Quantify Thermal Conductivity Impact on Thermopile Function

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Technology Background and Objectives

Thermopiles have evolved significantly since their inception in the early 19th century, originating from the Seebeck effect discovered in 1821. These devices convert thermal energy into electrical energy through the thermoelectric effect, making them valuable in various sensing and energy harvesting applications. The technology has progressed from simple thermocouples to sophisticated multi-junction arrays capable of detecting minute temperature differentials with high precision.

The evolution of thermopile technology has been driven by advancements in materials science, microfabrication techniques, and thermal management strategies. Early thermopiles utilized basic metal junctions, while modern versions incorporate semiconductor materials and thin-film technologies that significantly enhance performance characteristics. This progression has enabled thermopiles to achieve greater sensitivity, faster response times, and improved signal-to-noise ratios.

Thermal conductivity represents a critical parameter in thermopile function, directly influencing device performance across multiple dimensions. The efficiency of thermopiles fundamentally depends on maintaining temperature gradients across thermoelectric junctions, which is inherently affected by the thermal conductivity properties of constituent materials and surrounding structures. Understanding and quantifying this relationship is essential for optimizing thermopile design and performance.

Current research trends focus on enhancing thermopile sensitivity while minimizing power consumption, particularly for applications in portable electronics, medical devices, and IoT sensors. The miniaturization of thermopiles through MEMS (Micro-Electro-Mechanical Systems) technology has opened new application domains while introducing complex thermal management challenges that require sophisticated modeling and characterization techniques.

The primary technical objective of this investigation is to establish quantitative relationships between thermal conductivity parameters and key thermopile performance metrics. This includes developing mathematical models that accurately predict how variations in thermal conductivity affect temperature gradient formation, response time, sensitivity, and signal stability across different operating conditions and environmental factors.

Secondary objectives include identifying optimal material combinations and structural configurations that maximize thermopile efficiency by leveraging thermal conductivity properties. Additionally, we aim to develop standardized testing methodologies for characterizing thermal conductivity impacts on thermopile function, enabling more accurate performance predictions and facilitating comparison between different thermopile designs and implementations.

This research addresses the growing demand for high-performance thermal sensing solutions in emerging fields such as wearable health monitoring, environmental sensing, and precision industrial control systems, where understanding the thermal conductivity impact becomes increasingly critical for meeting stringent performance requirements.

The evolution of thermopile technology has been driven by advancements in materials science, microfabrication techniques, and thermal management strategies. Early thermopiles utilized basic metal junctions, while modern versions incorporate semiconductor materials and thin-film technologies that significantly enhance performance characteristics. This progression has enabled thermopiles to achieve greater sensitivity, faster response times, and improved signal-to-noise ratios.

Thermal conductivity represents a critical parameter in thermopile function, directly influencing device performance across multiple dimensions. The efficiency of thermopiles fundamentally depends on maintaining temperature gradients across thermoelectric junctions, which is inherently affected by the thermal conductivity properties of constituent materials and surrounding structures. Understanding and quantifying this relationship is essential for optimizing thermopile design and performance.

Current research trends focus on enhancing thermopile sensitivity while minimizing power consumption, particularly for applications in portable electronics, medical devices, and IoT sensors. The miniaturization of thermopiles through MEMS (Micro-Electro-Mechanical Systems) technology has opened new application domains while introducing complex thermal management challenges that require sophisticated modeling and characterization techniques.

The primary technical objective of this investigation is to establish quantitative relationships between thermal conductivity parameters and key thermopile performance metrics. This includes developing mathematical models that accurately predict how variations in thermal conductivity affect temperature gradient formation, response time, sensitivity, and signal stability across different operating conditions and environmental factors.

Secondary objectives include identifying optimal material combinations and structural configurations that maximize thermopile efficiency by leveraging thermal conductivity properties. Additionally, we aim to develop standardized testing methodologies for characterizing thermal conductivity impacts on thermopile function, enabling more accurate performance predictions and facilitating comparison between different thermopile designs and implementations.

This research addresses the growing demand for high-performance thermal sensing solutions in emerging fields such as wearable health monitoring, environmental sensing, and precision industrial control systems, where understanding the thermal conductivity impact becomes increasingly critical for meeting stringent performance requirements.

Market Applications and Demand Analysis

The thermopile sensor market has experienced significant growth in recent years, driven by increasing demand for non-contact temperature measurement solutions across multiple industries. The global thermopile detector market was valued at approximately $60 million in 2020 and is projected to reach $95 million by 2026, growing at a CAGR of 8.2% during the forecast period.

The healthcare sector represents one of the largest application areas for thermopile sensors, particularly in medical thermometry devices. The COVID-19 pandemic substantially accelerated this trend, with infrared thermometers becoming essential tools for fever screening. This application specifically highlights the critical importance of thermal conductivity optimization in thermopile function, as measurement accuracy directly impacts diagnostic reliability.

Consumer electronics constitutes another major market segment, with thermopile sensors being integrated into smartphones, tablets, and wearable devices for temperature sensing and thermal imaging capabilities. The automotive industry also demonstrates growing demand, utilizing thermopiles in advanced driver assistance systems (ADAS) for pedestrian detection and in climate control systems. In these applications, the ability to quantify and optimize thermal conductivity impacts directly correlates with device performance and reliability.

Industrial process monitoring represents a significant growth area, where thermopiles are employed for equipment condition monitoring, predictive maintenance, and process control. The energy efficiency sector also shows increasing adoption rates, with thermopile sensors being utilized in building automation systems and HVAC equipment to optimize energy consumption. In both sectors, thermal conductivity characteristics directly influence measurement accuracy and system performance.

Market research indicates that end-users across all sectors consistently prioritize measurement accuracy, response time, and long-term stability as key purchasing factors for thermopile-based devices. These performance metrics are directly influenced by thermal conductivity properties, highlighting the commercial relevance of research focused on quantifying these impacts.

Regional analysis shows North America and Europe currently leading the thermopile sensor market, with Asia-Pacific expected to demonstrate the highest growth rate over the next five years. This growth is primarily driven by increasing industrial automation and smart manufacturing initiatives in countries like China, Japan, and South Korea, where precise thermal measurement technologies are essential components.

The market landscape reveals a clear correlation between advances in thermal conductivity optimization and expanded application possibilities for thermopile technology. As research continues to quantify these relationships more precisely, new market opportunities are expected to emerge, particularly in emerging fields such as Internet of Things (IoT) devices, smart buildings, and advanced healthcare diagnostics.

The healthcare sector represents one of the largest application areas for thermopile sensors, particularly in medical thermometry devices. The COVID-19 pandemic substantially accelerated this trend, with infrared thermometers becoming essential tools for fever screening. This application specifically highlights the critical importance of thermal conductivity optimization in thermopile function, as measurement accuracy directly impacts diagnostic reliability.

Consumer electronics constitutes another major market segment, with thermopile sensors being integrated into smartphones, tablets, and wearable devices for temperature sensing and thermal imaging capabilities. The automotive industry also demonstrates growing demand, utilizing thermopiles in advanced driver assistance systems (ADAS) for pedestrian detection and in climate control systems. In these applications, the ability to quantify and optimize thermal conductivity impacts directly correlates with device performance and reliability.

Industrial process monitoring represents a significant growth area, where thermopiles are employed for equipment condition monitoring, predictive maintenance, and process control. The energy efficiency sector also shows increasing adoption rates, with thermopile sensors being utilized in building automation systems and HVAC equipment to optimize energy consumption. In both sectors, thermal conductivity characteristics directly influence measurement accuracy and system performance.

Market research indicates that end-users across all sectors consistently prioritize measurement accuracy, response time, and long-term stability as key purchasing factors for thermopile-based devices. These performance metrics are directly influenced by thermal conductivity properties, highlighting the commercial relevance of research focused on quantifying these impacts.

Regional analysis shows North America and Europe currently leading the thermopile sensor market, with Asia-Pacific expected to demonstrate the highest growth rate over the next five years. This growth is primarily driven by increasing industrial automation and smart manufacturing initiatives in countries like China, Japan, and South Korea, where precise thermal measurement technologies are essential components.

The market landscape reveals a clear correlation between advances in thermal conductivity optimization and expanded application possibilities for thermopile technology. As research continues to quantify these relationships more precisely, new market opportunities are expected to emerge, particularly in emerging fields such as Internet of Things (IoT) devices, smart buildings, and advanced healthcare diagnostics.

Current Thermal Conductivity Measurement Challenges

The accurate measurement of thermal conductivity presents significant challenges in the context of thermopile function quantification. Traditional methods such as the transient plane source technique, laser flash analysis, and steady-state methods each exhibit limitations when applied to the micro-scale environments where thermopiles operate. These limitations include spatial resolution constraints, temperature range restrictions, and difficulties in isolating thermal conductivity effects from other thermal phenomena.

Material heterogeneity compounds these challenges, as thermopiles typically incorporate multiple materials with varying thermal properties. The interfaces between these materials create thermal boundary resistances that are difficult to characterize using conventional measurement approaches. Furthermore, the anisotropic nature of many materials used in thermopile construction means that thermal conductivity varies with direction, requiring sophisticated three-dimensional measurement capabilities that many current technologies lack.

Temperature dependence represents another significant obstacle, as thermal conductivity values change substantially across the operational temperature range of thermopiles. Current measurement techniques often provide values at specific temperatures, failing to capture the dynamic thermal behavior across the entire functional range. This limitation becomes particularly problematic when attempting to model thermopile performance under varying environmental conditions.

Micro and nanoscale effects further complicate thermal conductivity measurements. As device dimensions approach the mean free path of heat carriers, classical heat conduction models become inadequate. Phonon boundary scattering, quantum confinement effects, and ballistic transport phenomena emerge at these scales, yet conventional measurement techniques are not designed to account for these effects.

Contact resistance between measurement probes and samples introduces significant uncertainty in thermal conductivity measurements. This becomes especially problematic for thin films and layered structures commonly used in thermopile devices, where the contact resistance can be comparable to or greater than the thermal resistance of the material itself.

Time-dependent thermal phenomena present additional challenges. Thermopiles often operate under transient conditions, yet many measurement techniques assume steady-state conditions or provide limited temporal resolution. This discrepancy leads to incomplete characterization of thermal behavior during actual device operation.

Calibration and standardization issues persist across the field, with different measurement techniques often yielding varying results for identical materials. The lack of universally accepted reference materials and standardized procedures for thermopile-specific applications creates significant uncertainty when comparing results across different studies or when translating laboratory measurements to practical device performance predictions.

Material heterogeneity compounds these challenges, as thermopiles typically incorporate multiple materials with varying thermal properties. The interfaces between these materials create thermal boundary resistances that are difficult to characterize using conventional measurement approaches. Furthermore, the anisotropic nature of many materials used in thermopile construction means that thermal conductivity varies with direction, requiring sophisticated three-dimensional measurement capabilities that many current technologies lack.

Temperature dependence represents another significant obstacle, as thermal conductivity values change substantially across the operational temperature range of thermopiles. Current measurement techniques often provide values at specific temperatures, failing to capture the dynamic thermal behavior across the entire functional range. This limitation becomes particularly problematic when attempting to model thermopile performance under varying environmental conditions.

Micro and nanoscale effects further complicate thermal conductivity measurements. As device dimensions approach the mean free path of heat carriers, classical heat conduction models become inadequate. Phonon boundary scattering, quantum confinement effects, and ballistic transport phenomena emerge at these scales, yet conventional measurement techniques are not designed to account for these effects.

Contact resistance between measurement probes and samples introduces significant uncertainty in thermal conductivity measurements. This becomes especially problematic for thin films and layered structures commonly used in thermopile devices, where the contact resistance can be comparable to or greater than the thermal resistance of the material itself.

Time-dependent thermal phenomena present additional challenges. Thermopiles often operate under transient conditions, yet many measurement techniques assume steady-state conditions or provide limited temporal resolution. This discrepancy leads to incomplete characterization of thermal behavior during actual device operation.

Calibration and standardization issues persist across the field, with different measurement techniques often yielding varying results for identical materials. The lack of universally accepted reference materials and standardized procedures for thermopile-specific applications creates significant uncertainty when comparing results across different studies or when translating laboratory measurements to practical device performance predictions.

Existing Thermal Conductivity Quantification Methods

01 Thermopile design for improved thermal conductivity

Specific design considerations in thermopiles can enhance thermal conductivity properties. These include optimizing the arrangement of thermoelectric junctions, selecting appropriate substrate materials, and implementing specialized structural configurations. Such designs can minimize thermal resistance pathways and improve heat transfer efficiency, resulting in more sensitive and accurate temperature measurements or energy harvesting capabilities.- Thermopile design for thermal conductivity measurement: Thermopiles can be designed specifically for measuring thermal conductivity of materials. These designs typically involve arranging thermocouples in specific configurations to detect temperature gradients across a sample. The thermopile sensors convert thermal energy into electrical signals, allowing for precise measurement of heat flow and thermal conductivity properties of various materials.

- Thermal isolation techniques in thermopile structures: Various thermal isolation techniques are employed in thermopile structures to minimize heat loss and improve measurement accuracy. These include using low thermal conductivity materials as substrates, creating suspended membrane structures, incorporating vacuum cavities, and designing thermal barriers. Effective thermal isolation enhances the sensitivity of thermopiles by ensuring that heat flows primarily through the intended measurement path.

- Material selection for thermopile thermal conductivity applications: The selection of materials with specific thermal conductivity properties is crucial for thermopile performance. Materials used in thermopile fabrication include semiconductors, metals with high Seebeck coefficients, and various substrate materials. The combination of materials with different thermal and electrical properties affects the sensitivity, response time, and overall efficiency of thermopile-based thermal conductivity measurement systems.

- Integration of thermopiles in thermal conductivity measurement systems: Thermopiles are integrated into comprehensive measurement systems for thermal conductivity analysis. These systems may include additional components such as reference temperature sensors, signal conditioning circuits, and data acquisition systems. The integration approach affects the overall system accuracy, calibration requirements, and applicability to different measurement scenarios, from laboratory settings to industrial environments.

- Advanced applications of thermopile thermal conductivity sensors: Thermopile-based thermal conductivity sensors find applications in various advanced fields. These include microfluidic thermal analysis, biomedical sensing, environmental monitoring, and industrial process control. The non-invasive nature of thermopile measurements, combined with their high sensitivity and stability, makes them suitable for applications requiring precise thermal property measurements under challenging conditions.

02 Materials selection for thermopile thermal conductivity

The selection of materials with specific thermal conductivity properties is crucial for thermopile performance. High thermal conductivity materials can be used for heat sinks and thermal spreaders, while low thermal conductivity materials can be employed for thermal isolation. Semiconductor materials, metal alloys, and composite structures with tailored thermal properties enable optimization of temperature gradients across thermopile junctions.Expand Specific Solutions03 Thermal isolation techniques in thermopile systems

Various thermal isolation techniques are employed to control heat flow in thermopile systems. These include creating suspended membrane structures, implementing vacuum or air gaps, using low thermal conductivity materials as barriers, and designing specific geometries to minimize thermal crosstalk. Effective thermal isolation ensures that temperature differences are maintained across thermoelectric junctions, maximizing voltage output and measurement sensitivity.Expand Specific Solutions04 Measurement and characterization of thermal conductivity in thermopiles

Various methods are used to measure and characterize thermal conductivity in thermopile systems. These include transient techniques, steady-state measurements, and comparative approaches. Advanced characterization tools help in understanding heat flow patterns, identifying thermal bottlenecks, and optimizing thermopile performance. Accurate thermal conductivity measurements are essential for designing efficient thermopile-based sensors and energy harvesters.Expand Specific Solutions05 Applications leveraging thermopile thermal conductivity properties

Thermopile thermal conductivity properties are leveraged in various applications including thermal imaging, temperature sensing, heat flux measurement, and energy harvesting. By carefully controlling thermal conductivity pathways, these devices can detect minute temperature differences, convert thermal gradients to electrical signals, and enable non-contact temperature measurement. Applications span medical diagnostics, industrial process monitoring, consumer electronics, and environmental sensing.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal conductivity measurement market is in a growth phase, with increasing demand driven by advancements in semiconductor, automotive, and consumer electronics industries. The market size is expanding as thermal management becomes critical in miniaturized devices and high-performance systems. Technologically, the field shows moderate maturity with established players like Texas Instruments, Philips, and Toyota leading commercial applications, while research institutions such as Wuhan University, Delft University of Technology, and Caltech drive innovation. Companies including Maxim Integrated, Alps Alpine, and X-FAB are developing specialized thermopile solutions with enhanced thermal conductivity sensitivity. The competitive landscape features collaboration between industry leaders and academic institutions, creating an ecosystem where fundamental research translates into practical applications for precise thermal conductivity quantification in thermopile functionality.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced thermopile sensor arrays with integrated thermal conductivity compensation mechanisms. Their technology utilizes a proprietary silicon-based microstructure that precisely controls heat flow paths through the thermopile junction. TI's approach incorporates multiple thermal reference points and differential measurement techniques to quantify and compensate for thermal conductivity variations in real-time. Their thermopile sensors feature suspended membrane structures with carefully engineered thermal isolation trenches that minimize parasitic heat conduction, allowing for more accurate temperature gradient measurements. TI has implemented specialized thin-film materials with precisely controlled thermal conductivity properties to optimize thermopile sensitivity while maintaining mechanical stability. Their integrated temperature coefficient correction algorithms dynamically adjust sensor output based on ambient thermal conductivity changes.

Strengths: Industry-leading integration of thermal management and signal processing on a single chip; exceptional temperature stability across wide operating ranges; high volume manufacturing capability with consistent quality. Weaknesses: Higher power consumption compared to some competitors; relatively complex calibration requirements for highest accuracy applications.

Koninklijke Philips NV

Technical Solution: Philips has developed a comprehensive thermal conductivity management framework for medical and consumer thermopile applications. Their approach centers on a multi-layer thermal isolation structure with carefully engineered thermal conductivity properties that optimize temperature gradient sensing. Philips' thermopile sensors incorporate specialized thermal reference elements with known thermal conductivity characteristics, enabling precise calibration and compensation for environmental variations. Their technology utilizes proprietary packaging techniques that create stable thermal environments around the thermopile junctions, minimizing interference from external thermal conductivity fluctuations. Philips has implemented advanced signal processing algorithms that dynamically adjust sensor output based on measured thermal conductivity parameters, ensuring consistent performance across varying operating conditions.

Strengths: Exceptional accuracy in medical-grade temperature sensing applications; comprehensive ecosystem of development tools and application support; strong integration with wireless communication technologies. Weaknesses: Higher price points than mass-market alternatives; more complex implementation requirements for optimal performance.

Key Patents in Thermopile Thermal Conductivity Research

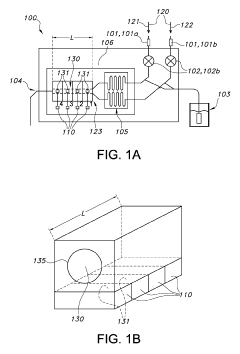

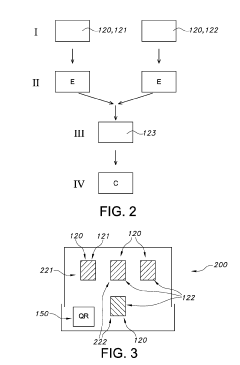

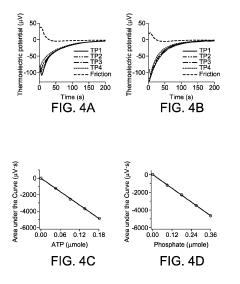

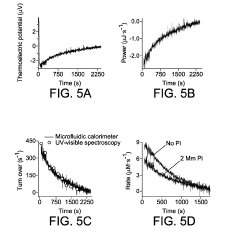

Calibration of a chip-based microfluidic calorimeter

PatentInactiveUS20190195701A1

Innovation

- A calibration method using the deprotonation reaction of a phosphate group is introduced, involving a buffer with a pH range of 7-9 and a compound with a phosphate group protonated in a pH range of 3-6, which generates heat measured by thermopiles, allowing for reliable calibration by relating thermopile signals to reference data from the deprotonating reaction.

Infra red sensor and method for fabricating the same

PatentInactiveEP1102333A3

Innovation

- The integration of a metal resistance layer on the surface of a semiconductor thermoelectric material, forming a thermopile sensor with a reduced internal resistance by adjusting the length of the metal conductor, which also enhances sensitivity and simplifies the fabrication process.

Material Science Advancements for Thermopile Efficiency

Recent advancements in material science have significantly enhanced thermopile efficiency through innovative approaches to thermal conductivity management. The development of novel composite materials with precisely engineered thermal properties has enabled manufacturers to optimize the temperature gradient across thermopile junctions, resulting in improved voltage generation efficiency. These materials combine high electrical conductivity with strategically controlled thermal conductivity, creating an ideal balance for thermopile operation.

Nanotechnology has played a pivotal role in this evolution, with nanoscale material manipulation allowing for unprecedented control over thermal interfaces. Carbon-based materials, particularly graphene and carbon nanotubes, have demonstrated exceptional potential due to their unique thermal transport characteristics that can be tailored through structural modifications. When incorporated into thermopile designs, these materials facilitate more efficient heat flow pathways while maintaining electrical isolation where needed.

Thin-film deposition techniques have evolved to enable the creation of multi-layered structures with alternating thermal conductivity properties. These engineered thermal barriers and pathways maximize the temperature differential across thermopile junctions while minimizing parasitic heat losses. Advanced manufacturing processes now allow for precise control of film thickness down to nanometer scales, creating optimized thermal management systems within extremely compact thermopile devices.

Ceramic-metal composites (cermets) represent another significant advancement, offering customizable thermal conductivity profiles while maintaining structural integrity under thermal cycling conditions. These materials provide excellent thermal stability and can be formulated to exhibit specific thermal conductivity values across different operating temperature ranges, enhancing thermopile performance in variable environmental conditions.

Polymer-based thermal interface materials have also undergone substantial improvement, with new formulations incorporating thermally conductive fillers that maintain flexibility while providing enhanced heat transfer capabilities. These materials are particularly valuable in applications requiring conformable interfaces between thermopile elements and heat sources or sinks, ensuring efficient thermal coupling without mechanical stress.

Computational materials science has accelerated these advancements through predictive modeling of thermal transport phenomena at multiple scales. Simulation tools now enable researchers to design material compositions with specific thermal conductivity profiles before physical prototyping, significantly reducing development cycles for new thermopile materials. This approach has led to the discovery of several promising material combinations that optimize the thermal-to-electrical energy conversion process fundamental to thermopile operation.

Nanotechnology has played a pivotal role in this evolution, with nanoscale material manipulation allowing for unprecedented control over thermal interfaces. Carbon-based materials, particularly graphene and carbon nanotubes, have demonstrated exceptional potential due to their unique thermal transport characteristics that can be tailored through structural modifications. When incorporated into thermopile designs, these materials facilitate more efficient heat flow pathways while maintaining electrical isolation where needed.

Thin-film deposition techniques have evolved to enable the creation of multi-layered structures with alternating thermal conductivity properties. These engineered thermal barriers and pathways maximize the temperature differential across thermopile junctions while minimizing parasitic heat losses. Advanced manufacturing processes now allow for precise control of film thickness down to nanometer scales, creating optimized thermal management systems within extremely compact thermopile devices.

Ceramic-metal composites (cermets) represent another significant advancement, offering customizable thermal conductivity profiles while maintaining structural integrity under thermal cycling conditions. These materials provide excellent thermal stability and can be formulated to exhibit specific thermal conductivity values across different operating temperature ranges, enhancing thermopile performance in variable environmental conditions.

Polymer-based thermal interface materials have also undergone substantial improvement, with new formulations incorporating thermally conductive fillers that maintain flexibility while providing enhanced heat transfer capabilities. These materials are particularly valuable in applications requiring conformable interfaces between thermopile elements and heat sources or sinks, ensuring efficient thermal coupling without mechanical stress.

Computational materials science has accelerated these advancements through predictive modeling of thermal transport phenomena at multiple scales. Simulation tools now enable researchers to design material compositions with specific thermal conductivity profiles before physical prototyping, significantly reducing development cycles for new thermopile materials. This approach has led to the discovery of several promising material combinations that optimize the thermal-to-electrical energy conversion process fundamental to thermopile operation.

Environmental Factors Affecting Measurement Accuracy

Environmental conditions significantly influence the accuracy of thermopile-based thermal conductivity measurements. Temperature fluctuations in the testing environment create thermal gradients that can interfere with the precise measurement of heat flow through the sample material. These ambient temperature variations may introduce measurement errors of up to 5-10% if not properly controlled or compensated for in the measurement protocol.

Humidity levels present another critical environmental factor affecting thermopile function. High humidity can lead to moisture absorption in certain sample materials, altering their thermal conductivity properties during measurement. Research indicates that relative humidity changes of 20% can modify the apparent thermal conductivity readings by 2-8% depending on the hygroscopic nature of the material being tested.

Air currents and ventilation systems in laboratory settings generate convective heat transfer that may disrupt the controlled heat flow necessary for accurate thermopile measurements. Even subtle air movements of 0.2-0.5 m/s can create measurement inconsistencies by introducing unintended cooling effects on the measurement apparatus.

Barometric pressure variations, though often overlooked, can affect the thermal conductivity of gaseous components within porous materials. Studies have shown that pressure changes of 10 kPa can alter thermal conductivity readings by approximately 1-3% in materials with significant porosity or air-filled cavities.

Electromagnetic interference (EMI) from nearby equipment represents a non-thermal environmental factor that can compromise measurement accuracy. Thermopiles generate microvolt-level signals that are susceptible to electrical noise, potentially introducing errors of 1-7% depending on the shielding effectiveness and proximity to EMI sources.

Vibration and mechanical disturbances affect the physical contact between the thermopile sensors and the test material, potentially creating air gaps that impede heat transfer. Research demonstrates that even minor vibrations of 0.1g can reduce measurement accuracy by 2-4% by altering the thermal contact resistance at the interface.

Dust and particulate contamination gradually accumulate on sensor surfaces, creating an insulating layer that reduces heat transfer efficiency. Long-term studies indicate that regular calibration is necessary as sensor sensitivity can decrease by 0.5-2% per month in dusty environments without proper maintenance protocols.

Addressing these environmental factors requires implementation of controlled testing environments, regular calibration procedures, and mathematical compensation algorithms to ensure reliable quantification of thermal conductivity using thermopile technology.

Humidity levels present another critical environmental factor affecting thermopile function. High humidity can lead to moisture absorption in certain sample materials, altering their thermal conductivity properties during measurement. Research indicates that relative humidity changes of 20% can modify the apparent thermal conductivity readings by 2-8% depending on the hygroscopic nature of the material being tested.

Air currents and ventilation systems in laboratory settings generate convective heat transfer that may disrupt the controlled heat flow necessary for accurate thermopile measurements. Even subtle air movements of 0.2-0.5 m/s can create measurement inconsistencies by introducing unintended cooling effects on the measurement apparatus.

Barometric pressure variations, though often overlooked, can affect the thermal conductivity of gaseous components within porous materials. Studies have shown that pressure changes of 10 kPa can alter thermal conductivity readings by approximately 1-3% in materials with significant porosity or air-filled cavities.

Electromagnetic interference (EMI) from nearby equipment represents a non-thermal environmental factor that can compromise measurement accuracy. Thermopiles generate microvolt-level signals that are susceptible to electrical noise, potentially introducing errors of 1-7% depending on the shielding effectiveness and proximity to EMI sources.

Vibration and mechanical disturbances affect the physical contact between the thermopile sensors and the test material, potentially creating air gaps that impede heat transfer. Research demonstrates that even minor vibrations of 0.1g can reduce measurement accuracy by 2-4% by altering the thermal contact resistance at the interface.

Dust and particulate contamination gradually accumulate on sensor surfaces, creating an insulating layer that reduces heat transfer efficiency. Long-term studies indicate that regular calibration is necessary as sensor sensitivity can decrease by 0.5-2% per month in dusty environments without proper maintenance protocols.

Addressing these environmental factors requires implementation of controlled testing environments, regular calibration procedures, and mathematical compensation algorithms to ensure reliable quantification of thermal conductivity using thermopile technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!