Thermopile Vs Thermocouple: Best for Precision Measurements

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Sensor Technology Background and Objectives

Temperature measurement technology has evolved significantly over the past century, with thermal sensors becoming increasingly critical in various industrial, scientific, and consumer applications. The development of precision temperature measurement devices can be traced back to the early 18th century with the invention of the first mercury thermometer. However, modern electronic thermal sensors began their development in the early 20th century, with thermocouples being among the first widely adopted electronic temperature measurement devices.

The evolution of thermal sensor technology has been driven by the growing demand for higher accuracy, faster response times, and greater reliability across multiple industries. Thermocouples, based on the Seebeck effect discovered in 1821, have dominated industrial temperature measurement for decades due to their simplicity, wide temperature range, and robustness. Meanwhile, thermopiles, which are essentially arrays of thermocouples connected in series, emerged as an alternative technology offering enhanced sensitivity for specific applications.

Recent technological advancements have significantly improved both thermocouple and thermopile technologies. Modern manufacturing techniques have enabled the production of more consistent and precise sensors, while developments in signal processing and calibration methods have further enhanced measurement accuracy. The miniaturization trend has also allowed for the integration of these sensors into increasingly compact devices, expanding their application scope.

The global thermal sensor market has experienced substantial growth, with a compound annual growth rate exceeding 6% over the past five years. This growth is primarily fueled by increasing automation in manufacturing, stringent quality control requirements, and the expansion of IoT applications requiring temperature monitoring capabilities.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of thermopile and thermocouple technologies specifically for precision measurement applications. We aim to evaluate their respective strengths and limitations across various performance parameters including accuracy, response time, temperature range, stability, and cost-effectiveness.

Additionally, this research seeks to identify the optimal application scenarios for each technology, considering factors such as environmental conditions, measurement requirements, and integration constraints. By understanding the fundamental principles and practical implementation challenges of both technologies, we can provide evidence-based recommendations for technology selection in different precision measurement contexts.

The findings from this research will serve as a foundation for strategic decision-making regarding sensor technology selection, development roadmaps, and potential innovation opportunities in thermal sensing applications where precision is paramount.

The evolution of thermal sensor technology has been driven by the growing demand for higher accuracy, faster response times, and greater reliability across multiple industries. Thermocouples, based on the Seebeck effect discovered in 1821, have dominated industrial temperature measurement for decades due to their simplicity, wide temperature range, and robustness. Meanwhile, thermopiles, which are essentially arrays of thermocouples connected in series, emerged as an alternative technology offering enhanced sensitivity for specific applications.

Recent technological advancements have significantly improved both thermocouple and thermopile technologies. Modern manufacturing techniques have enabled the production of more consistent and precise sensors, while developments in signal processing and calibration methods have further enhanced measurement accuracy. The miniaturization trend has also allowed for the integration of these sensors into increasingly compact devices, expanding their application scope.

The global thermal sensor market has experienced substantial growth, with a compound annual growth rate exceeding 6% over the past five years. This growth is primarily fueled by increasing automation in manufacturing, stringent quality control requirements, and the expansion of IoT applications requiring temperature monitoring capabilities.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of thermopile and thermocouple technologies specifically for precision measurement applications. We aim to evaluate their respective strengths and limitations across various performance parameters including accuracy, response time, temperature range, stability, and cost-effectiveness.

Additionally, this research seeks to identify the optimal application scenarios for each technology, considering factors such as environmental conditions, measurement requirements, and integration constraints. By understanding the fundamental principles and practical implementation challenges of both technologies, we can provide evidence-based recommendations for technology selection in different precision measurement contexts.

The findings from this research will serve as a foundation for strategic decision-making regarding sensor technology selection, development roadmaps, and potential innovation opportunities in thermal sensing applications where precision is paramount.

Market Demand Analysis for Precision Temperature Measurement

The global market for precision temperature measurement technologies has been experiencing robust growth, driven primarily by increasing demands across industrial automation, healthcare, automotive, and consumer electronics sectors. The precision temperature measurement market was valued at approximately $5.8 billion in 2022 and is projected to reach $8.3 billion by 2028, growing at a CAGR of 6.2% during the forecast period.

Industrial applications represent the largest market segment, accounting for nearly 40% of the total demand. Within this segment, manufacturing processes requiring precise temperature control—such as semiconductor fabrication, glass production, and metal processing—are key drivers. The need for higher accuracy, reliability, and repeatability in these processes has intensified the demand for advanced temperature sensing technologies like thermopiles and thermocouples.

Healthcare and life sciences constitute the fastest-growing segment, with an estimated growth rate of 7.8% annually. Applications in medical diagnostics, pharmaceutical manufacturing, and laboratory research require increasingly precise temperature measurements, often at the micro-scale level. Non-contact temperature measurement solutions are particularly sought after in this sector due to contamination concerns and the need for rapid measurements.

The automotive industry has also emerged as a significant market driver, particularly with the rise of electric vehicles (EVs). Battery thermal management systems in EVs require highly accurate temperature monitoring to ensure safety, efficiency, and longevity. This application alone is expected to generate $650 million in demand for precision temperature sensors by 2026.

Geographically, Asia-Pacific dominates the market with a 38% share, followed by North America (29%) and Europe (24%). China and India are witnessing the fastest growth rates due to rapid industrialization and increasing adoption of automation technologies.

Customer requirements are evolving toward solutions offering higher accuracy (±0.1°C or better), wider temperature ranges, faster response times, and enhanced durability in harsh environments. Additionally, there is growing demand for miniaturized sensors that can be integrated into compact devices and IoT systems.

The competitive landscape reveals a preference shift between thermopiles and thermocouples based on application requirements. Thermocouples currently hold a larger market share (approximately 58%) due to their lower cost and established presence, while thermopiles are gaining ground (annual growth rate of 8.3%) because of their superior precision in specific applications and non-contact measurement capabilities.

Industrial applications represent the largest market segment, accounting for nearly 40% of the total demand. Within this segment, manufacturing processes requiring precise temperature control—such as semiconductor fabrication, glass production, and metal processing—are key drivers. The need for higher accuracy, reliability, and repeatability in these processes has intensified the demand for advanced temperature sensing technologies like thermopiles and thermocouples.

Healthcare and life sciences constitute the fastest-growing segment, with an estimated growth rate of 7.8% annually. Applications in medical diagnostics, pharmaceutical manufacturing, and laboratory research require increasingly precise temperature measurements, often at the micro-scale level. Non-contact temperature measurement solutions are particularly sought after in this sector due to contamination concerns and the need for rapid measurements.

The automotive industry has also emerged as a significant market driver, particularly with the rise of electric vehicles (EVs). Battery thermal management systems in EVs require highly accurate temperature monitoring to ensure safety, efficiency, and longevity. This application alone is expected to generate $650 million in demand for precision temperature sensors by 2026.

Geographically, Asia-Pacific dominates the market with a 38% share, followed by North America (29%) and Europe (24%). China and India are witnessing the fastest growth rates due to rapid industrialization and increasing adoption of automation technologies.

Customer requirements are evolving toward solutions offering higher accuracy (±0.1°C or better), wider temperature ranges, faster response times, and enhanced durability in harsh environments. Additionally, there is growing demand for miniaturized sensors that can be integrated into compact devices and IoT systems.

The competitive landscape reveals a preference shift between thermopiles and thermocouples based on application requirements. Thermocouples currently hold a larger market share (approximately 58%) due to their lower cost and established presence, while thermopiles are gaining ground (annual growth rate of 8.3%) because of their superior precision in specific applications and non-contact measurement capabilities.

Current State and Challenges in Thermal Sensing Technology

The thermal sensing technology landscape has evolved significantly over the past decade, with thermopiles and thermocouples emerging as two dominant technologies for precision temperature measurement applications. Currently, thermocouples remain the most widely deployed temperature sensors globally, accounting for approximately 75% of all industrial temperature measurements due to their robustness, wide temperature range, and relatively low cost.

Thermopiles have gained substantial market share in recent years, particularly in non-contact infrared temperature sensing applications. The global thermal sensor market reached approximately $6.3 billion in 2022 and is projected to grow at a CAGR of 8.2% through 2028, driven by increasing demand for precision measurement in industrial automation, healthcare diagnostics, and consumer electronics.

Despite their widespread adoption, both technologies face significant technical challenges. Thermocouples suffer from inherent non-linearity in their voltage-temperature relationship, requiring complex calibration procedures. They are also susceptible to electrical noise and signal degradation over long transmission distances, with typical measurement errors ranging from ±0.5°C to ±2.0°C depending on thermocouple type and implementation quality.

Thermopiles, while offering advantages in non-contact sensing, face challenges related to emissivity variations of target surfaces, which can introduce measurement errors of up to 5% without proper compensation. Their performance is also affected by ambient temperature fluctuations, requiring sophisticated temperature compensation algorithms to maintain accuracy.

Geographically, North America and Europe lead in high-precision thermal sensing technology development, with Japan and South Korea emerging as innovation hubs for miniaturized thermal sensors. China has rapidly expanded its manufacturing capacity but still lags in developing proprietary high-precision sensing technologies.

A significant technical barrier for both technologies remains the trade-off between response time and measurement stability. Thermocouples typically offer faster response times (50-500ms) but with lower stability, while thermopiles provide better stability but slower response (typically 1-5 seconds for full reading stabilization).

Miniaturization presents another challenge, particularly for thermopiles which require maintaining thermal isolation between hot and cold junctions in increasingly compact form factors. Recent advances in MEMS technology have enabled thermopile sensors as small as 1.2mm × 1.2mm, though often with compromised performance characteristics.

Signal processing remains a critical challenge area, with both technologies requiring sophisticated analog front-end circuits and digital processing to achieve high precision. Modern implementations increasingly incorporate machine learning algorithms to compensate for non-linearities and environmental factors, though this adds computational complexity and power requirements.

Thermopiles have gained substantial market share in recent years, particularly in non-contact infrared temperature sensing applications. The global thermal sensor market reached approximately $6.3 billion in 2022 and is projected to grow at a CAGR of 8.2% through 2028, driven by increasing demand for precision measurement in industrial automation, healthcare diagnostics, and consumer electronics.

Despite their widespread adoption, both technologies face significant technical challenges. Thermocouples suffer from inherent non-linearity in their voltage-temperature relationship, requiring complex calibration procedures. They are also susceptible to electrical noise and signal degradation over long transmission distances, with typical measurement errors ranging from ±0.5°C to ±2.0°C depending on thermocouple type and implementation quality.

Thermopiles, while offering advantages in non-contact sensing, face challenges related to emissivity variations of target surfaces, which can introduce measurement errors of up to 5% without proper compensation. Their performance is also affected by ambient temperature fluctuations, requiring sophisticated temperature compensation algorithms to maintain accuracy.

Geographically, North America and Europe lead in high-precision thermal sensing technology development, with Japan and South Korea emerging as innovation hubs for miniaturized thermal sensors. China has rapidly expanded its manufacturing capacity but still lags in developing proprietary high-precision sensing technologies.

A significant technical barrier for both technologies remains the trade-off between response time and measurement stability. Thermocouples typically offer faster response times (50-500ms) but with lower stability, while thermopiles provide better stability but slower response (typically 1-5 seconds for full reading stabilization).

Miniaturization presents another challenge, particularly for thermopiles which require maintaining thermal isolation between hot and cold junctions in increasingly compact form factors. Recent advances in MEMS technology have enabled thermopile sensors as small as 1.2mm × 1.2mm, though often with compromised performance characteristics.

Signal processing remains a critical challenge area, with both technologies requiring sophisticated analog front-end circuits and digital processing to achieve high precision. Modern implementations increasingly incorporate machine learning algorithms to compensate for non-linearities and environmental factors, though this adds computational complexity and power requirements.

Comparative Analysis of Thermopile and Thermocouple Solutions

01 Precision enhancement techniques for thermopiles

Various techniques can be employed to enhance the precision of thermopiles in temperature measurement applications. These include improved material selection for thermopile junctions, optimized junction geometry, and advanced signal processing methods. By implementing these enhancements, the sensitivity and accuracy of thermopile-based temperature measurements can be significantly improved, making them suitable for high-precision applications.- Precision enhancement techniques for thermopiles: Various techniques can be employed to enhance the precision of thermopiles in temperature measurement applications. These include improved junction designs, specialized material selection, and advanced calibration methods. By optimizing the arrangement and number of thermocouples within the thermopile structure, measurement sensitivity can be significantly increased. Additionally, implementing compensation circuits helps minimize environmental interference and drift effects, resulting in more stable and accurate readings.

- Thermocouple material composition for improved accuracy: The selection and composition of thermocouple materials directly impact measurement precision. Advanced alloys and specialized metal combinations can be used to create thermocouples with enhanced Seebeck coefficients and reduced drift characteristics. These materials exhibit superior stability across wider temperature ranges and demonstrate improved resistance to oxidation and contamination. By carefully controlling the purity and processing of these materials, manufacturers can produce thermocouples with consistent performance characteristics and higher precision.

- Signal processing and calibration methods: Advanced signal processing techniques and calibration methods significantly improve the precision of thermopile and thermocouple measurements. Digital signal processing algorithms can filter noise, apply linearization corrections, and compensate for ambient temperature variations. Multi-point calibration procedures ensure accuracy across the entire operating range, while auto-calibration features allow for periodic adjustment to maintain precision over time. These methods can effectively reduce measurement uncertainty and improve the overall reliability of temperature sensing systems.

- Structural design innovations for thermal sensors: Innovative structural designs can enhance the precision of thermopiles and thermocouples. Microfabrication techniques allow for the creation of highly uniform junction arrays with minimal thermal mass, improving response time and measurement consistency. Specialized housing designs provide better thermal isolation and protection from environmental factors. Additionally, integrating reference junctions directly into the sensor package helps compensate for ambient temperature fluctuations, resulting in more accurate differential temperature measurements.

- Application-specific optimization techniques: Thermopiles and thermocouples can be optimized for specific applications to achieve maximum precision. For medical applications, sensors may be designed with biocompatible materials and specialized form factors. In industrial environments, robust packaging and protective coatings help maintain accuracy under harsh conditions. For scientific instrumentation, ultra-high precision designs may incorporate vacuum encapsulation and radiation shields to minimize thermal noise. These application-specific optimizations ensure that the sensors deliver the required precision for their intended use case.

02 Thermocouple material composition for improved precision

The material composition of thermocouples plays a crucial role in determining their precision. Specific alloy combinations can be selected to optimize the Seebeck coefficient, reduce drift, and enhance stability over time and across temperature ranges. Advanced metallurgical techniques can be used to create thermocouples with consistent properties, resulting in more reliable and precise temperature measurements.Expand Specific Solutions03 Calibration methods for high-precision temperature sensing

Calibration methods are essential for achieving high precision in thermopile and thermocouple measurements. These methods include multi-point calibration across the operating temperature range, reference junction compensation techniques, and automated calibration systems. Proper calibration can compensate for material inconsistencies, aging effects, and environmental factors that might otherwise reduce measurement precision.Expand Specific Solutions04 Signal conditioning and processing for thermocouples

Advanced signal conditioning and processing techniques can significantly improve the precision of thermocouple measurements. These include low-noise amplification, cold junction compensation, digital filtering, and analog-to-digital conversion with high resolution. By implementing sophisticated signal processing algorithms, the effects of electrical noise, thermal noise, and other interference sources can be minimized, resulting in more precise temperature readings.Expand Specific Solutions05 Structural design improvements for thermal sensors

The structural design of thermopiles and thermocouples significantly impacts their precision. Innovations include miniaturized junction arrays, improved thermal isolation, optimized heat flow paths, and protective encapsulation methods. These structural improvements can reduce thermal mass, minimize response time, and enhance measurement stability, leading to more precise temperature sensing capabilities in various environmental conditions.Expand Specific Solutions

Key Manufacturers and Competitors in Thermal Sensor Industry

The thermopile versus thermocouple precision measurement market is in a mature growth phase, with an estimated global market size of $2-3 billion annually. The technology landscape features established players like Watlow Electric Manufacturing and Heraeus Electro-Nite dominating industrial applications, while Fluke Corporation and Siemens AG lead in precision instrumentation. Technological maturity varies between the two sensor types, with thermocouples representing older, robust technology and thermopiles offering newer advantages in non-contact applications. Research institutions like Southeast University and Newcastle University continue advancing sensor technology, while specialized manufacturers such as Furuya Metal and Foreman Instrumentation focus on niche high-precision applications. The market shows increasing integration with IoT and automation systems, driving continued innovation despite the mature technology base.

Heraeus Electro-Nite International N.V.

Technical Solution: Heraeus Electro-Nite specializes in high-precision temperature measurement solutions for demanding industrial applications, particularly in metal processing. Their thermocouple technology incorporates proprietary noble metal alloys that maintain calibration stability even in extreme temperature environments exceeding 1700°C. Their QuickTip thermocouples feature specialized ceramic protection tubes that resist thermal shock and chemical attack while maintaining rapid response characteristics. For applications requiring non-contact measurement, their thermopile-based systems utilize advanced optical focusing techniques to achieve spot measurements with spatial resolution down to 5mm. Heraeus has developed specialized calibration procedures that account for material aging effects, ensuring measurement accuracy throughout the sensor lifecycle even in harsh industrial environments.

Strengths: Unmatched performance in high-temperature applications, exceptional durability in harsh chemical environments, and specialized solutions for molten metal measurements. Weaknesses: Higher initial investment compared to standard sensors, and some specialized products require application-specific implementation support.

Endress+Hauser Gmbh+Co KG

Technical Solution: Endress+Hauser has pioneered innovative approaches to temperature measurement through their iTEMP platform, which supports both thermopile and thermocouple technologies. Their thermocouples feature specialized mineral insulation materials that extend sensor life in harsh industrial environments, while their thermopile solutions incorporate vacuum-sealed reference junctions for enhanced stability. The company has developed proprietary thin-film manufacturing techniques that improve thermopile uniformity and repeatability. Their TempC diagnostic technology continuously monitors sensor health, predicting potential failures before they occur. Endress+Hauser's solutions include advanced digital communication protocols (HART, Profibus, Foundation Fieldbus) that enable integration with modern industrial automation systems while maintaining measurement integrity through the signal chain.

Strengths: Exceptional long-term stability in industrial environments, comprehensive diagnostic capabilities, and seamless integration with process control systems. Weaknesses: Complex configuration options can present a learning curve for new users, and premium pricing reflects the advanced capabilities.

Technical Deep Dive into Precision Measurement Innovations

MEMS-based photoacoustic cell

PatentActiveUS12111249B2

Innovation

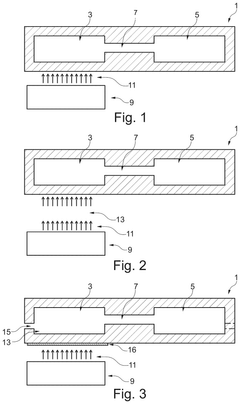

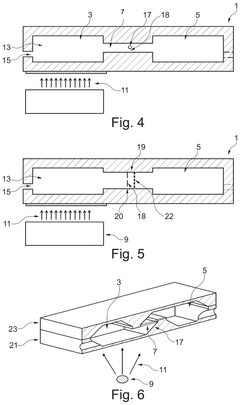

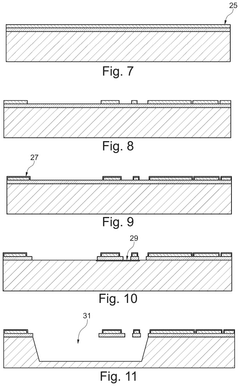

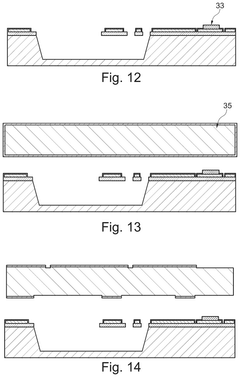

- A photoacoustic gas sensor design featuring a detection chamber and reference chamber arranged laterally and perpendicularly to the IR emitter, with a sensor channel connecting them, allowing for compact, robust, and sensitive gas concentration measurement using a multilayer substrate and MEMS technology.

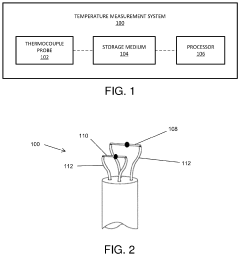

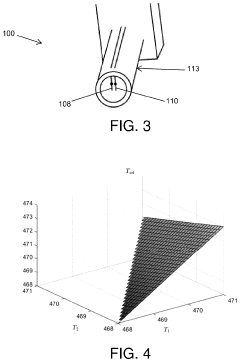

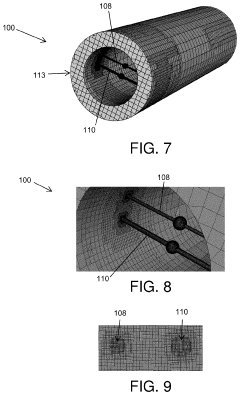

Temperature measurement system and method

PatentPendingUS20240142314A1

Innovation

- A temperature measurement system that includes a thermocouple probe, a computer-readable storage medium, and a processor, which forms a three-dimensional model of the probe, performs computational fluid dynamic analyses, and applies linear regression to correct for conduction errors, providing accurate gas temperature measurements.

Application-Specific Performance Considerations

When selecting between thermopiles and thermocouples for precision measurements, application-specific considerations play a crucial role in determining the optimal choice. In high-temperature industrial environments such as metal processing or glass manufacturing, thermocouples often outperform due to their wider temperature range capability (up to 2300°C for certain types) and robust construction that withstands harsh conditions. The Type K thermocouple, for instance, demonstrates superior performance in metallurgical applications where rapid temperature fluctuations occur.

Conversely, in medical diagnostics and non-contact temperature sensing applications, thermopiles demonstrate distinct advantages. Their ability to detect infrared radiation without direct contact makes them ideal for applications like tympanic thermometers and thermal imaging devices. The non-invasive nature of thermopile measurements becomes particularly valuable in clinical settings where patient comfort and infection control are paramount concerns.

Response time requirements significantly influence sensor selection across applications. Exposed junction thermocouples offer response times as fast as 50 milliseconds, making them suitable for dynamic processes requiring rapid feedback, such as combustion monitoring or plastic extrusion. Thermopiles typically exhibit slower response times (100-500 milliseconds) but provide superior stability in steady-state measurement scenarios.

Space constraints and integration requirements also dictate sensor selection. Thermopiles, with their integrated design and MEMS fabrication capabilities, offer significant advantages in miniaturized applications like wearable health monitors or compact electronic devices. Their lower power consumption further enhances suitability for battery-operated portable instruments.

Environmental factors including electromagnetic interference (EMI) susceptibility must be evaluated. Thermocouples generate relatively weak signals (typically microvolts) making them vulnerable to EMI in industrial settings with heavy machinery. Thermopiles, with their higher output signals and better signal-to-noise ratios, demonstrate superior performance in electrically noisy environments such as power plants or manufacturing facilities.

Budget considerations across different industries also influence sensor selection. While high-precision platinum thermocouples may be justified in semiconductor manufacturing where process accuracy directly impacts yield, more cost-effective thermopile solutions might be preferred in consumer electronics or HVAC applications where moderate precision is acceptable and production volumes are high.

Conversely, in medical diagnostics and non-contact temperature sensing applications, thermopiles demonstrate distinct advantages. Their ability to detect infrared radiation without direct contact makes them ideal for applications like tympanic thermometers and thermal imaging devices. The non-invasive nature of thermopile measurements becomes particularly valuable in clinical settings where patient comfort and infection control are paramount concerns.

Response time requirements significantly influence sensor selection across applications. Exposed junction thermocouples offer response times as fast as 50 milliseconds, making them suitable for dynamic processes requiring rapid feedback, such as combustion monitoring or plastic extrusion. Thermopiles typically exhibit slower response times (100-500 milliseconds) but provide superior stability in steady-state measurement scenarios.

Space constraints and integration requirements also dictate sensor selection. Thermopiles, with their integrated design and MEMS fabrication capabilities, offer significant advantages in miniaturized applications like wearable health monitors or compact electronic devices. Their lower power consumption further enhances suitability for battery-operated portable instruments.

Environmental factors including electromagnetic interference (EMI) susceptibility must be evaluated. Thermocouples generate relatively weak signals (typically microvolts) making them vulnerable to EMI in industrial settings with heavy machinery. Thermopiles, with their higher output signals and better signal-to-noise ratios, demonstrate superior performance in electrically noisy environments such as power plants or manufacturing facilities.

Budget considerations across different industries also influence sensor selection. While high-precision platinum thermocouples may be justified in semiconductor manufacturing where process accuracy directly impacts yield, more cost-effective thermopile solutions might be preferred in consumer electronics or HVAC applications where moderate precision is acceptable and production volumes are high.

Environmental Factors Affecting Measurement Accuracy

Environmental factors play a crucial role in determining the accuracy and reliability of temperature measurements when using thermopiles and thermocouples. These external conditions can significantly impact measurement precision and must be carefully considered when selecting between these technologies for specific applications.

Ambient temperature fluctuations represent one of the most significant environmental challenges. Thermocouples are particularly susceptible to cold junction compensation errors when ambient temperatures change rapidly. In contrast, thermopiles with integrated reference junctions offer better stability in fluctuating environments, though they still require calibration adjustments when operating across wide temperature ranges.

Electromagnetic interference (EMI) affects both technologies differently. Thermocouples, especially those with long lead wires, can act as antennas that pick up electromagnetic noise from nearby equipment, power lines, or radio frequency sources. This interference manifests as measurement instability or offset errors. Thermopiles, being higher impedance devices, may require additional shielding in electrically noisy environments but generally demonstrate superior EMI immunity compared to thermocouples.

Humidity and moisture exposure present significant challenges, particularly in industrial settings. High humidity environments can cause insulation degradation in thermocouple wires, leading to signal leakage and measurement drift over time. Thermopiles, typically housed in sealed packages, offer better protection against moisture-related degradation but may still suffer from condensation effects on optical elements if used in infrared sensing applications.

Air flow and thermal gradients within the measurement environment can create substantial measurement errors. Thermocouples respond more quickly to these changes due to their lower thermal mass, potentially leading to reading fluctuations in environments with inconsistent air movement. Thermopiles, with their larger thermal mass, provide more stable readings in such conditions but sacrifice response time.

Corrosive or chemically active atmospheres pose serious challenges to measurement integrity. Thermocouple materials can undergo chemical degradation when exposed to certain gases or liquids, altering their thermoelectric properties and causing calibration drift. Thermopiles, while generally better protected within their packaging, may still experience degradation of their housing materials or optical components in harsh chemical environments.

Mechanical vibration and shock can affect both technologies by potentially altering the physical characteristics of sensing elements. Thermocouples may experience work hardening of wire junctions under vibration, changing their thermoelectric properties. Thermopiles, with their more complex internal structure, can suffer from mechanical stress that affects the alignment of thermal elements and reference junctions.

Human Engineering Consultant:

## Role:

You are a corporate R&D expert with ten years of experience, primarily responsible for forward-looking technology research to support long-term strategic planning and product development.

Could you please create a technical research report section on "Environmental Factors Affecting Measurement Accuracy" for the topic "Thermopile Vs Thermocouple: Best for Precision Measurements"?

Ambient temperature fluctuations represent one of the most significant environmental challenges. Thermocouples are particularly susceptible to cold junction compensation errors when ambient temperatures change rapidly. In contrast, thermopiles with integrated reference junctions offer better stability in fluctuating environments, though they still require calibration adjustments when operating across wide temperature ranges.

Electromagnetic interference (EMI) affects both technologies differently. Thermocouples, especially those with long lead wires, can act as antennas that pick up electromagnetic noise from nearby equipment, power lines, or radio frequency sources. This interference manifests as measurement instability or offset errors. Thermopiles, being higher impedance devices, may require additional shielding in electrically noisy environments but generally demonstrate superior EMI immunity compared to thermocouples.

Humidity and moisture exposure present significant challenges, particularly in industrial settings. High humidity environments can cause insulation degradation in thermocouple wires, leading to signal leakage and measurement drift over time. Thermopiles, typically housed in sealed packages, offer better protection against moisture-related degradation but may still suffer from condensation effects on optical elements if used in infrared sensing applications.

Air flow and thermal gradients within the measurement environment can create substantial measurement errors. Thermocouples respond more quickly to these changes due to their lower thermal mass, potentially leading to reading fluctuations in environments with inconsistent air movement. Thermopiles, with their larger thermal mass, provide more stable readings in such conditions but sacrifice response time.

Corrosive or chemically active atmospheres pose serious challenges to measurement integrity. Thermocouple materials can undergo chemical degradation when exposed to certain gases or liquids, altering their thermoelectric properties and causing calibration drift. Thermopiles, while generally better protected within their packaging, may still experience degradation of their housing materials or optical components in harsh chemical environments.

Mechanical vibration and shock can affect both technologies by potentially altering the physical characteristics of sensing elements. Thermocouples may experience work hardening of wire junctions under vibration, changing their thermoelectric properties. Thermopiles, with their more complex internal structure, can suffer from mechanical stress that affects the alignment of thermal elements and reference junctions.

Human Engineering Consultant:

## Role:

You are a corporate R&D expert with ten years of experience, primarily responsible for forward-looking technology research to support long-term strategic planning and product development.

Could you please create a technical research report section on "Environmental Factors Affecting Measurement Accuracy" for the topic "Thermopile Vs Thermocouple: Best for Precision Measurements"?

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!