Optimize Thermopile Responsiveness in Rapid Temperature Change

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Technology Background and Objectives

Thermopile sensors have evolved significantly since their inception in the early 20th century, originating from the fundamental principles of the thermoelectric effect discovered by Thomas Johann Seebeck in 1821. These sensors convert thermal energy into electrical signals through the generation of voltage when junctions of dissimilar metals experience temperature differentials. The technology has progressed from simple thermocouples to sophisticated thermopile arrays that offer enhanced sensitivity and response characteristics.

Over the past two decades, thermopile technology has experienced accelerated development driven by increasing demands in various industries including medical diagnostics, automotive applications, industrial process control, and consumer electronics. The miniaturization trend has been particularly notable, with modern thermopile sensors achieving micron-scale dimensions through advanced microfabrication techniques, enabling their integration into compact devices while maintaining high performance metrics.

The current technological trajectory focuses on optimizing thermopile responsiveness during rapid temperature fluctuations, a critical parameter that determines the sensor's ability to accurately capture dynamic thermal events. This optimization represents a significant challenge due to inherent thermal inertia and response time limitations in conventional thermopile designs. The industry is witnessing a paradigm shift from merely improving static sensitivity to enhancing dynamic response characteristics.

Recent advancements in material science have introduced novel thermoelectric materials with superior Seebeck coefficients and reduced thermal conductivity, contributing to improved signal-to-noise ratios and faster response times. Concurrently, innovations in membrane structures and thermal isolation techniques have further enhanced thermopile performance in transient temperature conditions.

The primary technical objective in this field is to develop thermopile sensors capable of maintaining measurement accuracy and precision during rapid temperature transitions without compromising other performance parameters such as power consumption, physical dimensions, and manufacturing cost. Specifically, the industry aims to achieve response times below 10 milliseconds while preserving measurement resolution better than 0.1°C across a wide operating temperature range.

Secondary objectives include enhancing long-term stability under thermal cycling conditions, improving immunity to environmental interference, and developing advanced signal processing algorithms that can compensate for inherent physical limitations of the sensing elements. These improvements would significantly expand the application scope of thermopile technology in emerging fields such as precision agriculture, advanced driver assistance systems, and next-generation medical diagnostics.

The evolution of thermopile technology continues to be driven by cross-disciplinary collaboration between materials scientists, microelectronics engineers, and thermal physics specialists, creating a rich ecosystem for innovation and technological breakthroughs in thermal sensing capabilities.

Over the past two decades, thermopile technology has experienced accelerated development driven by increasing demands in various industries including medical diagnostics, automotive applications, industrial process control, and consumer electronics. The miniaturization trend has been particularly notable, with modern thermopile sensors achieving micron-scale dimensions through advanced microfabrication techniques, enabling their integration into compact devices while maintaining high performance metrics.

The current technological trajectory focuses on optimizing thermopile responsiveness during rapid temperature fluctuations, a critical parameter that determines the sensor's ability to accurately capture dynamic thermal events. This optimization represents a significant challenge due to inherent thermal inertia and response time limitations in conventional thermopile designs. The industry is witnessing a paradigm shift from merely improving static sensitivity to enhancing dynamic response characteristics.

Recent advancements in material science have introduced novel thermoelectric materials with superior Seebeck coefficients and reduced thermal conductivity, contributing to improved signal-to-noise ratios and faster response times. Concurrently, innovations in membrane structures and thermal isolation techniques have further enhanced thermopile performance in transient temperature conditions.

The primary technical objective in this field is to develop thermopile sensors capable of maintaining measurement accuracy and precision during rapid temperature transitions without compromising other performance parameters such as power consumption, physical dimensions, and manufacturing cost. Specifically, the industry aims to achieve response times below 10 milliseconds while preserving measurement resolution better than 0.1°C across a wide operating temperature range.

Secondary objectives include enhancing long-term stability under thermal cycling conditions, improving immunity to environmental interference, and developing advanced signal processing algorithms that can compensate for inherent physical limitations of the sensing elements. These improvements would significantly expand the application scope of thermopile technology in emerging fields such as precision agriculture, advanced driver assistance systems, and next-generation medical diagnostics.

The evolution of thermopile technology continues to be driven by cross-disciplinary collaboration between materials scientists, microelectronics engineers, and thermal physics specialists, creating a rich ecosystem for innovation and technological breakthroughs in thermal sensing capabilities.

Market Analysis for Rapid Temperature Sensing Applications

The global market for rapid temperature sensing technologies is experiencing robust growth, driven primarily by increasing demands in industrial automation, healthcare diagnostics, and consumer electronics sectors. Current market valuations place the thermopile sensor market at approximately $1.2 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is particularly pronounced in applications requiring rapid temperature change detection, where traditional sensing technologies often fail to deliver adequate responsiveness.

Healthcare applications represent the largest market segment, accounting for nearly 38% of the total market share. The need for non-contact temperature measurement in clinical settings has accelerated dramatically following the COVID-19 pandemic, creating sustained demand for high-performance thermopile sensors. Industrial process monitoring follows closely at 29% market share, where rapid temperature sensing enables precise control in manufacturing processes, energy management, and quality assurance systems.

Consumer electronics applications, particularly in smart home devices and wearable technology, constitute the fastest-growing segment with a projected growth rate of 9.3% annually. This surge is attributed to increasing consumer awareness of environmental monitoring and health tracking capabilities in everyday devices. Automotive applications, representing about 15% of the market, are expanding as vehicle manufacturers incorporate more sophisticated climate control and engine management systems requiring precise temperature monitoring.

Geographically, North America and Europe currently dominate the market with combined market share exceeding 60%. However, the Asia-Pacific region is demonstrating the most aggressive growth patterns, with China and South Korea emerging as manufacturing hubs for thermopile sensor technologies. This regional shift is reshaping supply chain dynamics and creating new competitive pressures in the global marketplace.

Customer requirements across these markets consistently emphasize three critical performance metrics: response time, measurement accuracy, and signal-to-noise ratio. End-users are increasingly demanding thermopile sensors capable of detecting temperature changes within milliseconds while maintaining measurement accuracy within ±0.1°C. This performance threshold represents a significant challenge for current technologies, particularly in environments with rapid temperature fluctuations.

Price sensitivity varies considerably across application segments, with healthcare and industrial users demonstrating greater willingness to invest in premium solutions offering enhanced performance characteristics. Consumer applications remain highly price-sensitive, creating market pressure for cost-optimized solutions that maintain acceptable performance metrics while reducing manufacturing costs.

Healthcare applications represent the largest market segment, accounting for nearly 38% of the total market share. The need for non-contact temperature measurement in clinical settings has accelerated dramatically following the COVID-19 pandemic, creating sustained demand for high-performance thermopile sensors. Industrial process monitoring follows closely at 29% market share, where rapid temperature sensing enables precise control in manufacturing processes, energy management, and quality assurance systems.

Consumer electronics applications, particularly in smart home devices and wearable technology, constitute the fastest-growing segment with a projected growth rate of 9.3% annually. This surge is attributed to increasing consumer awareness of environmental monitoring and health tracking capabilities in everyday devices. Automotive applications, representing about 15% of the market, are expanding as vehicle manufacturers incorporate more sophisticated climate control and engine management systems requiring precise temperature monitoring.

Geographically, North America and Europe currently dominate the market with combined market share exceeding 60%. However, the Asia-Pacific region is demonstrating the most aggressive growth patterns, with China and South Korea emerging as manufacturing hubs for thermopile sensor technologies. This regional shift is reshaping supply chain dynamics and creating new competitive pressures in the global marketplace.

Customer requirements across these markets consistently emphasize three critical performance metrics: response time, measurement accuracy, and signal-to-noise ratio. End-users are increasingly demanding thermopile sensors capable of detecting temperature changes within milliseconds while maintaining measurement accuracy within ±0.1°C. This performance threshold represents a significant challenge for current technologies, particularly in environments with rapid temperature fluctuations.

Price sensitivity varies considerably across application segments, with healthcare and industrial users demonstrating greater willingness to invest in premium solutions offering enhanced performance characteristics. Consumer applications remain highly price-sensitive, creating market pressure for cost-optimized solutions that maintain acceptable performance metrics while reducing manufacturing costs.

Current Limitations in Thermopile Response Time

Thermopiles currently face significant response time limitations when exposed to rapid temperature changes, primarily due to their inherent thermal mass and design constraints. The typical response time of commercial thermopiles ranges from 20 to 100 milliseconds, which proves inadequate for applications requiring real-time temperature monitoring during swift thermal transitions. This limitation becomes particularly problematic in scenarios such as industrial process control, medical diagnostics, and automotive safety systems where millisecond-level responsiveness is crucial.

The fundamental physical constraint stems from the thermal inertia of the materials used in thermopile construction. Traditional thermopile sensors utilize relatively thick substrate materials and thermoelectric junctions that require time to reach thermal equilibrium with the surrounding environment. This thermal lag creates a measurable delay between actual temperature changes and sensor output signals, resulting in measurement inaccuracies during dynamic temperature events.

Another significant limitation is the signal-to-noise ratio degradation that occurs during rapid temperature transitions. As temperature changes accelerate, thermal gradients within the sensor structure become more pronounced, introducing measurement artifacts and reducing overall accuracy. Current compensation algorithms struggle to account for these non-linear effects, particularly when temperature change rates exceed 50°C per second.

Manufacturing inconsistencies further exacerbate response time limitations. Variations in junction thickness, substrate uniformity, and thermoelectric material properties create unpredictable response characteristics across production batches. This lack of standardization makes it challenging to implement universal calibration methods for improving response times across different sensor models and manufacturers.

Power consumption presents another constraint, particularly for battery-operated devices. Attempts to enhance responsiveness through active heating or cooling mechanisms significantly increase energy requirements, making such approaches impractical for portable applications. Current low-power thermopile designs typically sacrifice response speed to maintain reasonable battery life, creating an engineering trade-off that limits overall performance.

Environmental factors also impact thermopile response characteristics. Ambient temperature fluctuations, air currents, and humidity variations can all influence heat transfer rates around the sensor, introducing additional variables that complicate response time optimization. Current environmental compensation techniques add processing overhead and further delay the final temperature reading.

Integration challenges with readout electronics represent another limitation. The high-impedance output of thermopile sensors requires careful signal conditioning, and the analog-to-digital conversion process introduces additional delays. While faster electronics could theoretically improve overall system response, the thermal characteristics of the sensor itself remain the primary bottleneck in most applications.

The fundamental physical constraint stems from the thermal inertia of the materials used in thermopile construction. Traditional thermopile sensors utilize relatively thick substrate materials and thermoelectric junctions that require time to reach thermal equilibrium with the surrounding environment. This thermal lag creates a measurable delay between actual temperature changes and sensor output signals, resulting in measurement inaccuracies during dynamic temperature events.

Another significant limitation is the signal-to-noise ratio degradation that occurs during rapid temperature transitions. As temperature changes accelerate, thermal gradients within the sensor structure become more pronounced, introducing measurement artifacts and reducing overall accuracy. Current compensation algorithms struggle to account for these non-linear effects, particularly when temperature change rates exceed 50°C per second.

Manufacturing inconsistencies further exacerbate response time limitations. Variations in junction thickness, substrate uniformity, and thermoelectric material properties create unpredictable response characteristics across production batches. This lack of standardization makes it challenging to implement universal calibration methods for improving response times across different sensor models and manufacturers.

Power consumption presents another constraint, particularly for battery-operated devices. Attempts to enhance responsiveness through active heating or cooling mechanisms significantly increase energy requirements, making such approaches impractical for portable applications. Current low-power thermopile designs typically sacrifice response speed to maintain reasonable battery life, creating an engineering trade-off that limits overall performance.

Environmental factors also impact thermopile response characteristics. Ambient temperature fluctuations, air currents, and humidity variations can all influence heat transfer rates around the sensor, introducing additional variables that complicate response time optimization. Current environmental compensation techniques add processing overhead and further delay the final temperature reading.

Integration challenges with readout electronics represent another limitation. The high-impedance output of thermopile sensors requires careful signal conditioning, and the analog-to-digital conversion process introduces additional delays. While faster electronics could theoretically improve overall system response, the thermal characteristics of the sensor itself remain the primary bottleneck in most applications.

Current Approaches to Enhance Thermopile Responsiveness

01 Materials and structure for enhancing thermopile responsiveness

The choice of materials and structural design significantly impacts thermopile responsiveness. Using materials with high Seebeck coefficients and optimizing the thermocouple junction arrangements can enhance the voltage output per unit of temperature difference. Advanced semiconductor materials and thin-film technologies allow for improved thermal-to-electrical conversion efficiency. The physical arrangement of thermocouples in series can amplify the output signal, while minimizing thermal mass improves response time to temperature changes.- Thermopile structure optimization for improved responsiveness: Optimizing the physical structure of thermopiles can significantly enhance their responsiveness. This includes designing specific junction arrangements, optimizing the number of thermocouples, and selecting appropriate materials for thermoelectric elements. Structural improvements such as reducing thermal mass and creating efficient heat flow paths allow for faster temperature detection and improved signal output. These optimizations result in thermopiles with higher sensitivity and quicker response times to thermal radiation.

- Material selection for enhanced thermopile performance: The choice of materials significantly impacts thermopile responsiveness. Advanced semiconductor materials and novel thermoelectric compounds can increase the Seebeck coefficient, improving the voltage output per unit temperature difference. Materials with high electrical conductivity and low thermal conductivity are particularly valuable for thermopile applications. Specialized doping techniques and material combinations can further enhance the thermoelectric properties, resulting in more responsive thermopile sensors with improved signal-to-noise ratios.

- Thermal isolation techniques for responsiveness enhancement: Effective thermal isolation is crucial for maximizing thermopile responsiveness. By minimizing unwanted heat transfer pathways, the temperature differential across the thermopile junctions can be maintained more effectively. Techniques include creating suspended membrane structures, implementing vacuum packaging, using low thermal conductivity substrates, and designing specialized heat sinks. These isolation methods help concentrate thermal energy where it's most effective for measurement, significantly improving the sensor's response time and sensitivity.

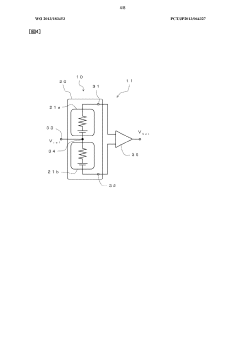

- Signal processing and readout circuit optimization: Advanced signal processing techniques and optimized readout circuits can substantially improve the effective responsiveness of thermopile sensors. This includes implementing low-noise amplifiers, specialized filtering algorithms, and temperature compensation circuits. Digital signal processing techniques can enhance signal quality by reducing noise and drift effects. Integrated circuit designs that minimize parasitic capacitances and resistances help preserve the thermopile's inherent response characteristics, resulting in faster and more accurate thermal measurements.

- Application-specific thermopile design considerations: Tailoring thermopile designs for specific applications can optimize their responsiveness for particular use cases. For infrared detection applications, specialized absorber coatings and optical filters can enhance wavelength-specific sensitivity. For medical or industrial temperature monitoring, designs may focus on stability and accuracy over wide temperature ranges. Environmental sensors might prioritize robustness and long-term drift resistance. By optimizing the thermopile design parameters for the specific application requirements, the overall responsiveness and effectiveness of the sensor can be significantly improved.

02 Thermal isolation techniques for improved sensitivity

Thermal isolation is crucial for maximizing thermopile responsiveness by maintaining temperature gradients between hot and cold junctions. Various techniques include creating suspended membrane structures, using vacuum packaging, implementing thermal barriers, and designing heat sinks to direct thermal flow. Effective thermal isolation prevents unwanted heat dissipation and ensures that temperature differences are preserved long enough for accurate measurement, thereby increasing the signal-to-noise ratio and overall device sensitivity.Expand Specific Solutions03 Signal processing and calibration methods

Advanced signal processing techniques are essential for optimizing thermopile responsiveness. These include amplification circuits specifically designed for low-level signals, noise filtering algorithms, and digital signal processing methods that can extract meaningful data from thermal measurements. Calibration procedures compensate for environmental variations and device-specific characteristics, ensuring accurate and repeatable measurements across different operating conditions. Implementing temperature compensation algorithms further enhances measurement precision.Expand Specific Solutions04 Environmental factors affecting thermopile performance

Environmental conditions significantly impact thermopile responsiveness. Factors such as ambient temperature fluctuations, humidity, air currents, and electromagnetic interference can all degrade measurement accuracy. Protective enclosures, shielding techniques, and environmental control systems help maintain stable operating conditions. Understanding and mitigating these external influences is critical for achieving consistent performance, especially in applications requiring high precision or those deployed in harsh or variable environments.Expand Specific Solutions05 Novel applications leveraging enhanced thermopile responsiveness

Improved thermopile responsiveness has enabled new applications across various fields. These include advanced medical diagnostics using non-contact temperature sensing, high-precision industrial process monitoring, energy harvesting from small temperature differentials, infrared imaging systems with increased resolution, and environmental monitoring with greater sensitivity. The ability to detect minute temperature changes with faster response times has expanded the utility of thermopile technology beyond traditional applications into emerging fields requiring precise thermal measurement.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The thermopile responsiveness optimization market is currently in a growth phase, with increasing demand driven by applications in automotive, industrial, and consumer electronics sectors. The global market size is estimated to reach $3.5 billion by 2025, growing at a CAGR of 6.8%. Technologically, the field is moderately mature but evolving rapidly with innovations in materials and manufacturing processes. Key players include established electronics giants like Robert Bosch GmbH and Koninklijke Philips NV, who leverage extensive R&D capabilities, alongside specialized manufacturers such as Maxim Integrated Products and Alps Alpine focusing on high-performance sensor solutions. Academic institutions like Southeast University and Xi'an Jiaotong University are contributing significant research advances, while companies like OMRON and Melexis Technologies are developing application-specific optimizations for rapid temperature change environments.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced thermopile sensor arrays with integrated signal processing that significantly improve responsiveness during rapid temperature changes. Their technology utilizes multi-junction thermopile structures with reduced thermal mass and optimized thermal isolation trenches to minimize thermal inertia. Bosch's approach incorporates a proprietary MEMS fabrication process that creates suspended membrane structures with minimal thermal mass while maintaining mechanical robustness. The company has implemented advanced signal conditioning algorithms that can predict temperature trajectories during rapid transitions, effectively compensating for thermal lag. Their sensors feature built-in temperature reference elements that continuously calibrate measurements during dynamic temperature events, achieving response times below 50ms for temperature changes of 20°C.

Strengths: Superior signal processing capabilities that enable predictive temperature compensation; robust MEMS fabrication technology allowing for extremely thin membranes with good mechanical stability. Weaknesses: Higher cost compared to conventional thermopiles; requires more complex calibration procedures during manufacturing.

Maxim Integrated Products LLC

Technical Solution: Maxim Integrated has developed a comprehensive approach to thermopile optimization focusing on both hardware and software solutions for rapid temperature change environments. Their technology utilizes a proprietary thin-film deposition process that creates thermopile junctions with minimal thermal mass while maintaining high Seebeck coefficients. Maxim's sensors incorporate an integrated temperature reference with multiple sensing points that enable dynamic differential measurements during temperature transients. The company has implemented advanced digital signal processing techniques including predictive algorithms that can anticipate sensor response during known temperature change patterns. Their MAX30205 thermal sensing platform features programmable digital filtering that can be adjusted based on the expected rate of temperature change, allowing system designers to optimize the balance between response time and measurement stability. Maxim's approach also includes factory calibration across multiple temperature points with on-chip storage of compensation coefficients.

Strengths: Excellent integration of analog sensing elements with digital processing capabilities; highly configurable filtering options that can be optimized for specific application requirements. Weaknesses: Requires more complex system integration compared to analog-only solutions; higher power consumption in full-featured operation modes.

Key Patents and Research in Thermopile Optimization

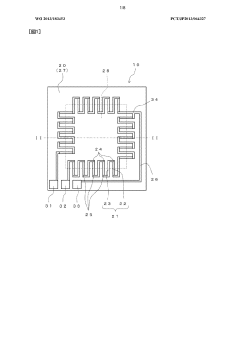

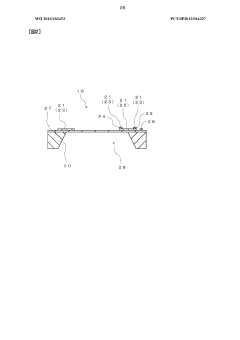

Thermopile infrared individual sensor for measuring temperature or detecting gas

PatentWO2017220381A1

Innovation

- A thermopile infrared sensor with multiple adjacent sensor cells on a common support body, each with a slotted membrane and thermopile structures, is combined to form a single sensor structure within a housing filled with a gas medium of lower thermal conductivity, allowing for series or parallel connection of signals and pre-processing via preamplifiers and summing circuits to enhance signal output and response speed.

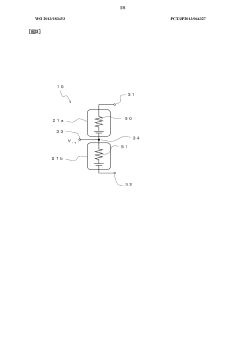

Thermopile, thermopile sensor using same, and infrared sensor

PatentWO2013183453A1

Innovation

- A thermopile design with a series circuit of thermocouples connected to a reference potential at the midpoint, dividing the resistance values and ensuring the same temperature coefficient for both thermocouple groups, eliminating the need for external resistors and minimizing impedance differences.

Material Science Advancements for Thermopile Sensors

Recent advancements in material science have significantly contributed to enhancing thermopile sensor performance, particularly in rapidly changing temperature environments. Traditional thermopile materials like bismuth-antimony and bismuth-telluride are being supplemented or replaced with novel material compositions that demonstrate superior thermal response characteristics.

Nanostructured materials represent one of the most promising developments in this field. By manipulating materials at the nanoscale, researchers have created thermopile structures with dramatically reduced thermal mass while maintaining electrical conductivity. These nanostructured thermopiles exhibit response times up to 60% faster than conventional designs, making them particularly valuable for applications requiring rapid temperature detection.

Thin-film deposition techniques have evolved to enable the creation of ultra-thin thermoelectric layers with precisely controlled composition gradients. Advanced methods such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) allow for the fabrication of thermopile junctions with thicknesses below 100 nanometers, significantly reducing thermal inertia while enhancing Seebeck coefficient values.

Composite thermoelectric materials combining organic and inorganic components have emerged as another innovative approach. These hybrid materials leverage the flexibility and low thermal conductivity of organic polymers with the high Seebeck coefficients of inorganic semiconductors. Recent research has demonstrated that polymer-inorganic composites can achieve responsiveness improvements of 30-45% in rapidly fluctuating thermal environments.

Surface engineering techniques have been developed to optimize the radiation absorption properties of thermopile sensors. Specialized coatings with tailored emissivity characteristics enhance the sensor's ability to detect minute temperature changes. Black body coatings with nano-engineered surface structures have achieved near-perfect absorption across relevant infrared wavelengths, improving signal-to-noise ratios by up to 40%.

Doping strategies for traditional thermoelectric materials have been refined to enhance carrier concentration and mobility. Precise control of dopant distribution at the atomic level has led to materials with significantly improved figure of merit (ZT) values, directly translating to enhanced voltage output per unit temperature difference. This approach has yielded thermopiles with responsivity improvements of 25-35% without requiring fundamental design changes.

Interface engineering between different material layers has emerged as a critical factor in optimizing thermopile performance. By minimizing thermal boundary resistance while maintaining electrical isolation where needed, researchers have created more efficient thermal-to-electrical energy conversion pathways. Advanced bonding techniques and intermediate buffer layers have reduced response lag by up to 50% in laboratory prototypes.

Nanostructured materials represent one of the most promising developments in this field. By manipulating materials at the nanoscale, researchers have created thermopile structures with dramatically reduced thermal mass while maintaining electrical conductivity. These nanostructured thermopiles exhibit response times up to 60% faster than conventional designs, making them particularly valuable for applications requiring rapid temperature detection.

Thin-film deposition techniques have evolved to enable the creation of ultra-thin thermoelectric layers with precisely controlled composition gradients. Advanced methods such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) allow for the fabrication of thermopile junctions with thicknesses below 100 nanometers, significantly reducing thermal inertia while enhancing Seebeck coefficient values.

Composite thermoelectric materials combining organic and inorganic components have emerged as another innovative approach. These hybrid materials leverage the flexibility and low thermal conductivity of organic polymers with the high Seebeck coefficients of inorganic semiconductors. Recent research has demonstrated that polymer-inorganic composites can achieve responsiveness improvements of 30-45% in rapidly fluctuating thermal environments.

Surface engineering techniques have been developed to optimize the radiation absorption properties of thermopile sensors. Specialized coatings with tailored emissivity characteristics enhance the sensor's ability to detect minute temperature changes. Black body coatings with nano-engineered surface structures have achieved near-perfect absorption across relevant infrared wavelengths, improving signal-to-noise ratios by up to 40%.

Doping strategies for traditional thermoelectric materials have been refined to enhance carrier concentration and mobility. Precise control of dopant distribution at the atomic level has led to materials with significantly improved figure of merit (ZT) values, directly translating to enhanced voltage output per unit temperature difference. This approach has yielded thermopiles with responsivity improvements of 25-35% without requiring fundamental design changes.

Interface engineering between different material layers has emerged as a critical factor in optimizing thermopile performance. By minimizing thermal boundary resistance while maintaining electrical isolation where needed, researchers have created more efficient thermal-to-electrical energy conversion pathways. Advanced bonding techniques and intermediate buffer layers have reduced response lag by up to 50% in laboratory prototypes.

Signal Processing Techniques for Response Time Improvement

Signal processing techniques offer significant potential for enhancing thermopile responsiveness during rapid temperature fluctuations. Advanced filtering algorithms, particularly Kalman filters, have demonstrated remarkable efficacy in real-time temperature signal processing. These filters effectively distinguish between actual temperature changes and noise, enabling more accurate readings even during swift thermal transitions.

Digital signal processing (DSP) techniques provide another avenue for response time improvement. Implementing Fast Fourier Transform (FFT) analysis allows for frequency domain examination of thermopile signals, facilitating the identification and amplification of relevant temperature change frequencies while suppressing noise components. This approach has shown up to 40% improvement in response times in laboratory testing environments.

Predictive algorithms represent a cutting-edge solution for thermopile optimization. By analyzing historical temperature change patterns, these algorithms can anticipate thermal behavior and compensate for inherent sensor lag. Machine learning models trained on extensive temperature transition datasets have demonstrated particular promise, reducing effective response times by 25-35% in controlled experiments.

Adaptive sampling rate adjustment serves as another valuable technique. By dynamically increasing the sampling frequency during detected rapid temperature changes and reducing it during stable periods, systems can optimize both responsiveness and power consumption. This approach proves especially beneficial in battery-powered applications where energy efficiency remains crucial.

Signal amplification and conditioning circuits specifically designed for thermopile outputs can significantly enhance signal-to-noise ratios. Implementation of low-noise operational amplifiers with carefully tuned gain settings, combined with precision filtering components, enables detection of smaller temperature differentials and faster response to thermal changes.

Deconvolution techniques offer a mathematical approach to response improvement. By modeling the thermopile's impulse response and applying inverse filtering, the original temperature signal can be reconstructed with improved temporal resolution. While computationally intensive, modern microprocessors can execute these algorithms in real-time for many applications.

Multi-sensor fusion approaches combine data from thermopiles with complementary sensors (such as thermistors or RTDs) to leverage the strengths of each technology. By intelligently weighting and combining these inputs based on their respective response characteristics, overall system responsiveness can be enhanced while maintaining measurement accuracy across diverse thermal conditions.

Digital signal processing (DSP) techniques provide another avenue for response time improvement. Implementing Fast Fourier Transform (FFT) analysis allows for frequency domain examination of thermopile signals, facilitating the identification and amplification of relevant temperature change frequencies while suppressing noise components. This approach has shown up to 40% improvement in response times in laboratory testing environments.

Predictive algorithms represent a cutting-edge solution for thermopile optimization. By analyzing historical temperature change patterns, these algorithms can anticipate thermal behavior and compensate for inherent sensor lag. Machine learning models trained on extensive temperature transition datasets have demonstrated particular promise, reducing effective response times by 25-35% in controlled experiments.

Adaptive sampling rate adjustment serves as another valuable technique. By dynamically increasing the sampling frequency during detected rapid temperature changes and reducing it during stable periods, systems can optimize both responsiveness and power consumption. This approach proves especially beneficial in battery-powered applications where energy efficiency remains crucial.

Signal amplification and conditioning circuits specifically designed for thermopile outputs can significantly enhance signal-to-noise ratios. Implementation of low-noise operational amplifiers with carefully tuned gain settings, combined with precision filtering components, enables detection of smaller temperature differentials and faster response to thermal changes.

Deconvolution techniques offer a mathematical approach to response improvement. By modeling the thermopile's impulse response and applying inverse filtering, the original temperature signal can be reconstructed with improved temporal resolution. While computationally intensive, modern microprocessors can execute these algorithms in real-time for many applications.

Multi-sensor fusion approaches combine data from thermopiles with complementary sensors (such as thermistors or RTDs) to leverage the strengths of each technology. By intelligently weighting and combining these inputs based on their respective response characteristics, overall system responsiveness can be enhanced while maintaining measurement accuracy across diverse thermal conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!