How to Compare Thermopile Sensitivity in Different Environments

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Sensitivity Background and Objectives

Thermopile sensors have evolved significantly since their inception in the early 19th century, following the discovery of the thermoelectric effect by Thomas Johann Seebeck in 1821. This technology has progressed from simple thermocouples to sophisticated infrared detection systems used across multiple industries. The fundamental operating principle remains consistent: thermopiles convert thermal energy into electrical signals by leveraging temperature differentials across junctions of dissimilar metals.

Recent technological advancements have dramatically improved thermopile sensitivity, miniaturization capabilities, and integration potential. Modern thermopiles now achieve detection resolutions in the millikelvin range, representing orders of magnitude improvement over early designs. This evolution has expanded their application scope from basic temperature measurement to complex thermal imaging, gas analysis, and medical diagnostics.

The primary objective of comparing thermopile sensitivity across different environments is to establish standardized evaluation methodologies that account for the complex interplay of environmental factors affecting performance. These factors include ambient temperature fluctuations, humidity variations, atmospheric composition, electromagnetic interference, and mechanical vibrations—all of which can significantly impact measurement accuracy and reliability.

Current industry challenges center on the lack of universally accepted testing protocols that enable meaningful cross-comparison of thermopile performance under diverse operating conditions. This gap hampers technology advancement and complicates selection processes for specific applications. Establishing such standardized comparison frameworks would accelerate innovation cycles and improve application-specific optimization.

The technical goals of this research include developing comprehensive testing methodologies that isolate and quantify environmental influences on thermopile sensitivity, creating mathematical models that predict performance variations across different conditions, and establishing calibration techniques that compensate for environmental factors. Additionally, we aim to identify optimal thermopile designs for specific environmental challenges.

Market trends indicate growing demand for high-sensitivity thermopiles in emerging fields such as autonomous vehicles, smart buildings, and wearable health monitoring devices. These applications require sensors that maintain consistent performance across widely varying environmental conditions, from extreme temperatures to high humidity and vibration scenarios.

Understanding how to effectively compare thermopile sensitivity across different environments will enable manufacturers to develop more robust sensors, help system integrators select appropriate components for specific applications, and allow end-users to implement more effective calibration and maintenance protocols. This knowledge is particularly crucial as thermopiles increasingly serve in mission-critical applications where reliability under varying conditions is paramount.

Recent technological advancements have dramatically improved thermopile sensitivity, miniaturization capabilities, and integration potential. Modern thermopiles now achieve detection resolutions in the millikelvin range, representing orders of magnitude improvement over early designs. This evolution has expanded their application scope from basic temperature measurement to complex thermal imaging, gas analysis, and medical diagnostics.

The primary objective of comparing thermopile sensitivity across different environments is to establish standardized evaluation methodologies that account for the complex interplay of environmental factors affecting performance. These factors include ambient temperature fluctuations, humidity variations, atmospheric composition, electromagnetic interference, and mechanical vibrations—all of which can significantly impact measurement accuracy and reliability.

Current industry challenges center on the lack of universally accepted testing protocols that enable meaningful cross-comparison of thermopile performance under diverse operating conditions. This gap hampers technology advancement and complicates selection processes for specific applications. Establishing such standardized comparison frameworks would accelerate innovation cycles and improve application-specific optimization.

The technical goals of this research include developing comprehensive testing methodologies that isolate and quantify environmental influences on thermopile sensitivity, creating mathematical models that predict performance variations across different conditions, and establishing calibration techniques that compensate for environmental factors. Additionally, we aim to identify optimal thermopile designs for specific environmental challenges.

Market trends indicate growing demand for high-sensitivity thermopiles in emerging fields such as autonomous vehicles, smart buildings, and wearable health monitoring devices. These applications require sensors that maintain consistent performance across widely varying environmental conditions, from extreme temperatures to high humidity and vibration scenarios.

Understanding how to effectively compare thermopile sensitivity across different environments will enable manufacturers to develop more robust sensors, help system integrators select appropriate components for specific applications, and allow end-users to implement more effective calibration and maintenance protocols. This knowledge is particularly crucial as thermopiles increasingly serve in mission-critical applications where reliability under varying conditions is paramount.

Market Analysis for Thermopile Applications

The global thermopile sensor market has demonstrated robust growth, reaching approximately $78 million in 2022 and projected to expand at a CAGR of 8.2% through 2028. This growth is primarily driven by increasing demand across multiple sectors including consumer electronics, automotive, healthcare, and industrial applications. Thermopile sensors' ability to measure temperature without physical contact has positioned them as critical components in various high-growth markets.

In consumer electronics, thermopile sensors have gained significant traction in smartphones and wearable devices for temperature monitoring applications. The market penetration in this segment has increased by 12% annually since 2019, with major manufacturers incorporating these sensors for enhanced functionality. The COVID-19 pandemic accelerated adoption in consumer health devices, creating a new market segment worth approximately $15 million in 2022.

The automotive sector represents another substantial market for thermopile applications, particularly in advanced driver-assistance systems (ADAS) and cabin comfort management. With the transition toward autonomous vehicles, demand for high-sensitivity thermopile arrays has increased by 18% year-over-year, as these sensors provide critical environmental data for vehicle operation and passenger safety.

Industrial applications constitute the largest market segment, accounting for 38% of total thermopile sensor demand. Process monitoring, predictive maintenance, and energy efficiency applications drive consistent growth in this sector. The push toward Industry 4.0 and IoT integration has created new opportunities for thermopile sensor manufacturers, with smart factories implementing these sensors at a rate 2.5 times higher than traditional manufacturing facilities.

Healthcare applications represent the fastest-growing segment with a 14.3% annual growth rate. Medical thermography, patient monitoring systems, and diagnostic equipment increasingly rely on high-sensitivity thermopile arrays. The market for medical-grade thermopile sensors reached $12 million in 2022, with specialized applications commanding premium pricing.

Regional analysis indicates North America and Europe currently dominate the market with 32% and 28% market share respectively, primarily due to advanced industrial and healthcare infrastructure. However, Asia-Pacific is experiencing the fastest growth at 10.5% annually, driven by rapid industrialization and consumer electronics manufacturing.

The competitive landscape features established players like TE Connectivity, Excelitas Technologies, and Heimann Sensor controlling approximately 65% of the market. However, emerging manufacturers from China and South Korea are gaining market share by offering cost-competitive solutions with improving performance metrics, particularly in consumer electronics applications.

In consumer electronics, thermopile sensors have gained significant traction in smartphones and wearable devices for temperature monitoring applications. The market penetration in this segment has increased by 12% annually since 2019, with major manufacturers incorporating these sensors for enhanced functionality. The COVID-19 pandemic accelerated adoption in consumer health devices, creating a new market segment worth approximately $15 million in 2022.

The automotive sector represents another substantial market for thermopile applications, particularly in advanced driver-assistance systems (ADAS) and cabin comfort management. With the transition toward autonomous vehicles, demand for high-sensitivity thermopile arrays has increased by 18% year-over-year, as these sensors provide critical environmental data for vehicle operation and passenger safety.

Industrial applications constitute the largest market segment, accounting for 38% of total thermopile sensor demand. Process monitoring, predictive maintenance, and energy efficiency applications drive consistent growth in this sector. The push toward Industry 4.0 and IoT integration has created new opportunities for thermopile sensor manufacturers, with smart factories implementing these sensors at a rate 2.5 times higher than traditional manufacturing facilities.

Healthcare applications represent the fastest-growing segment with a 14.3% annual growth rate. Medical thermography, patient monitoring systems, and diagnostic equipment increasingly rely on high-sensitivity thermopile arrays. The market for medical-grade thermopile sensors reached $12 million in 2022, with specialized applications commanding premium pricing.

Regional analysis indicates North America and Europe currently dominate the market with 32% and 28% market share respectively, primarily due to advanced industrial and healthcare infrastructure. However, Asia-Pacific is experiencing the fastest growth at 10.5% annually, driven by rapid industrialization and consumer electronics manufacturing.

The competitive landscape features established players like TE Connectivity, Excelitas Technologies, and Heimann Sensor controlling approximately 65% of the market. However, emerging manufacturers from China and South Korea are gaining market share by offering cost-competitive solutions with improving performance metrics, particularly in consumer electronics applications.

Current Challenges in Environmental Sensitivity Testing

Despite significant advancements in thermopile technology, comparing sensor sensitivity across different environments remains a formidable challenge for researchers and manufacturers. The primary difficulty stems from the inherent variability of environmental conditions that directly impact thermopile performance metrics. Temperature fluctuations, humidity levels, atmospheric pressure, and air currents all introduce variables that can significantly alter measurement outcomes, making standardized comparison methodologies elusive.

Current testing protocols often fail to account for the complex interplay between multiple environmental factors. For instance, while a testing procedure might control ambient temperature, it may inadequately address how humidity variations simultaneously affect thermal conductivity and heat transfer mechanisms around the sensor. This creates substantial discrepancies when comparing sensitivity data from different testing facilities or environmental conditions.

Calibration drift represents another significant obstacle in environmental sensitivity testing. Thermopiles exposed to varying environmental conditions over time may experience baseline shifts that are difficult to quantify and compensate for in comparative analyses. The lack of universally accepted correction algorithms for these environmental dependencies further complicates the establishment of reliable comparison frameworks.

The miniaturization trend in thermopile sensors introduces additional complexities. As sensors become smaller, their susceptibility to environmental fluctuations increases proportionally, with micro-scale thermopiles demonstrating heightened sensitivity to even minor environmental variations. This scaling effect is inadequately addressed in current testing methodologies, which often apply standards developed for larger sensor formats.

Cross-sensitivity issues present yet another challenge. Thermopiles designed to measure specific thermal radiation may exhibit unintended sensitivity to non-target environmental factors. For example, sensors optimized for human body temperature detection might respond differently to background infrared radiation in various environments, creating false positives or measurement inaccuracies that complicate comparative analysis.

Industry standardization remains fragmented, with different manufacturers employing proprietary testing protocols that prioritize environmental factors relevant to their specific applications. This lack of harmonized testing standards makes it exceptionally difficult to compare sensitivity specifications across different product lines or manufacturers, limiting the ability of end-users to make informed decisions based on performance metrics.

Real-time compensation for environmental variations represents the frontier challenge in this domain. While static calibration techniques exist, dynamic adjustment algorithms that can continuously account for changing environmental conditions during operation remain underdeveloped. This gap significantly impacts the reliability of sensitivity comparisons in field applications where environmental conditions rarely remain constant.

Current testing protocols often fail to account for the complex interplay between multiple environmental factors. For instance, while a testing procedure might control ambient temperature, it may inadequately address how humidity variations simultaneously affect thermal conductivity and heat transfer mechanisms around the sensor. This creates substantial discrepancies when comparing sensitivity data from different testing facilities or environmental conditions.

Calibration drift represents another significant obstacle in environmental sensitivity testing. Thermopiles exposed to varying environmental conditions over time may experience baseline shifts that are difficult to quantify and compensate for in comparative analyses. The lack of universally accepted correction algorithms for these environmental dependencies further complicates the establishment of reliable comparison frameworks.

The miniaturization trend in thermopile sensors introduces additional complexities. As sensors become smaller, their susceptibility to environmental fluctuations increases proportionally, with micro-scale thermopiles demonstrating heightened sensitivity to even minor environmental variations. This scaling effect is inadequately addressed in current testing methodologies, which often apply standards developed for larger sensor formats.

Cross-sensitivity issues present yet another challenge. Thermopiles designed to measure specific thermal radiation may exhibit unintended sensitivity to non-target environmental factors. For example, sensors optimized for human body temperature detection might respond differently to background infrared radiation in various environments, creating false positives or measurement inaccuracies that complicate comparative analysis.

Industry standardization remains fragmented, with different manufacturers employing proprietary testing protocols that prioritize environmental factors relevant to their specific applications. This lack of harmonized testing standards makes it exceptionally difficult to compare sensitivity specifications across different product lines or manufacturers, limiting the ability of end-users to make informed decisions based on performance metrics.

Real-time compensation for environmental variations represents the frontier challenge in this domain. While static calibration techniques exist, dynamic adjustment algorithms that can continuously account for changing environmental conditions during operation remain underdeveloped. This gap significantly impacts the reliability of sensitivity comparisons in field applications where environmental conditions rarely remain constant.

Established Methodologies for Sensitivity Comparison

01 Material selection for thermopile sensitivity enhancement

The sensitivity of thermopiles can be significantly improved through careful selection of thermoelectric materials. Using materials with high Seebeck coefficients and optimizing the junction materials can increase the voltage output per unit of temperature difference. Advanced semiconductor materials and thin-film technologies have enabled the development of thermopiles with enhanced sensitivity for various sensing applications.- Thermopile structure design for enhanced sensitivity: The sensitivity of thermopiles can be improved through structural design modifications. This includes optimizing the arrangement of thermocouple junctions, using specific materials for thermocouples, and designing the absorber area to maximize heat collection. The number of thermocouples in series and their spatial arrangement significantly affects the output voltage and sensitivity of the thermopile sensor.

- Material selection for thermopile sensitivity improvement: The choice of materials for thermopile elements significantly impacts sensitivity. High Seebeck coefficient materials like bismuth-telluride, antimony-bismuth, and polysilicon-metal combinations can enhance the thermoelectric effect. Advanced semiconductor materials and thin-film technologies allow for greater temperature differentials between hot and cold junctions, resulting in improved voltage output and sensitivity.

- Vacuum packaging and thermal isolation techniques: Vacuum packaging and thermal isolation techniques are employed to enhance thermopile sensitivity by reducing thermal losses. By minimizing heat conduction and convection between the hot and cold junctions, these techniques maintain larger temperature gradients. Specialized membrane structures, air gaps, and cavity designs help isolate the sensing element from the substrate, improving the overall sensitivity of the thermopile sensor.

- Signal processing and amplification methods: Advanced signal processing and amplification techniques can significantly enhance the effective sensitivity of thermopile sensors. This includes using specialized integrated circuits for signal conditioning, implementing noise reduction algorithms, and employing digital filtering techniques. Chopper stabilization, auto-zeroing circuits, and temperature compensation methods help minimize drift and offset errors, resulting in improved sensitivity and measurement accuracy.

- Calibration and compensation techniques: Calibration and compensation techniques are essential for optimizing thermopile sensitivity across varying environmental conditions. These include temperature compensation circuits, reference junction monitoring, and software-based correction algorithms. By accounting for ambient temperature variations, aging effects, and other environmental factors, these techniques ensure consistent sensitivity and measurement accuracy throughout the operational lifetime of the thermopile sensor.

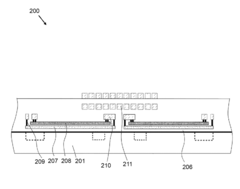

02 Structural design optimization for thermopile sensors

The physical structure and geometry of thermopile sensors directly impact their sensitivity. Optimizing the number of thermocouple junctions, their arrangement, and the overall sensor architecture can enhance thermal isolation and improve signal output. Advanced designs incorporate suspended membrane structures, vacuum packaging, and optimized heat flow paths to maximize temperature gradients across the thermocouples.Expand Specific Solutions03 Signal processing techniques for sensitivity improvement

Various signal processing methods can be employed to enhance the effective sensitivity of thermopile sensors. These include amplification circuits, noise filtering, offset compensation, and digital signal processing algorithms. Advanced readout integrated circuits (ROICs) specifically designed for thermopiles can significantly improve signal-to-noise ratio and overall system sensitivity.Expand Specific Solutions04 Calibration methods for thermopile sensitivity

Precise calibration techniques are essential for maximizing thermopile sensitivity in practical applications. These methods include temperature compensation algorithms, reference junction control, and factory calibration procedures. Advanced calibration approaches use machine learning algorithms to account for environmental variations and aging effects, ensuring consistent sensitivity across operating conditions.Expand Specific Solutions05 Packaging and thermal isolation techniques

The packaging and thermal management of thermopile sensors play crucial roles in determining their sensitivity. Vacuum packaging, thermal isolation structures, and heat sink designs can significantly enhance temperature differentials across the sensor. Micromachined structures and advanced MEMS fabrication techniques enable improved thermal isolation, reducing heat losses and increasing the temperature gradient across the thermocouples.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermopile sensitivity comparison market is currently in a growth phase, with increasing demand for precise thermal measurement across diverse environments. The global market is estimated to reach $1.2 billion by 2025, driven by applications in consumer electronics, automotive, and medical sectors. Leading players like Texas Instruments, Excelitas Technologies, and PerkinElmer have established mature technologies with high sensitivity coefficients, while Apple and Philips are investing in miniaturized thermopile arrays for consumer applications. Emerging competitors such as Sensirion and Flusso are developing environment-adaptive calibration algorithms. The technology maturity varies significantly, with established companies offering solutions with ±0.1°C accuracy in controlled environments, while newer entrants focus on compensating for environmental variables through advanced signal processing and AI-driven calibration techniques.

Koninklijke Philips NV

Technical Solution: Philips has developed a standardized methodology for thermopile sensitivity comparison across environments through their Adaptive Thermal Sensing (ATS) framework. Their approach utilizes reference calibration chambers where thermopiles are characterized against NIST-traceable blackbody sources while environmental parameters are precisely controlled and systematically varied. Philips employs a multi-point calibration technique where each thermopile sensor undergoes sensitivity mapping at discrete temperature and humidity combinations spanning the intended operational range[7]. Their technology incorporates specialized substrate materials with low thermal conductivity coefficients to minimize environmental interference with the sensing elements. Philips has pioneered thin-film deposition techniques that optimize the Seebeck effect in their thermopile junctions while maintaining consistent performance across temperature variations. Their medical-grade thermopiles feature hermetically sealed packages with internal temperature reference structures that enable continuous self-calibration. The company's comparative testing protocol involves parallel testing of multiple sensors under identical conditions to establish statistical performance baselines and identify manufacturing variations that might affect environmental sensitivity[8].

Strengths: Exceptional repeatability and precision due to rigorous calibration methodologies. Medical-grade reliability ensures consistent performance in critical applications. Weaknesses: Higher production costs due to extensive calibration requirements. Larger physical footprint for models with comprehensive environmental compensation features.

Raytheon Co.

Technical Solution: Raytheon has developed advanced methodologies for thermopile sensitivity comparison in varying environments through their Environmental Resilient Infrared Sensing (ERIS) program. Their approach employs military-grade environmental testing chambers capable of simulating extreme conditions from arctic to desert environments while maintaining precise control over temperature, humidity, pressure, and air movement parameters. Raytheon's thermopile characterization process involves exposing sensors to calibrated blackbody sources across multiple wavelength bands while systematically varying environmental conditions to generate comprehensive sensitivity matrices[9]. Their technology incorporates specialized vacuum packaging with multi-layer radiation shields to minimize environmental interference. Raytheon has implemented proprietary signal processing algorithms that apply dynamic compensation factors based on real-time environmental measurements from auxiliary sensors integrated within their thermopile packages. Their comparative testing methodology includes accelerated life testing under environmental stress conditions to predict long-term sensitivity stability. For defense applications, Raytheon has developed hardened thermopile arrays with enhanced resistance to thermal shock, vibration, and electromagnetic interference, ensuring consistent sensitivity measurements even in hostile operational environments[10].

Strengths: Exceptional environmental resilience allows operation in extreme conditions where conventional thermopiles would fail. Superior long-term stability due to military-grade packaging and materials. Weaknesses: Significantly higher cost compared to commercial alternatives. Larger size and weight due to ruggedized construction and additional shielding requirements.

Key Patents and Technical Literature Review

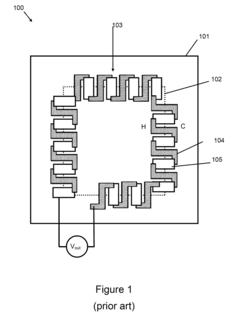

Thermoelectric bias voltage generator

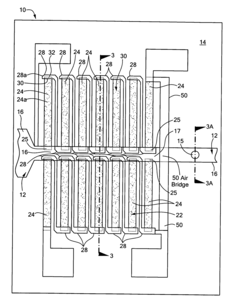

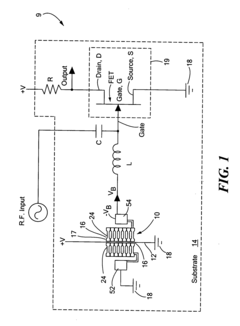

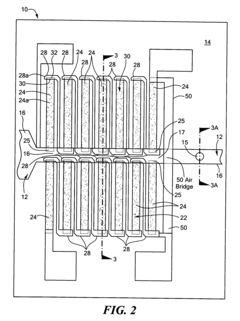

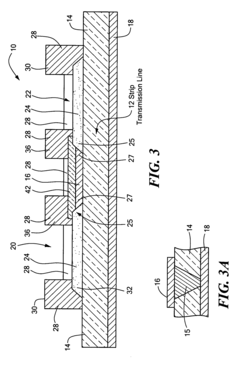

PatentActiveUS20070125414A1

Innovation

- A thermoelectric bias voltage generator using a thermopile with its positive terminal ground-referenced, generating a negative potential from a positive DC voltage supply, allowing for on-chip integration with FETs and eliminating the need for external power supplies or complex converters.

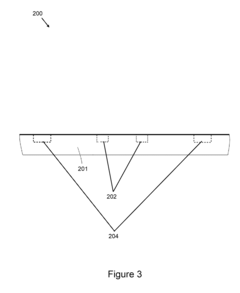

Thermopile test structure and methods employing same

PatentActiveUS20170363477A1

Innovation

- Integrated thermopile test structures with temperature-sensitive elements positioned below the thermopile, allowing for robust monitoring of intrinsic sensitivity and operation without the need for back-etching, enabling efficient characterization at the wafer testing stage and reducing waste and cost.

Environmental Factors Impact Assessment

Environmental conditions significantly influence thermopile sensor performance, creating challenges for accurate sensitivity comparisons across different settings. Temperature variations directly affect the Seebeck coefficient of thermopile materials, altering the voltage output per unit of incident radiation. Research indicates that for most semiconductor-based thermopiles, sensitivity decreases approximately 0.2-0.4% per degree Celsius increase above room temperature, necessitating temperature compensation mechanisms for reliable measurements.

Humidity levels impact thermopile sensitivity through multiple mechanisms. Water vapor absorption alters the transmission properties of infrared radiation, potentially reducing the signal reaching the sensor. Additionally, condensation on optical components or the sensor itself can dramatically decrease sensitivity and introduce measurement errors. Studies show sensitivity reductions of up to 15% when relative humidity increases from 30% to 90% in non-hermetically sealed devices.

Atmospheric pressure variations affect thermal conductivity of the gas surrounding the thermopile, influencing heat transfer dynamics and consequently altering sensitivity profiles. This effect becomes particularly pronounced in applications involving altitude changes or pressure-controlled environments, with sensitivity shifts of 1-3% observed across normal atmospheric pressure ranges.

Electromagnetic interference (EMI) represents another critical environmental factor, as thermopiles generate microvolt-level signals susceptible to electrical noise. Industrial environments with high EMI levels may require additional shielding to maintain measurement integrity. Testing has demonstrated that unshielded thermopiles can experience signal-to-noise ratio degradation exceeding 60% in high-EMI environments compared to controlled laboratory conditions.

Air flow patterns around the sensor significantly impact thermal equilibrium, with convective cooling potentially reducing apparent sensitivity by dissipating heat that would otherwise contribute to the temperature gradient. Research indicates that air velocities of just 1-2 m/s can reduce measured sensitivity by 5-10% compared to still-air conditions, depending on sensor packaging and mounting configuration.

Dust accumulation and contamination on optical filters or sensor surfaces progressively degrade sensitivity over time, with particulate matter blocking incident radiation. Field studies demonstrate sensitivity reductions of 0.5-2% per month in industrial environments without regular maintenance protocols. This degradation follows non-linear patterns, accelerating as contamination increases beyond certain thresholds.

These environmental dependencies necessitate standardized testing protocols that either control environmental variables or compensate for their effects when comparing thermopile sensitivities across different operational scenarios. Comprehensive environmental characterization should be considered an essential component of thermopile sensitivity assessment methodologies.

Humidity levels impact thermopile sensitivity through multiple mechanisms. Water vapor absorption alters the transmission properties of infrared radiation, potentially reducing the signal reaching the sensor. Additionally, condensation on optical components or the sensor itself can dramatically decrease sensitivity and introduce measurement errors. Studies show sensitivity reductions of up to 15% when relative humidity increases from 30% to 90% in non-hermetically sealed devices.

Atmospheric pressure variations affect thermal conductivity of the gas surrounding the thermopile, influencing heat transfer dynamics and consequently altering sensitivity profiles. This effect becomes particularly pronounced in applications involving altitude changes or pressure-controlled environments, with sensitivity shifts of 1-3% observed across normal atmospheric pressure ranges.

Electromagnetic interference (EMI) represents another critical environmental factor, as thermopiles generate microvolt-level signals susceptible to electrical noise. Industrial environments with high EMI levels may require additional shielding to maintain measurement integrity. Testing has demonstrated that unshielded thermopiles can experience signal-to-noise ratio degradation exceeding 60% in high-EMI environments compared to controlled laboratory conditions.

Air flow patterns around the sensor significantly impact thermal equilibrium, with convective cooling potentially reducing apparent sensitivity by dissipating heat that would otherwise contribute to the temperature gradient. Research indicates that air velocities of just 1-2 m/s can reduce measured sensitivity by 5-10% compared to still-air conditions, depending on sensor packaging and mounting configuration.

Dust accumulation and contamination on optical filters or sensor surfaces progressively degrade sensitivity over time, with particulate matter blocking incident radiation. Field studies demonstrate sensitivity reductions of 0.5-2% per month in industrial environments without regular maintenance protocols. This degradation follows non-linear patterns, accelerating as contamination increases beyond certain thresholds.

These environmental dependencies necessitate standardized testing protocols that either control environmental variables or compensate for their effects when comparing thermopile sensitivities across different operational scenarios. Comprehensive environmental characterization should be considered an essential component of thermopile sensitivity assessment methodologies.

Standardization and Calibration Protocols

To effectively compare thermopile sensitivity across different environments, standardized protocols and calibration methods are essential. These protocols ensure measurement consistency and reliability regardless of environmental variations. The International Electrotechnical Commission (IEC) has established several standards, including IEC 60751 and IEC 60584, which provide guidelines for temperature sensor calibration applicable to thermopiles. These standards define reference conditions, measurement procedures, and acceptable tolerance ranges.

Calibration of thermopiles should follow a two-tier approach: primary calibration against national standards and secondary calibration for routine laboratory use. Primary calibration requires specialized equipment such as blackbody radiation sources with precisely controlled temperatures, typically maintained at national metrology institutes. Secondary calibration can be performed using transfer standard radiometers that have been calibrated against primary standards.

Environmental compensation techniques form a critical component of standardization protocols. Temperature compensation circuits, which adjust the output signal based on ambient temperature measurements, can significantly reduce environmental interference. Similarly, humidity compensation algorithms can be implemented to account for variations in atmospheric moisture content that might affect infrared transmission.

Cross-laboratory validation represents another essential aspect of standardization. Round-robin testing, where identical thermopile samples are measured at different laboratories under controlled conditions, helps establish measurement reproducibility and identify systematic errors in calibration procedures. These collaborative exercises have revealed that without proper standardization, inter-laboratory variations can exceed 15% for identical thermopile sensors.

Documentation requirements constitute a fundamental element of calibration protocols. Each calibration procedure must be thoroughly documented, including environmental conditions (temperature, humidity, pressure), equipment used, reference standards employed, and uncertainty calculations. This documentation ensures traceability and allows for meaningful comparison of results obtained in different environments.

Uncertainty analysis frameworks provide the mathematical foundation for comparing thermopile sensitivity measurements. The Guide to the Expression of Uncertainty in Measurement (GUM) methodology should be applied to quantify all sources of uncertainty, including environmental factors, reference standard accuracy, and measurement system limitations. This comprehensive approach enables the calculation of combined standard uncertainty and expanded uncertainty with defined confidence levels, typically 95%.

Regular recalibration schedules must be established based on stability analysis of the thermopile sensors. Most industrial applications require recalibration intervals of 6-12 months, though this may vary depending on the specific sensor technology and operating environment. Drift analysis during recalibration provides valuable data on long-term stability and can inform adjustments to calibration intervals.

Calibration of thermopiles should follow a two-tier approach: primary calibration against national standards and secondary calibration for routine laboratory use. Primary calibration requires specialized equipment such as blackbody radiation sources with precisely controlled temperatures, typically maintained at national metrology institutes. Secondary calibration can be performed using transfer standard radiometers that have been calibrated against primary standards.

Environmental compensation techniques form a critical component of standardization protocols. Temperature compensation circuits, which adjust the output signal based on ambient temperature measurements, can significantly reduce environmental interference. Similarly, humidity compensation algorithms can be implemented to account for variations in atmospheric moisture content that might affect infrared transmission.

Cross-laboratory validation represents another essential aspect of standardization. Round-robin testing, where identical thermopile samples are measured at different laboratories under controlled conditions, helps establish measurement reproducibility and identify systematic errors in calibration procedures. These collaborative exercises have revealed that without proper standardization, inter-laboratory variations can exceed 15% for identical thermopile sensors.

Documentation requirements constitute a fundamental element of calibration protocols. Each calibration procedure must be thoroughly documented, including environmental conditions (temperature, humidity, pressure), equipment used, reference standards employed, and uncertainty calculations. This documentation ensures traceability and allows for meaningful comparison of results obtained in different environments.

Uncertainty analysis frameworks provide the mathematical foundation for comparing thermopile sensitivity measurements. The Guide to the Expression of Uncertainty in Measurement (GUM) methodology should be applied to quantify all sources of uncertainty, including environmental factors, reference standard accuracy, and measurement system limitations. This comprehensive approach enables the calculation of combined standard uncertainty and expanded uncertainty with defined confidence levels, typically 95%.

Regular recalibration schedules must be established based on stability analysis of the thermopile sensors. Most industrial applications require recalibration intervals of 6-12 months, though this may vary depending on the specific sensor technology and operating environment. Drift analysis during recalibration provides valuable data on long-term stability and can inform adjustments to calibration intervals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!