Optimizing Thermopile Sensor Output for Infrared Detection

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Sensor Technology Background and Objectives

Thermopile sensors have evolved significantly since their inception in the early 20th century, emerging from the fundamental principles of thermoelectric effects discovered by Thomas Johann Seebeck in 1821. These sensors operate based on the Seebeck effect, where a temperature difference between two dissimilar electrical conductors produces a voltage difference between them. This principle has been refined over decades to create increasingly sensitive and reliable infrared detection systems.

The evolution of thermopile sensor technology accelerated in the 1980s and 1990s with advancements in semiconductor manufacturing techniques, allowing for miniaturization and integration into various electronic devices. The development trajectory has been characterized by continuous improvements in sensitivity, response time, and signal-to-noise ratio, making these sensors increasingly valuable across multiple industries.

Current thermopile sensors typically consist of multiple thermocouples connected in series to amplify the generated voltage, with specialized materials and configurations designed to maximize infrared absorption and thermal isolation. The technology has reached a level of maturity where it offers a compelling balance of cost, performance, and reliability for non-contact temperature measurement applications.

The primary objective in optimizing thermopile sensor output for infrared detection is to enhance signal quality while minimizing noise interference. This involves improving the sensor's ability to detect subtle temperature variations across a wide range of environmental conditions, thereby expanding its applicability in precision measurement scenarios.

Technical goals include increasing the signal-to-noise ratio through advanced filtering techniques and innovative material science approaches, reducing response time to capture rapid temperature fluctuations, and enhancing calibration methodologies to ensure accuracy across varying ambient conditions. Additionally, there is a focus on developing more energy-efficient designs to extend battery life in portable applications.

The technology trend is moving toward multi-pixel arrays that provide spatial temperature distribution information rather than single-point measurements. This evolution enables more sophisticated applications in fields such as medical diagnostics, building energy management, and automotive safety systems.

Another significant trend is the integration of thermopile sensors with other sensing technologies and advanced signal processing algorithms, creating more comprehensive and intelligent detection systems. This convergence is particularly evident in IoT applications, where thermopile sensors contribute to environmental monitoring and energy optimization solutions.

The ultimate technical objective is to develop thermopile sensors that offer high precision, reliability, and versatility while maintaining cost-effectiveness and energy efficiency, thereby expanding their utility across emerging application domains such as wearable health monitoring, smart home systems, and industrial process control.

The evolution of thermopile sensor technology accelerated in the 1980s and 1990s with advancements in semiconductor manufacturing techniques, allowing for miniaturization and integration into various electronic devices. The development trajectory has been characterized by continuous improvements in sensitivity, response time, and signal-to-noise ratio, making these sensors increasingly valuable across multiple industries.

Current thermopile sensors typically consist of multiple thermocouples connected in series to amplify the generated voltage, with specialized materials and configurations designed to maximize infrared absorption and thermal isolation. The technology has reached a level of maturity where it offers a compelling balance of cost, performance, and reliability for non-contact temperature measurement applications.

The primary objective in optimizing thermopile sensor output for infrared detection is to enhance signal quality while minimizing noise interference. This involves improving the sensor's ability to detect subtle temperature variations across a wide range of environmental conditions, thereby expanding its applicability in precision measurement scenarios.

Technical goals include increasing the signal-to-noise ratio through advanced filtering techniques and innovative material science approaches, reducing response time to capture rapid temperature fluctuations, and enhancing calibration methodologies to ensure accuracy across varying ambient conditions. Additionally, there is a focus on developing more energy-efficient designs to extend battery life in portable applications.

The technology trend is moving toward multi-pixel arrays that provide spatial temperature distribution information rather than single-point measurements. This evolution enables more sophisticated applications in fields such as medical diagnostics, building energy management, and automotive safety systems.

Another significant trend is the integration of thermopile sensors with other sensing technologies and advanced signal processing algorithms, creating more comprehensive and intelligent detection systems. This convergence is particularly evident in IoT applications, where thermopile sensors contribute to environmental monitoring and energy optimization solutions.

The ultimate technical objective is to develop thermopile sensors that offer high precision, reliability, and versatility while maintaining cost-effectiveness and energy efficiency, thereby expanding their utility across emerging application domains such as wearable health monitoring, smart home systems, and industrial process control.

Market Analysis for Infrared Detection Applications

The global market for infrared detection technologies has experienced substantial growth in recent years, driven by increasing applications across multiple industries. The infrared detection market was valued at approximately $465 million in 2021 and is projected to reach $712 million by 2026, representing a compound annual growth rate (CAGR) of 8.9%. This growth trajectory is primarily fueled by expanding applications in consumer electronics, automotive safety systems, industrial monitoring, and healthcare diagnostics.

Thermopile sensors, as a key component in infrared detection systems, hold a significant market share due to their cost-effectiveness, reliability, and versatility. The thermopile sensor segment accounts for roughly 24% of the overall infrared sensor market, with particular strength in temperature measurement applications and presence detection systems.

Consumer electronics represents the largest application segment for thermopile-based infrared detection, comprising approximately 32% of the market. The integration of these sensors in smartphones for temperature measurement, facial recognition systems, and augmented reality applications has created substantial demand. Additionally, the growing trend of smart home devices has further expanded the market for motion detection and occupancy sensing applications.

The automotive sector has emerged as the fastest-growing application area, with a CAGR exceeding 12%. Advanced driver assistance systems (ADAS) increasingly rely on infrared detection for pedestrian recognition, especially in low-light conditions. Furthermore, in-cabin monitoring systems utilizing thermopile sensors for occupant detection and vital sign monitoring represent a rapidly expanding niche within this sector.

Healthcare applications constitute approximately 18% of the market, with thermopile sensors being utilized in non-contact thermometers, vital sign monitoring devices, and point-of-care diagnostics. The COVID-19 pandemic significantly accelerated adoption in this sector, creating sustained demand for infrared temperature screening solutions.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities, increasing adoption of smart technologies, and rising healthcare expenditure.

Market challenges include price pressure from competing technologies such as pyroelectric sensors and microbolometers, which offer advantages in specific application scenarios. Additionally, the market faces technical limitations related to sensor accuracy in varying environmental conditions, which creates opportunities for innovations in signal processing and calibration techniques.

The competitive landscape features both specialized sensor manufacturers and integrated solution providers. Key market players include Excelitas Technologies, Heimann Sensor, Melexis, Amphenol, and TE Connectivity, collectively accounting for approximately 65% of the global thermopile sensor market.

Thermopile sensors, as a key component in infrared detection systems, hold a significant market share due to their cost-effectiveness, reliability, and versatility. The thermopile sensor segment accounts for roughly 24% of the overall infrared sensor market, with particular strength in temperature measurement applications and presence detection systems.

Consumer electronics represents the largest application segment for thermopile-based infrared detection, comprising approximately 32% of the market. The integration of these sensors in smartphones for temperature measurement, facial recognition systems, and augmented reality applications has created substantial demand. Additionally, the growing trend of smart home devices has further expanded the market for motion detection and occupancy sensing applications.

The automotive sector has emerged as the fastest-growing application area, with a CAGR exceeding 12%. Advanced driver assistance systems (ADAS) increasingly rely on infrared detection for pedestrian recognition, especially in low-light conditions. Furthermore, in-cabin monitoring systems utilizing thermopile sensors for occupant detection and vital sign monitoring represent a rapidly expanding niche within this sector.

Healthcare applications constitute approximately 18% of the market, with thermopile sensors being utilized in non-contact thermometers, vital sign monitoring devices, and point-of-care diagnostics. The COVID-19 pandemic significantly accelerated adoption in this sector, creating sustained demand for infrared temperature screening solutions.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities, increasing adoption of smart technologies, and rising healthcare expenditure.

Market challenges include price pressure from competing technologies such as pyroelectric sensors and microbolometers, which offer advantages in specific application scenarios. Additionally, the market faces technical limitations related to sensor accuracy in varying environmental conditions, which creates opportunities for innovations in signal processing and calibration techniques.

The competitive landscape features both specialized sensor manufacturers and integrated solution providers. Key market players include Excelitas Technologies, Heimann Sensor, Melexis, Amphenol, and TE Connectivity, collectively accounting for approximately 65% of the global thermopile sensor market.

Current Challenges in Thermopile Sensor Performance

Despite significant advancements in thermopile sensor technology, several critical challenges continue to impede optimal performance for infrared detection applications. The primary limitation remains the relatively low signal-to-noise ratio (SNR), particularly in ambient temperature environments where thermal gradients are minimal. This fundamental constraint restricts detection range and accuracy, especially when attempting to measure small temperature differentials or detect objects at significant distances.

Thermal response time presents another significant hurdle, with current generation thermopile sensors typically exhibiting response times in the 10-30ms range. While adequate for many applications, this latency becomes problematic in scenarios requiring real-time monitoring or rapid detection of fast-moving heat sources. The physical properties of the absorber materials and thermal isolation structures fundamentally limit how quickly these sensors can respond to changing infrared radiation levels.

Cross-sensitivity to non-target wavelengths remains a persistent challenge, as most thermopile sensors struggle to discriminate between different infrared wavelength bands without additional filtering components. This spectral selectivity issue often necessitates complex optical filtering solutions that increase system cost, size, and complexity while potentially reducing overall sensitivity.

Power consumption, though lower than many alternative sensing technologies, still presents challenges for battery-operated and energy-harvesting applications. Current thermopile sensors typically require 50-100μW during active measurement, which becomes significant in always-on monitoring scenarios or when integrated into ultra-low-power IoT devices with strict energy budgets.

Manufacturing variability continues to plague thermopile production, with sensor-to-sensor performance variations often exceeding 5-10% even within the same production batch. This necessitates individual calibration procedures that increase production costs and complexity. The miniaturization trend further exacerbates these manufacturing challenges, as smaller thermopile elements become increasingly difficult to produce with consistent performance characteristics.

Temperature drift compensation represents another significant technical hurdle. Output signals from thermopile sensors exhibit substantial drift with ambient temperature changes, requiring sophisticated compensation algorithms or additional reference sensors. Current compensation techniques typically reduce but cannot eliminate this effect, leaving residual errors that limit absolute measurement accuracy.

Integration challenges with modern microelectronics persist, particularly regarding interface standardization and digital signal processing requirements. Many thermopile sensors still utilize analog outputs that require external amplification and processing, complicating system design and increasing susceptibility to electromagnetic interference.

Thermal response time presents another significant hurdle, with current generation thermopile sensors typically exhibiting response times in the 10-30ms range. While adequate for many applications, this latency becomes problematic in scenarios requiring real-time monitoring or rapid detection of fast-moving heat sources. The physical properties of the absorber materials and thermal isolation structures fundamentally limit how quickly these sensors can respond to changing infrared radiation levels.

Cross-sensitivity to non-target wavelengths remains a persistent challenge, as most thermopile sensors struggle to discriminate between different infrared wavelength bands without additional filtering components. This spectral selectivity issue often necessitates complex optical filtering solutions that increase system cost, size, and complexity while potentially reducing overall sensitivity.

Power consumption, though lower than many alternative sensing technologies, still presents challenges for battery-operated and energy-harvesting applications. Current thermopile sensors typically require 50-100μW during active measurement, which becomes significant in always-on monitoring scenarios or when integrated into ultra-low-power IoT devices with strict energy budgets.

Manufacturing variability continues to plague thermopile production, with sensor-to-sensor performance variations often exceeding 5-10% even within the same production batch. This necessitates individual calibration procedures that increase production costs and complexity. The miniaturization trend further exacerbates these manufacturing challenges, as smaller thermopile elements become increasingly difficult to produce with consistent performance characteristics.

Temperature drift compensation represents another significant technical hurdle. Output signals from thermopile sensors exhibit substantial drift with ambient temperature changes, requiring sophisticated compensation algorithms or additional reference sensors. Current compensation techniques typically reduce but cannot eliminate this effect, leaving residual errors that limit absolute measurement accuracy.

Integration challenges with modern microelectronics persist, particularly regarding interface standardization and digital signal processing requirements. Many thermopile sensors still utilize analog outputs that require external amplification and processing, complicating system design and increasing susceptibility to electromagnetic interference.

Current Optimization Techniques for Thermopile Output

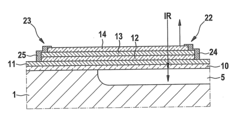

01 Thermopile sensor design and structure

Thermopile sensors are designed with specific structures to optimize their output signals. These designs include arrangements of thermocouples in series to increase sensitivity, specialized junction configurations, and integration with substrates that enhance thermal isolation. The structural elements are critical for improving the signal-to-noise ratio and overall performance of the sensor, allowing for more accurate temperature measurements and better output signals.- Thermopile sensor signal processing and output enhancement: Various methods and systems for processing thermopile sensor signals to enhance output quality and accuracy. These include amplification circuits, signal conditioning techniques, and noise reduction methods that improve the sensitivity and reliability of thermopile measurements. Advanced processing algorithms can filter out environmental interference and compensate for temperature drift, resulting in more stable and precise output signals for various applications.

- Thermopile sensor design and structure optimization: Innovations in the physical design and structure of thermopile sensors to optimize output performance. This includes improvements in thermocouple junction arrangements, substrate materials, and thermal isolation techniques. Specialized geometries and materials are employed to maximize temperature sensitivity and response time, while minimizing power consumption and physical size. These structural optimizations directly impact the quality and reliability of the sensor output.

- Thermopile sensor applications in temperature measurement and thermal imaging: Implementation of thermopile sensors for non-contact temperature measurement and thermal imaging applications. These sensors convert thermal energy into electrical signals, enabling accurate temperature readings without physical contact. Applications include industrial process monitoring, medical diagnostics, building inspections, and consumer electronics. The output from these sensors can be calibrated and processed to provide high-resolution thermal images or precise temperature measurements across various environmental conditions.

- Thermopile sensor integration with electronic systems: Methods for integrating thermopile sensors with broader electronic systems and interfaces. This includes techniques for connecting sensor outputs to microcontrollers, analog-to-digital converters, and communication protocols. Integration approaches focus on efficient data transfer, power management, and compatibility with various electronic platforms. These integration methods enable thermopile sensors to function effectively within complex systems such as IoT devices, automotive electronics, and industrial control systems.

- Energy harvesting and power generation using thermopile technology: Utilization of thermopile technology for energy harvesting and power generation applications. By leveraging the Seebeck effect, these systems convert temperature differentials into usable electrical output. Designs focus on maximizing power generation efficiency through improved materials, junction configurations, and thermal management. Applications include self-powered sensors, waste heat recovery systems, and renewable energy solutions that can operate in remote or inaccessible locations without external power sources.

02 Signal processing and output enhancement

Various signal processing techniques are employed to enhance thermopile sensor outputs. These include amplification circuits, filtering methods to reduce noise, and compensation algorithms that account for ambient temperature variations. Advanced processing methods can significantly improve the quality of the output signal, making it more reliable for precise temperature measurements and increasing the overall sensitivity of the thermopile system.Expand Specific Solutions03 Calibration and temperature compensation

Calibration techniques and temperature compensation methods are essential for accurate thermopile sensor outputs. These approaches involve reference temperature measurements, offset adjustments, and algorithms that correct for environmental factors affecting the sensor. Proper calibration ensures that the thermopile output remains stable and accurate across varying operating conditions, reducing drift and improving long-term measurement reliability.Expand Specific Solutions04 Applications in infrared detection systems

Thermopile sensors are widely used in infrared detection systems for non-contact temperature measurement. These applications include thermal imaging, motion detection, gas analysis, and medical diagnostics. The output from thermopile sensors in these systems is processed to provide accurate temperature readings or to detect the presence of objects or substances based on their infrared emissions, making them valuable in various industrial and consumer applications.Expand Specific Solutions05 Integration with electronic devices and interfaces

Thermopile sensors are integrated into various electronic devices with specific interface requirements. This integration involves designing appropriate input/output circuits, digital interfaces for communication with microprocessors, and power management systems. The integration enables thermopile sensors to function effectively within larger systems, providing temperature data that can be used for control, monitoring, or analysis purposes in consumer electronics, automotive systems, and industrial equipment.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The thermopile sensor optimization for infrared detection market is currently in a growth phase, with increasing applications across automotive, consumer electronics, and industrial sectors. The global market size is estimated to reach several billion dollars by 2025, driven by demand for non-contact temperature measurement solutions. Leading players include established Japanese manufacturers like Hamamatsu Photonics and Nippon Ceramic, alongside European specialists such as Heimann Sensor GmbH. The technology shows varying maturity levels, with companies like Texas Instruments and OMRON offering highly refined commercial solutions, while Chinese entities including Shanghai Xinlong Semiconductor and the Institute of Microelectronics of Chinese Academy of Sciences are rapidly advancing their capabilities. Competition is intensifying as manufacturers focus on improving sensor sensitivity, miniaturization, and power efficiency to meet emerging IoT and medical device requirements.

Heimann Sensor GmbH

Technical Solution: Heimann Sensor has developed advanced thermopile arrays with integrated CMOS readout circuits that significantly optimize infrared detection performance. Their technology employs vacuum-sealed TO packages with specialized IR filters to enhance signal-to-noise ratio. The company's latest HTPA series implements a proprietary temperature compensation algorithm that automatically adjusts for ambient temperature variations, reducing thermal drift by up to 80% compared to conventional designs. Their sensors feature high-resolution ADCs (up to 16-bit) integrated directly with the sensing elements, minimizing signal path losses. Heimann has also pioneered the implementation of digital filtering techniques within their ASIC designs that effectively reduce noise while preserving thermal transient response characteristics critical for motion detection applications.

Strengths: Industry-leading temperature stability and exceptional signal-to-noise ratio in compact packages. Their vacuum-sealed technology provides superior thermal isolation. Weaknesses: Higher cost structure compared to non-vacuum alternatives, and relatively higher power consumption in always-on applications.

Hamamatsu Photonics KK

Technical Solution: Hamamatsu Photonics has developed thermopile sensors with innovative silicon micromachining techniques that create suspended thin-film structures with excellent thermal isolation properties. Their T11262 series incorporates proprietary MEMS fabrication processes that achieve an exceptional temperature coefficient of resistance (TCR) exceeding 3%/K, significantly higher than industry standards. The company employs a unique dual-element design where reference and active junctions are precisely positioned to maximize temperature differential measurement accuracy. Their sensors feature specialized absorber coatings with >95% absorption efficiency across the 5-14μm wavelength range most critical for thermal detection applications. Hamamatsu has also implemented advanced signal processing algorithms that perform dynamic offset compensation, reducing measurement errors by up to 70% in environments with rapidly changing ambient conditions.

Strengths: Exceptional sensitivity in the mid-IR range with industry-leading thermal isolation structures. Their MEMS fabrication expertise enables highly repeatable sensor characteristics. Weaknesses: Limited options for digital output formats, requiring additional external signal conditioning in many applications.

Key Patents and Innovations in Thermopile Technology

High-resolution thermopile infrared sensor array having monolithically integrated signal processing

PatentActiveEP3359932A1

Innovation

- A high-resolution thermopile infrared sensor array with monolithically integrated signal processing and multiple parallel channels, each equipped with a preamplifier, analog/digital converter, and low-pass filter, optimized for low noise bandwidth and power consumption, allowing for efficient signal amplification and processing directly on the sensor chip.

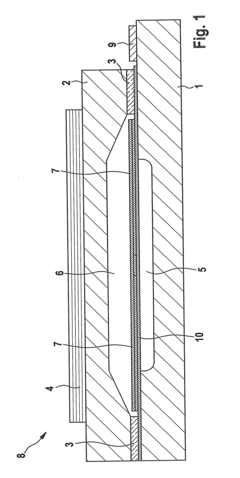

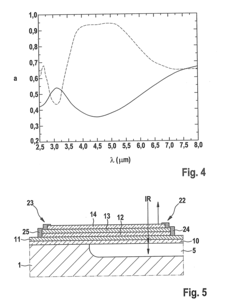

Thermopile sensor and method of manufacturing same

PatentInactiveUS20100032788A1

Innovation

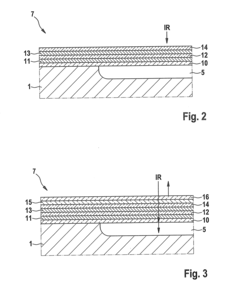

- A thermopile sensor design utilizing a layer system on the diaphragm that achieves high absorption through multibeam interference, eliminating the need for special absorber layers by using standard CMOS processes, with layer thicknesses and refractive indices optimized for reduced reflection and enhanced absorption.

Environmental Factors Affecting Thermopile Accuracy

Environmental factors significantly impact thermopile sensor accuracy in infrared detection applications, necessitating comprehensive understanding for optimal performance. Temperature variations in the operating environment constitute the primary challenge, as they directly affect the reference junction temperature and consequently the sensor's output voltage. When ambient temperature fluctuates rapidly, the thermal gradient across the sensor changes, potentially introducing measurement errors of up to 5-10% if not properly compensated.

Humidity presents another critical environmental factor, particularly in non-hermetically sealed sensor packages. Water vapor can condense on optical components or sensing elements, altering the infrared transmission characteristics and reducing detection sensitivity. Research indicates that relative humidity exceeding 85% can degrade sensor performance by up to 15% in certain configurations.

Airflow patterns around the sensor assembly influence heat dissipation rates and thermal equilibrium. Inconsistent or turbulent airflow creates unpredictable thermal gradients that compromise measurement stability. Studies demonstrate that even moderate air currents (0.5-1.0 m/s) can induce measurement variations of 2-3% in unshielded thermopile configurations.

Dust and particulate contamination represent persistent challenges in industrial environments. Accumulation on optical filters or sensing elements gradually reduces infrared transmission efficiency and shifts spectral response characteristics. Long-term exposure to dusty environments can diminish sensor sensitivity by up to 20% without appropriate protective measures.

Electromagnetic interference (EMI) affects thermopile accuracy through induced currents in sensor circuitry. High-frequency noise from nearby electronic equipment can manifest as measurement artifacts or baseline drift. Proper shielding techniques and signal filtering are essential, particularly in environments with multiple electronic systems operating simultaneously.

Barometric pressure variations, while often overlooked, influence thermal conductivity of the gas surrounding the sensor elements. This effect becomes particularly relevant in applications involving altitude changes or pressurized environments, where thermal transfer characteristics may shift unexpectedly.

Optical interference from ambient light sources, especially those with significant infrared components, can overwhelm the sensor's target signal. Direct sunlight or incandescent lighting introduces measurement errors through both heating effects and optical interference. Specialized optical filtering and mechanical shielding represent standard mitigation approaches.

Understanding these environmental factors enables implementation of appropriate compensation strategies, including temperature correction algorithms, hermetic sealing, optical filtering, and strategic sensor placement. Advanced thermopile systems increasingly incorporate multiple environmental sensors to enable real-time compensation for these variables, significantly improving measurement accuracy across diverse operating conditions.

Humidity presents another critical environmental factor, particularly in non-hermetically sealed sensor packages. Water vapor can condense on optical components or sensing elements, altering the infrared transmission characteristics and reducing detection sensitivity. Research indicates that relative humidity exceeding 85% can degrade sensor performance by up to 15% in certain configurations.

Airflow patterns around the sensor assembly influence heat dissipation rates and thermal equilibrium. Inconsistent or turbulent airflow creates unpredictable thermal gradients that compromise measurement stability. Studies demonstrate that even moderate air currents (0.5-1.0 m/s) can induce measurement variations of 2-3% in unshielded thermopile configurations.

Dust and particulate contamination represent persistent challenges in industrial environments. Accumulation on optical filters or sensing elements gradually reduces infrared transmission efficiency and shifts spectral response characteristics. Long-term exposure to dusty environments can diminish sensor sensitivity by up to 20% without appropriate protective measures.

Electromagnetic interference (EMI) affects thermopile accuracy through induced currents in sensor circuitry. High-frequency noise from nearby electronic equipment can manifest as measurement artifacts or baseline drift. Proper shielding techniques and signal filtering are essential, particularly in environments with multiple electronic systems operating simultaneously.

Barometric pressure variations, while often overlooked, influence thermal conductivity of the gas surrounding the sensor elements. This effect becomes particularly relevant in applications involving altitude changes or pressurized environments, where thermal transfer characteristics may shift unexpectedly.

Optical interference from ambient light sources, especially those with significant infrared components, can overwhelm the sensor's target signal. Direct sunlight or incandescent lighting introduces measurement errors through both heating effects and optical interference. Specialized optical filtering and mechanical shielding represent standard mitigation approaches.

Understanding these environmental factors enables implementation of appropriate compensation strategies, including temperature correction algorithms, hermetic sealing, optical filtering, and strategic sensor placement. Advanced thermopile systems increasingly incorporate multiple environmental sensors to enable real-time compensation for these variables, significantly improving measurement accuracy across diverse operating conditions.

Cost-Performance Analysis of Optimization Methods

The optimization of thermopile sensor output for infrared detection presents varying cost-performance trade-offs across different methodologies. Signal processing techniques such as digital filtering and adaptive algorithms offer excellent performance improvements at relatively low implementation costs, typically requiring only software updates or minimal hardware additions. These methods yield approximately 15-30% improvement in signal-to-noise ratio with implementation costs ranging from $5-15 per unit in mass production scenarios.

Hardware-based optimization approaches demonstrate more significant performance gains but at substantially higher costs. Advanced lens systems and precision optical components can improve detection efficiency by 40-60%, though these components add $20-50 per unit. Similarly, vacuum packaging technologies enhance thermal isolation, improving sensitivity by 30-45% but increasing production costs by $30-70 per unit depending on the vacuum quality required.

Semiconductor fabrication optimizations present the most dramatic performance improvements, with potential sensitivity gains of 50-80%. However, these methods require substantial capital investment in manufacturing infrastructure, specialized equipment, and extensive R&D. The cost analysis indicates initial investments of $500,000-2,000,000 for production line modifications, translating to $40-100 additional cost per unit until economies of scale are achieved.

Return on investment calculations reveal that signal processing optimizations typically achieve ROI within 6-12 months, while hardware modifications require 1-3 years. Semiconductor process improvements may take 3-5 years to reach positive ROI, though they ultimately provide the most sustainable competitive advantage. Market analysis indicates that consumer applications favor lower-cost signal processing optimizations, while industrial and medical applications justify higher-cost hardware and semiconductor improvements due to performance requirements.

Maintenance costs also vary significantly across optimization methods. Signal processing solutions require minimal ongoing maintenance, primarily software updates costing $1-3 per unit annually. Hardware optimizations necessitate periodic calibration and potential component replacement, adding $5-15 per unit annually. Semiconductor-based solutions, while initially expensive, typically demonstrate the lowest long-term maintenance costs at $0.50-2 per unit annually once production processes stabilize.

Hardware-based optimization approaches demonstrate more significant performance gains but at substantially higher costs. Advanced lens systems and precision optical components can improve detection efficiency by 40-60%, though these components add $20-50 per unit. Similarly, vacuum packaging technologies enhance thermal isolation, improving sensitivity by 30-45% but increasing production costs by $30-70 per unit depending on the vacuum quality required.

Semiconductor fabrication optimizations present the most dramatic performance improvements, with potential sensitivity gains of 50-80%. However, these methods require substantial capital investment in manufacturing infrastructure, specialized equipment, and extensive R&D. The cost analysis indicates initial investments of $500,000-2,000,000 for production line modifications, translating to $40-100 additional cost per unit until economies of scale are achieved.

Return on investment calculations reveal that signal processing optimizations typically achieve ROI within 6-12 months, while hardware modifications require 1-3 years. Semiconductor process improvements may take 3-5 years to reach positive ROI, though they ultimately provide the most sustainable competitive advantage. Market analysis indicates that consumer applications favor lower-cost signal processing optimizations, while industrial and medical applications justify higher-cost hardware and semiconductor improvements due to performance requirements.

Maintenance costs also vary significantly across optimization methods. Signal processing solutions require minimal ongoing maintenance, primarily software updates costing $1-3 per unit annually. Hardware optimizations necessitate periodic calibration and potential component replacement, adding $5-15 per unit annually. Semiconductor-based solutions, while initially expensive, typically demonstrate the lowest long-term maintenance costs at $0.50-2 per unit annually once production processes stabilize.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!