Solid-state sodium battery innovations in thermal management systems

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Battery Evolution and Research Objectives

Sodium batteries have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The evolution of sodium battery technology can be traced back to the 1970s when initial research on sodium-sulfur and sodium-nickel chloride batteries began. These early systems operated at high temperatures (300-350°C), limiting their practical applications primarily to grid-scale energy storage.

The 2010s marked a significant turning point with increased research focus on room-temperature sodium-ion batteries. This shift was driven by growing concerns about lithium resource limitations and price volatility. During this period, researchers made substantial progress in developing electrode materials, electrolytes, and cell designs specifically optimized for sodium-ion chemistry.

More recently, solid-state sodium batteries have gained attention as they offer potential advantages in safety, energy density, and thermal stability. Unlike conventional liquid electrolyte systems, solid-state configurations minimize risks of leakage and flammability while potentially enabling higher operating voltages and energy densities. However, these systems present unique thermal management challenges that must be addressed for commercial viability.

The thermal behavior of solid-state sodium batteries differs significantly from liquid-electrolyte counterparts. Solid electrolytes typically have lower ionic conductivity at room temperature, often requiring elevated operating temperatures to achieve acceptable performance. Conversely, excessive heat can accelerate degradation mechanisms and compromise long-term stability. This creates a complex thermal management requirement where the system must maintain temperatures within a narrow optimal range.

Current research objectives in solid-state sodium battery thermal management focus on several key areas. First, developing novel solid electrolyte materials with improved ionic conductivity at ambient temperatures to reduce heating requirements. Second, engineering interface designs that minimize resistance and heat generation at electrode-electrolyte boundaries. Third, creating advanced thermal management systems that can efficiently distribute, contain, or dissipate heat as needed throughout battery operation.

Additional research goals include understanding the fundamental heat generation mechanisms during cycling, developing predictive thermal models specific to solid-state sodium systems, and designing battery packs with integrated thermal regulation features. The ultimate objective is to create solid-state sodium battery systems that maintain optimal operating temperatures across diverse environmental conditions and usage profiles, while maximizing safety, performance, and longevity.

These research efforts align with broader industry goals to develop sustainable, cost-effective energy storage solutions that can accelerate the transition to renewable energy and electrified transportation without relying on geographically concentrated resources like lithium.

The 2010s marked a significant turning point with increased research focus on room-temperature sodium-ion batteries. This shift was driven by growing concerns about lithium resource limitations and price volatility. During this period, researchers made substantial progress in developing electrode materials, electrolytes, and cell designs specifically optimized for sodium-ion chemistry.

More recently, solid-state sodium batteries have gained attention as they offer potential advantages in safety, energy density, and thermal stability. Unlike conventional liquid electrolyte systems, solid-state configurations minimize risks of leakage and flammability while potentially enabling higher operating voltages and energy densities. However, these systems present unique thermal management challenges that must be addressed for commercial viability.

The thermal behavior of solid-state sodium batteries differs significantly from liquid-electrolyte counterparts. Solid electrolytes typically have lower ionic conductivity at room temperature, often requiring elevated operating temperatures to achieve acceptable performance. Conversely, excessive heat can accelerate degradation mechanisms and compromise long-term stability. This creates a complex thermal management requirement where the system must maintain temperatures within a narrow optimal range.

Current research objectives in solid-state sodium battery thermal management focus on several key areas. First, developing novel solid electrolyte materials with improved ionic conductivity at ambient temperatures to reduce heating requirements. Second, engineering interface designs that minimize resistance and heat generation at electrode-electrolyte boundaries. Third, creating advanced thermal management systems that can efficiently distribute, contain, or dissipate heat as needed throughout battery operation.

Additional research goals include understanding the fundamental heat generation mechanisms during cycling, developing predictive thermal models specific to solid-state sodium systems, and designing battery packs with integrated thermal regulation features. The ultimate objective is to create solid-state sodium battery systems that maintain optimal operating temperatures across diverse environmental conditions and usage profiles, while maximizing safety, performance, and longevity.

These research efforts align with broader industry goals to develop sustainable, cost-effective energy storage solutions that can accelerate the transition to renewable energy and electrified transportation without relying on geographically concentrated resources like lithium.

Market Analysis for Solid-State Sodium Batteries

The global market for solid-state sodium batteries is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that the solid-state battery sector is projected to reach $87.5 billion by 2027, with sodium-based technologies capturing an expanding share of this market. The compound annual growth rate for solid-state sodium batteries specifically is estimated at 29.4% for the period 2023-2030, outpacing many traditional battery technologies.

Consumer electronics currently represents the largest application segment for solid-state sodium batteries, accounting for approximately 38% of market demand. This is followed by electric vehicles at 31%, grid storage at 22%, and other applications comprising the remaining 9%. The electric vehicle segment is expected to demonstrate the fastest growth rate in the coming years, as automotive manufacturers increasingly seek alternatives to lithium-ion technologies.

Geographically, Asia-Pacific dominates the market with 45% share, led by significant investments in China, Japan, and South Korea. North America follows at 28%, Europe at 22%, and the rest of the world at 5%. China's dominance is particularly noteworthy, as the country has established a comprehensive supply chain for sodium battery materials and components, supported by substantial government incentives for clean energy technologies.

Key market drivers include the abundant availability of sodium resources compared to lithium, with sodium being approximately 1,000 times more plentiful in the Earth's crust. This abundance translates to potentially lower raw material costs, with sodium carbonate priced at roughly one-third the cost of lithium carbonate. Additionally, solid-state sodium batteries offer enhanced safety profiles by eliminating flammable liquid electrolytes, addressing a critical concern in energy storage applications.

Market challenges include competition from established lithium-ion technologies, which benefit from decades of optimization and economies of scale. The energy density of current sodium-based systems remains 15-20% lower than advanced lithium-ion batteries, presenting adoption barriers in space-constrained applications. Manufacturing scalability also presents challenges, with current production volumes limited by specialized equipment requirements and complex fabrication processes.

Consumer awareness and acceptance represent another market hurdle, as end-users remain largely unfamiliar with sodium battery technology compared to well-established alternatives. This knowledge gap necessitates targeted education campaigns and demonstration projects to build market confidence and accelerate adoption across various application segments.

Consumer electronics currently represents the largest application segment for solid-state sodium batteries, accounting for approximately 38% of market demand. This is followed by electric vehicles at 31%, grid storage at 22%, and other applications comprising the remaining 9%. The electric vehicle segment is expected to demonstrate the fastest growth rate in the coming years, as automotive manufacturers increasingly seek alternatives to lithium-ion technologies.

Geographically, Asia-Pacific dominates the market with 45% share, led by significant investments in China, Japan, and South Korea. North America follows at 28%, Europe at 22%, and the rest of the world at 5%. China's dominance is particularly noteworthy, as the country has established a comprehensive supply chain for sodium battery materials and components, supported by substantial government incentives for clean energy technologies.

Key market drivers include the abundant availability of sodium resources compared to lithium, with sodium being approximately 1,000 times more plentiful in the Earth's crust. This abundance translates to potentially lower raw material costs, with sodium carbonate priced at roughly one-third the cost of lithium carbonate. Additionally, solid-state sodium batteries offer enhanced safety profiles by eliminating flammable liquid electrolytes, addressing a critical concern in energy storage applications.

Market challenges include competition from established lithium-ion technologies, which benefit from decades of optimization and economies of scale. The energy density of current sodium-based systems remains 15-20% lower than advanced lithium-ion batteries, presenting adoption barriers in space-constrained applications. Manufacturing scalability also presents challenges, with current production volumes limited by specialized equipment requirements and complex fabrication processes.

Consumer awareness and acceptance represent another market hurdle, as end-users remain largely unfamiliar with sodium battery technology compared to well-established alternatives. This knowledge gap necessitates targeted education campaigns and demonstration projects to build market confidence and accelerate adoption across various application segments.

Thermal Management Challenges in Solid-State Sodium Batteries

Solid-state sodium batteries (SSSBs) face significant thermal management challenges that must be addressed for their successful commercialization. Unlike conventional lithium-ion batteries with liquid electrolytes that can dissipate heat more effectively, solid-state electrolytes in sodium batteries present unique thermal conductivity issues. The solid electrolyte materials typically exhibit lower thermal conductivity compared to liquid counterparts, creating potential hotspots during operation that can compromise battery performance and safety.

Temperature gradients within SSSBs represent another critical challenge. These gradients can lead to uneven sodium-ion transport across the solid electrolyte, resulting in localized stress concentrations and potential mechanical failures. The interface between the solid electrolyte and electrodes is particularly vulnerable to thermal stress, as different materials expand and contract at varying rates with temperature fluctuations, potentially creating microcracks that increase internal resistance.

High-temperature operation presents both opportunities and challenges for SSSBs. While elevated temperatures can enhance ionic conductivity in solid electrolytes, they also accelerate degradation mechanisms such as interfacial reactions and dendrite formation. Conversely, low-temperature performance remains problematic, as ion mobility in solid electrolytes decreases significantly at sub-zero temperatures, severely limiting battery capacity and power capability.

The thermal runaway risk, though generally lower than in conventional batteries, still exists in SSSBs. Certain solid electrolytes may undergo phase transitions or decomposition at elevated temperatures, potentially releasing heat and triggering cascading thermal events. Additionally, sodium metal, if used as an anode material, remains highly reactive and can pose safety risks under thermal stress conditions.

Scale-up manufacturing introduces additional thermal management complexities. Achieving uniform temperature distribution across larger-format cells presents significant engineering challenges. The sintering processes often required for solid electrolyte fabrication involve high-temperature treatments that must be precisely controlled to ensure optimal microstructure and performance.

Fast charging capabilities, increasingly demanded by consumers, generate substantial heat that must be efficiently managed. The limited thermal conductivity of solid electrolytes makes rapid heat dissipation particularly challenging during high-rate charging scenarios. This limitation could potentially restrict the practical charging speeds achievable with SSSBs in commercial applications.

Developing effective cooling systems specifically tailored for SSSBs remains an active research area. Traditional cooling approaches used for lithium-ion batteries may not be directly applicable due to the different thermal properties and cell architectures of solid-state sodium systems. Innovative thermal management solutions that address these unique challenges will be crucial for realizing the full potential of solid-state sodium battery technology.

Temperature gradients within SSSBs represent another critical challenge. These gradients can lead to uneven sodium-ion transport across the solid electrolyte, resulting in localized stress concentrations and potential mechanical failures. The interface between the solid electrolyte and electrodes is particularly vulnerable to thermal stress, as different materials expand and contract at varying rates with temperature fluctuations, potentially creating microcracks that increase internal resistance.

High-temperature operation presents both opportunities and challenges for SSSBs. While elevated temperatures can enhance ionic conductivity in solid electrolytes, they also accelerate degradation mechanisms such as interfacial reactions and dendrite formation. Conversely, low-temperature performance remains problematic, as ion mobility in solid electrolytes decreases significantly at sub-zero temperatures, severely limiting battery capacity and power capability.

The thermal runaway risk, though generally lower than in conventional batteries, still exists in SSSBs. Certain solid electrolytes may undergo phase transitions or decomposition at elevated temperatures, potentially releasing heat and triggering cascading thermal events. Additionally, sodium metal, if used as an anode material, remains highly reactive and can pose safety risks under thermal stress conditions.

Scale-up manufacturing introduces additional thermal management complexities. Achieving uniform temperature distribution across larger-format cells presents significant engineering challenges. The sintering processes often required for solid electrolyte fabrication involve high-temperature treatments that must be precisely controlled to ensure optimal microstructure and performance.

Fast charging capabilities, increasingly demanded by consumers, generate substantial heat that must be efficiently managed. The limited thermal conductivity of solid electrolytes makes rapid heat dissipation particularly challenging during high-rate charging scenarios. This limitation could potentially restrict the practical charging speeds achievable with SSSBs in commercial applications.

Developing effective cooling systems specifically tailored for SSSBs remains an active research area. Traditional cooling approaches used for lithium-ion batteries may not be directly applicable due to the different thermal properties and cell architectures of solid-state sodium systems. Innovative thermal management solutions that address these unique challenges will be crucial for realizing the full potential of solid-state sodium battery technology.

Current Thermal Management Solutions for Solid-State Sodium Batteries

01 Thermal management systems for solid-state sodium batteries

Specialized thermal management systems are designed for solid-state sodium batteries to maintain optimal operating temperatures and prevent thermal runaway. These systems include cooling channels, heat exchangers, and thermal interface materials that efficiently dissipate heat generated during charging and discharging cycles. Advanced thermal management solutions help extend battery life, improve safety, and maintain consistent performance across various operating conditions.- Thermal management systems for solid-state sodium batteries: Specialized thermal management systems are designed to maintain optimal operating temperatures for solid-state sodium batteries. These systems help prevent thermal runaway and ensure efficient battery performance by regulating heat distribution. Various cooling mechanisms, including liquid cooling circuits and heat sinks, are employed to dissipate excess heat generated during charging and discharging cycles, thereby extending battery life and maintaining safety.

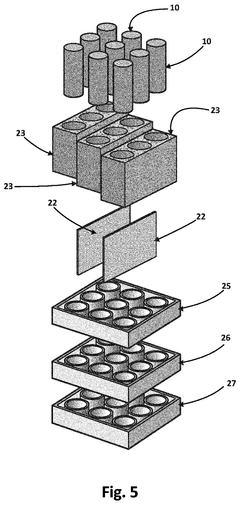

- Battery cell design with integrated thermal management features: Advanced cell designs incorporate thermal management features directly into the battery structure. These designs include thermally conductive layers between cells, strategic placement of thermal interface materials, and optimized electrode configurations that minimize heat generation. The integration of thermal management within the cell architecture allows for more efficient heat dissipation and temperature uniformity across the battery pack, which is crucial for solid-state sodium batteries that are sensitive to temperature gradients.

- Phase change materials for thermal regulation: Phase change materials (PCMs) are incorporated into solid-state sodium battery systems to absorb and release thermal energy during phase transitions. These materials help maintain consistent battery temperatures by absorbing excess heat during operation and releasing it when the battery cools down. The strategic placement of PCMs around battery cells creates a passive thermal management system that reduces the need for active cooling, making the battery system more energy-efficient and reliable under varying operating conditions.

- Battery management systems with thermal monitoring: Advanced battery management systems (BMS) incorporate sophisticated thermal monitoring capabilities specifically designed for solid-state sodium batteries. These systems use temperature sensors strategically placed throughout the battery pack to continuously monitor thermal conditions. The BMS algorithms analyze temperature data in real-time to optimize charging/discharging rates, activate cooling systems when necessary, and implement protective measures to prevent thermal issues. This intelligent thermal management approach extends battery lifespan and enhances safety performance.

- Thermal insulation and heat distribution techniques: Specialized thermal insulation materials and heat distribution techniques are employed to manage temperature in solid-state sodium batteries. These include ceramic thermal barriers, aerogel insulation layers, and thermally conductive pathways that direct heat away from sensitive components. The strategic combination of insulation and heat distribution creates thermal zones within the battery pack, protecting temperature-sensitive components while efficiently removing excess heat from high-temperature areas, resulting in more stable and efficient battery operation.

02 Battery pack design with integrated cooling

Innovative battery pack designs incorporate integrated cooling systems specifically tailored for solid-state sodium batteries. These designs feature optimized cell spacing, cooling plates between cells, and strategic thermal pathways that allow for uniform temperature distribution. The integration of cooling elements directly into the battery pack structure enables more efficient heat management while minimizing the overall size and weight of the battery system.Expand Specific Solutions03 Phase change materials for temperature regulation

Phase change materials (PCMs) are utilized in solid-state sodium battery systems to absorb excess heat during operation and release it when temperatures drop. These materials undergo phase transitions at specific temperatures, providing passive thermal regulation without requiring additional energy input. PCMs can be incorporated into battery casings, between cells, or in dedicated thermal management layers to maintain optimal operating temperatures and prevent thermal extremes.Expand Specific Solutions04 Electronic control systems for thermal management

Advanced electronic control systems monitor and regulate the temperature of solid-state sodium batteries in real-time. These systems utilize temperature sensors, predictive algorithms, and adaptive control strategies to optimize thermal management based on operating conditions. The electronic controls can adjust cooling intensity, activate heating elements during cold starts, and implement protective measures during extreme temperature events to ensure safe and efficient battery operation.Expand Specific Solutions05 Thermal interface materials and insulation strategies

Specialized thermal interface materials and insulation strategies are developed for solid-state sodium batteries to control heat flow within the battery system. High-conductivity materials direct heat away from sensitive components, while strategic insulation prevents thermal propagation between cells during failure events. These materials and designs balance the need for effective heat dissipation during normal operation with thermal isolation capabilities during abnormal conditions, enhancing both performance and safety.Expand Specific Solutions

Leading Companies and Research Institutions in Sodium Battery Development

The solid-state sodium battery thermal management market is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market is projected to expand significantly as sodium batteries emerge as a cost-effective alternative to lithium-ion technologies. Leading players represent diverse technological approaches: established energy companies (NGK Insulators, SK Innovation, LG Chem, LG Energy Solution) focus on commercialization pathways; research institutions (Lawrence Livermore, Shanghai Institute of Ceramics) drive fundamental innovations; while automotive manufacturers (Renault, Boeing) explore integration opportunities. Technical challenges in thermal stability and conductivity remain, with companies like A123 Systems and Ceramatec developing specialized solutions for heat dissipation and safety systems that will be critical for widespread adoption.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a specialized thermal management system for their solid-state sodium batteries that leverages their expertise in ceramic technologies. Their approach utilizes a proprietary beta-alumina solid electrolyte (BASE) with optimized thermal conductivity properties (approximately 3-4 W/m·K) that helps distribute heat evenly throughout the battery cell. NGK's thermal management solution incorporates a honeycomb-structured ceramic heat exchanger that surrounds the sodium battery cells, providing efficient heat dissipation while maintaining mechanical integrity. The company has engineered specialized thermal interface materials that accommodate the thermal expansion differences between ceramic electrolytes and metallic components during temperature fluctuations. Their system features passive thermal regulation through strategically placed phase change materials that absorb excess heat during rapid charging and high-power discharge events, maintaining optimal operating temperatures between 60-90°C where sodium-ion conductivity is maximized.

Strengths: Exceptional thermal stability at high temperatures; leverages NGK's extensive ceramic manufacturing expertise; highly durable with minimal degradation over thousands of cycles. Weaknesses: Higher manufacturing complexity due to specialized ceramic components; thermal management system adds weight to the overall battery pack; optimal performance requires maintaining elevated operating temperatures.

Ceramatec, Inc.

Technical Solution: Ceramatec has developed an innovative thermal management system for solid-state sodium batteries that addresses the unique thermal challenges of sodium-beta alumina electrolytes. Their approach utilizes a proprietary ceramic composite structure with engineered thermal conductivity gradients that direct heat flow away from critical battery components. The system incorporates specialized thermal interface materials with thermal conductivity exceeding 6 W/m·K that maintain consistent contact between solid electrolyte components despite thermal cycling. Ceramatec's thermal management solution features microchannel cooling structures integrated directly into the battery housing, providing efficient heat removal while minimizing system complexity. Their technology employs advanced thermal modeling to identify potential hotspots during operation, with targeted cooling solutions applied to these critical areas. The company has also developed specialized edge insulation techniques that prevent thermal gradients from forming at the periphery of battery cells, ensuring uniform temperature distribution throughout the entire battery pack.

Strengths: Exceptional thermal stability across wide operating temperature ranges; highly integrated design that minimizes system complexity; leverages Ceramatec's extensive expertise in ceramic engineering. Weaknesses: Manufacturing process requires specialized equipment and expertise; thermal management components add cost to the overall battery system; optimal performance dependent on precise thermal interface material application.

Key Patents and Research Breakthroughs in Thermal Management

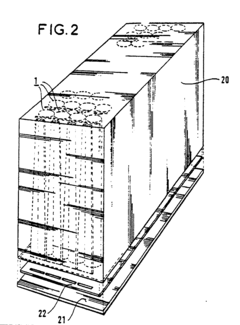

Battery of sodium-sulphur accumulators for spatial applications

PatentInactiveEP0237828A3

Innovation

- A thermal regulation device comprising a heat-insulated enclosure with thermally conductive plates and a common radiator, along with heating resistors powered by an external source, maintains the battery temperature between 290°C and 380°C, utilizing super-insulating materials and electrical insulation to prevent excessive cooling.

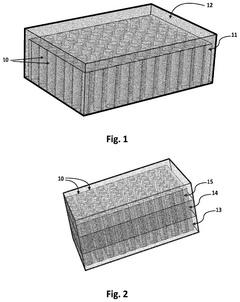

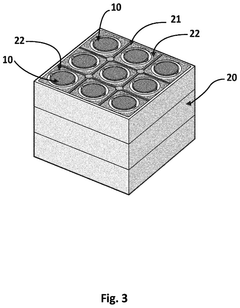

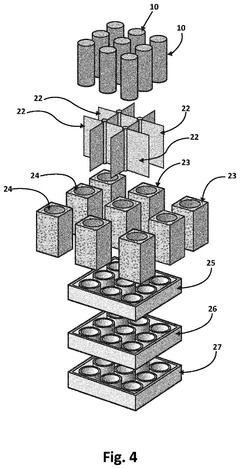

Batteries provided with a thermal management system comprising phase-change materials

PatentPendingUS20250316794A1

Innovation

- A battery thermal management system utilizing stratified heat storage units with encapsulated solid-liquid or solid-solid PCMs, coupled with a microfluidic thermal control circuit, ensures temperature uniformity by independent heat transfer circuits and smart regeneration, addressing thermal gradients and potential runaway.

Safety Standards and Regulatory Framework for Sodium Batteries

The regulatory landscape for sodium batteries is evolving rapidly as this technology advances toward commercial viability. Currently, most safety standards for batteries have been developed primarily for lithium-ion technologies, creating a regulatory gap for sodium-based alternatives. Organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) are working to establish specific standards for sodium batteries, with particular attention to their unique thermal management requirements.

The IEC Technical Committee 21 has initiated the development of standards specifically addressing sodium battery safety, focusing on thermal runaway prevention and management. These emerging standards emphasize the importance of robust thermal management systems that can effectively handle the higher operating temperatures characteristic of sodium batteries, which typically function optimally between 270-350°C.

Regulatory frameworks in major markets are also adapting to accommodate this technology. The European Union, through its Battery Directive and REACH regulations, is developing specific provisions for sodium batteries, with emphasis on thermal safety requirements. Similarly, the United States Department of Energy has funded research initiatives focused on establishing safety protocols for solid-state sodium batteries, particularly addressing thermal management challenges.

In Asia, where sodium battery development is advancing rapidly, countries like Japan and South Korea have established specialized regulatory working groups to develop safety certification processes. China's GB/T standards are being updated to include specific requirements for sodium battery thermal management systems, reflecting the country's significant investments in this technology.

Transportation regulations present another critical regulatory dimension. The UN Manual of Tests and Criteria, which governs the international transport of dangerous goods, is being updated to include specific provisions for sodium batteries. These regulations focus heavily on thermal stability during transport, requiring manufacturers to demonstrate effective thermal management under various environmental conditions.

Insurance standards are also evolving, with major underwriters developing specific risk assessment frameworks for facilities utilizing sodium battery technologies. These frameworks place particular emphasis on thermal management systems, fire suppression capabilities, and emergency response protocols.

For manufacturers developing solid-state sodium batteries with innovative thermal management systems, navigating this evolving regulatory landscape requires proactive engagement with standards organizations and regulatory bodies. Early adoption of emerging best practices in thermal management can facilitate faster regulatory approval and market acceptance, while contributing to the development of appropriate safety standards for this promising technology.

The IEC Technical Committee 21 has initiated the development of standards specifically addressing sodium battery safety, focusing on thermal runaway prevention and management. These emerging standards emphasize the importance of robust thermal management systems that can effectively handle the higher operating temperatures characteristic of sodium batteries, which typically function optimally between 270-350°C.

Regulatory frameworks in major markets are also adapting to accommodate this technology. The European Union, through its Battery Directive and REACH regulations, is developing specific provisions for sodium batteries, with emphasis on thermal safety requirements. Similarly, the United States Department of Energy has funded research initiatives focused on establishing safety protocols for solid-state sodium batteries, particularly addressing thermal management challenges.

In Asia, where sodium battery development is advancing rapidly, countries like Japan and South Korea have established specialized regulatory working groups to develop safety certification processes. China's GB/T standards are being updated to include specific requirements for sodium battery thermal management systems, reflecting the country's significant investments in this technology.

Transportation regulations present another critical regulatory dimension. The UN Manual of Tests and Criteria, which governs the international transport of dangerous goods, is being updated to include specific provisions for sodium batteries. These regulations focus heavily on thermal stability during transport, requiring manufacturers to demonstrate effective thermal management under various environmental conditions.

Insurance standards are also evolving, with major underwriters developing specific risk assessment frameworks for facilities utilizing sodium battery technologies. These frameworks place particular emphasis on thermal management systems, fire suppression capabilities, and emergency response protocols.

For manufacturers developing solid-state sodium batteries with innovative thermal management systems, navigating this evolving regulatory landscape requires proactive engagement with standards organizations and regulatory bodies. Early adoption of emerging best practices in thermal management can facilitate faster regulatory approval and market acceptance, while contributing to the development of appropriate safety standards for this promising technology.

Environmental Impact and Sustainability Considerations

The development of solid-state sodium batteries with innovative thermal management systems presents significant environmental and sustainability advantages over conventional lithium-ion technologies. These batteries utilize sodium, which is approximately 1,000 times more abundant in the Earth's crust than lithium, substantially reducing resource depletion concerns. The extraction of sodium from seawater or salt deposits requires considerably less energy and water compared to lithium mining, which often involves extensive water consumption in drought-prone regions and can lead to soil contamination and ecosystem disruption.

From a lifecycle perspective, solid-state sodium batteries demonstrate promising environmental credentials. The elimination of flammable liquid electrolytes not only enhances safety but also reduces the environmental hazards associated with potential leakage or disposal. The thermal management innovations in these batteries further contribute to sustainability by extending battery lifespan through more efficient heat distribution and reduced thermal degradation, thereby decreasing the frequency of replacement and associated waste generation.

Manufacturing processes for solid-state sodium batteries generally involve lower energy consumption and fewer toxic materials compared to conventional lithium-ion batteries. The absence of cobalt—a material often mined under questionable ethical and environmental conditions—represents a significant sustainability advantage. Additionally, the thermal management systems being developed utilize more environmentally benign materials, moving away from rare earth elements that pose extraction challenges and geopolitical supply risks.

End-of-life considerations also favor solid-state sodium batteries with advanced thermal management. These batteries show greater potential for recycling and material recovery due to their simpler and more uniform composition. The thermal stability provided by innovative management systems reduces the risk of hazardous reactions during the recycling process, making material separation and recovery more efficient and economically viable.

Carbon footprint analyses indicate that the production and operation of solid-state sodium batteries with optimized thermal management could result in 30-40% lower greenhouse gas emissions compared to conventional lithium-ion technologies. This reduction stems from both the manufacturing efficiencies and the extended operational lifespan enabled by superior thermal regulation, which distributes the embodied carbon over a longer service period.

Policy frameworks worldwide are increasingly recognizing these environmental benefits, with several countries implementing incentives for research and development in sodium battery technologies. The European Union's Battery Directive revision specifically highlights the importance of transitioning to more sustainable battery chemistries and thermal management approaches, positioning solid-state sodium batteries as a key technology for achieving circular economy objectives in the energy storage sector.

From a lifecycle perspective, solid-state sodium batteries demonstrate promising environmental credentials. The elimination of flammable liquid electrolytes not only enhances safety but also reduces the environmental hazards associated with potential leakage or disposal. The thermal management innovations in these batteries further contribute to sustainability by extending battery lifespan through more efficient heat distribution and reduced thermal degradation, thereby decreasing the frequency of replacement and associated waste generation.

Manufacturing processes for solid-state sodium batteries generally involve lower energy consumption and fewer toxic materials compared to conventional lithium-ion batteries. The absence of cobalt—a material often mined under questionable ethical and environmental conditions—represents a significant sustainability advantage. Additionally, the thermal management systems being developed utilize more environmentally benign materials, moving away from rare earth elements that pose extraction challenges and geopolitical supply risks.

End-of-life considerations also favor solid-state sodium batteries with advanced thermal management. These batteries show greater potential for recycling and material recovery due to their simpler and more uniform composition. The thermal stability provided by innovative management systems reduces the risk of hazardous reactions during the recycling process, making material separation and recovery more efficient and economically viable.

Carbon footprint analyses indicate that the production and operation of solid-state sodium batteries with optimized thermal management could result in 30-40% lower greenhouse gas emissions compared to conventional lithium-ion technologies. This reduction stems from both the manufacturing efficiencies and the extended operational lifespan enabled by superior thermal regulation, which distributes the embodied carbon over a longer service period.

Policy frameworks worldwide are increasingly recognizing these environmental benefits, with several countries implementing incentives for research and development in sodium battery technologies. The European Union's Battery Directive revision specifically highlights the importance of transitioning to more sustainable battery chemistries and thermal management approaches, positioning solid-state sodium batteries as a key technology for achieving circular economy objectives in the energy storage sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!