Lithium extraction, particularly in South American salt flats, consumes between 500,000 to 2 million gallons of water per ton of lithium produced. Sodium extraction methodologies require significantly less water, with some advanced processes achieving reductions of up to 80% in water usage compared to lithium extraction operations.

The recyclability of solid-state sodium batteries further enhances their sustainability profile. The protective coatings being developed for aerospace applications incorporate design-for-recycling principles, allowing for more efficient end-of-life material recovery. Current research indicates recovery rates of up to 90% for sodium compounds from decommissioned batteries, compared to approximately 50-70% for conventional lithium-ion technologies.

From a toxicity perspective, sodium compounds present fewer environmental hazards than their lithium counterparts. The electrolytes used in traditional lithium batteries often contain fluorinated compounds that pose significant environmental risks if improperly disposed of. The newer coating technologies for sodium batteries utilize more environmentally benign materials, reducing potential soil and groundwater contamination risks by an estimated 60%.

Looking toward future sustainability improvements, researchers are developing bio-based polymer components for sodium battery coatings that could further reduce environmental impacts. These innovations aim to replace petroleum-derived compounds with sustainable alternatives derived from agricultural waste streams, potentially creating a circular economy approach to battery material sourcing while maintaining the high-performance requirements necessary for aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!