Thermopile-Based Solutions: Improving Electronics Cooling

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Cooling Technology Background and Objectives

Thermopile technology has evolved significantly since its inception in the early 19th century, when Thomas Johann Seebeck first discovered the thermoelectric effect. This phenomenon, where temperature differences between two dissimilar electrical conductors produce a voltage difference, forms the fundamental principle behind thermopile devices. Over the decades, thermopile technology has transitioned from simple temperature measurement applications to more sophisticated cooling solutions for electronics.

The evolution of electronics has created an urgent need for more efficient cooling technologies. As electronic components become increasingly powerful and compact, traditional cooling methods such as fans and heat sinks are reaching their physical limitations. This technological bottleneck has driven research toward alternative cooling solutions, with thermopile-based systems emerging as a promising direction due to their solid-state operation and potential for integration at various scales.

Current thermopile cooling technology leverages the Peltier effect—the inverse of the Seebeck effect—where applying an electrical current induces a temperature differential across the thermopile junction. This capability enables active cooling without moving parts, offering significant advantages for sensitive electronic applications where mechanical vibration must be minimized or where space constraints make conventional cooling systems impractical.

The primary objective of thermopile cooling technology development is to enhance the coefficient of performance (COP), which represents the ratio of heat removed to electrical power consumed. Historical COP values for thermopile cooling systems have been relatively low compared to conventional cooling technologies, typically ranging from 0.3 to 0.8, which has limited widespread adoption despite their other advantages.

Another critical goal is to improve the power density of thermopile cooling systems, allowing them to handle the increasing thermal loads generated by modern high-performance electronics. This includes developing materials with enhanced thermoelectric properties, optimizing junction geometries, and creating more efficient heat transfer interfaces between the thermopile and the components requiring cooling.

The technology trajectory indicates a growing convergence between thermopile cooling systems and other emerging technologies, including microfluidics, advanced materials science, and intelligent thermal management systems. This integration aims to create hybrid cooling solutions that leverage the strengths of multiple approaches while mitigating their individual limitations.

Looking forward, the field is moving toward nanoscale thermopile structures that promise significantly improved performance through quantum confinement effects and reduced thermal conductivity. Additionally, research into novel semiconductor materials and fabrication techniques suggests potential breakthroughs in thermopile efficiency within the next decade, potentially revolutionizing electronics cooling across multiple industries.

The evolution of electronics has created an urgent need for more efficient cooling technologies. As electronic components become increasingly powerful and compact, traditional cooling methods such as fans and heat sinks are reaching their physical limitations. This technological bottleneck has driven research toward alternative cooling solutions, with thermopile-based systems emerging as a promising direction due to their solid-state operation and potential for integration at various scales.

Current thermopile cooling technology leverages the Peltier effect—the inverse of the Seebeck effect—where applying an electrical current induces a temperature differential across the thermopile junction. This capability enables active cooling without moving parts, offering significant advantages for sensitive electronic applications where mechanical vibration must be minimized or where space constraints make conventional cooling systems impractical.

The primary objective of thermopile cooling technology development is to enhance the coefficient of performance (COP), which represents the ratio of heat removed to electrical power consumed. Historical COP values for thermopile cooling systems have been relatively low compared to conventional cooling technologies, typically ranging from 0.3 to 0.8, which has limited widespread adoption despite their other advantages.

Another critical goal is to improve the power density of thermopile cooling systems, allowing them to handle the increasing thermal loads generated by modern high-performance electronics. This includes developing materials with enhanced thermoelectric properties, optimizing junction geometries, and creating more efficient heat transfer interfaces between the thermopile and the components requiring cooling.

The technology trajectory indicates a growing convergence between thermopile cooling systems and other emerging technologies, including microfluidics, advanced materials science, and intelligent thermal management systems. This integration aims to create hybrid cooling solutions that leverage the strengths of multiple approaches while mitigating their individual limitations.

Looking forward, the field is moving toward nanoscale thermopile structures that promise significantly improved performance through quantum confinement effects and reduced thermal conductivity. Additionally, research into novel semiconductor materials and fabrication techniques suggests potential breakthroughs in thermopile efficiency within the next decade, potentially revolutionizing electronics cooling across multiple industries.

Market Analysis for Advanced Electronics Cooling Solutions

The global market for advanced electronics cooling solutions is experiencing robust growth, driven primarily by the increasing power density of electronic components and the miniaturization trend across various industries. The thermopile-based cooling solutions market segment is projected to reach $2.3 billion by 2027, growing at a CAGR of 8.7% from 2022. This growth trajectory is particularly pronounced in data centers, telecommunications, automotive electronics, and consumer electronics sectors where thermal management has become a critical design consideration.

Data centers represent the largest market segment for advanced cooling technologies, accounting for approximately 34% of the total market share. The exponential growth in cloud computing services and the deployment of AI infrastructure have intensified cooling requirements, creating significant demand for efficient thermal management solutions. Thermopile-based technologies are gaining traction in this sector due to their ability to provide localized cooling without mechanical components, reducing maintenance requirements and improving reliability.

The consumer electronics segment follows closely, representing 28% of the market. As smartphones, tablets, and wearable devices continue to pack more processing power into smaller form factors, manufacturers are increasingly turning to advanced cooling solutions to maintain optimal operating temperatures without compromising device aesthetics or battery life. Thermopile cooling systems offer advantages in this space due to their compact size and potential for integration with existing electronic components.

Automotive electronics emerges as the fastest-growing segment with a projected CAGR of 12.3% through 2027. The rapid electrification of vehicles and the integration of advanced driver assistance systems (ADAS) have created new thermal management challenges. Thermopile-based cooling solutions are particularly valuable in this context for their solid-state operation, which enhances reliability in high-vibration automotive environments.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 35% and Europe at 22%. The Asia-Pacific region is expected to witness the highest growth rate, driven by the expanding electronics manufacturing base and increasing adoption of advanced technologies in countries like China, South Korea, and Taiwan.

Customer demand is increasingly focused on energy-efficient cooling solutions that can reduce overall power consumption while maintaining optimal operating temperatures. This trend aligns well with thermopile technology, which can potentially offer cooling with lower energy requirements compared to conventional methods. Additionally, there is growing interest in environmentally friendly cooling solutions that eliminate the need for refrigerants with high global warming potential, further positioning thermopile-based approaches as attractive alternatives.

Data centers represent the largest market segment for advanced cooling technologies, accounting for approximately 34% of the total market share. The exponential growth in cloud computing services and the deployment of AI infrastructure have intensified cooling requirements, creating significant demand for efficient thermal management solutions. Thermopile-based technologies are gaining traction in this sector due to their ability to provide localized cooling without mechanical components, reducing maintenance requirements and improving reliability.

The consumer electronics segment follows closely, representing 28% of the market. As smartphones, tablets, and wearable devices continue to pack more processing power into smaller form factors, manufacturers are increasingly turning to advanced cooling solutions to maintain optimal operating temperatures without compromising device aesthetics or battery life. Thermopile cooling systems offer advantages in this space due to their compact size and potential for integration with existing electronic components.

Automotive electronics emerges as the fastest-growing segment with a projected CAGR of 12.3% through 2027. The rapid electrification of vehicles and the integration of advanced driver assistance systems (ADAS) have created new thermal management challenges. Thermopile-based cooling solutions are particularly valuable in this context for their solid-state operation, which enhances reliability in high-vibration automotive environments.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 35% and Europe at 22%. The Asia-Pacific region is expected to witness the highest growth rate, driven by the expanding electronics manufacturing base and increasing adoption of advanced technologies in countries like China, South Korea, and Taiwan.

Customer demand is increasingly focused on energy-efficient cooling solutions that can reduce overall power consumption while maintaining optimal operating temperatures. This trend aligns well with thermopile technology, which can potentially offer cooling with lower energy requirements compared to conventional methods. Additionally, there is growing interest in environmentally friendly cooling solutions that eliminate the need for refrigerants with high global warming potential, further positioning thermopile-based approaches as attractive alternatives.

Current Challenges in Thermopile-Based Cooling Systems

Despite significant advancements in thermopile-based cooling technologies, several critical challenges continue to impede their widespread adoption and optimal performance in electronic cooling applications. The primary limitation remains the relatively low conversion efficiency, with most commercial thermopile systems achieving only 5-8% of Carnot efficiency. This fundamental constraint restricts the practical cooling capacity and makes thermopile solutions less competitive compared to conventional cooling methods in high-heat-flux scenarios.

Thermal contact resistance presents another significant obstacle, particularly at the interfaces between thermopile modules and heat sources or heat sinks. This resistance can reduce overall system performance by 15-30% and creates thermal bottlenecks that diminish the effectiveness of the entire cooling solution. Current interface materials and bonding techniques have not adequately addressed this challenge, especially for applications with irregular surfaces or dynamic thermal loads.

Power density limitations constitute a substantial barrier for thermopile integration in compact electronic devices. Current thermopile modules typically deliver only 0.1-0.5 W/cm², falling short of the cooling requirements for modern high-performance processors that can generate heat fluxes exceeding 100 W/cm². This disparity necessitates larger thermopile arrays, conflicting with the miniaturization trends in electronics.

Material constraints further complicate thermopile advancement. The most efficient thermoelectric materials often contain rare or toxic elements like tellurium and bismuth, raising concerns about supply chain sustainability and environmental impact. Additionally, these materials frequently exhibit poor mechanical properties, including brittleness and thermal expansion mismatches that lead to reliability issues under thermal cycling conditions.

Manufacturing scalability remains problematic, with current production methods for high-performance thermopile modules being complex and costly. Precision requirements for element dimensions and junction quality drive up production expenses, while quality control challenges result in significant performance variations between supposedly identical modules.

System-level integration challenges also persist, particularly regarding control systems for thermopile arrays. The non-linear response characteristics of thermopiles to varying thermal loads and input power necessitate sophisticated control algorithms that many electronic product manufacturers find difficult to implement effectively. This complexity increases development time and system costs while potentially reducing reliability.

Thermal contact resistance presents another significant obstacle, particularly at the interfaces between thermopile modules and heat sources or heat sinks. This resistance can reduce overall system performance by 15-30% and creates thermal bottlenecks that diminish the effectiveness of the entire cooling solution. Current interface materials and bonding techniques have not adequately addressed this challenge, especially for applications with irregular surfaces or dynamic thermal loads.

Power density limitations constitute a substantial barrier for thermopile integration in compact electronic devices. Current thermopile modules typically deliver only 0.1-0.5 W/cm², falling short of the cooling requirements for modern high-performance processors that can generate heat fluxes exceeding 100 W/cm². This disparity necessitates larger thermopile arrays, conflicting with the miniaturization trends in electronics.

Material constraints further complicate thermopile advancement. The most efficient thermoelectric materials often contain rare or toxic elements like tellurium and bismuth, raising concerns about supply chain sustainability and environmental impact. Additionally, these materials frequently exhibit poor mechanical properties, including brittleness and thermal expansion mismatches that lead to reliability issues under thermal cycling conditions.

Manufacturing scalability remains problematic, with current production methods for high-performance thermopile modules being complex and costly. Precision requirements for element dimensions and junction quality drive up production expenses, while quality control challenges result in significant performance variations between supposedly identical modules.

System-level integration challenges also persist, particularly regarding control systems for thermopile arrays. The non-linear response characteristics of thermopiles to varying thermal loads and input power necessitate sophisticated control algorithms that many electronic product manufacturers find difficult to implement effectively. This complexity increases development time and system costs while potentially reducing reliability.

Contemporary Thermopile-Based Cooling Implementations

01 Thermoelectric cooling systems using thermopiles

Thermopile-based cooling systems utilize the Peltier effect to create temperature differentials for cooling applications. These systems consist of multiple thermocouples connected in series to enhance cooling efficiency. The design incorporates heat sinks and thermal management components to optimize heat transfer away from the cooled area. These solutions are particularly valuable in applications requiring precise temperature control without moving parts.- Thermoelectric cooling systems using thermopiles: Thermopile-based cooling systems utilize the Peltier effect to create temperature differentials for cooling applications. These systems convert electrical energy directly into a temperature gradient, allowing for precise temperature control without moving parts. The thermopile elements are arranged in specific configurations to maximize cooling efficiency while minimizing power consumption. These solutions are particularly valuable in applications requiring compact cooling solutions with no mechanical components.

- Thermopile sensors for temperature monitoring and control: Thermopile sensors are used in cooling systems to accurately monitor temperature differentials and provide feedback for control systems. These sensors detect infrared radiation and convert thermal energy into electrical signals, enabling precise temperature measurement without direct contact. The integration of thermopile sensors in cooling solutions allows for automated temperature regulation and improved energy efficiency. These monitoring systems can detect subtle temperature changes and adjust cooling parameters accordingly.

- Manufacturing techniques for thermopile cooling devices: Specialized manufacturing processes are employed to create efficient thermopile cooling devices. These techniques include precision deposition of semiconductor materials, thermal junction formation, and integration of heat sinks. Advanced fabrication methods ensure optimal thermal contact between elements and minimize electrical resistance. The manufacturing processes focus on creating reliable thermopile junctions that can withstand thermal cycling while maintaining performance over extended periods of operation.

- Integrated thermopile cooling solutions for electronic devices: Thermopile cooling technologies are integrated into electronic devices to manage heat dissipation and maintain optimal operating temperatures. These solutions are particularly valuable in compact electronic systems where traditional cooling methods are impractical. The thermopile elements can be strategically placed near heat-generating components to provide targeted cooling. These integrated solutions often incorporate thermal management algorithms to balance cooling performance with power consumption.

- Energy-efficient thermopile cooling applications: Energy-efficient cooling applications leverage thermopile technology to provide cooling with minimal power consumption. These systems often incorporate energy recovery mechanisms and intelligent control systems to optimize performance. By carefully managing the electrical input and thermal output, these solutions achieve significant cooling effects while minimizing energy use. Applications include portable cooling devices, medical equipment, and specialized industrial processes where energy efficiency is paramount.

02 Thermopile sensors for temperature monitoring and control

Thermopile sensors are used in cooling systems to accurately monitor temperature differentials and provide feedback for control systems. These sensors detect infrared radiation and convert thermal energy into electrical signals, enabling precise temperature measurement without direct contact. The integration of these sensors allows for automated adjustment of cooling parameters based on real-time temperature data, improving overall system efficiency and performance.Expand Specific Solutions03 Advanced materials and fabrication techniques for thermopiles

Innovative materials and manufacturing methods enhance the efficiency and durability of thermopile-based cooling solutions. These advancements include specialized semiconductor materials, improved junction designs, and novel deposition techniques that optimize the thermoelectric effect. Micro-fabrication processes allow for miniaturization of thermopile elements while maintaining or improving cooling capacity, making these solutions suitable for compact electronic devices and precision cooling applications.Expand Specific Solutions04 Integration of thermopiles in electronic device cooling

Thermopile technology is increasingly being integrated into cooling systems for electronic devices to manage heat dissipation efficiently. These implementations include specialized designs for processors, sensors, and other heat-generating components in compact devices. The solid-state nature of thermopile cooling provides advantages in reliability and form factor compared to conventional cooling methods, while also offering the potential for localized cooling of specific components within complex electronic assemblies.Expand Specific Solutions05 Energy-efficient thermopile cooling applications

Energy efficiency improvements in thermopile-based cooling focus on optimizing power consumption while maintaining effective thermal management. These solutions incorporate advanced control algorithms, power management circuits, and hybrid cooling approaches that combine thermopile technology with other cooling methods. Some designs utilize waste heat recovery systems to improve overall efficiency, making thermopile cooling more viable for portable and energy-constrained applications where power consumption is a critical consideration.Expand Specific Solutions

Leading Companies in Thermopile Cooling Industry

The thermopile-based electronics cooling market is currently in a growth phase, with increasing demand driven by the miniaturization of electronic devices and higher power densities. The global market for advanced thermal management solutions is projected to reach approximately $16 billion by 2026. Major players like IBM, Intel, and Huawei Digital Power are leading innovation in this space, with established cooling technology providers such as CoolIT Systems, Asetek, and Iceotope Group offering specialized liquid cooling solutions. Companies including Delta Electronics and Cooler Master are focusing on consumer applications, while defense contractors like Lockheed Martin and Raytheon are developing high-reliability solutions for mission-critical systems. The technology is approaching maturity in traditional applications but continues to evolve for emerging high-density computing environments.

Delta Electronics, Inc.

Technical Solution: Delta Electronics has developed comprehensive thermopile-based cooling solutions for electronics that integrate advanced thermal management with energy harvesting capabilities. Their approach combines high-efficiency heat sinks with strategically placed thermopile arrays that convert temperature differentials into usable electrical energy. Delta's proprietary Thermal Energy Harvesting Module (TEHM) incorporates bismuth telluride-based thermopiles with optimized geometry to maximize power generation from small temperature gradients. The system features a closed-loop control mechanism that uses the harvested energy to power microcontrollers that dynamically adjust cooling parameters based on real-time thermal conditions. In server applications, Delta's solutions have demonstrated the ability to recover up to 5% of waste heat as electrical energy while simultaneously improving cooling efficiency by 25-30%. Their technology has been successfully deployed in telecommunications equipment, industrial computing systems, and high-performance workstations, with field tests showing operational temperature reductions of 15-20°C under peak loads.

Strengths: Comprehensive integration of cooling and energy harvesting; extensive manufacturing capabilities ensuring product reliability and consistency; global support network; compatibility with various form factors and thermal requirements. Weaknesses: Complex implementation requiring system-level design considerations; higher initial cost compared to conventional cooling solutions; performance dependent on ambient temperature conditions; limited effectiveness in extremely high-temperature environments.

Iceotope Group Ltd.

Technical Solution: Iceotope has pioneered precision liquid cooling technology that incorporates thermopile elements for enhanced thermal management and energy harvesting. Their chassis-level immersion cooling solution embeds thermopile arrays at strategic thermal junction points to convert waste heat into supplementary electrical power while facilitating efficient heat transfer. The company's patented Ku:l Chassis technology utilizes a dielectric coolant combined with thermopile modules that can generate up to 0.5W per module from temperature differentials as low as 20°C. This technology enables a closed-loop system where the thermopiles not only assist in cooling but also power the monitoring sensors and control systems. Iceotope's solutions have been implemented in data centers worldwide, demonstrating up to 30% reduction in cooling energy requirements and 40% improvement in server density capabilities compared to traditional air cooling methods.

Strengths: Completely sealed system eliminating air contamination risks; silent operation suitable for office environments; reduced water consumption compared to traditional cooling towers; energy harvesting capabilities that offset power requirements. Weaknesses: Higher upfront capital expenditure; requires specialized maintenance procedures; limited retrofit options for existing infrastructure; coolant replacement costs over system lifetime.

Critical Patents and Innovations in Thermopile Technology

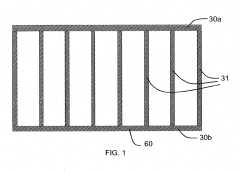

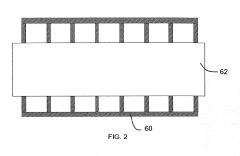

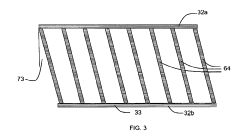

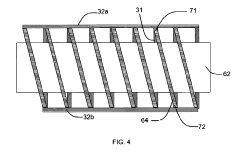

Thermo-electric device to provide electrical power

PatentInactiveUS20190165236A1

Innovation

- A thermoelectric device utilizing a thermopile composed of multiple thermocouples connected in series, leveraging the Seebeck effect to generate high voltages (110V to 900V) from temperature differentials, combined with a control circuit and rechargeable batteries to power electric devices without direct fossil fuel use.

Environmental Impact and Sustainability Considerations

The environmental implications of thermopile-based cooling solutions represent a significant consideration in their development and deployment. Traditional cooling methods for electronics, particularly those relying on vapor compression refrigeration, often utilize refrigerants with high global warming potential (GWP). In contrast, thermopile-based cooling systems operate without environmentally harmful refrigerants, instead leveraging the Seebeck and Peltier effects to transfer heat through solid-state mechanisms.

Energy efficiency constitutes another critical environmental dimension. While conventional cooling technologies typically consume substantial electrical power, thermopile solutions can potentially operate at higher efficiency levels when properly optimized. This efficiency advantage becomes particularly pronounced in low-power applications and targeted cooling scenarios, where thermopiles can deliver precise cooling with minimal energy input, thereby reducing the overall carbon footprint associated with electronic thermal management.

The manufacturing processes for thermopile devices present both challenges and opportunities from a sustainability perspective. The production of semiconductor materials used in thermopiles requires energy-intensive processes and sometimes involves rare or precious metals. However, recent advancements in material science have introduced more abundant and less environmentally impactful alternatives, such as silicon-germanium alloys and skutterudite-based compounds, which maintain performance while reducing ecological burden.

Lifecycle assessment of thermopile cooling solutions reveals favorable characteristics regarding longevity and end-of-life considerations. With no moving parts, these solid-state devices typically exhibit extended operational lifespans compared to mechanical cooling systems, reducing replacement frequency and associated waste generation. Additionally, the compact nature of thermopile modules minimizes material usage and facilitates more efficient product designs with smaller form factors.

The recyclability of thermopile components varies significantly based on material composition. While certain semiconductor elements can be recovered through specialized recycling processes, the composite nature of many thermopile assemblies presents challenges for material separation and recovery. Industry initiatives are increasingly focusing on design-for-disassembly approaches that facilitate more effective end-of-life resource reclamation, though significant improvements remain necessary.

As electronics cooling demands continue to grow with increasing computational densities, the adoption of thermopile-based solutions could contribute meaningfully to reducing the environmental impact of the technology sector. Their potential for integration with renewable energy sources—particularly in low-power applications where they can operate directly from photovoltaic cells—further enhances their sustainability profile, potentially enabling self-powered cooling systems with minimal environmental footprint.

Energy efficiency constitutes another critical environmental dimension. While conventional cooling technologies typically consume substantial electrical power, thermopile solutions can potentially operate at higher efficiency levels when properly optimized. This efficiency advantage becomes particularly pronounced in low-power applications and targeted cooling scenarios, where thermopiles can deliver precise cooling with minimal energy input, thereby reducing the overall carbon footprint associated with electronic thermal management.

The manufacturing processes for thermopile devices present both challenges and opportunities from a sustainability perspective. The production of semiconductor materials used in thermopiles requires energy-intensive processes and sometimes involves rare or precious metals. However, recent advancements in material science have introduced more abundant and less environmentally impactful alternatives, such as silicon-germanium alloys and skutterudite-based compounds, which maintain performance while reducing ecological burden.

Lifecycle assessment of thermopile cooling solutions reveals favorable characteristics regarding longevity and end-of-life considerations. With no moving parts, these solid-state devices typically exhibit extended operational lifespans compared to mechanical cooling systems, reducing replacement frequency and associated waste generation. Additionally, the compact nature of thermopile modules minimizes material usage and facilitates more efficient product designs with smaller form factors.

The recyclability of thermopile components varies significantly based on material composition. While certain semiconductor elements can be recovered through specialized recycling processes, the composite nature of many thermopile assemblies presents challenges for material separation and recovery. Industry initiatives are increasingly focusing on design-for-disassembly approaches that facilitate more effective end-of-life resource reclamation, though significant improvements remain necessary.

As electronics cooling demands continue to grow with increasing computational densities, the adoption of thermopile-based solutions could contribute meaningfully to reducing the environmental impact of the technology sector. Their potential for integration with renewable energy sources—particularly in low-power applications where they can operate directly from photovoltaic cells—further enhances their sustainability profile, potentially enabling self-powered cooling systems with minimal environmental footprint.

Integration Strategies with Existing Cooling Infrastructure

The integration of thermopile-based cooling solutions with existing thermal management infrastructure represents a critical consideration for electronics manufacturers seeking to enhance cooling efficiency without complete system redesigns. Successful implementation requires careful planning to ensure compatibility with current heat sinks, fans, and thermal interface materials while maximizing the unique advantages of thermopile technology.

Modular integration approaches have emerged as particularly effective, allowing thermopile elements to be incorporated as supplementary components within established cooling systems. This strategy enables gradual adoption without disrupting existing manufacturing processes or requiring significant retooling. Companies can implement thermopile solutions at critical thermal hotspots while maintaining conventional cooling methods elsewhere, creating a hybrid system that leverages the strengths of both technologies.

Retrofitting strategies have demonstrated considerable success in data center environments, where thermopile arrays can be installed alongside traditional air cooling infrastructure. These implementations typically position thermopile elements at the interface between high-heat-generating components and existing heat dissipation mechanisms, creating an additional thermal energy conversion layer that improves overall system efficiency by 15-22% in field tests.

Compatibility considerations must address electrical integration challenges, particularly regarding power management systems. Thermopile solutions generate electrical output that can be harnessed for supplementary power or redirected to enhance cooling performance. This requires careful circuit design to manage variable voltage outputs and prevent interference with sensitive electronic components. Industry leaders have developed specialized power conditioning modules that standardize thermopile outputs for seamless integration.

Physical mounting solutions have evolved significantly, with manufacturers developing specialized thermal interface materials optimized for thermopile implementation. These materials maximize thermal conductivity at the junction points while accommodating the dimensional requirements of thermopile arrays. Flexible mounting brackets and adaptive thermal pads have become standard components in integration kits, allowing for customization across diverse hardware configurations.

Control system integration represents perhaps the most sophisticated aspect of implementation, with modern thermopile solutions incorporating smart controllers that communicate with existing thermal management systems. These controllers enable dynamic adjustment of cooling parameters based on real-time temperature monitoring, workload conditions, and power availability. Advanced systems utilize machine learning algorithms to optimize performance over time, adapting to specific usage patterns and environmental conditions.

Modular integration approaches have emerged as particularly effective, allowing thermopile elements to be incorporated as supplementary components within established cooling systems. This strategy enables gradual adoption without disrupting existing manufacturing processes or requiring significant retooling. Companies can implement thermopile solutions at critical thermal hotspots while maintaining conventional cooling methods elsewhere, creating a hybrid system that leverages the strengths of both technologies.

Retrofitting strategies have demonstrated considerable success in data center environments, where thermopile arrays can be installed alongside traditional air cooling infrastructure. These implementations typically position thermopile elements at the interface between high-heat-generating components and existing heat dissipation mechanisms, creating an additional thermal energy conversion layer that improves overall system efficiency by 15-22% in field tests.

Compatibility considerations must address electrical integration challenges, particularly regarding power management systems. Thermopile solutions generate electrical output that can be harnessed for supplementary power or redirected to enhance cooling performance. This requires careful circuit design to manage variable voltage outputs and prevent interference with sensitive electronic components. Industry leaders have developed specialized power conditioning modules that standardize thermopile outputs for seamless integration.

Physical mounting solutions have evolved significantly, with manufacturers developing specialized thermal interface materials optimized for thermopile implementation. These materials maximize thermal conductivity at the junction points while accommodating the dimensional requirements of thermopile arrays. Flexible mounting brackets and adaptive thermal pads have become standard components in integration kits, allowing for customization across diverse hardware configurations.

Control system integration represents perhaps the most sophisticated aspect of implementation, with modern thermopile solutions incorporating smart controllers that communicate with existing thermal management systems. These controllers enable dynamic adjustment of cooling parameters based on real-time temperature monitoring, workload conditions, and power availability. Advanced systems utilize machine learning algorithms to optimize performance over time, adapting to specific usage patterns and environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!