Enhance Thermopile Calibration Techniques for Precision

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Calibration Background and Objectives

Thermopile sensors have evolved significantly since their inception in the early 20th century, transitioning from rudimentary thermal detection devices to sophisticated temperature measurement instruments. The development trajectory has been characterized by continuous improvements in sensitivity, accuracy, and response time, driven by advancements in materials science and manufacturing techniques. Recent years have witnessed an accelerated pace of innovation, particularly in miniaturization and integration capabilities, enabling thermopiles to be incorporated into increasingly compact and complex systems.

The current technological landscape presents both opportunities and challenges for thermopile calibration. While these sensors offer non-contact temperature measurement with relatively low cost and power consumption, their accuracy is heavily dependent on precise calibration procedures. Traditional calibration methods often fail to account for environmental variables and material aging effects, resulting in measurement drift and reduced reliability in field applications.

The primary objective of enhancing thermopile calibration techniques is to achieve unprecedented levels of measurement precision across varying environmental conditions. This involves developing robust calibration protocols that can compensate for ambient temperature fluctuations, humidity variations, and aging-related performance degradation. Additionally, there is a pressing need to reduce calibration time while maintaining or improving accuracy, thereby addressing industry demands for more efficient manufacturing processes.

Another critical goal is the standardization of calibration methodologies across different thermopile sensor types and applications. Current practices vary significantly between manufacturers and industries, creating inconsistencies in performance metrics and complicating cross-platform integration. Establishing universal calibration standards would facilitate broader adoption of thermopile technology in emerging fields such as autonomous vehicles, advanced medical diagnostics, and smart building systems.

From a technical perspective, the enhancement of thermopile calibration techniques aims to push the boundaries of measurement resolution beyond current limitations. This includes developing compensation algorithms for non-linear response characteristics and exploring novel reference temperature sources with improved stability. The ultimate target is to achieve sub-millikelvin resolution with long-term stability, enabling applications in scientific research and high-precision industrial processes that were previously inaccessible to thermopile technology.

Looking forward, the evolution of thermopile calibration techniques is expected to incorporate artificial intelligence and machine learning approaches, allowing for adaptive calibration that continuously optimizes sensor performance based on operational data. This represents a paradigm shift from static, factory-based calibration to dynamic, in-situ adjustment mechanisms that can maintain precision throughout the sensor's lifecycle.

The current technological landscape presents both opportunities and challenges for thermopile calibration. While these sensors offer non-contact temperature measurement with relatively low cost and power consumption, their accuracy is heavily dependent on precise calibration procedures. Traditional calibration methods often fail to account for environmental variables and material aging effects, resulting in measurement drift and reduced reliability in field applications.

The primary objective of enhancing thermopile calibration techniques is to achieve unprecedented levels of measurement precision across varying environmental conditions. This involves developing robust calibration protocols that can compensate for ambient temperature fluctuations, humidity variations, and aging-related performance degradation. Additionally, there is a pressing need to reduce calibration time while maintaining or improving accuracy, thereby addressing industry demands for more efficient manufacturing processes.

Another critical goal is the standardization of calibration methodologies across different thermopile sensor types and applications. Current practices vary significantly between manufacturers and industries, creating inconsistencies in performance metrics and complicating cross-platform integration. Establishing universal calibration standards would facilitate broader adoption of thermopile technology in emerging fields such as autonomous vehicles, advanced medical diagnostics, and smart building systems.

From a technical perspective, the enhancement of thermopile calibration techniques aims to push the boundaries of measurement resolution beyond current limitations. This includes developing compensation algorithms for non-linear response characteristics and exploring novel reference temperature sources with improved stability. The ultimate target is to achieve sub-millikelvin resolution with long-term stability, enabling applications in scientific research and high-precision industrial processes that were previously inaccessible to thermopile technology.

Looking forward, the evolution of thermopile calibration techniques is expected to incorporate artificial intelligence and machine learning approaches, allowing for adaptive calibration that continuously optimizes sensor performance based on operational data. This represents a paradigm shift from static, factory-based calibration to dynamic, in-situ adjustment mechanisms that can maintain precision throughout the sensor's lifecycle.

Market Demand for High-Precision Temperature Sensing

The global market for high-precision temperature sensing technologies has experienced significant growth in recent years, driven primarily by increasing demands across multiple industries for more accurate, reliable, and consistent temperature measurements. The thermopile sensor market specifically is projected to reach $2.3 billion by 2027, growing at a CAGR of 8.2% from 2022, with calibration technologies representing a critical segment of this expanding market.

Healthcare and medical diagnostics constitute one of the largest demand sectors, where non-contact infrared thermometers utilizing thermopile sensors have become essential tools for patient monitoring. The COVID-19 pandemic dramatically accelerated this trend, creating unprecedented demand for devices capable of rapid, accurate temperature screening. Post-pandemic, the market has stabilized but remains significantly larger than pre-2020 levels, with continued emphasis on precision calibration to ensure measurement accuracy.

Industrial process control represents another substantial market segment, where even minor temperature measurement inaccuracies can result in significant quality issues and operational inefficiencies. Manufacturing facilities, particularly in semiconductor production, pharmaceuticals, and food processing, require temperature sensing with precision levels of ±0.1°C or better. This demand has intensified with the implementation of Industry 4.0 initiatives, where integrated sensor networks require consistent calibration across multiple measurement points.

The automotive industry has emerged as a rapidly growing market for high-precision thermopile sensors, particularly with the expansion of electric vehicles. Battery thermal management systems require exceptionally accurate temperature monitoring to optimize performance and prevent thermal runaway conditions. Market analysis indicates that automotive applications for precision-calibrated thermopile sensors will grow at 12.4% annually through 2028.

Consumer electronics manufacturers have also increased their requirements for precision temperature sensing, incorporating thermopile arrays in smartphones, wearables, and smart home devices. These applications demand miniaturized sensors with factory calibration that maintains accuracy throughout the product lifecycle, creating new challenges for calibration technology developers.

Aerospace and defense applications represent a premium segment of the market, where extreme operating conditions necessitate sophisticated calibration techniques that can compensate for environmental variables while maintaining measurement integrity. Though smaller in volume than consumer applications, this sector drives significant innovation in calibration methodologies due to its stringent requirements.

Market research indicates that end-users increasingly prioritize sensors with self-calibration capabilities, reduced drift characteristics, and compatibility with digital calibration systems. This trend is pushing manufacturers to develop more sophisticated calibration techniques that can be implemented both during production and throughout the operational lifecycle of thermopile-based devices.

Healthcare and medical diagnostics constitute one of the largest demand sectors, where non-contact infrared thermometers utilizing thermopile sensors have become essential tools for patient monitoring. The COVID-19 pandemic dramatically accelerated this trend, creating unprecedented demand for devices capable of rapid, accurate temperature screening. Post-pandemic, the market has stabilized but remains significantly larger than pre-2020 levels, with continued emphasis on precision calibration to ensure measurement accuracy.

Industrial process control represents another substantial market segment, where even minor temperature measurement inaccuracies can result in significant quality issues and operational inefficiencies. Manufacturing facilities, particularly in semiconductor production, pharmaceuticals, and food processing, require temperature sensing with precision levels of ±0.1°C or better. This demand has intensified with the implementation of Industry 4.0 initiatives, where integrated sensor networks require consistent calibration across multiple measurement points.

The automotive industry has emerged as a rapidly growing market for high-precision thermopile sensors, particularly with the expansion of electric vehicles. Battery thermal management systems require exceptionally accurate temperature monitoring to optimize performance and prevent thermal runaway conditions. Market analysis indicates that automotive applications for precision-calibrated thermopile sensors will grow at 12.4% annually through 2028.

Consumer electronics manufacturers have also increased their requirements for precision temperature sensing, incorporating thermopile arrays in smartphones, wearables, and smart home devices. These applications demand miniaturized sensors with factory calibration that maintains accuracy throughout the product lifecycle, creating new challenges for calibration technology developers.

Aerospace and defense applications represent a premium segment of the market, where extreme operating conditions necessitate sophisticated calibration techniques that can compensate for environmental variables while maintaining measurement integrity. Though smaller in volume than consumer applications, this sector drives significant innovation in calibration methodologies due to its stringent requirements.

Market research indicates that end-users increasingly prioritize sensors with self-calibration capabilities, reduced drift characteristics, and compatibility with digital calibration systems. This trend is pushing manufacturers to develop more sophisticated calibration techniques that can be implemented both during production and throughout the operational lifecycle of thermopile-based devices.

Current Thermopile Calibration Challenges

Despite significant advancements in thermopile technology, calibration remains a persistent challenge that limits the precision and reliability of these temperature measurement devices. Current calibration methodologies face several critical obstacles that impede the achievement of optimal performance in high-precision applications. The fundamental issue lies in the inherent non-linearity of thermopile response across wide temperature ranges, which traditional calibration approaches struggle to address adequately.

Environmental factors present substantial challenges during the calibration process. Ambient temperature fluctuations, air currents, and humidity variations can introduce significant measurement errors that are difficult to isolate and compensate for. These environmental dependencies create inconsistencies in calibration results, particularly when calibration environments differ from operational conditions.

Reference standard traceability poses another significant challenge. The accuracy of thermopile calibration is fundamentally limited by the accuracy of the reference standards used. Current practices often rely on secondary or tertiary standards that introduce cumulative uncertainties into the calibration chain, compromising the ultimate precision achievable.

Temporal stability issues further complicate calibration efforts. Thermopiles exhibit drift characteristics over time due to material aging, thermal cycling, and environmental exposure. Current calibration methodologies inadequately account for these long-term stability factors, necessitating frequent recalibration and reducing confidence in measurements between calibration intervals.

The thermal response time of thermopiles presents additional calibration difficulties. Different models and designs exhibit varying thermal time constants, which must be properly characterized during calibration. Current techniques often apply static calibration points that fail to capture the dynamic response characteristics critical for transient temperature measurement applications.

Interoperability between different calibration facilities remains problematic. The lack of standardized calibration protocols leads to inconsistent results when the same thermopile is calibrated at different facilities. This variability undermines confidence in measurement accuracy and complicates cross-comparison of data from different sources.

Manufacturing variations between individual thermopile sensors necessitate individual calibration, which is time-consuming and costly. Current batch calibration approaches fail to address unit-to-unit variations adequately, resulting in compromised accuracy for individual sensors.

Finally, the calibration of thermopiles for extreme temperature ranges presents unique challenges. At very high or low temperatures, reference standards become less reliable, and the behavior of the thermopile materials themselves may change in ways that are difficult to model and compensate for in calibration algorithms.

Environmental factors present substantial challenges during the calibration process. Ambient temperature fluctuations, air currents, and humidity variations can introduce significant measurement errors that are difficult to isolate and compensate for. These environmental dependencies create inconsistencies in calibration results, particularly when calibration environments differ from operational conditions.

Reference standard traceability poses another significant challenge. The accuracy of thermopile calibration is fundamentally limited by the accuracy of the reference standards used. Current practices often rely on secondary or tertiary standards that introduce cumulative uncertainties into the calibration chain, compromising the ultimate precision achievable.

Temporal stability issues further complicate calibration efforts. Thermopiles exhibit drift characteristics over time due to material aging, thermal cycling, and environmental exposure. Current calibration methodologies inadequately account for these long-term stability factors, necessitating frequent recalibration and reducing confidence in measurements between calibration intervals.

The thermal response time of thermopiles presents additional calibration difficulties. Different models and designs exhibit varying thermal time constants, which must be properly characterized during calibration. Current techniques often apply static calibration points that fail to capture the dynamic response characteristics critical for transient temperature measurement applications.

Interoperability between different calibration facilities remains problematic. The lack of standardized calibration protocols leads to inconsistent results when the same thermopile is calibrated at different facilities. This variability undermines confidence in measurement accuracy and complicates cross-comparison of data from different sources.

Manufacturing variations between individual thermopile sensors necessitate individual calibration, which is time-consuming and costly. Current batch calibration approaches fail to address unit-to-unit variations adequately, resulting in compromised accuracy for individual sensors.

Finally, the calibration of thermopiles for extreme temperature ranges presents unique challenges. At very high or low temperatures, reference standards become less reliable, and the behavior of the thermopile materials themselves may change in ways that are difficult to model and compensate for in calibration algorithms.

State-of-the-Art Calibration Techniques

01 Reference-based calibration methods

Calibration of thermopiles can be achieved by comparing their output against reference standards or known temperature sources. This approach involves using precision reference temperature sensors or blackbody radiation sources to establish accurate calibration points. The method typically requires controlled environmental conditions and may involve multiple calibration points across the thermopile's operating range to ensure accuracy across different temperature scenarios.- Reference-based calibration methods: Calibration of thermopiles can be achieved by comparing their output against reference standards or known temperature sources. This approach involves using precision reference temperature sensors or blackbody radiation sources to establish accurate calibration points. The method typically requires controlled environmental conditions and may involve multiple calibration points across the thermopile's operating range to ensure linearity and accuracy across different temperature measurements.

- Temperature compensation techniques: Temperature compensation techniques are essential for improving thermopile measurement precision by accounting for ambient temperature variations that can affect sensor output. These methods involve using additional temperature sensors to monitor the thermopile's own temperature and applying correction algorithms to compensate for thermal drift. Advanced compensation techniques may include real-time adjustment factors based on environmental conditions, ensuring consistent measurement accuracy across varying operating environments.

- Digital signal processing for calibration: Digital signal processing techniques enhance thermopile calibration precision by applying sophisticated algorithms to raw sensor data. These methods include digital filtering to reduce noise, signal averaging to improve stability, and mathematical correction models that account for non-linearities in sensor response. Advanced processing may incorporate machine learning algorithms that adapt calibration parameters based on historical performance data, resulting in significantly improved measurement accuracy and reliability.

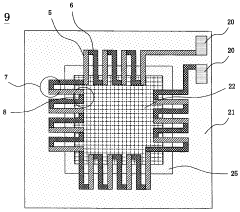

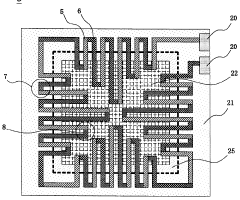

- Multi-point calibration systems: Multi-point calibration systems improve thermopile precision by characterizing sensor response across multiple temperature points rather than simple offset corrections. This approach creates comprehensive calibration curves that account for non-linear behavior across the full measurement range. Implementation typically involves automated testing equipment that exposes the thermopile to precisely controlled temperature conditions at multiple setpoints, generating calibration coefficients that are stored in device memory for real-time correction during operation.

- In-situ calibration and self-calibration methods: In-situ and self-calibration methods allow thermopiles to maintain precision without removing them from their operating environment. These techniques incorporate built-in reference elements or periodic automated calibration routines that can be triggered during system operation. Self-calibrating thermopiles may include internal reference temperature sources or utilize known physical constants as calibration references. This approach is particularly valuable for applications where sensor removal for laboratory calibration is impractical or where measurement conditions change frequently.

02 Temperature compensation techniques

Temperature compensation techniques are essential for improving thermopile measurement precision by accounting for ambient temperature variations that can affect sensor output. These methods involve using additional temperature sensors to monitor ambient conditions and applying correction algorithms to adjust thermopile readings accordingly. Advanced compensation techniques may include real-time adjustment factors based on characterized sensor behavior across temperature ranges, significantly enhancing measurement accuracy in varying environmental conditions.Expand Specific Solutions03 Digital signal processing for calibration

Digital signal processing techniques enhance thermopile calibration precision by applying sophisticated algorithms to raw sensor data. These methods include digital filtering to reduce noise, signal averaging to improve stability, and mathematical correction models that account for non-linearities in sensor response. Advanced processing may incorporate machine learning algorithms that adapt to sensor characteristics over time, maintaining calibration accuracy throughout the thermopile's operational lifetime.Expand Specific Solutions04 In-situ and automated calibration systems

In-situ calibration systems allow thermopiles to be calibrated within their operational environment, eliminating errors that might occur when transferring calibration from laboratory to field conditions. These systems often incorporate automated procedures that periodically verify and adjust calibration parameters without human intervention. Such approaches may use built-in reference sources or environmental monitoring to maintain calibration accuracy over extended periods, particularly important for thermopiles deployed in remote or inaccessible locations.Expand Specific Solutions05 Multi-point and dynamic calibration techniques

Multi-point calibration techniques improve thermopile precision by characterizing sensor response across multiple temperature points rather than simple offset and gain corrections. This approach creates comprehensive calibration curves that account for non-linear behavior in different operating regions. Dynamic calibration extends this concept by continuously adjusting calibration parameters based on operating conditions, sensor aging, and other factors that might affect measurement accuracy over time. These advanced methods are particularly valuable for applications requiring extremely high precision or operating in challenging environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Thermopile calibration technology is currently in a growth phase, with the global market expected to reach significant expansion due to increasing demand for precision temperature measurement across industries. The competitive landscape features established players like Texas Instruments and Robert Bosch GmbH leading commercial applications, while research institutions such as Korea Research Institute of Standards & Science and Advanced Industrial Science & Technology drive innovation in calibration methodologies. Companies like Applied Materials and Intel are advancing semiconductor-based thermopile solutions, while specialized firms like Welch Allyn focus on medical applications. The technology shows varying maturity levels across sectors, with industrial applications being more developed than emerging fields like IoT temperature sensing, where companies including Sony Semiconductor Solutions are making significant investments to enhance precision and reliability.

Korea Research Institute of Standards & Science

Technical Solution: The Korea Research Institute of Standards & Science (KRISS) has developed a metrologically-sound thermopile calibration technique that establishes traceability to international temperature standards. Their approach utilizes primary fixed-point blackbody calibrators that realize the defining fixed points of the International Temperature Scale of 1990 (ITS-90). KRISS's calibration system incorporates a high-stability vacuum chamber with temperature control stability better than ±0.01°C and a precision aperture mechanism that enables accurate solid angle calculations. Their methodology includes a comprehensive uncertainty analysis that accounts for all contributing factors including blackbody emissivity variations, size-of-source effects, and detector non-linearity. The institute has pioneered a novel spectral response characterization technique that allows for more accurate correction of wavelength-dependent sensitivity variations in thermopile sensors. Their calibration procedure includes a rigorous validation process using multiple independent reference standards to ensure measurement consistency. This approach enables calibration uncertainties as low as 0.1% (k=2) for industrial thermopile sensors, providing a national measurement standard that supports various industries requiring high-precision temperature measurements.

Strengths: Unparalleled measurement traceability to international standards; comprehensive uncertainty quantification enhances reliability; scientifically rigorous methodology ensures defensible results. Weaknesses: Extremely specialized equipment requirements limit widespread implementation; time-intensive calibration procedures reduce throughput; primarily focused on laboratory standards rather than field applications.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed a sophisticated thermopile calibration system specifically designed for semiconductor manufacturing environments where temperature precision is critical. Their approach utilizes a reference cavity blackbody calibration method combined with advanced statistical process control techniques. The system features a temperature-controlled calibration chamber that can simulate precise thermal conditions from 20°C to 1200°C with stability better than ±0.05°C. Applied Materials' solution incorporates a multi-wavelength compensation algorithm that accounts for emissivity variations across different materials and surface conditions. Their calibration process includes an innovative drift prediction model that analyzes historical sensor performance data to anticipate and correct for long-term stability issues before they impact measurement accuracy. The system also employs real-time verification against redundant temperature sensing technologies (RTDs and thermocouples) to ensure continuous calibration integrity. This comprehensive approach enables their thermopile sensors to achieve measurement uncertainties below 0.3% across the full temperature range, critical for advanced semiconductor processes where thermal management directly impacts yield and device performance.

Strengths: Exceptional stability in harsh industrial environments; comprehensive drift compensation ensures long-term measurement reliability; seamless integration with factory automation systems. Weaknesses: Significant infrastructure requirements for implementation; higher initial cost compared to conventional solutions; requires specialized technical expertise for maintenance and optimization.

Critical Patents and Technical Innovations

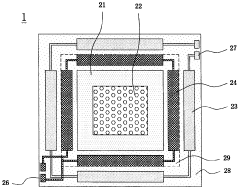

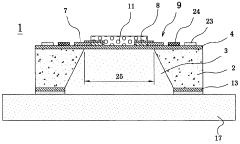

Infrared temperature sensor calibration system and method

PatentInactiveEP2820395A1

Innovation

- A system and method utilizing a passive target object with uniform temperature and emissivity matching real-world conditions, combined with a standard infrared sensor and calibration unit, to compare measurements and automatically calibrate test sensors, ensuring accuracy and reducing costs.

Thermopile sensor and temperature measuring method by infrared rays

PatentWO2001050102A1

Innovation

- Incorporating a resistor with a self-regulating positive temperature coefficient characteristic in the thermopile sensor, which maintains the cold junction at a constant bias temperature, synchronizing the thermal response speed with the thermopile output, and using a semiconductor heating element and thermistor for precise temperature measurement.

Environmental Factors Affecting Calibration Accuracy

Environmental factors play a critical role in thermopile calibration accuracy, often introducing significant measurement uncertainties when not properly controlled. Temperature fluctuations in the calibration environment represent the most prominent challenge, as even minor ambient temperature variations can induce thermal gradients across the thermopile sensor assembly. These gradients create differential thermal expansion of components and alter the reference junction temperature, directly impacting measurement accuracy. Research indicates that a 1°C ambient temperature change can introduce errors exceeding 0.5% in uncorrected thermopile readings.

Humidity levels similarly affect calibration precision through multiple mechanisms. High humidity environments (>70% RH) can cause condensation on sensor surfaces, altering thermal conductivity pathways and creating parasitic thermal junctions. Additionally, moisture absorption by insulating materials changes their thermal characteristics over time. Studies by the National Metrology Institute demonstrated that uncontrolled humidity variations can contribute up to 0.3% measurement uncertainty in precision thermopile applications.

Air currents and ventilation patterns within calibration facilities create non-uniform cooling effects across sensor surfaces. Even subtle air movements of 0.2 m/s can generate localized cooling that disrupts the thermal equilibrium necessary for precise calibration. This effect becomes particularly problematic when calibrating low-output thermopiles where signal-to-noise ratios are already challenging.

Electromagnetic interference (EMI) represents another significant environmental factor affecting thermopile calibration. Modern laboratory environments contain numerous EMI sources that can couple into thermopile circuits, particularly during the amplification stage. Frequencies between 50Hz-400kHz have been identified as especially problematic, with induced errors proportional to thermopile lead length and circuit impedance.

Barometric pressure variations, while often overlooked, affect convective heat transfer coefficients around the thermopile assembly. This becomes particularly relevant when calibrating thermopiles intended for applications across different altitudes or pressure environments. Research indicates approximately 0.1% measurement shift per 10 kPa pressure differential from calibration conditions.

Dust and particulate contamination gradually alter the emissivity and absorptivity characteristics of thermopile surfaces, creating progressive calibration drift. This effect is particularly pronounced in infrared-sensing thermopiles where optical surface properties directly influence measurement accuracy. Implementing cleanroom protocols for precision thermopile calibration has demonstrated up to 30% improvement in long-term calibration stability.

Humidity levels similarly affect calibration precision through multiple mechanisms. High humidity environments (>70% RH) can cause condensation on sensor surfaces, altering thermal conductivity pathways and creating parasitic thermal junctions. Additionally, moisture absorption by insulating materials changes their thermal characteristics over time. Studies by the National Metrology Institute demonstrated that uncontrolled humidity variations can contribute up to 0.3% measurement uncertainty in precision thermopile applications.

Air currents and ventilation patterns within calibration facilities create non-uniform cooling effects across sensor surfaces. Even subtle air movements of 0.2 m/s can generate localized cooling that disrupts the thermal equilibrium necessary for precise calibration. This effect becomes particularly problematic when calibrating low-output thermopiles where signal-to-noise ratios are already challenging.

Electromagnetic interference (EMI) represents another significant environmental factor affecting thermopile calibration. Modern laboratory environments contain numerous EMI sources that can couple into thermopile circuits, particularly during the amplification stage. Frequencies between 50Hz-400kHz have been identified as especially problematic, with induced errors proportional to thermopile lead length and circuit impedance.

Barometric pressure variations, while often overlooked, affect convective heat transfer coefficients around the thermopile assembly. This becomes particularly relevant when calibrating thermopiles intended for applications across different altitudes or pressure environments. Research indicates approximately 0.1% measurement shift per 10 kPa pressure differential from calibration conditions.

Dust and particulate contamination gradually alter the emissivity and absorptivity characteristics of thermopile surfaces, creating progressive calibration drift. This effect is particularly pronounced in infrared-sensing thermopiles where optical surface properties directly influence measurement accuracy. Implementing cleanroom protocols for precision thermopile calibration has demonstrated up to 30% improvement in long-term calibration stability.

Industry Standards and Certification Requirements

The thermopile sensor industry operates under stringent regulatory frameworks that ensure measurement accuracy and reliability across various applications. ISO/IEC 17025 serves as the cornerstone standard for calibration laboratories, establishing comprehensive requirements for testing and calibration competence. Organizations working with thermopile sensors must demonstrate compliance with these standards through accreditation processes that validate their calibration procedures and uncertainty calculations.

NIST (National Institute of Standards and Technology) provides traceability chains essential for thermopile calibration, publishing specific guidelines in their Technical Note 1297 regarding expression of measurement uncertainty. These guidelines have been widely adopted across industries utilizing thermal measurement technologies. Similarly, the International Electrotechnical Commission (IEC) has developed standards specifically addressing infrared temperature measurement devices, including IEC 80601-2-59 for medical thermography equipment.

For industrial applications, ASTM E1256 outlines standard test methods for radiation thermometers, while ASTM E2847 addresses calibration of non-contact infrared thermometers. These standards define acceptable performance parameters, calibration intervals, and verification procedures that manufacturers and calibration laboratories must follow to ensure measurement integrity.

Certification requirements vary by application domain. Medical device manufacturers incorporating thermopile sensors must comply with FDA regulations in the United States, including 21 CFR Part 820 for quality system regulation, and obtain CE marking in Europe under the Medical Device Regulation (MDR). Industrial applications often require compliance with ISO 9001 quality management systems, with additional sector-specific certifications.

Aerospace and defense applications demand adherence to AS9100 standards, with specialized calibration requirements defined in documents like NASA's Measurement Quality Assurance Handbook. Automotive applications follow IATF 16949 standards, with specific thermal measurement requirements outlined in component testing protocols.

Emerging trends in standardization include the development of specific protocols for high-precision thermopile arrays used in thermal imaging, with organizations like BIPM (International Bureau of Weights and Measures) working on new calibration methodologies. Additionally, industry consortia are establishing application-specific standards for emerging fields like autonomous vehicle thermal sensing and advanced medical diagnostics, where thermopile technology plays a critical role.

Compliance with these standards typically requires documented calibration procedures, uncertainty budgets, regular proficiency testing, and periodic audits by accreditation bodies. Organizations seeking to enhance thermopile calibration precision must maintain awareness of evolving standards and certification requirements to ensure continued regulatory compliance and market acceptance.

NIST (National Institute of Standards and Technology) provides traceability chains essential for thermopile calibration, publishing specific guidelines in their Technical Note 1297 regarding expression of measurement uncertainty. These guidelines have been widely adopted across industries utilizing thermal measurement technologies. Similarly, the International Electrotechnical Commission (IEC) has developed standards specifically addressing infrared temperature measurement devices, including IEC 80601-2-59 for medical thermography equipment.

For industrial applications, ASTM E1256 outlines standard test methods for radiation thermometers, while ASTM E2847 addresses calibration of non-contact infrared thermometers. These standards define acceptable performance parameters, calibration intervals, and verification procedures that manufacturers and calibration laboratories must follow to ensure measurement integrity.

Certification requirements vary by application domain. Medical device manufacturers incorporating thermopile sensors must comply with FDA regulations in the United States, including 21 CFR Part 820 for quality system regulation, and obtain CE marking in Europe under the Medical Device Regulation (MDR). Industrial applications often require compliance with ISO 9001 quality management systems, with additional sector-specific certifications.

Aerospace and defense applications demand adherence to AS9100 standards, with specialized calibration requirements defined in documents like NASA's Measurement Quality Assurance Handbook. Automotive applications follow IATF 16949 standards, with specific thermal measurement requirements outlined in component testing protocols.

Emerging trends in standardization include the development of specific protocols for high-precision thermopile arrays used in thermal imaging, with organizations like BIPM (International Bureau of Weights and Measures) working on new calibration methodologies. Additionally, industry consortia are establishing application-specific standards for emerging fields like autonomous vehicle thermal sensing and advanced medical diagnostics, where thermopile technology plays a critical role.

Compliance with these standards typically requires documented calibration procedures, uncertainty budgets, regular proficiency testing, and periodic audits by accreditation bodies. Organizations seeking to enhance thermopile calibration precision must maintain awareness of evolving standards and certification requirements to ensure continued regulatory compliance and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!