Testing Thermopile Effectiveness in Outdoor Urban Environments

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Technology Background and Objectives

Thermopile technology has evolved significantly since its inception in the early 19th century, when Thomas Johann Seebeck first discovered the thermoelectric effect. This phenomenon, which allows for the direct conversion of temperature differences into electrical voltage, forms the fundamental operating principle of thermopiles. Over the decades, thermopile sensors have transitioned from simple laboratory instruments to sophisticated detection devices with applications spanning multiple industries.

The evolution of thermopile technology has been marked by continuous improvements in sensitivity, response time, and form factor. Early thermopiles consisted of multiple thermocouples connected in series to amplify the small voltage generated by temperature differentials. Modern thermopile sensors incorporate advanced semiconductor manufacturing techniques, resulting in miniaturized devices with enhanced performance characteristics and reduced production costs.

In urban environments, thermopile technology faces unique challenges and opportunities. The complex thermal landscapes of cities—characterized by heat islands, reflective surfaces, and variable weather conditions—create a demanding testing ground for thermopile effectiveness. Understanding how these sensors perform in such dynamic settings is crucial for applications ranging from building energy management to environmental monitoring and urban planning.

The primary objective of testing thermopile effectiveness in outdoor urban environments is to evaluate sensor performance under real-world conditions that cannot be adequately simulated in laboratory settings. This includes assessing accuracy across varying ambient temperatures, humidity levels, and exposure to direct sunlight, precipitation, and air pollution—all factors that can potentially affect sensor readings and longevity.

Another key goal is to determine the optimal deployment strategies for thermopile sensors in urban settings. This involves identifying ideal mounting locations, orientation considerations, and protective housing requirements to maximize data reliability while minimizing maintenance needs. The research aims to establish standardized testing protocols that can be replicated across different urban environments globally.

Furthermore, this technical exploration seeks to bridge the gap between theoretical thermopile capabilities and practical implementation challenges. By systematically documenting performance variations under diverse urban conditions, the research will contribute to the development of more robust calibration algorithms and compensation techniques tailored specifically for outdoor urban applications.

The long-term technological objective extends beyond mere performance validation to enabling new applications in smart city infrastructure. As urban centers increasingly adopt data-driven approaches to energy management, environmental monitoring, and public safety, reliable thermal sensing technologies become essential components of the urban technological ecosystem. Testing thermopile effectiveness represents a critical step toward realizing the full potential of these sensors in creating more sustainable, efficient, and responsive urban environments.

The evolution of thermopile technology has been marked by continuous improvements in sensitivity, response time, and form factor. Early thermopiles consisted of multiple thermocouples connected in series to amplify the small voltage generated by temperature differentials. Modern thermopile sensors incorporate advanced semiconductor manufacturing techniques, resulting in miniaturized devices with enhanced performance characteristics and reduced production costs.

In urban environments, thermopile technology faces unique challenges and opportunities. The complex thermal landscapes of cities—characterized by heat islands, reflective surfaces, and variable weather conditions—create a demanding testing ground for thermopile effectiveness. Understanding how these sensors perform in such dynamic settings is crucial for applications ranging from building energy management to environmental monitoring and urban planning.

The primary objective of testing thermopile effectiveness in outdoor urban environments is to evaluate sensor performance under real-world conditions that cannot be adequately simulated in laboratory settings. This includes assessing accuracy across varying ambient temperatures, humidity levels, and exposure to direct sunlight, precipitation, and air pollution—all factors that can potentially affect sensor readings and longevity.

Another key goal is to determine the optimal deployment strategies for thermopile sensors in urban settings. This involves identifying ideal mounting locations, orientation considerations, and protective housing requirements to maximize data reliability while minimizing maintenance needs. The research aims to establish standardized testing protocols that can be replicated across different urban environments globally.

Furthermore, this technical exploration seeks to bridge the gap between theoretical thermopile capabilities and practical implementation challenges. By systematically documenting performance variations under diverse urban conditions, the research will contribute to the development of more robust calibration algorithms and compensation techniques tailored specifically for outdoor urban applications.

The long-term technological objective extends beyond mere performance validation to enabling new applications in smart city infrastructure. As urban centers increasingly adopt data-driven approaches to energy management, environmental monitoring, and public safety, reliable thermal sensing technologies become essential components of the urban technological ecosystem. Testing thermopile effectiveness represents a critical step toward realizing the full potential of these sensors in creating more sustainable, efficient, and responsive urban environments.

Market Analysis for Outdoor Thermal Sensing Applications

The outdoor thermal sensing market is experiencing significant growth driven by increasing urbanization, climate change concerns, and the expansion of smart city initiatives worldwide. Current market valuations place the global thermal sensing technology sector at approximately $5.2 billion, with outdoor applications representing nearly 30% of this market. Annual growth rates for outdoor thermal sensing applications consistently exceed 12%, outpacing many other sensor technology segments.

Urban environmental monitoring represents the largest application segment, accounting for roughly 40% of the outdoor thermal sensing market. This is followed by building energy management (25%), public safety and security systems (20%), and emerging applications in autonomous vehicles and urban planning (15%). The market demonstrates strong regional variations, with North America currently leading adoption rates, followed closely by Europe and rapidly expanding implementations across Asia-Pacific regions, particularly in China, Japan, and South Korea.

Thermopile sensors specifically occupy a strategic position within this landscape due to their favorable cost-performance ratio compared to alternatives like bolometers or microbolometers. The average price point for commercial-grade thermopile arrays suitable for urban deployment has decreased by approximately 35% over the past five years, significantly expanding potential application scenarios.

Customer demand patterns reveal growing interest in integrated sensing solutions that combine thermal data with other environmental parameters. Over 65% of recent RFPs from municipal customers specify multi-parameter sensing capabilities, with thermal measurement as a core requirement. This trend toward integration presents both opportunities and challenges for thermopile technology providers.

Key market drivers include increasingly stringent building energy codes, expanding urban heat island mitigation programs, and growing investment in climate resilience infrastructure. The COVID-19 pandemic also accelerated adoption of thermal sensing for public health applications, creating new market segments that have persisted beyond the immediate crisis.

Competitive analysis indicates moderate market concentration, with the top five manufacturers controlling approximately 58% of global thermopile sensor production. However, the application layer remains highly fragmented, with numerous software and systems integration companies developing specialized solutions for different vertical markets.

Market barriers include concerns about measurement accuracy in variable outdoor conditions, calibration challenges in diverse urban environments, and competition from alternative sensing technologies. Despite these challenges, forecast models predict continued strong growth, with outdoor thermal sensing applications potentially reaching $9.7 billion by 2028, representing a compound annual growth rate of 13.2% from current levels.

Urban environmental monitoring represents the largest application segment, accounting for roughly 40% of the outdoor thermal sensing market. This is followed by building energy management (25%), public safety and security systems (20%), and emerging applications in autonomous vehicles and urban planning (15%). The market demonstrates strong regional variations, with North America currently leading adoption rates, followed closely by Europe and rapidly expanding implementations across Asia-Pacific regions, particularly in China, Japan, and South Korea.

Thermopile sensors specifically occupy a strategic position within this landscape due to their favorable cost-performance ratio compared to alternatives like bolometers or microbolometers. The average price point for commercial-grade thermopile arrays suitable for urban deployment has decreased by approximately 35% over the past five years, significantly expanding potential application scenarios.

Customer demand patterns reveal growing interest in integrated sensing solutions that combine thermal data with other environmental parameters. Over 65% of recent RFPs from municipal customers specify multi-parameter sensing capabilities, with thermal measurement as a core requirement. This trend toward integration presents both opportunities and challenges for thermopile technology providers.

Key market drivers include increasingly stringent building energy codes, expanding urban heat island mitigation programs, and growing investment in climate resilience infrastructure. The COVID-19 pandemic also accelerated adoption of thermal sensing for public health applications, creating new market segments that have persisted beyond the immediate crisis.

Competitive analysis indicates moderate market concentration, with the top five manufacturers controlling approximately 58% of global thermopile sensor production. However, the application layer remains highly fragmented, with numerous software and systems integration companies developing specialized solutions for different vertical markets.

Market barriers include concerns about measurement accuracy in variable outdoor conditions, calibration challenges in diverse urban environments, and competition from alternative sensing technologies. Despite these challenges, forecast models predict continued strong growth, with outdoor thermal sensing applications potentially reaching $9.7 billion by 2028, representing a compound annual growth rate of 13.2% from current levels.

Current Challenges in Urban Environmental Thermopile Deployment

The deployment of thermopile sensors in urban environments presents several significant challenges that impact their effectiveness and reliability. Urban settings create complex thermal landscapes due to the heat island effect, where concrete, asphalt, and building materials absorb and re-radiate heat differently than natural environments. This phenomenon creates temperature gradients and microclimates that can vary dramatically within short distances, complicating accurate thermopile readings and calibration.

Environmental contamination poses another substantial challenge. Urban air contains particulates, pollutants, and moisture that can accumulate on sensor surfaces, degrading performance over time. These contaminants can alter the emissivity characteristics of the thermopile's sensing elements, leading to measurement drift and reduced accuracy without regular maintenance protocols.

Power supply constraints further complicate deployment scenarios. While thermopiles themselves consume minimal power, the supporting electronics for signal processing, data storage, and transmission require consistent energy sources. In outdoor urban settings, traditional grid connections may be impractical or costly, necessitating battery or renewable energy solutions that introduce additional maintenance requirements and potential points of failure.

Signal interference represents a critical technical hurdle in dense urban environments. The proliferation of wireless communications, electrical infrastructure, and electromagnetic fields can introduce noise into thermopile measurement circuits. This interference can be particularly problematic for the low-level signals generated by thermopile sensors, requiring sophisticated filtering and shielding solutions.

Physical security and vandalism concerns also impact deployment strategies. Exposed sensors in public urban spaces face risks of damage, theft, or tampering that can compromise data integrity or cause complete system failure. Protective enclosures must balance security with the need to maintain proper exposure to the thermal environment being measured.

Weather variability introduces additional complications. Rapid temperature fluctuations, precipitation, wind, and solar radiation can all affect thermopile readings. Urban canyons created by tall buildings can generate unpredictable wind patterns that alter thermal signatures, while direct sunlight exposure can overwhelm sensors designed to detect subtle temperature differences.

Calibration and reference standards present ongoing challenges. Urban environments lack the controlled conditions typically used for sensor calibration, making it difficult to establish reliable baselines. The dynamic nature of urban thermal landscapes requires adaptive calibration approaches that can account for seasonal variations and changing urban development patterns.

Data interpretation complexity rounds out the major challenges. Converting raw thermopile signals into meaningful environmental insights requires sophisticated algorithms that can account for the unique characteristics of urban settings, including reflected radiation from buildings, anthropogenic heat sources, and the three-dimensional nature of the urban thermal environment.

Environmental contamination poses another substantial challenge. Urban air contains particulates, pollutants, and moisture that can accumulate on sensor surfaces, degrading performance over time. These contaminants can alter the emissivity characteristics of the thermopile's sensing elements, leading to measurement drift and reduced accuracy without regular maintenance protocols.

Power supply constraints further complicate deployment scenarios. While thermopiles themselves consume minimal power, the supporting electronics for signal processing, data storage, and transmission require consistent energy sources. In outdoor urban settings, traditional grid connections may be impractical or costly, necessitating battery or renewable energy solutions that introduce additional maintenance requirements and potential points of failure.

Signal interference represents a critical technical hurdle in dense urban environments. The proliferation of wireless communications, electrical infrastructure, and electromagnetic fields can introduce noise into thermopile measurement circuits. This interference can be particularly problematic for the low-level signals generated by thermopile sensors, requiring sophisticated filtering and shielding solutions.

Physical security and vandalism concerns also impact deployment strategies. Exposed sensors in public urban spaces face risks of damage, theft, or tampering that can compromise data integrity or cause complete system failure. Protective enclosures must balance security with the need to maintain proper exposure to the thermal environment being measured.

Weather variability introduces additional complications. Rapid temperature fluctuations, precipitation, wind, and solar radiation can all affect thermopile readings. Urban canyons created by tall buildings can generate unpredictable wind patterns that alter thermal signatures, while direct sunlight exposure can overwhelm sensors designed to detect subtle temperature differences.

Calibration and reference standards present ongoing challenges. Urban environments lack the controlled conditions typically used for sensor calibration, making it difficult to establish reliable baselines. The dynamic nature of urban thermal landscapes requires adaptive calibration approaches that can account for seasonal variations and changing urban development patterns.

Data interpretation complexity rounds out the major challenges. Converting raw thermopile signals into meaningful environmental insights requires sophisticated algorithms that can account for the unique characteristics of urban settings, including reflected radiation from buildings, anthropogenic heat sources, and the three-dimensional nature of the urban thermal environment.

Existing Testing Methodologies for Outdoor Thermopile Performance

01 Thermopile design and structure optimization

The effectiveness of thermopiles can be significantly improved through structural optimization. This includes designing thermopiles with specific junction arrangements, optimizing the number of thermocouples, and selecting appropriate materials for the thermoelectric elements. Advanced fabrication techniques allow for the creation of thermopiles with higher sensitivity and better thermal response. These structural improvements enhance the voltage output and overall performance of thermopile sensors.- Thermopile design optimization for improved sensitivity: Optimizing the design of thermopiles can significantly enhance their effectiveness. This includes improving the thermoelectric materials, junction configurations, and overall structure. By carefully selecting materials with high Seebeck coefficients and optimizing the number and arrangement of thermocouples, the voltage output and sensitivity of thermopiles can be increased. Advanced manufacturing techniques allow for more precise fabrication of thermopile elements, resulting in better performance and reliability.

- Thermal isolation techniques for thermopiles: Effective thermal isolation is crucial for maximizing thermopile performance. Various techniques are employed to minimize unwanted heat transfer, including the use of suspended membrane structures, vacuum packaging, and specialized insulating materials. By reducing thermal conductivity between the hot and cold junctions, the temperature gradient can be maintained more effectively, resulting in higher output signals. These isolation techniques are particularly important in applications requiring high sensitivity or rapid response times.

- Integration of thermopiles in sensing and detection systems: Thermopiles are effectively integrated into various sensing and detection systems to measure temperature differences, radiation, and heat flow. When combined with appropriate signal processing circuits and calibration methods, thermopiles can provide accurate measurements in applications such as infrared detection, gas analysis, and thermal imaging. The effectiveness of these integrated systems depends on the proper matching of thermopile characteristics with application requirements and environmental conditions.

- Environmental compensation and calibration methods: To enhance thermopile effectiveness in varying conditions, environmental compensation and calibration methods are essential. These include temperature compensation circuits, reference junction techniques, and software algorithms that adjust for ambient temperature fluctuations. Advanced calibration procedures can account for non-linearities in thermopile response and aging effects. These methods significantly improve measurement accuracy and long-term stability, particularly in applications exposed to changing environmental conditions.

- Novel thermopile materials and fabrication techniques: Research into novel materials and fabrication techniques has led to significant improvements in thermopile effectiveness. This includes the development of thin-film thermopiles, nanoscale thermoelectric materials, and flexible thermopile arrays. Advanced deposition methods and microfabrication techniques allow for the creation of thermopiles with enhanced performance characteristics. These innovations have expanded the application range of thermopiles and improved their reliability, sensitivity, and response time.

02 Material selection for improved thermopile performance

The choice of materials significantly impacts thermopile effectiveness. Using materials with high Seebeck coefficients and optimal thermal conductivity properties can enhance the voltage generation capability of thermopiles. Advanced semiconductor materials, alloys, and thin-film technologies have been developed to maximize the temperature difference across thermopile junctions. These material innovations lead to improved sensitivity, faster response times, and greater energy conversion efficiency in thermopile devices.Expand Specific Solutions03 Thermal management techniques for thermopiles

Effective thermal management is crucial for maximizing thermopile performance. This includes designing appropriate heat sinks, thermal isolation structures, and optimizing heat flow paths. By enhancing the temperature gradient across the thermopile junctions, these techniques increase the voltage output and improve the signal-to-noise ratio. Advanced thermal management approaches also help in reducing response time and improving the stability of thermopile measurements under varying environmental conditions.Expand Specific Solutions04 Integration of thermopiles in sensing and detection systems

Thermopiles can be effectively integrated into various sensing and detection systems to enhance their capabilities. This includes incorporating thermopiles in infrared sensors, gas analyzers, thermal imaging devices, and medical diagnostic equipment. The integration often involves combining thermopiles with signal processing circuits, optical components, and other sensors to create comprehensive detection systems. These integrated solutions improve measurement accuracy, extend detection range, and enable new applications for thermopile technology.Expand Specific Solutions05 Novel applications enhancing thermopile utility

Innovative applications have been developed to expand the utility and effectiveness of thermopiles. These include using thermopiles in energy harvesting systems, wearable devices, automotive sensors, and environmental monitoring equipment. By adapting thermopile technology to these diverse applications, researchers have enhanced their functionality and practical value. These novel implementations often require specialized designs and configurations to optimize thermopile performance for specific use cases and operating environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermal Sensing

The thermopile effectiveness testing market in outdoor urban environments is currently in a growth phase, with increasing applications in smart city infrastructure, environmental monitoring, and energy efficiency solutions. The market is expanding as urban centers globally prioritize sustainable development and climate resilience. Key players include established electronics manufacturers like OMRON, Maxim Integrated Products, and PixArt Imaging, who bring significant expertise in sensor technology. Research institutions such as Southeast University and Shenzhen Institutes of Advanced Technology are advancing the technical capabilities, while companies like Apple and LG Electronics are integrating thermopile technology into consumer products. The technology is approaching maturity for basic applications but continues to evolve for complex urban environmental monitoring, with companies like Hefei Haizheng Environmental Monitoring specializing in advanced environmental sensing solutions.

Koninklijke Philips NV

Technical Solution: Philips has engineered thermopile sensor systems optimized for outdoor urban monitoring applications. Their technology employs multi-element thermopile arrays with specialized optical designs that maintain detection accuracy across varying urban environmental conditions. Philips' outdoor thermopile solutions feature proprietary weatherproofing techniques that protect sensitive components while maintaining thermal conductivity pathways essential for accurate readings. Their systems incorporate advanced digital signal processing that applies machine learning algorithms to distinguish between relevant thermal signatures and environmental noise common in complex urban settings. Philips has also developed specialized housing designs that minimize the impact of direct sunlight and precipitation on sensor performance, a critical factor for outdoor deployment in urban environments.

Strengths: Excellent long-term stability in outdoor installations; sophisticated signal processing capabilities for complex urban environments; comprehensive weatherproofing solutions. Weaknesses: Relatively high power consumption compared to simpler thermopile implementations; more complex installation requirements.

Alps Alpine Co., Ltd.

Technical Solution: Alps Alpine has developed specialized thermopile sensor technology optimized for outdoor urban environmental monitoring. Their thermopile solutions feature proprietary lens structures that maintain focus and sensitivity across the temperature extremes encountered in urban settings. The company's outdoor thermopile systems incorporate advanced temperature compensation circuits that adjust for ambient temperature variations, maintaining measurement accuracy within ±1°C across a -20°C to +85°C operating range. Alps Alpine's urban monitoring thermopiles utilize specialized filtering technologies that reduce interference from urban heat sources while preserving detection sensitivity for targeted applications. Their sensors include integrated weatherproofing features designed specifically to withstand urban pollution, precipitation, and temperature fluctuations without degradation of performance.

Strengths: Exceptional durability in harsh urban environments; compact form factor suitable for discreet urban installation; low power consumption ideal for battery-powered urban monitoring stations. Weaknesses: Somewhat limited detection range compared to larger thermopile arrays; requires periodic recalibration in heavily polluted urban environments.

Critical Patents and Innovations in Thermopile Sensor Technology

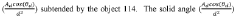

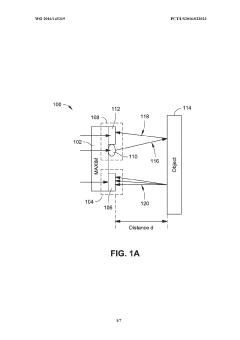

Device and method for temperature correction using a proximity sensor in a non-contact thermopile thermometer

PatentWO2016145319A1

Innovation

- A temperature measurement device equipped with a thermopile temperature sensor and a proximity sensor, where the proximity sensor detects the distance between the thermopile and the object, and a controller uses this information to correct the temperature measurement by accounting for the received radiation and distance, providing an accurate reading.

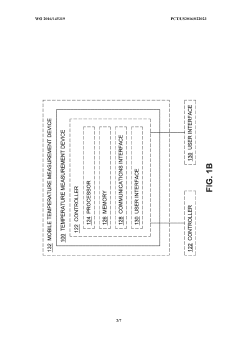

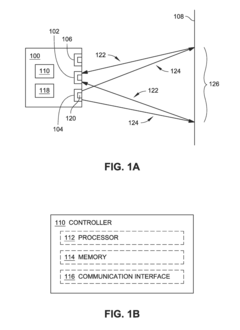

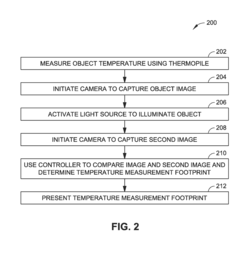

Heat imaging thermopile device and method

PatentActiveUS20160265977A1

Innovation

- A temperature measurement footprint device comprising a thermopile, a camera, and a light source, controlled by a processor, which captures images before and during illumination to determine and present a temperature measurement footprint, providing an indication of the area being measured.

Environmental Factors Affecting Thermopile Accuracy in Cities

Urban environments present unique challenges for thermopile sensor accuracy due to the complex interplay of various environmental factors. The urban heat island effect significantly impacts temperature measurements, with concrete, asphalt, and building materials absorbing and radiating heat differently than natural landscapes. This creates temperature gradients that can vary by 2-5°C within short distances, potentially leading to measurement discrepancies when thermopiles are deployed across urban areas.

Air pollution in cities introduces particulate matter and aerosols that can interfere with infrared radiation detection. These particles can absorb, scatter, or reflect infrared signals, reducing the signal-to-noise ratio and compromising measurement accuracy. Studies indicate that heavy pollution conditions can degrade thermopile accuracy by up to 15% compared to clean air environments.

Wind patterns in urban canyons create turbulent airflows that affect heat distribution and thermal equilibrium around sensors. Buildings create complex wind tunnels that can rapidly change local temperatures and introduce convective cooling effects that may not be uniformly distributed. These micro-climate variations can cause fluctuating readings that do not represent the broader environmental conditions.

Reflective surfaces from glass buildings, windows, and metallic structures generate infrared reflections that can confuse thermopile sensors. These reflections can create false hotspots or cold spots in the measurement field, particularly problematic for wide-angle thermopile arrays attempting to map thermal distributions across urban landscapes.

Humidity levels, which tend to vary significantly in urban environments due to human activities, water features, and vegetation distribution, affect infrared transmission through the atmosphere. Higher humidity can attenuate certain infrared wavelengths, potentially requiring calibration adjustments for accurate temperature sensing.

Seasonal variations compound these challenges, with winter conditions introducing snow cover that dramatically alters surface reflectivity and summer conditions exacerbating heat island effects. Diurnal temperature cycles in cities also differ from rural areas, with urban areas typically experiencing slower cooling at night due to heat retention in built structures.

Shadow patterns from tall buildings create dynamic temperature zones that shift throughout the day. These transient shadows can cause rapid temperature fluctuations of several degrees within minutes as surfaces move between direct sunlight and shade, challenging the temporal resolution capabilities of thermopile sensors and necessitating more frequent sampling or spatial averaging techniques to maintain measurement reliability.

Air pollution in cities introduces particulate matter and aerosols that can interfere with infrared radiation detection. These particles can absorb, scatter, or reflect infrared signals, reducing the signal-to-noise ratio and compromising measurement accuracy. Studies indicate that heavy pollution conditions can degrade thermopile accuracy by up to 15% compared to clean air environments.

Wind patterns in urban canyons create turbulent airflows that affect heat distribution and thermal equilibrium around sensors. Buildings create complex wind tunnels that can rapidly change local temperatures and introduce convective cooling effects that may not be uniformly distributed. These micro-climate variations can cause fluctuating readings that do not represent the broader environmental conditions.

Reflective surfaces from glass buildings, windows, and metallic structures generate infrared reflections that can confuse thermopile sensors. These reflections can create false hotspots or cold spots in the measurement field, particularly problematic for wide-angle thermopile arrays attempting to map thermal distributions across urban landscapes.

Humidity levels, which tend to vary significantly in urban environments due to human activities, water features, and vegetation distribution, affect infrared transmission through the atmosphere. Higher humidity can attenuate certain infrared wavelengths, potentially requiring calibration adjustments for accurate temperature sensing.

Seasonal variations compound these challenges, with winter conditions introducing snow cover that dramatically alters surface reflectivity and summer conditions exacerbating heat island effects. Diurnal temperature cycles in cities also differ from rural areas, with urban areas typically experiencing slower cooling at night due to heat retention in built structures.

Shadow patterns from tall buildings create dynamic temperature zones that shift throughout the day. These transient shadows can cause rapid temperature fluctuations of several degrees within minutes as surfaces move between direct sunlight and shade, challenging the temporal resolution capabilities of thermopile sensors and necessitating more frequent sampling or spatial averaging techniques to maintain measurement reliability.

Standardization and Calibration Protocols for Outdoor Thermal Sensing

Standardization and calibration protocols are essential for ensuring the reliability and accuracy of thermopile sensors deployed in outdoor urban environments. These protocols must address the unique challenges posed by varying weather conditions, urban heat island effects, and diverse surface materials that can significantly impact thermal readings.

The establishment of baseline calibration procedures requires reference measurements under controlled conditions before deployment. This involves comparing thermopile outputs against laboratory-grade thermal reference instruments across a range of temperatures typically encountered in urban settings (-20°C to 60°C). Calibration curves must be developed for each sensor unit to account for manufacturing variations and ensure consistency across sensor networks.

Field calibration protocols should include regular in-situ verification against portable reference instruments. This process should occur at different times of day and under various weather conditions to capture the full spectrum of environmental influences. Recommended frequency for field calibration is quarterly, with additional verification following extreme weather events that might affect sensor performance.

Environmental correction factors represent a critical component of standardization. Protocols must include methodologies for compensating for ambient temperature, humidity, wind speed, and solar radiation effects on thermopile readings. Mathematical models should be developed to apply these corrections automatically within the data processing pipeline, with coefficients updated seasonally to account for changing environmental conditions.

Data validation frameworks should establish clear thresholds for identifying anomalous readings. These include rate-of-change limits (typically 5°C per minute for urban environments), comparison with nearby sensors, and correlation with meteorological data. Automated flagging systems should mark potentially erroneous data for human review while maintaining the original raw data for reference.

Documentation standards must be comprehensive, including sensor specifications, calibration dates, environmental conditions during calibration, correction factors applied, and uncertainty calculations. This metadata should accompany all thermal measurements to ensure proper interpretation and cross-comparison between different deployment sites.

Inter-laboratory comparison programs should be established to verify calibration consistency across different research groups and municipal agencies deploying thermopile networks. Annual round-robin testing using standardized reference targets can help identify systematic biases and improve overall measurement quality across the urban sensing community.

Uncertainty quantification methodologies must be standardized to provide clear confidence intervals for all thermal measurements. This includes propagating uncertainties from calibration procedures, environmental corrections, and sensor drift over time to provide end users with realistic error bounds for decision-making processes based on thermal data.

The establishment of baseline calibration procedures requires reference measurements under controlled conditions before deployment. This involves comparing thermopile outputs against laboratory-grade thermal reference instruments across a range of temperatures typically encountered in urban settings (-20°C to 60°C). Calibration curves must be developed for each sensor unit to account for manufacturing variations and ensure consistency across sensor networks.

Field calibration protocols should include regular in-situ verification against portable reference instruments. This process should occur at different times of day and under various weather conditions to capture the full spectrum of environmental influences. Recommended frequency for field calibration is quarterly, with additional verification following extreme weather events that might affect sensor performance.

Environmental correction factors represent a critical component of standardization. Protocols must include methodologies for compensating for ambient temperature, humidity, wind speed, and solar radiation effects on thermopile readings. Mathematical models should be developed to apply these corrections automatically within the data processing pipeline, with coefficients updated seasonally to account for changing environmental conditions.

Data validation frameworks should establish clear thresholds for identifying anomalous readings. These include rate-of-change limits (typically 5°C per minute for urban environments), comparison with nearby sensors, and correlation with meteorological data. Automated flagging systems should mark potentially erroneous data for human review while maintaining the original raw data for reference.

Documentation standards must be comprehensive, including sensor specifications, calibration dates, environmental conditions during calibration, correction factors applied, and uncertainty calculations. This metadata should accompany all thermal measurements to ensure proper interpretation and cross-comparison between different deployment sites.

Inter-laboratory comparison programs should be established to verify calibration consistency across different research groups and municipal agencies deploying thermopile networks. Annual round-robin testing using standardized reference targets can help identify systematic biases and improve overall measurement quality across the urban sensing community.

Uncertainty quantification methodologies must be standardized to provide clear confidence intervals for all thermal measurements. This includes propagating uncertainties from calibration procedures, environmental corrections, and sensor drift over time to provide end users with realistic error bounds for decision-making processes based on thermal data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!