Thermopile Vs Photovoltaic: Efficiency in Energy Harvesting

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile and Photovoltaic Energy Harvesting Background

Energy harvesting technologies have evolved significantly over the past decades, with thermopile and photovoltaic systems emerging as two prominent approaches for converting ambient energy into usable electrical power. These technologies represent different methodologies for energy conversion, each with distinct historical development paths and underlying physical principles.

Thermopile technology traces its roots to the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821. This phenomenon describes how temperature differences between two dissimilar electrical conductors can produce a voltage difference. The practical implementation of this effect led to the development of thermopiles, which consist of multiple thermocouples connected in series to enhance voltage output.

Photovoltaic technology, conversely, is based on the photoelectric effect first observed by Alexandre Edmond Becquerel in 1839. However, significant progress in this field only occurred in the mid-20th century with the development of silicon-based solar cells at Bell Laboratories in 1954. This breakthrough marked the beginning of modern photovoltaic technology.

Both technologies have undergone substantial refinement over time. Thermopile development has focused on improving thermoelectric materials to enhance the Seebeck coefficient and reduce thermal conductivity, thereby increasing conversion efficiency. Notable advances include the introduction of bismuth telluride compounds in the 1950s and more recent developments in nanostructured materials and quantum well structures.

Photovoltaic technology has seen even more dramatic improvements, evolving from early silicon cells with efficiencies below 6% to modern multi-junction cells exceeding 40% efficiency under concentrated sunlight. The development trajectory has included crystalline silicon cells, thin-film technologies, and emerging technologies like perovskite solar cells.

The fundamental operating principles of these technologies differ significantly. Thermopiles generate electricity based on temperature gradients, converting thermal energy directly into electrical energy without moving parts. This makes them particularly valuable in environments with significant temperature differentials or waste heat sources.

Photovoltaic systems, meanwhile, directly convert photon energy from light sources (primarily sunlight) into electricity through the photovoltaic effect in semiconductor materials. This process is dependent on light intensity and spectral characteristics rather than temperature differences.

The evolution of both technologies has been driven by increasing global demand for sustainable energy solutions and the need for power sources in remote or off-grid applications. Recent technological trends have focused on improving efficiency, reducing costs, and expanding the range of applications for both thermopile and photovoltaic energy harvesting systems.

Thermopile technology traces its roots to the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821. This phenomenon describes how temperature differences between two dissimilar electrical conductors can produce a voltage difference. The practical implementation of this effect led to the development of thermopiles, which consist of multiple thermocouples connected in series to enhance voltage output.

Photovoltaic technology, conversely, is based on the photoelectric effect first observed by Alexandre Edmond Becquerel in 1839. However, significant progress in this field only occurred in the mid-20th century with the development of silicon-based solar cells at Bell Laboratories in 1954. This breakthrough marked the beginning of modern photovoltaic technology.

Both technologies have undergone substantial refinement over time. Thermopile development has focused on improving thermoelectric materials to enhance the Seebeck coefficient and reduce thermal conductivity, thereby increasing conversion efficiency. Notable advances include the introduction of bismuth telluride compounds in the 1950s and more recent developments in nanostructured materials and quantum well structures.

Photovoltaic technology has seen even more dramatic improvements, evolving from early silicon cells with efficiencies below 6% to modern multi-junction cells exceeding 40% efficiency under concentrated sunlight. The development trajectory has included crystalline silicon cells, thin-film technologies, and emerging technologies like perovskite solar cells.

The fundamental operating principles of these technologies differ significantly. Thermopiles generate electricity based on temperature gradients, converting thermal energy directly into electrical energy without moving parts. This makes them particularly valuable in environments with significant temperature differentials or waste heat sources.

Photovoltaic systems, meanwhile, directly convert photon energy from light sources (primarily sunlight) into electricity through the photovoltaic effect in semiconductor materials. This process is dependent on light intensity and spectral characteristics rather than temperature differences.

The evolution of both technologies has been driven by increasing global demand for sustainable energy solutions and the need for power sources in remote or off-grid applications. Recent technological trends have focused on improving efficiency, reducing costs, and expanding the range of applications for both thermopile and photovoltaic energy harvesting systems.

Market Analysis for Energy Harvesting Technologies

The global energy harvesting market is experiencing robust growth, projected to reach $1.3 billion by 2027, with a compound annual growth rate of approximately 8.4% from 2022. This expansion is primarily driven by increasing demand for sustainable energy solutions, the proliferation of IoT devices requiring autonomous power sources, and growing environmental concerns regarding traditional energy generation methods.

Within this landscape, thermopile and photovoltaic technologies represent two distinct approaches to energy harvesting with varying market penetration and application domains. Photovoltaic technology currently dominates the energy harvesting market, accounting for roughly 65% of market share due to its established manufacturing infrastructure, decreasing production costs, and relatively high efficiency rates in direct sunlight conditions.

Thermopile technology, while occupying a smaller market segment at approximately 12%, is witnessing accelerated growth in specific applications where temperature differentials are readily available. The industrial sector represents the largest market for thermopile-based energy harvesting, particularly in manufacturing environments where waste heat is abundant.

Consumer electronics constitute another rapidly expanding market segment for both technologies, with wearable devices, smart home systems, and portable electronics increasingly incorporating energy harvesting components to extend battery life or enable completely battery-free operation. This segment is expected to grow at 11.2% annually through 2027.

Geographically, North America and Europe lead in adoption of advanced energy harvesting technologies, collectively representing 58% of the global market. However, Asia-Pacific regions are demonstrating the fastest growth rates, particularly in countries with expanding manufacturing sectors such as China, South Korea, and India.

Market barriers include initial implementation costs, efficiency limitations in real-world conditions, and integration challenges with existing systems. For photovoltaic technology specifically, market penetration faces obstacles in environments with limited light exposure, while thermopile solutions struggle with size constraints and lower power density compared to competing technologies.

Emerging market opportunities include building-integrated energy harvesting systems, automotive applications for both technologies, and hybrid systems that combine multiple harvesting methods to maximize energy capture across varying environmental conditions. The transportation sector in particular represents a high-potential growth area, with an estimated market value of $210 million by 2026.

Customer demand increasingly favors solutions offering higher energy conversion efficiency, smaller form factors, and greater durability, with particular emphasis on technologies that can operate effectively in diverse environmental conditions rather than controlled laboratory settings.

Within this landscape, thermopile and photovoltaic technologies represent two distinct approaches to energy harvesting with varying market penetration and application domains. Photovoltaic technology currently dominates the energy harvesting market, accounting for roughly 65% of market share due to its established manufacturing infrastructure, decreasing production costs, and relatively high efficiency rates in direct sunlight conditions.

Thermopile technology, while occupying a smaller market segment at approximately 12%, is witnessing accelerated growth in specific applications where temperature differentials are readily available. The industrial sector represents the largest market for thermopile-based energy harvesting, particularly in manufacturing environments where waste heat is abundant.

Consumer electronics constitute another rapidly expanding market segment for both technologies, with wearable devices, smart home systems, and portable electronics increasingly incorporating energy harvesting components to extend battery life or enable completely battery-free operation. This segment is expected to grow at 11.2% annually through 2027.

Geographically, North America and Europe lead in adoption of advanced energy harvesting technologies, collectively representing 58% of the global market. However, Asia-Pacific regions are demonstrating the fastest growth rates, particularly in countries with expanding manufacturing sectors such as China, South Korea, and India.

Market barriers include initial implementation costs, efficiency limitations in real-world conditions, and integration challenges with existing systems. For photovoltaic technology specifically, market penetration faces obstacles in environments with limited light exposure, while thermopile solutions struggle with size constraints and lower power density compared to competing technologies.

Emerging market opportunities include building-integrated energy harvesting systems, automotive applications for both technologies, and hybrid systems that combine multiple harvesting methods to maximize energy capture across varying environmental conditions. The transportation sector in particular represents a high-potential growth area, with an estimated market value of $210 million by 2026.

Customer demand increasingly favors solutions offering higher energy conversion efficiency, smaller form factors, and greater durability, with particular emphasis on technologies that can operate effectively in diverse environmental conditions rather than controlled laboratory settings.

Current Technical Limitations and Challenges

Despite significant advancements in both thermopile and photovoltaic technologies for energy harvesting, several technical limitations and challenges persist that impact their efficiency and widespread adoption. These challenges vary between the two technologies and significantly influence their performance in different application scenarios.

Thermopile technology faces fundamental efficiency constraints due to the Carnot limit, which theoretically caps conversion efficiency based on temperature differentials. In practical applications, thermopiles typically achieve only 5-8% efficiency, with state-of-the-art systems rarely exceeding 10%. This low efficiency becomes particularly problematic in environments with minimal temperature gradients, severely limiting energy output.

Material limitations further constrain thermopile development, as the Seebeck coefficients of commercially viable materials remain suboptimal. Current thermoelectric materials like bismuth telluride and lead telluride present challenges including toxicity, scarcity, and high production costs, hampering large-scale implementation. Additionally, these materials often exhibit poor performance at extreme temperatures, restricting their operational range.

Photovoltaic technology, while generally more efficient than thermopiles, confronts its own set of challenges. Traditional silicon-based PV cells have theoretical efficiency limits of approximately 33% (Shockley-Queisser limit), with commercial modules typically achieving only 15-22% efficiency. This limitation stems from fundamental physical constraints including spectral losses, recombination losses, and reflection losses.

Environmental factors significantly impact photovoltaic performance, with efficiency degrading under non-optimal conditions such as partial shading, dust accumulation, and temperature variations. Most silicon PV cells experience a 0.3-0.5% efficiency reduction per degree Celsius above standard testing conditions, creating substantial performance gaps between laboratory and real-world environments.

Durability and lifespan issues affect both technologies. Thermopiles suffer from thermal cycling fatigue and material degradation at interface junctions, while photovoltaics experience light-induced degradation and encapsulation breakdown over time. These reliability concerns directly impact the long-term economic viability of both energy harvesting approaches.

Scale-dependent challenges also exist, with thermopiles struggling to maintain efficiency when scaled up to industrial levels, and photovoltaics facing manufacturing complexity and increased defect rates at larger production volumes. The integration of either technology into existing energy infrastructure presents additional technical hurdles related to power conditioning, storage solutions, and grid compatibility.

Recent research indicates that hybrid systems combining both technologies might overcome some individual limitations, but integration challenges and cost considerations have thus far limited commercial implementation of such approaches. The development of more efficient, cost-effective materials and manufacturing processes remains a critical research priority for both technologies.

Thermopile technology faces fundamental efficiency constraints due to the Carnot limit, which theoretically caps conversion efficiency based on temperature differentials. In practical applications, thermopiles typically achieve only 5-8% efficiency, with state-of-the-art systems rarely exceeding 10%. This low efficiency becomes particularly problematic in environments with minimal temperature gradients, severely limiting energy output.

Material limitations further constrain thermopile development, as the Seebeck coefficients of commercially viable materials remain suboptimal. Current thermoelectric materials like bismuth telluride and lead telluride present challenges including toxicity, scarcity, and high production costs, hampering large-scale implementation. Additionally, these materials often exhibit poor performance at extreme temperatures, restricting their operational range.

Photovoltaic technology, while generally more efficient than thermopiles, confronts its own set of challenges. Traditional silicon-based PV cells have theoretical efficiency limits of approximately 33% (Shockley-Queisser limit), with commercial modules typically achieving only 15-22% efficiency. This limitation stems from fundamental physical constraints including spectral losses, recombination losses, and reflection losses.

Environmental factors significantly impact photovoltaic performance, with efficiency degrading under non-optimal conditions such as partial shading, dust accumulation, and temperature variations. Most silicon PV cells experience a 0.3-0.5% efficiency reduction per degree Celsius above standard testing conditions, creating substantial performance gaps between laboratory and real-world environments.

Durability and lifespan issues affect both technologies. Thermopiles suffer from thermal cycling fatigue and material degradation at interface junctions, while photovoltaics experience light-induced degradation and encapsulation breakdown over time. These reliability concerns directly impact the long-term economic viability of both energy harvesting approaches.

Scale-dependent challenges also exist, with thermopiles struggling to maintain efficiency when scaled up to industrial levels, and photovoltaics facing manufacturing complexity and increased defect rates at larger production volumes. The integration of either technology into existing energy infrastructure presents additional technical hurdles related to power conditioning, storage solutions, and grid compatibility.

Recent research indicates that hybrid systems combining both technologies might overcome some individual limitations, but integration challenges and cost considerations have thus far limited commercial implementation of such approaches. The development of more efficient, cost-effective materials and manufacturing processes remains a critical research priority for both technologies.

Comparative Analysis of Thermopile and Photovoltaic Solutions

01 Thermopile efficiency improvements

Thermopile technology efficiency can be enhanced through various design modifications and material selections. These improvements include optimizing the thermoelectric materials, increasing the temperature gradient across the thermopile junctions, and reducing thermal losses. Advanced junction designs and novel semiconductor materials with higher Seebeck coefficients contribute to better conversion of thermal energy to electrical energy, resulting in higher overall efficiency of thermopile-based energy harvesting systems.- Efficiency improvements in thermopile technology: Thermopile technology efficiency can be enhanced through various design improvements and material selections. These include optimizing the thermoelectric materials, improving thermal gradient management, and enhancing the junction quality between different materials. Advanced manufacturing techniques can reduce internal resistance and increase power output. Some designs incorporate specialized heat collectors and insulators to maximize temperature differentials across the thermopile elements.

- Photovoltaic cell efficiency enhancements: Photovoltaic technology efficiency can be improved through various approaches including advanced semiconductor materials, multi-junction cell designs, and surface treatments. Innovations in electron transport layers, light-trapping structures, and anti-reflection coatings help maximize light absorption and conversion. Novel doping techniques and band gap engineering allow for broader spectrum utilization, while reducing recombination losses contributes to higher overall efficiency in solar energy conversion.

- Hybrid thermopile-photovoltaic systems: Hybrid systems combining thermopile and photovoltaic technologies can achieve higher overall efficiency by utilizing different portions of the solar spectrum. These integrated designs allow photovoltaic cells to convert visible light while thermopiles harvest waste heat or infrared radiation. Such complementary approaches enable more complete energy harvesting from incident solar radiation. Some designs incorporate specialized heat management systems to optimize the operating temperature of both technologies simultaneously.

- Measurement and testing methods for efficiency evaluation: Advanced measurement and testing methodologies are crucial for accurately evaluating the efficiency of both thermopile and photovoltaic technologies. These include standardized testing protocols under controlled conditions, real-time monitoring systems, and specialized equipment for characterizing performance parameters. Techniques such as quantum efficiency measurements, thermal imaging, and accelerated lifetime testing help identify efficiency limitations and validate improvement strategies. Computer modeling and simulation tools support the optimization process.

- Environmental and operational factors affecting efficiency: Environmental and operational conditions significantly impact the efficiency of both thermopile and photovoltaic technologies. Factors such as ambient temperature, solar irradiance levels, humidity, and dust accumulation can affect performance. Advanced systems incorporate adaptive controls, tracking mechanisms, cooling systems, and self-cleaning surfaces to maintain optimal efficiency under varying conditions. Some designs include specialized encapsulation and protective measures to extend operational lifetime and maintain efficiency over extended periods.

02 Photovoltaic cell efficiency enhancements

Photovoltaic technology efficiency can be improved through various approaches including advanced cell architectures, novel semiconductor materials, and surface treatments. Multi-junction designs, thin-film technologies, and concentration systems help maximize light absorption and energy conversion. Additional efficiency gains come from reducing reflection losses, improving charge carrier collection, and optimizing bandgap engineering to capture a broader spectrum of solar radiation, ultimately leading to higher conversion efficiencies in solar energy systems.Expand Specific Solutions03 Hybrid thermopile-photovoltaic systems

Hybrid systems combining thermopile and photovoltaic technologies can achieve higher overall energy conversion efficiency by utilizing different portions of the electromagnetic spectrum. While photovoltaic cells convert visible light directly to electricity, thermopiles can harvest waste heat or infrared radiation. These complementary technologies, when integrated into a single system, allow for more comprehensive energy harvesting from solar radiation, improving the total system efficiency beyond what either technology could achieve independently.Expand Specific Solutions04 Measurement and testing methods for efficiency

Accurate measurement and testing methods are crucial for determining the efficiency of thermopile and photovoltaic technologies. These methods include standardized testing protocols, specialized equipment for measuring thermal and electrical parameters, and simulation techniques to predict performance under various conditions. Advanced characterization tools enable researchers to identify loss mechanisms, optimize device parameters, and validate theoretical models, leading to continuous improvements in energy conversion efficiency.Expand Specific Solutions05 Environmental and operational factors affecting efficiency

Environmental and operational factors significantly impact the efficiency of both thermopile and photovoltaic technologies. Temperature variations, solar irradiance levels, humidity, dust accumulation, and aging all affect performance. Cooling systems, tracking mechanisms, and protective coatings can be implemented to mitigate these effects. Understanding and controlling these factors through advanced monitoring systems and adaptive operational strategies helps maintain optimal efficiency throughout the system lifecycle.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The thermopile versus photovoltaic energy harvesting landscape is currently in a growth phase, with the global energy harvesting market expected to expand significantly. While photovoltaic technology dominates with higher efficiency in direct sunlight conditions, thermopiles excel in thermal gradient environments. Leading research institutions like MIT, Texas Instruments, and Samsung Display are advancing photovoltaic efficiency, while companies such as ROHM, Hitachi, and BYD focus on thermopile innovations. Ambient Photonics and SolarEdge are pioneering low-light PV solutions, while research collaborations between universities and corporations are driving technological breakthroughs in both domains. The competition is intensifying as applications expand across IoT, consumer electronics, and renewable energy sectors.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced thermopile energy harvesting systems that utilize temperature gradients to generate electricity through the Seebeck effect. Their research focuses on thin-film thermopile arrays with nanoscale engineering to maximize power density. MIT's approach incorporates novel semiconductor materials with high Seebeck coefficients and low thermal conductivity, achieving conversion efficiencies of up to 5-7% in laboratory settings. They've pioneered multi-stage thermopile configurations that can operate effectively with temperature differentials as low as 1-2°C, making them suitable for body heat and ambient temperature harvesting. MIT researchers have also developed hybrid systems that combine thermopiles with thermal concentration mechanisms to enhance energy capture from low-grade heat sources.

Strengths: Superior performance in low temperature differential environments; excellent durability with no moving parts; ability to harvest energy continuously regardless of lighting conditions. Weaknesses: Lower overall efficiency compared to photovoltaics in direct sunlight; requires constant temperature differential; higher manufacturing complexity for high-performance thin-film implementations.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed comprehensive energy harvesting solutions incorporating both thermopile and photovoltaic technologies with specialized power management integrated circuits (PMICs). Their thermopile implementation utilizes proprietary semiconductor materials optimized for thermal energy conversion in consumer and industrial applications. TI's BQ25570 and BQ25505 ultra-low-power harvesting chips are specifically designed to operate with thermopile inputs as low as 100mV, employing maximum power point tracking (MPPT) algorithms tailored for thermal gradients. For photovoltaic harvesting, TI has created specialized boost converters with 90%+ efficiency even at sub-microwatt input levels. Their integrated approach combines harvesting technology with ultra-low-power microcontrollers and sensors, enabling complete self-powered systems that can operate perpetually from ambient energy sources.

Strengths: Industry-leading power management efficiency for both technologies; comprehensive system solutions including storage management; extensive deployment experience across multiple industries. Weaknesses: Relies on third-party core harvesting technologies rather than fundamental materials innovation; optimization focused primarily on electronics rather than the energy conversion elements themselves.

Critical Patents and Research in Energy Conversion Efficiency

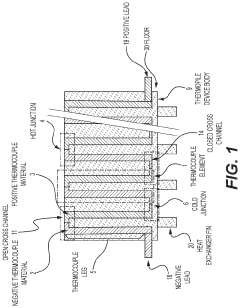

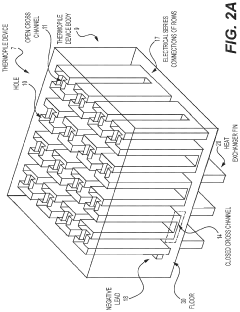

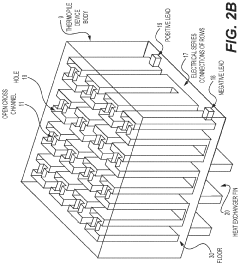

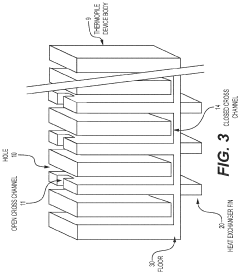

Thermopile Assembly Providing a Massive Electrical Series of Thermocouple Elements

PatentInactiveUS20200370965A1

Innovation

- A thermopile assembly using a heat-resistant, electrically-insulative container with cross-channels to form hot and cold junctions from common, stable thermocouple materials, allowing for the creation of a massive electrical series of thermocouples that can operate effectively at high temperatures through 3D printing and sintering processes.

Solar collector for converting directly heat energy into electric energy

PatentWO1979000626A1

Innovation

- A thermopile composed of series-connected thermocouples, where one contact point is heated by solar radiation and the other cooled by a fluid, leveraging thermoelectricity to generate electrical energy, with a plate collector design using quartz sand and embedded wires, and a reversible heat pump system for energy storage and conversion.

Material Science Advancements for Energy Harvesting

Recent advancements in material science have significantly transformed the landscape of energy harvesting technologies, particularly in the comparison between thermopile and photovoltaic systems. The development of novel materials with enhanced thermal and electrical properties has been pivotal in improving the efficiency of thermopile-based energy harvesters. Nanostructured materials such as bismuth telluride and antimony telluride have demonstrated superior Seebeck coefficients, enabling thermopiles to generate higher voltage outputs from smaller temperature gradients.

For photovoltaic systems, perovskite materials have emerged as game-changers, offering theoretical efficiency limits approaching those of traditional silicon-based cells but with significantly reduced production costs and material requirements. These materials exhibit exceptional light absorption properties across a broader spectrum, making them particularly effective in varied lighting conditions. Additionally, multi-junction solar cells incorporating different bandgap materials have pushed conversion efficiencies beyond 45% in laboratory settings.

Flexible substrate technologies have revolutionized both thermopile and photovoltaic applications, allowing for integration into curved surfaces and wearable devices. Polymer-based substrates with embedded conductive networks have enabled thermopiles to harvest energy from body heat more effectively, while flexible photovoltaic films can now be applied to various surfaces without compromising efficiency.

Metamaterials designed to manipulate electromagnetic waves have enhanced photovoltaic performance by trapping light within the active layer, increasing absorption rates and consequently improving energy conversion. Similarly, phononic metamaterials have been developed to control heat flow in thermopiles, optimizing temperature gradients and enhancing power generation.

Carbon-based materials, including graphene and carbon nanotubes, have demonstrated promising results in both technologies. In thermopiles, these materials offer excellent thermal conductivity with minimal electrical resistance, while in photovoltaics, they serve as transparent electrodes with superior charge transport properties. Hybrid organic-inorganic composites have also shown potential in bridging the efficiency gap between these technologies.

Self-healing materials represent another frontier, addressing the degradation issues that plague both technologies. These materials can repair microcracks and structural defects autonomously, extending operational lifetimes and maintaining performance levels over extended periods. This advancement is particularly valuable for outdoor applications where environmental stressors accelerate material degradation.

The convergence of these material science breakthroughs has narrowed the efficiency gap between thermopile and photovoltaic technologies, with each finding specialized applications based on their unique advantages. As research continues, we anticipate further innovations in material design that may eventually lead to hybrid systems capitalizing on the strengths of both approaches.

For photovoltaic systems, perovskite materials have emerged as game-changers, offering theoretical efficiency limits approaching those of traditional silicon-based cells but with significantly reduced production costs and material requirements. These materials exhibit exceptional light absorption properties across a broader spectrum, making them particularly effective in varied lighting conditions. Additionally, multi-junction solar cells incorporating different bandgap materials have pushed conversion efficiencies beyond 45% in laboratory settings.

Flexible substrate technologies have revolutionized both thermopile and photovoltaic applications, allowing for integration into curved surfaces and wearable devices. Polymer-based substrates with embedded conductive networks have enabled thermopiles to harvest energy from body heat more effectively, while flexible photovoltaic films can now be applied to various surfaces without compromising efficiency.

Metamaterials designed to manipulate electromagnetic waves have enhanced photovoltaic performance by trapping light within the active layer, increasing absorption rates and consequently improving energy conversion. Similarly, phononic metamaterials have been developed to control heat flow in thermopiles, optimizing temperature gradients and enhancing power generation.

Carbon-based materials, including graphene and carbon nanotubes, have demonstrated promising results in both technologies. In thermopiles, these materials offer excellent thermal conductivity with minimal electrical resistance, while in photovoltaics, they serve as transparent electrodes with superior charge transport properties. Hybrid organic-inorganic composites have also shown potential in bridging the efficiency gap between these technologies.

Self-healing materials represent another frontier, addressing the degradation issues that plague both technologies. These materials can repair microcracks and structural defects autonomously, extending operational lifetimes and maintaining performance levels over extended periods. This advancement is particularly valuable for outdoor applications where environmental stressors accelerate material degradation.

The convergence of these material science breakthroughs has narrowed the efficiency gap between thermopile and photovoltaic technologies, with each finding specialized applications based on their unique advantages. As research continues, we anticipate further innovations in material design that may eventually lead to hybrid systems capitalizing on the strengths of both approaches.

Environmental Impact and Sustainability Considerations

The environmental impact of energy harvesting technologies is becoming increasingly important as the world shifts towards sustainable energy solutions. When comparing thermopile and photovoltaic technologies, several key environmental considerations emerge that influence their sustainability profiles throughout their lifecycle.

Thermopile systems generally have a lower environmental footprint during manufacturing compared to photovoltaic cells. The production of thermopiles involves fewer toxic chemicals and rare earth elements, resulting in reduced extraction-related environmental damage. Additionally, thermopile manufacturing typically consumes less energy and produces fewer greenhouse gas emissions than the energy-intensive silicon purification processes required for photovoltaic cell production.

However, photovoltaic technology demonstrates superior long-term environmental benefits through higher energy conversion efficiency in most applications. This higher efficiency translates to greater energy yield over the operational lifetime, effectively offsetting the initial manufacturing environmental costs. Modern photovoltaic systems can achieve conversion efficiencies of 15-22% in commercial applications, while thermopiles typically operate at 5-8% efficiency under optimal conditions.

Both technologies contribute positively to carbon emission reduction by harvesting energy that would otherwise be wasted. Thermopiles excel in recovering waste heat from industrial processes, potentially reducing the need for additional energy generation. Photovoltaics, meanwhile, directly convert abundant solar energy without producing operational emissions, supporting decarbonization efforts across various sectors.

End-of-life considerations reveal further distinctions. Photovoltaic panels contain materials that require specialized recycling processes, including semiconductor materials and sometimes heavy metals that pose environmental risks if improperly disposed of. Current recycling rates for photovoltaic panels remain suboptimal, with only about 10% being effectively recycled globally. Thermopiles, constructed primarily from metal alloys, present fewer recycling challenges and contain materials that are more readily recoverable through existing metal recycling infrastructure.

Water usage patterns also differ significantly between these technologies. Photovoltaic manufacturing is water-intensive, requiring approximately 10-20 gallons per square meter of panel produced. Thermopiles require substantially less water during production. However, during operation, photovoltaics require minimal water (primarily for cleaning), while some thermopile applications in industrial settings may involve water-based cooling systems.

Land use impact varies by implementation context. Large-scale photovoltaic installations can occupy significant land area, potentially competing with agricultural or conservation uses. Thermopile systems, typically integrated into existing industrial infrastructure or waste heat sources, generally have minimal additional land requirements, offering advantages in densely developed environments.

Thermopile systems generally have a lower environmental footprint during manufacturing compared to photovoltaic cells. The production of thermopiles involves fewer toxic chemicals and rare earth elements, resulting in reduced extraction-related environmental damage. Additionally, thermopile manufacturing typically consumes less energy and produces fewer greenhouse gas emissions than the energy-intensive silicon purification processes required for photovoltaic cell production.

However, photovoltaic technology demonstrates superior long-term environmental benefits through higher energy conversion efficiency in most applications. This higher efficiency translates to greater energy yield over the operational lifetime, effectively offsetting the initial manufacturing environmental costs. Modern photovoltaic systems can achieve conversion efficiencies of 15-22% in commercial applications, while thermopiles typically operate at 5-8% efficiency under optimal conditions.

Both technologies contribute positively to carbon emission reduction by harvesting energy that would otherwise be wasted. Thermopiles excel in recovering waste heat from industrial processes, potentially reducing the need for additional energy generation. Photovoltaics, meanwhile, directly convert abundant solar energy without producing operational emissions, supporting decarbonization efforts across various sectors.

End-of-life considerations reveal further distinctions. Photovoltaic panels contain materials that require specialized recycling processes, including semiconductor materials and sometimes heavy metals that pose environmental risks if improperly disposed of. Current recycling rates for photovoltaic panels remain suboptimal, with only about 10% being effectively recycled globally. Thermopiles, constructed primarily from metal alloys, present fewer recycling challenges and contain materials that are more readily recoverable through existing metal recycling infrastructure.

Water usage patterns also differ significantly between these technologies. Photovoltaic manufacturing is water-intensive, requiring approximately 10-20 gallons per square meter of panel produced. Thermopiles require substantially less water during production. However, during operation, photovoltaics require minimal water (primarily for cleaning), while some thermopile applications in industrial settings may involve water-based cooling systems.

Land use impact varies by implementation context. Large-scale photovoltaic installations can occupy significant land area, potentially competing with agricultural or conservation uses. Thermopile systems, typically integrated into existing industrial infrastructure or waste heat sources, generally have minimal additional land requirements, offering advantages in densely developed environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!