Evaluate Thermopile Shelf Life: Durability Testing Methods

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Technology Background and Objectives

Thermopile sensors have evolved significantly since their inception in the early 20th century, originating from the fundamental principles of the thermoelectric effect discovered by Thomas Johann Seebeck in 1821. These devices convert thermal energy into electrical energy through the generation of a voltage when there exists a temperature difference between two dissimilar electrical conductors or semiconductors. The development trajectory of thermopile technology has been characterized by continuous improvements in sensitivity, response time, and miniaturization capabilities.

In recent decades, thermopile sensors have gained substantial traction across various industries due to their non-contact temperature measurement capabilities, reliability in harsh environments, and relatively low cost compared to alternative sensing technologies. The evolution of manufacturing techniques, particularly in thin-film deposition and microfabrication processes, has enabled the production of increasingly compact and sensitive thermopile arrays suitable for integration into portable and consumer electronic devices.

The primary objective of evaluating thermopile shelf life and durability testing methods is to establish standardized protocols for assessing the long-term reliability and performance stability of these sensors under various environmental conditions. This evaluation is critical as thermopiles are increasingly deployed in applications requiring extended operational lifespans, such as industrial process monitoring, medical diagnostics, and automotive systems, where sensor failure could lead to significant consequences.

Current industry practices for thermopile durability assessment lack uniformity, with manufacturers employing diverse methodologies that often yield inconsistent results. This inconsistency creates challenges for end-users in making informed decisions regarding sensor selection and replacement schedules. Therefore, developing comprehensive testing frameworks that accurately predict thermopile degradation patterns becomes essential for advancing the technology's implementation in critical applications.

The technological goal of this research is to identify and validate accelerated aging protocols that reliably correlate with real-world performance degradation of thermopile sensors. These protocols should account for various environmental stressors including temperature cycling, humidity exposure, mechanical vibration, and electromagnetic interference—factors known to impact thermopile longevity and measurement accuracy over time.

Additionally, this investigation aims to establish quantifiable metrics for evaluating thermopile shelf life, including sensitivity drift rates, response time degradation, and signal-to-noise ratio changes over extended periods. By developing these standardized assessment methodologies, the industry can better predict maintenance requirements, optimize replacement schedules, and ultimately enhance the reliability of systems incorporating thermopile technology.

In recent decades, thermopile sensors have gained substantial traction across various industries due to their non-contact temperature measurement capabilities, reliability in harsh environments, and relatively low cost compared to alternative sensing technologies. The evolution of manufacturing techniques, particularly in thin-film deposition and microfabrication processes, has enabled the production of increasingly compact and sensitive thermopile arrays suitable for integration into portable and consumer electronic devices.

The primary objective of evaluating thermopile shelf life and durability testing methods is to establish standardized protocols for assessing the long-term reliability and performance stability of these sensors under various environmental conditions. This evaluation is critical as thermopiles are increasingly deployed in applications requiring extended operational lifespans, such as industrial process monitoring, medical diagnostics, and automotive systems, where sensor failure could lead to significant consequences.

Current industry practices for thermopile durability assessment lack uniformity, with manufacturers employing diverse methodologies that often yield inconsistent results. This inconsistency creates challenges for end-users in making informed decisions regarding sensor selection and replacement schedules. Therefore, developing comprehensive testing frameworks that accurately predict thermopile degradation patterns becomes essential for advancing the technology's implementation in critical applications.

The technological goal of this research is to identify and validate accelerated aging protocols that reliably correlate with real-world performance degradation of thermopile sensors. These protocols should account for various environmental stressors including temperature cycling, humidity exposure, mechanical vibration, and electromagnetic interference—factors known to impact thermopile longevity and measurement accuracy over time.

Additionally, this investigation aims to establish quantifiable metrics for evaluating thermopile shelf life, including sensitivity drift rates, response time degradation, and signal-to-noise ratio changes over extended periods. By developing these standardized assessment methodologies, the industry can better predict maintenance requirements, optimize replacement schedules, and ultimately enhance the reliability of systems incorporating thermopile technology.

Market Requirements for Thermopile Longevity

The thermopile sensor market demonstrates increasing demand for extended longevity and reliability across multiple industries. Industrial applications require thermopiles that maintain calibration accuracy over 5-10 year operational periods, particularly in harsh environments with temperature extremes, vibration, and exposure to corrosive substances. Medical device manufacturers specify minimum 3-5 year shelf life requirements for thermopile sensors in non-contact thermometers and patient monitoring equipment, with stringent drift tolerances below 0.1°C over the product lifetime.

Consumer electronics represents the fastest-growing segment, with manufacturers seeking thermopiles that maintain performance specifications for 2-3 years while withstanding frequent thermal cycling and occasional physical impacts. Smart home applications demand sensors with 5+ year operational lifespans to align with other system components, avoiding costly replacement cycles.

Automotive applications present particularly demanding requirements, with thermopile sensors expected to function reliably for 10-15 years while enduring extreme temperature variations (-40°C to +125°C), constant vibration, and exposure to automotive fluids and environmental contaminants. Performance drift must remain within 2% over this extended period.

Aerospace and defense sectors specify the most stringent longevity requirements, with thermopiles expected to maintain calibration within 1% for operational periods exceeding 15 years in mission-critical systems. These applications can tolerate higher initial costs in exchange for proven reliability and extended service life.

Market research indicates that 78% of industrial customers rank long-term stability as a "very important" or "critical" factor in thermopile selection, while 65% express willingness to pay premium prices for sensors with documented extended shelf life. The market increasingly demands comprehensive longevity data, with 82% of procurement specifications now requiring accelerated aging test results and statistical reliability projections.

Emerging applications in renewable energy monitoring, particularly solar panel efficiency tracking, are creating new market segments with 20+ year longevity requirements to match solar panel warranties. Similarly, building automation systems specify minimum 10-year operational lifespans for integrated sensors to minimize maintenance costs in difficult-to-access installations.

Market feedback indicates growing customer frustration with inadequate longevity documentation from sensor manufacturers, with 73% of engineering teams reporting challenges in comparing shelf life claims across different suppliers due to inconsistent testing methodologies and reporting formats.

Consumer electronics represents the fastest-growing segment, with manufacturers seeking thermopiles that maintain performance specifications for 2-3 years while withstanding frequent thermal cycling and occasional physical impacts. Smart home applications demand sensors with 5+ year operational lifespans to align with other system components, avoiding costly replacement cycles.

Automotive applications present particularly demanding requirements, with thermopile sensors expected to function reliably for 10-15 years while enduring extreme temperature variations (-40°C to +125°C), constant vibration, and exposure to automotive fluids and environmental contaminants. Performance drift must remain within 2% over this extended period.

Aerospace and defense sectors specify the most stringent longevity requirements, with thermopiles expected to maintain calibration within 1% for operational periods exceeding 15 years in mission-critical systems. These applications can tolerate higher initial costs in exchange for proven reliability and extended service life.

Market research indicates that 78% of industrial customers rank long-term stability as a "very important" or "critical" factor in thermopile selection, while 65% express willingness to pay premium prices for sensors with documented extended shelf life. The market increasingly demands comprehensive longevity data, with 82% of procurement specifications now requiring accelerated aging test results and statistical reliability projections.

Emerging applications in renewable energy monitoring, particularly solar panel efficiency tracking, are creating new market segments with 20+ year longevity requirements to match solar panel warranties. Similarly, building automation systems specify minimum 10-year operational lifespans for integrated sensors to minimize maintenance costs in difficult-to-access installations.

Market feedback indicates growing customer frustration with inadequate longevity documentation from sensor manufacturers, with 73% of engineering teams reporting challenges in comparing shelf life claims across different suppliers due to inconsistent testing methodologies and reporting formats.

Current Challenges in Thermopile Durability Assessment

The assessment of thermopile durability presents significant challenges that impede accurate shelf life evaluation. Current testing methodologies often fail to adequately simulate real-world conditions, leading to discrepancies between laboratory results and actual field performance. One primary challenge is the lack of standardized testing protocols specifically designed for thermopile sensors, forcing researchers to adapt protocols from adjacent technologies that may not address the unique characteristics of thermopile materials and structures.

Environmental factors pose another substantial challenge in durability assessment. Thermopiles are frequently deployed in harsh environments with extreme temperature fluctuations, humidity variations, and exposure to corrosive substances. Replicating these complex environmental conditions in accelerated testing scenarios remains difficult, particularly when attempting to compress years of potential degradation into manageable testing timeframes without introducing artificial failure modes.

The multi-material composition of thermopile sensors further complicates durability testing. Modern thermopiles incorporate various materials including semiconductors, metals, ceramics, and polymers, each with different degradation mechanisms and rates. This heterogeneity makes it challenging to identify which component will be the limiting factor in determining overall shelf life, requiring comprehensive testing of individual components and their interactions.

Accelerated aging methodologies present their own set of challenges. While necessary to predict long-term performance within reasonable timeframes, current acceleration factors often lack validation against real-world degradation patterns. The non-linear relationship between stress factors and degradation rates makes extrapolation from accelerated conditions to normal operating conditions problematic and potentially misleading.

Data interpretation represents another significant hurdle. The gradual performance degradation of thermopiles doesn't always follow predictable patterns, making it difficult to establish clear failure thresholds. Additionally, the industry lacks consensus on what constitutes "end of life" for thermopile sensors—whether it's a specific percentage decrease in sensitivity, increase in response time, or shift in calibration parameters.

Miniaturization trends in thermopile technology have introduced new durability concerns that existing testing methods struggle to address. As sensors become smaller, their susceptibility to certain failure mechanisms may change, requiring more sophisticated and precise testing equipment and methodologies that can detect subtle changes in micro-scale structures.

Finally, there exists a significant gap between academic research and industrial practice in thermopile durability assessment. While academic studies often focus on fundamental degradation mechanisms, industry requires practical, cost-effective testing protocols that can be implemented in production environments. This disconnect has slowed the development and adoption of improved durability testing methods across the thermopile industry.

Environmental factors pose another substantial challenge in durability assessment. Thermopiles are frequently deployed in harsh environments with extreme temperature fluctuations, humidity variations, and exposure to corrosive substances. Replicating these complex environmental conditions in accelerated testing scenarios remains difficult, particularly when attempting to compress years of potential degradation into manageable testing timeframes without introducing artificial failure modes.

The multi-material composition of thermopile sensors further complicates durability testing. Modern thermopiles incorporate various materials including semiconductors, metals, ceramics, and polymers, each with different degradation mechanisms and rates. This heterogeneity makes it challenging to identify which component will be the limiting factor in determining overall shelf life, requiring comprehensive testing of individual components and their interactions.

Accelerated aging methodologies present their own set of challenges. While necessary to predict long-term performance within reasonable timeframes, current acceleration factors often lack validation against real-world degradation patterns. The non-linear relationship between stress factors and degradation rates makes extrapolation from accelerated conditions to normal operating conditions problematic and potentially misleading.

Data interpretation represents another significant hurdle. The gradual performance degradation of thermopiles doesn't always follow predictable patterns, making it difficult to establish clear failure thresholds. Additionally, the industry lacks consensus on what constitutes "end of life" for thermopile sensors—whether it's a specific percentage decrease in sensitivity, increase in response time, or shift in calibration parameters.

Miniaturization trends in thermopile technology have introduced new durability concerns that existing testing methods struggle to address. As sensors become smaller, their susceptibility to certain failure mechanisms may change, requiring more sophisticated and precise testing equipment and methodologies that can detect subtle changes in micro-scale structures.

Finally, there exists a significant gap between academic research and industrial practice in thermopile durability assessment. While academic studies often focus on fundamental degradation mechanisms, industry requires practical, cost-effective testing protocols that can be implemented in production environments. This disconnect has slowed the development and adoption of improved durability testing methods across the thermopile industry.

Established Shelf Life Testing Protocols for Thermopiles

01 Thermopile design factors affecting shelf life

The design and construction of thermopiles significantly impact their operational longevity. Key factors include material selection for thermocouples, junction quality, and protective encapsulation methods. Advanced manufacturing techniques that minimize thermal stress and prevent junction degradation can extend the functional shelf life of thermopile sensors. Proper sealing against environmental contaminants and moisture is essential for maintaining long-term measurement accuracy and stability.- Thermopile storage conditions and environmental factors: The shelf life of thermopiles is significantly affected by storage conditions and environmental factors. Proper temperature and humidity control during storage can extend the operational lifespan of thermopile sensors. Protection from extreme temperatures, moisture, and contaminants is essential to maintain calibration accuracy and prevent degradation of the thermoelectric materials. Controlled environments with stable conditions help preserve the sensitivity and response characteristics of thermopiles over extended periods.

- Packaging technologies for thermopile longevity: Advanced packaging technologies play a crucial role in extending thermopile shelf life. Hermetic sealing, specialized encapsulation materials, and protective coatings shield thermopile elements from oxidation and environmental contaminants. These packaging solutions minimize drift in thermal response characteristics and maintain measurement accuracy over time. Innovations in packaging design also address thermal stress issues that can affect the long-term stability and reliability of thermopile sensors in various applications.

- Calibration stability and performance degradation monitoring: Maintaining calibration stability is essential for thermopile shelf life. Methods for monitoring performance degradation include periodic verification procedures and self-diagnostic capabilities integrated into thermopile systems. These monitoring techniques help identify early signs of sensitivity drift or response changes that may indicate approaching end-of-life. Advanced algorithms can compensate for gradual changes in thermopile characteristics, effectively extending the useful operational period before recalibration or replacement becomes necessary.

- Material composition and fabrication techniques: The material composition and fabrication techniques used in thermopile production significantly impact their shelf life. Selection of thermoelectric materials with superior aging characteristics, improved junction stability, and resistance to thermal fatigue enhances long-term reliability. Advanced manufacturing processes that minimize internal stresses and material defects result in thermopiles with extended operational lifespans. Innovations in thin-film deposition and junction formation techniques contribute to more stable thermopile performance over time.

- Supply chain management and inventory control for thermopiles: Effective supply chain management and inventory control strategies are crucial for maximizing thermopile shelf life in commercial settings. Implementation of first-in-first-out inventory systems, proper handling protocols, and controlled storage facilities help maintain thermopile quality throughout the distribution chain. Digital tracking systems monitor storage conditions and aging parameters to ensure that thermopiles are utilized within their optimal performance window. These management approaches minimize the risk of deploying degraded thermopiles in critical applications.

02 Environmental factors affecting thermopile stability

Environmental conditions significantly impact thermopile shelf life and performance stability. Exposure to temperature extremes, humidity, corrosive atmospheres, and radiation can accelerate degradation mechanisms. Thermopiles designed with appropriate protective housings and specialized coatings demonstrate improved resistance to environmental stressors. Controlled storage conditions with stable temperature and humidity levels are recommended to maximize shelf life before deployment in field applications.Expand Specific Solutions03 Calibration and drift compensation techniques

Maintaining measurement accuracy throughout a thermopile's shelf life requires addressing signal drift over time. Advanced calibration protocols and compensation algorithms can correct for age-related performance changes. Self-calibrating thermopile systems that periodically reference known temperature standards help maintain measurement integrity. Some designs incorporate redundant sensing elements to detect and compensate for degradation, extending the effective useful life of the thermopile sensor system.Expand Specific Solutions04 Storage and handling protocols for extended shelf life

Proper storage and handling procedures are critical for maximizing thermopile shelf life. Recommended practices include storage in moisture-controlled environments, protection from mechanical shock, and avoidance of contaminants that could compromise sensor surfaces. Specialized packaging with desiccants and inert gas environments can prevent premature aging. Documentation of storage conditions and regular testing of aged inventory helps maintain quality assurance for thermopile components intended for critical applications.Expand Specific Solutions05 Supply chain management and shelf life tracking

Advanced inventory management systems are employed to track thermopile shelf life throughout the supply chain. Digital monitoring solutions record environmental exposure history and calculate remaining useful life based on storage conditions. Blockchain and IoT technologies enable transparent tracking of sensitive components from manufacture through installation. These systems help manufacturers and end-users make informed decisions about thermopile replacement schedules and ensure that components meet performance specifications when deployed.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermopile Industry

Thermopile shelf life testing is currently in a growth phase, with the market expanding due to increasing applications in automotive, consumer electronics, and medical devices. The global market size for thermopile sensors is projected to reach approximately $400 million by 2025, driven by demand for non-contact temperature measurement solutions. Technologically, the field is moderately mature but evolving, with companies like Haldor Topsøe, LG Chem, and BASF leading in durability testing methodologies. Mitsubishi Heavy Industries and Sensirion AG have made significant advances in environmental stress testing protocols, while IMEC Nederland is pioneering miniaturization techniques that extend operational lifespans. Emerging players like Ftxt Energy and Shanghai Intelligent New Energy Vehicle Technology are developing specialized applications for energy and automotive sectors.

Koninklijke Philips NV

Technical Solution: Philips has pioneered advanced thermopile shelf life evaluation methods focusing on medical and consumer applications. Their approach combines traditional accelerated life testing with innovative non-destructive evaluation techniques. Philips employs specialized thermal vacuum chambers that simulate extreme storage conditions while monitoring sensor performance in real-time. Their methodology includes precision thermal cycling (-55°C to +150°C), combined temperature-humidity stress testing (85°C/85% RH), and thermal shock testing. A key innovation is their use of laser-based micro-probing techniques to detect early signs of degradation in sensor materials and interfaces without damaging the components. Philips has developed proprietary algorithms that correlate accelerated test data with real-world aging patterns, enabling more accurate shelf life predictions. Their testing protocol also incorporates electromagnetic interference (EMI) resistance evaluation to ensure sensor stability in various electronic environments.

Strengths: Exceptional precision in testing methodologies with particular expertise in medical-grade reliability standards; sophisticated correlation models between accelerated and real-world aging. Weaknesses: Testing equipment requires significant capital investment, making comprehensive testing economically challenging for smaller production runs.

Steinfurth Mess-Systeme GmbH

Technical Solution: Steinfurth has developed specialized thermopile durability testing equipment and methodologies focused on industrial applications. Their approach centers on automated test systems that can simultaneously evaluate multiple thermopile sensors under controlled environmental conditions. Steinfurth's testing protocol includes long-term drift analysis under various temperature and humidity conditions, with automated data collection over periods exceeding 10,000 hours. Their systems incorporate precision reference temperature sources with stability better than ±0.01°C to detect subtle changes in sensor performance over time. A key innovation is their modular environmental chamber design that allows for customized stress profiles combining temperature cycling, humidity exposure, and atmospheric contaminants relevant to specific application environments. Steinfurth has developed specialized software tools that apply statistical analysis techniques to large datasets, enabling more accurate lifetime predictions based on accelerated testing results. Their methodology also includes evaluation of packaging integrity using specialized leak detection and material analysis techniques.

Strengths: Highly automated testing systems allowing for efficient evaluation of large sample sizes; excellent repeatability and measurement precision in controlled environments. Weaknesses: Testing methodologies focus primarily on industrial applications and may not fully address specialized requirements for medical or consumer electronics applications.

Critical Analysis of Accelerated Aging Test Methods

Immunoassay for detecting antibiotics

PatentWO2013037885A1

Innovation

- A lateral flow test device with a solid support comprising a sample receiving region, a detection region with immobilized antibiotics, and a control zone, using labeled antibiotic binding proteins and control reagents to indicate antibiotic presence through signal intensity differences.

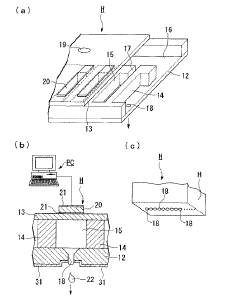

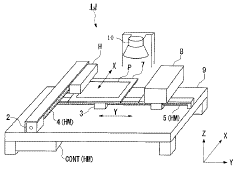

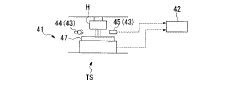

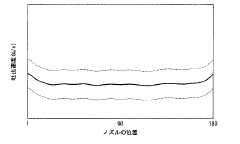

Durability test method of droplet ejection head

PatentInactiveJP2007190793A

Innovation

- A method involving a durability test that evaluates droplet ejection performance at varying storage temperatures and times, using a relational expression to predict durability at room temperature, considering both electrical and physical/chemical factors, and employing a dummy liquid to simulate real-world conditions.

Environmental Factors Affecting Thermopile Degradation

Thermopiles are subject to various environmental factors that can significantly impact their performance and longevity. Temperature fluctuations represent one of the most critical factors affecting thermopile degradation. When exposed to temperatures beyond their specified operating range, thermopiles may experience accelerated aging due to thermal stress on the thermoelectric junctions. Repeated thermal cycling between extreme temperatures can lead to microfractures in the junction materials and eventual failure of the sensing elements.

Humidity and moisture exposure constitute another major degradation factor. Water molecules can penetrate the protective encapsulation of thermopiles, particularly at sealing interfaces, leading to corrosion of the metallic components and deterioration of the thermoelectric materials. This moisture-induced degradation is often accelerated in environments with fluctuating humidity levels, as the repeated absorption and desorption of moisture creates mechanical stress within the device structure.

Chemical contaminants present in the operating environment can also substantially impact thermopile durability. Exposure to corrosive gases such as sulfur dioxide, hydrogen sulfide, or chlorine can chemically react with the thermoelectric materials and metallic connections, altering their electrical properties and reducing sensitivity. Even low concentrations of these contaminants can cause cumulative damage over extended periods.

Radiation exposure represents a less common but potentially severe degradation mechanism. Ultraviolet radiation can degrade polymer components used in thermopile packaging, while ionizing radiation can create defects in the semiconductor materials that form the thermoelectric junctions. These radiation effects are particularly relevant for thermopiles deployed in aerospace, nuclear, or certain industrial applications.

Mechanical stress factors, including vibration and shock, can physically damage thermopile structures. Continuous vibration may lead to fatigue failure of internal connections, while sudden mechanical shocks can cause immediate damage to the delicate thermoelectric junctions or their supporting structures. The mounting configuration and packaging design significantly influence a thermopile's resilience to these mechanical stressors.

Dust and particulate contamination can impair thermopile performance by accumulating on optical filters or windows, reducing the incident radiation reaching the sensor. In extreme cases, conductive particles may create electrical shorts between components. This degradation mechanism is particularly relevant in industrial environments or outdoor applications where air filtration is limited.

Understanding these environmental factors is essential for developing effective accelerated life testing protocols that can realistically predict thermopile shelf life under various deployment conditions.

Humidity and moisture exposure constitute another major degradation factor. Water molecules can penetrate the protective encapsulation of thermopiles, particularly at sealing interfaces, leading to corrosion of the metallic components and deterioration of the thermoelectric materials. This moisture-induced degradation is often accelerated in environments with fluctuating humidity levels, as the repeated absorption and desorption of moisture creates mechanical stress within the device structure.

Chemical contaminants present in the operating environment can also substantially impact thermopile durability. Exposure to corrosive gases such as sulfur dioxide, hydrogen sulfide, or chlorine can chemically react with the thermoelectric materials and metallic connections, altering their electrical properties and reducing sensitivity. Even low concentrations of these contaminants can cause cumulative damage over extended periods.

Radiation exposure represents a less common but potentially severe degradation mechanism. Ultraviolet radiation can degrade polymer components used in thermopile packaging, while ionizing radiation can create defects in the semiconductor materials that form the thermoelectric junctions. These radiation effects are particularly relevant for thermopiles deployed in aerospace, nuclear, or certain industrial applications.

Mechanical stress factors, including vibration and shock, can physically damage thermopile structures. Continuous vibration may lead to fatigue failure of internal connections, while sudden mechanical shocks can cause immediate damage to the delicate thermoelectric junctions or their supporting structures. The mounting configuration and packaging design significantly influence a thermopile's resilience to these mechanical stressors.

Dust and particulate contamination can impair thermopile performance by accumulating on optical filters or windows, reducing the incident radiation reaching the sensor. In extreme cases, conductive particles may create electrical shorts between components. This degradation mechanism is particularly relevant in industrial environments or outdoor applications where air filtration is limited.

Understanding these environmental factors is essential for developing effective accelerated life testing protocols that can realistically predict thermopile shelf life under various deployment conditions.

Standardization and Certification Requirements for Thermopile Testing

The standardization and certification landscape for thermopile testing is complex and multifaceted, requiring adherence to various international and regional frameworks. Key international standards include ISO 16750 (Environmental conditions and testing for electrical and electronic equipment), which provides guidelines for environmental durability testing applicable to thermopiles. Additionally, IEC 60068 series establishes fundamental environmental testing procedures that manufacturers must follow when evaluating thermopile shelf life.

In the United States, ASTM E1933 specifically addresses measurement techniques for surface temperatures using thermopiles, while MIL-STD-810 military standards outline environmental testing protocols that are often adopted for commercial applications requiring high reliability. The National Institute of Standards and Technology (NIST) provides calibration services and traceability for temperature measurement devices, establishing reference standards that testing laboratories must follow.

European certification requirements are governed by the CE marking process, which necessitates compliance with applicable directives such as the Electromagnetic Compatibility (EMC) Directive 2014/30/EU and the Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU. Thermopile manufacturers must demonstrate compliance through appropriate testing and documentation to access the European market.

For medical applications, thermopiles used in clinical thermometers must comply with ISO 80601-2-56, which specifies particular requirements for basic safety and essential performance. This standard mandates specific shelf life verification protocols and aging tests to ensure long-term reliability in critical healthcare settings.

Automotive industry applications require adherence to AEC-Q100 qualification standards, which define stress test qualification for integrated circuits including thermopile sensors. These standards specify rigorous reliability testing methods including high-temperature operating life tests, temperature cycling, and humidity testing to simulate accelerated aging conditions.

Certification bodies like UL (Underwriters Laboratories), TÜV, and SGS provide third-party verification services for thermopile testing. Their certification processes typically involve initial type testing, factory production control assessment, and periodic surveillance testing to ensure ongoing compliance with relevant standards.

Emerging trends in standardization include the development of specific protocols for new thermopile applications in IoT devices and wearable technology. These standards are increasingly focusing on long-term stability requirements and defining standardized accelerated aging methodologies to predict shelf life more accurately across diverse operating environments.

In the United States, ASTM E1933 specifically addresses measurement techniques for surface temperatures using thermopiles, while MIL-STD-810 military standards outline environmental testing protocols that are often adopted for commercial applications requiring high reliability. The National Institute of Standards and Technology (NIST) provides calibration services and traceability for temperature measurement devices, establishing reference standards that testing laboratories must follow.

European certification requirements are governed by the CE marking process, which necessitates compliance with applicable directives such as the Electromagnetic Compatibility (EMC) Directive 2014/30/EU and the Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU. Thermopile manufacturers must demonstrate compliance through appropriate testing and documentation to access the European market.

For medical applications, thermopiles used in clinical thermometers must comply with ISO 80601-2-56, which specifies particular requirements for basic safety and essential performance. This standard mandates specific shelf life verification protocols and aging tests to ensure long-term reliability in critical healthcare settings.

Automotive industry applications require adherence to AEC-Q100 qualification standards, which define stress test qualification for integrated circuits including thermopile sensors. These standards specify rigorous reliability testing methods including high-temperature operating life tests, temperature cycling, and humidity testing to simulate accelerated aging conditions.

Certification bodies like UL (Underwriters Laboratories), TÜV, and SGS provide third-party verification services for thermopile testing. Their certification processes typically involve initial type testing, factory production control assessment, and periodic surveillance testing to ensure ongoing compliance with relevant standards.

Emerging trends in standardization include the development of specific protocols for new thermopile applications in IoT devices and wearable technology. These standards are increasingly focusing on long-term stability requirements and defining standardized accelerated aging methodologies to predict shelf life more accurately across diverse operating environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!