Thermopile Sensors: Best Practices for Environmental Sensing

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Sensor Technology Evolution and Objectives

Thermopile sensors have evolved significantly since their inception in the early 20th century, with their development closely tied to advancements in thermoelectric materials and semiconductor manufacturing technologies. Initially developed as basic temperature measurement devices, these sensors have transformed into sophisticated environmental sensing tools capable of detecting minute temperature variations through non-contact infrared radiation measurement.

The evolution of thermopile sensor technology can be traced through several key phases. In the 1950s and 1960s, early commercial thermopile sensors emerged, primarily used in industrial temperature monitoring applications. The 1970s and 1980s witnessed significant improvements in sensitivity and response time, expanding their application scope. The 1990s marked a turning point with the miniaturization of thermopile arrays, enabling more complex sensing capabilities.

The 2000s brought integration with MEMS (Micro-Electro-Mechanical Systems) technology, dramatically reducing size while improving performance characteristics. This period also saw the development of multi-element thermopile arrays capable of creating thermal images. Recent advancements since 2010 have focused on enhancing signal processing capabilities, reducing power consumption, and improving environmental stability.

Current technological trends in thermopile sensors include the development of higher pixel density arrays, improved temperature resolution (now reaching millikelvin levels), and enhanced signal-to-noise ratios. Integration with IoT platforms and AI-driven analytics represents the cutting edge of thermopile applications, enabling predictive environmental monitoring and smart building management.

The primary objective of modern thermopile sensor technology is to achieve optimal environmental sensing performance while addressing several key challenges. These include improving accuracy across varying ambient conditions, reducing cross-sensitivity to non-target environmental factors, minimizing power consumption for battery-operated devices, and enhancing long-term stability and calibration retention.

Future development goals include further miniaturization without compromising performance, improved multi-spectral sensing capabilities, better integration with complementary sensor technologies (humidity, pressure, gas), and development of self-calibrating systems that maintain accuracy over extended periods without manual intervention.

The technology roadmap also emphasizes cost reduction strategies to enable mass deployment in consumer applications, smart buildings, and environmental monitoring networks. As environmental sensing becomes increasingly critical for climate monitoring, energy efficiency, and public health applications, thermopile sensors are positioned to play a pivotal role in providing accurate, reliable, and cost-effective thermal measurement solutions.

The evolution of thermopile sensor technology can be traced through several key phases. In the 1950s and 1960s, early commercial thermopile sensors emerged, primarily used in industrial temperature monitoring applications. The 1970s and 1980s witnessed significant improvements in sensitivity and response time, expanding their application scope. The 1990s marked a turning point with the miniaturization of thermopile arrays, enabling more complex sensing capabilities.

The 2000s brought integration with MEMS (Micro-Electro-Mechanical Systems) technology, dramatically reducing size while improving performance characteristics. This period also saw the development of multi-element thermopile arrays capable of creating thermal images. Recent advancements since 2010 have focused on enhancing signal processing capabilities, reducing power consumption, and improving environmental stability.

Current technological trends in thermopile sensors include the development of higher pixel density arrays, improved temperature resolution (now reaching millikelvin levels), and enhanced signal-to-noise ratios. Integration with IoT platforms and AI-driven analytics represents the cutting edge of thermopile applications, enabling predictive environmental monitoring and smart building management.

The primary objective of modern thermopile sensor technology is to achieve optimal environmental sensing performance while addressing several key challenges. These include improving accuracy across varying ambient conditions, reducing cross-sensitivity to non-target environmental factors, minimizing power consumption for battery-operated devices, and enhancing long-term stability and calibration retention.

Future development goals include further miniaturization without compromising performance, improved multi-spectral sensing capabilities, better integration with complementary sensor technologies (humidity, pressure, gas), and development of self-calibrating systems that maintain accuracy over extended periods without manual intervention.

The technology roadmap also emphasizes cost reduction strategies to enable mass deployment in consumer applications, smart buildings, and environmental monitoring networks. As environmental sensing becomes increasingly critical for climate monitoring, energy efficiency, and public health applications, thermopile sensors are positioned to play a pivotal role in providing accurate, reliable, and cost-effective thermal measurement solutions.

Market Analysis for Environmental Sensing Applications

The environmental sensing market utilizing thermopile sensors has experienced substantial growth, driven by increasing awareness of environmental monitoring needs across various sectors. The global environmental sensors market was valued at approximately $1.37 billion in 2020 and is projected to reach $2.19 billion by 2026, growing at a CAGR of 8.2% during the forecast period. Thermopile sensors represent a significant segment within this market due to their reliability in temperature and infrared radiation detection applications.

Industrial applications constitute the largest market segment for thermopile-based environmental sensing, accounting for roughly 35% of the total market share. This dominance stems from the critical need for precise temperature monitoring in manufacturing processes, equipment maintenance, and facility management. The HVAC sector follows closely, representing about 28% of the market, where thermopile sensors enable energy-efficient climate control systems and contribute to smart building initiatives.

Consumer electronics applications have shown the most rapid growth rate at approximately 12% annually, as thermopile sensors are increasingly integrated into smartphones, wearables, and smart home devices for ambient temperature sensing and presence detection. The automotive sector accounts for approximately 15% of the market, utilizing these sensors for climate control systems and occupant detection.

Geographically, North America leads the market with approximately 32% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth potential, with China and India driving demand through rapid industrialization and smart city initiatives. The Middle East and Africa regions show emerging interest, particularly in environmental monitoring applications related to climate change and urban development.

Key market drivers include increasingly stringent environmental regulations, growing demand for energy-efficient systems, and the expansion of IoT and smart home technologies. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of environmental monitoring in public health contexts, particularly for applications involving non-contact temperature measurement.

Market challenges include price sensitivity in consumer applications, technical limitations in extreme environments, and competition from alternative sensing technologies. Despite these challenges, the market outlook remains positive, with innovations in miniaturization, power efficiency, and multi-parameter sensing capabilities expected to expand applications and market penetration of thermopile sensor technology in environmental monitoring systems.

Industrial applications constitute the largest market segment for thermopile-based environmental sensing, accounting for roughly 35% of the total market share. This dominance stems from the critical need for precise temperature monitoring in manufacturing processes, equipment maintenance, and facility management. The HVAC sector follows closely, representing about 28% of the market, where thermopile sensors enable energy-efficient climate control systems and contribute to smart building initiatives.

Consumer electronics applications have shown the most rapid growth rate at approximately 12% annually, as thermopile sensors are increasingly integrated into smartphones, wearables, and smart home devices for ambient temperature sensing and presence detection. The automotive sector accounts for approximately 15% of the market, utilizing these sensors for climate control systems and occupant detection.

Geographically, North America leads the market with approximately 32% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth potential, with China and India driving demand through rapid industrialization and smart city initiatives. The Middle East and Africa regions show emerging interest, particularly in environmental monitoring applications related to climate change and urban development.

Key market drivers include increasingly stringent environmental regulations, growing demand for energy-efficient systems, and the expansion of IoT and smart home technologies. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of environmental monitoring in public health contexts, particularly for applications involving non-contact temperature measurement.

Market challenges include price sensitivity in consumer applications, technical limitations in extreme environments, and competition from alternative sensing technologies. Despite these challenges, the market outlook remains positive, with innovations in miniaturization, power efficiency, and multi-parameter sensing capabilities expected to expand applications and market penetration of thermopile sensor technology in environmental monitoring systems.

Current Capabilities and Technical Limitations

Thermopile sensors have evolved significantly in recent years, demonstrating enhanced capabilities for environmental sensing applications. Modern thermopile sensors can detect temperature variations with high precision, typically achieving resolution down to 0.1°C or better. They offer measurement ranges from -40°C to +125°C, making them suitable for diverse environmental monitoring scenarios. Response times have improved substantially, with current models capable of registering temperature changes within 30-100 milliseconds, enabling real-time monitoring applications.

The non-contact nature of thermopile sensors represents a significant advantage, allowing temperature measurement without physical contact with the target object. This feature is particularly valuable in scenarios where contact measurement might be impractical or potentially damaging. Additionally, these sensors demonstrate remarkable stability over extended periods, with drift rates typically below 0.1°C per year, ensuring reliable long-term environmental monitoring.

Power efficiency stands as another notable strength, with modern thermopile sensors consuming as little as 5-50 μW during operation. This low power consumption makes them ideal for battery-powered and energy-harvesting applications in remote environmental sensing deployments. Their compact form factor, often measuring less than 5mm², facilitates integration into space-constrained environmental monitoring systems.

Despite these advancements, thermopile sensors face several technical limitations. Ambient temperature fluctuations can significantly impact measurement accuracy, necessitating sophisticated compensation algorithms. Most current implementations achieve compensation effectiveness of ±2°C across their operating range, though this remains an area requiring further refinement.

Field of view constraints present another challenge, as standard thermopile sensors typically offer viewing angles between 50° and 120°. This limitation can restrict their effectiveness in applications requiring broader environmental coverage or more focused measurement areas. Specialized optics can modify these parameters but often at increased cost and complexity.

Cross-sensitivity to non-thermal radiation sources represents a persistent technical challenge. Current filtering technologies can reduce but not eliminate interference from visible light and other electromagnetic radiation, potentially introducing measurement errors in certain environmental conditions.

Resolution limitations become apparent when detecting small temperature differentials, particularly at distance. While laboratory-grade thermopile arrays can distinguish temperature differences of 0.1°C, this capability degrades significantly with increasing distance and in challenging environmental conditions. The signal-to-noise ratio deteriorates in environments with minimal temperature contrast between the target and background.

The non-contact nature of thermopile sensors represents a significant advantage, allowing temperature measurement without physical contact with the target object. This feature is particularly valuable in scenarios where contact measurement might be impractical or potentially damaging. Additionally, these sensors demonstrate remarkable stability over extended periods, with drift rates typically below 0.1°C per year, ensuring reliable long-term environmental monitoring.

Power efficiency stands as another notable strength, with modern thermopile sensors consuming as little as 5-50 μW during operation. This low power consumption makes them ideal for battery-powered and energy-harvesting applications in remote environmental sensing deployments. Their compact form factor, often measuring less than 5mm², facilitates integration into space-constrained environmental monitoring systems.

Despite these advancements, thermopile sensors face several technical limitations. Ambient temperature fluctuations can significantly impact measurement accuracy, necessitating sophisticated compensation algorithms. Most current implementations achieve compensation effectiveness of ±2°C across their operating range, though this remains an area requiring further refinement.

Field of view constraints present another challenge, as standard thermopile sensors typically offer viewing angles between 50° and 120°. This limitation can restrict their effectiveness in applications requiring broader environmental coverage or more focused measurement areas. Specialized optics can modify these parameters but often at increased cost and complexity.

Cross-sensitivity to non-thermal radiation sources represents a persistent technical challenge. Current filtering technologies can reduce but not eliminate interference from visible light and other electromagnetic radiation, potentially introducing measurement errors in certain environmental conditions.

Resolution limitations become apparent when detecting small temperature differentials, particularly at distance. While laboratory-grade thermopile arrays can distinguish temperature differences of 0.1°C, this capability degrades significantly with increasing distance and in challenging environmental conditions. The signal-to-noise ratio deteriorates in environments with minimal temperature contrast between the target and background.

State-of-the-Art Implementation Methodologies

01 Design and fabrication of thermopile sensors

The design and fabrication of thermopile sensors involve specific materials and structures to optimize performance. Key considerations include the selection of thermoelectric materials with high Seebeck coefficients, proper substrate materials for thermal isolation, and microfabrication techniques to create efficient thermopile junctions. Advanced designs may incorporate vacuum packaging to reduce thermal losses and specialized membrane structures to improve sensitivity. Proper junction arrangement and thermal gradient management are essential for maximizing the output signal.- Design and fabrication of thermopile sensors: The design and fabrication of thermopile sensors involve specific techniques to optimize performance. Key considerations include material selection, structural design, and manufacturing processes that enhance sensitivity and reliability. Advanced fabrication methods can improve thermal isolation, reduce noise, and increase the signal-to-noise ratio. Proper substrate selection and junction design are critical for maximizing the thermoelectric effect and ensuring accurate temperature measurements.

- Calibration and accuracy improvement techniques: Calibration is essential for ensuring thermopile sensor accuracy across various operating conditions. Best practices include multi-point calibration procedures, compensation for ambient temperature variations, and drift correction algorithms. Regular recalibration schedules and validation against reference standards help maintain measurement integrity. Advanced signal processing techniques can further enhance accuracy by filtering noise and compensating for environmental factors that might affect sensor readings.

- Integration with IoT and smart systems: Thermopile sensors can be effectively integrated into Internet of Things (IoT) and smart systems for various applications. Best practices include implementing appropriate communication protocols, optimizing power consumption for battery-operated devices, and developing robust data handling mechanisms. Edge computing capabilities can be incorporated to process sensor data locally before transmission, reducing bandwidth requirements and enabling real-time responses. Security measures should be implemented to protect sensor data and prevent unauthorized access.

- Application-specific optimization strategies: Thermopile sensors require specific optimization strategies depending on their application context. For medical applications, considerations include body temperature compensation and patient safety. In industrial settings, ruggedization against harsh environments and extended temperature ranges is crucial. For consumer electronics, miniaturization and power efficiency are prioritized. Each application domain requires tailored signal processing algorithms, housing designs, and interface specifications to maximize performance and reliability.

- Testing and quality assurance protocols: Comprehensive testing and quality assurance protocols are essential for thermopile sensor reliability. Best practices include environmental stress testing, accelerated aging tests, and statistical process control during manufacturing. Performance verification should include sensitivity, response time, and cross-sensitivity evaluations. Automated test equipment can ensure consistent quality across production batches. Documentation of test results and traceability to calibration standards are important for regulatory compliance and customer confidence.

02 Calibration and accuracy improvement techniques

Maintaining accuracy in thermopile sensor measurements requires proper calibration procedures and error compensation techniques. This includes temperature compensation algorithms to account for ambient temperature variations, periodic recalibration to address drift, and signal processing methods to filter noise. Advanced calibration may involve multi-point temperature references and mathematical models to correct for non-linearity. Implementing these practices ensures reliable measurements across varying environmental conditions and extends the useful life of the sensor system.Expand Specific Solutions03 Integration with electronic systems and signal processing

Effective integration of thermopile sensors with electronic systems requires careful consideration of signal conditioning circuits, amplification methods, and analog-to-digital conversion techniques. Best practices include using low-noise amplifiers matched to thermopile impedance, implementing appropriate filtering to remove electromagnetic interference, and selecting optimal sampling rates for the application. Advanced implementations may incorporate microcontrollers for on-device processing, digital signal processing algorithms for enhanced measurement precision, and communication protocols for system integration.Expand Specific Solutions04 Application-specific optimization for thermal sensing

Thermopile sensors can be optimized for specific applications such as non-contact temperature measurement, thermal imaging, gas detection, and motion sensing. Best practices include selecting appropriate optical filters to target specific infrared wavelengths, designing custom housings for environmental protection, and optimizing field of view for the intended application. For gas detection applications, specialized absorption chambers may be integrated, while motion detection systems benefit from specific lens arrangements and detection algorithms tailored to human presence.Expand Specific Solutions05 Maintenance and reliability enhancement

Ensuring long-term reliability of thermopile sensor systems involves proper maintenance procedures and protective measures. Best practices include regular cleaning of optical surfaces to prevent measurement drift, protection against condensation and contamination, and implementation of self-diagnostic routines to detect sensor degradation. Environmental considerations such as vibration isolation, electromagnetic shielding, and proper thermal management of the sensor housing are crucial for maintaining measurement stability. Implementing redundancy in critical applications and establishing regular performance verification protocols helps ensure continuous reliable operation.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

Thermopile sensor technology is currently in a growth phase, with the market expanding due to increasing applications in environmental sensing, automotive systems, and consumer electronics. The global market size is projected to reach significant value as demand for non-contact temperature measurement solutions grows. From a technical maturity perspective, established players like Texas Instruments, Robert Bosch GmbH, and Excelitas Technologies lead with advanced product portfolios, while companies such as OMRON, Maxim Integrated, and Apple are integrating these sensors into innovative applications. Emerging players like Flusso Ltd. and Yeying Microelectronics are focusing on miniaturization and improved sensitivity. The competitive landscape shows a mix of large electronics manufacturers and specialized sensor companies, with differentiation occurring through precision, power efficiency, and integration capabilities.

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative thermopile sensor platform called BME688 that integrates environmental sensing capabilities for temperature, humidity, pressure, and gas detection in a single compact package. Their thermopile technology utilizes a silicon-based sensor array with specialized membrane structures that maximize thermal isolation and improve sensitivity. For environmental monitoring applications, Bosch has implemented a proprietary low-noise amplifier design that achieves a noise equivalent temperature difference (NETD) of less than 100mK. The BME688 platform incorporates advanced digital signal processing with AI-based algorithms that can identify specific environmental patterns and compensate for cross-sensitivities between different measured parameters. Bosch's thermopile sensors feature a unique suspended membrane design that minimizes thermal mass and enables rapid response times of less than 1 second. Their technology includes integrated temperature compensation circuits that maintain accuracy across a wide operating range (-40°C to +85°C) and specialized optical filters that can be optimized for specific gas detection applications in environmental monitoring.

Strengths: Highly integrated solution combining multiple environmental parameters in a single package; excellent power efficiency (<3.5mW during active measurement); sophisticated AI algorithms for pattern recognition and environmental analysis. Weaknesses: Slightly lower absolute accuracy compared to specialized single-parameter sensors; more complex calibration requirements; higher initial implementation cost though potentially lower total system cost.

Exergen Corp.

Technical Solution: Exergen has developed advanced thermopile sensor technology specifically optimized for environmental sensing applications. Their patented Temporal Scanner™ technology utilizes a proprietary infrared (IR) thermopile sensor array that captures thousands of readings per second to create highly accurate thermal profiles. For environmental monitoring, Exergen has adapted this technology to create non-contact temperature measurement solutions that can detect minute temperature variations across surfaces. Their thermopile sensors feature specialized silicon-based thermopile detectors with vacuum-sealed packaging to minimize thermal noise and maximize sensitivity. The company has pioneered the implementation of automatic ambient temperature compensation algorithms that dynamically adjust readings based on environmental conditions, significantly improving accuracy in fluctuating environments. Exergen's sensors incorporate proprietary signal processing techniques that filter out interference from humidity variations and air currents, making them particularly effective for HVAC applications and building automation systems.

Strengths: Superior accuracy (±0.1°C) in varying ambient conditions; proprietary filtering algorithms that reduce environmental noise; extremely fast response time (50-100ms). Weaknesses: Higher cost compared to conventional thermistors; requires more complex signal processing; slightly larger form factor than some competing technologies.

Key Patents and Technical Innovations

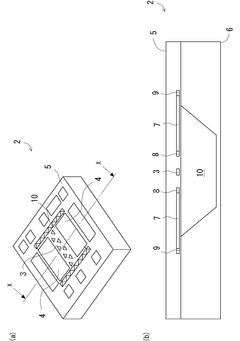

Thermopile sensor

PatentWO2022030039A1

Innovation

- A thermopile sensor design featuring a monolithic structure with a metal protective film covering the circuit and cold junction areas, improving electromagnetic shielding and reducing temperature sensitivity errors, while maintaining a thin film portion to cover the cavity area and expose metal terminals for signal processing.

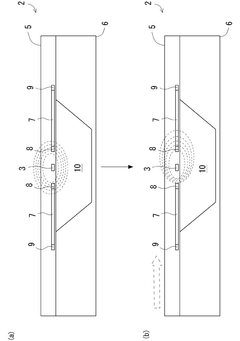

Thermopile sensor and radiation thermometer with a thermopile sensor

PatentWO1998041828A1

Innovation

- The thermopile sensor design ensures that cold and hot spots heat up or cool down at the same rate by compensating for thermal capacity differences through balanced thermal insulation relative to the housing, eliminating temperature gradients through uniform heat transport via conduction, convection, and radiation, without requiring complex stabilization or correction devices.

Calibration and Accuracy Enhancement Techniques

Calibration techniques for thermopile sensors represent a critical aspect of ensuring reliable environmental sensing performance. Factory calibration serves as the foundation, where manufacturers establish baseline performance parameters under controlled conditions. This process typically involves exposing sensors to precisely known temperature differentials and recording output responses to create calibration curves. However, factory calibration alone often proves insufficient for high-precision applications due to component aging, environmental variations, and installation-specific factors.

Field calibration supplements factory settings by adjusting sensor parameters in the actual deployment environment. This process typically requires reference measurements from higher-accuracy instruments to establish correction factors. Multi-point calibration, where sensors are calibrated at several temperature points across their operating range, significantly improves accuracy compared to single-point methods. For environmental sensing applications, calibration should ideally occur under conditions that closely match expected operational scenarios.

Advanced digital signal processing techniques substantially enhance thermopile sensor accuracy. Adaptive filtering algorithms can effectively reduce noise while preserving signal integrity, particularly important for detecting subtle temperature changes. Temperature compensation algorithms address the inherent sensitivity of thermopile sensors to ambient temperature fluctuations by applying correction factors based on secondary temperature measurements. These algorithms typically utilize lookup tables or mathematical models derived from extensive characterization data.

Drift compensation represents another crucial accuracy enhancement technique. Thermopile sensors naturally experience output drift over time due to aging effects and material property changes. Implementing periodic auto-calibration routines or algorithmic drift prediction models can maintain measurement accuracy throughout the sensor's operational lifetime. Some advanced systems incorporate reference temperature sources that activate at predetermined intervals to recalibrate the sensor and correct for drift.

Cross-sensitivity mitigation techniques address the challenge of thermopile sensors responding to non-target stimuli. This includes compensating for humidity effects, which can alter thermal conductivity and emissivity characteristics, and implementing optical filters to isolate specific infrared wavelengths of interest while rejecting others. For environmental sensing applications, particularly those deployed outdoors, additional compensation for solar radiation effects becomes essential to prevent false readings during daylight hours.

Statistical methods further enhance measurement reliability through techniques like ensemble averaging, where multiple readings are combined to reduce random error effects. Kalman filtering proves particularly valuable for dynamic environmental monitoring, as it optimally combines prediction models with actual measurements to produce more accurate results than either approach alone. These advanced calibration and accuracy enhancement techniques collectively enable thermopile sensors to deliver laboratory-grade performance in challenging real-world environmental sensing applications.

Field calibration supplements factory settings by adjusting sensor parameters in the actual deployment environment. This process typically requires reference measurements from higher-accuracy instruments to establish correction factors. Multi-point calibration, where sensors are calibrated at several temperature points across their operating range, significantly improves accuracy compared to single-point methods. For environmental sensing applications, calibration should ideally occur under conditions that closely match expected operational scenarios.

Advanced digital signal processing techniques substantially enhance thermopile sensor accuracy. Adaptive filtering algorithms can effectively reduce noise while preserving signal integrity, particularly important for detecting subtle temperature changes. Temperature compensation algorithms address the inherent sensitivity of thermopile sensors to ambient temperature fluctuations by applying correction factors based on secondary temperature measurements. These algorithms typically utilize lookup tables or mathematical models derived from extensive characterization data.

Drift compensation represents another crucial accuracy enhancement technique. Thermopile sensors naturally experience output drift over time due to aging effects and material property changes. Implementing periodic auto-calibration routines or algorithmic drift prediction models can maintain measurement accuracy throughout the sensor's operational lifetime. Some advanced systems incorporate reference temperature sources that activate at predetermined intervals to recalibrate the sensor and correct for drift.

Cross-sensitivity mitigation techniques address the challenge of thermopile sensors responding to non-target stimuli. This includes compensating for humidity effects, which can alter thermal conductivity and emissivity characteristics, and implementing optical filters to isolate specific infrared wavelengths of interest while rejecting others. For environmental sensing applications, particularly those deployed outdoors, additional compensation for solar radiation effects becomes essential to prevent false readings during daylight hours.

Statistical methods further enhance measurement reliability through techniques like ensemble averaging, where multiple readings are combined to reduce random error effects. Kalman filtering proves particularly valuable for dynamic environmental monitoring, as it optimally combines prediction models with actual measurements to produce more accurate results than either approach alone. These advanced calibration and accuracy enhancement techniques collectively enable thermopile sensors to deliver laboratory-grade performance in challenging real-world environmental sensing applications.

Environmental Factors Affecting Sensor Performance

Thermopile sensors, while highly effective for environmental sensing applications, are significantly influenced by various environmental factors that can impact their performance, accuracy, and reliability. Understanding these factors is crucial for implementing effective sensing solutions and developing appropriate compensation strategies.

Temperature fluctuations represent the most significant environmental challenge for thermopile sensors. These devices operate based on temperature differentials, making them inherently sensitive to ambient temperature changes. When the ambient temperature rapidly shifts, it can create thermal gradients within the sensor package itself, potentially leading to measurement errors of up to 5-10% if not properly compensated. Most modern thermopile implementations incorporate temperature compensation algorithms, but these require careful calibration across the expected operating temperature range.

Humidity levels present another critical factor affecting thermopile sensor performance. High humidity environments can cause condensation on sensor surfaces, particularly when operating near the dew point. This condensation layer can attenuate the infrared signals that thermopile sensors detect, resulting in reduced sensitivity and measurement accuracy. In applications where relative humidity regularly exceeds 80%, protective housing with desiccants or heating elements may be necessary to maintain optimal performance.

Airflow patterns around thermopile sensors can significantly impact their thermal equilibrium. Inconsistent or turbulent airflow creates uneven cooling effects across the sensor surface, potentially introducing measurement artifacts. This is particularly problematic in applications like HVAC monitoring or outdoor environmental sensing, where natural air currents are unpredictable. Proper sensor placement and the use of radiation shields or baffles can help mitigate these effects.

Dust and particulate contamination represent a long-term degradation factor for thermopile sensors. Accumulation of particles on the sensor window gradually reduces infrared transmission, leading to decreased sensitivity over time. In industrial environments or outdoor installations, this degradation can occur more rapidly, necessitating regular maintenance or the implementation of self-cleaning mechanisms such as air purge systems.

Electromagnetic interference (EMI) can also affect thermopile sensor readings, particularly in industrial settings with high-power equipment nearby. The low-level signals generated by thermopile sensors are susceptible to electrical noise, which can manifest as measurement instability or offset errors. Proper shielding, grounding practices, and signal filtering are essential for maintaining measurement integrity in electromagnetically noisy environments.

Understanding these environmental factors and implementing appropriate mitigation strategies is essential for achieving reliable, accurate environmental sensing with thermopile technology. System designers must consider the specific environmental conditions of the intended application and incorporate suitable protective measures and compensation techniques accordingly.

Temperature fluctuations represent the most significant environmental challenge for thermopile sensors. These devices operate based on temperature differentials, making them inherently sensitive to ambient temperature changes. When the ambient temperature rapidly shifts, it can create thermal gradients within the sensor package itself, potentially leading to measurement errors of up to 5-10% if not properly compensated. Most modern thermopile implementations incorporate temperature compensation algorithms, but these require careful calibration across the expected operating temperature range.

Humidity levels present another critical factor affecting thermopile sensor performance. High humidity environments can cause condensation on sensor surfaces, particularly when operating near the dew point. This condensation layer can attenuate the infrared signals that thermopile sensors detect, resulting in reduced sensitivity and measurement accuracy. In applications where relative humidity regularly exceeds 80%, protective housing with desiccants or heating elements may be necessary to maintain optimal performance.

Airflow patterns around thermopile sensors can significantly impact their thermal equilibrium. Inconsistent or turbulent airflow creates uneven cooling effects across the sensor surface, potentially introducing measurement artifacts. This is particularly problematic in applications like HVAC monitoring or outdoor environmental sensing, where natural air currents are unpredictable. Proper sensor placement and the use of radiation shields or baffles can help mitigate these effects.

Dust and particulate contamination represent a long-term degradation factor for thermopile sensors. Accumulation of particles on the sensor window gradually reduces infrared transmission, leading to decreased sensitivity over time. In industrial environments or outdoor installations, this degradation can occur more rapidly, necessitating regular maintenance or the implementation of self-cleaning mechanisms such as air purge systems.

Electromagnetic interference (EMI) can also affect thermopile sensor readings, particularly in industrial settings with high-power equipment nearby. The low-level signals generated by thermopile sensors are susceptible to electrical noise, which can manifest as measurement instability or offset errors. Proper shielding, grounding practices, and signal filtering are essential for maintaining measurement integrity in electromagnetically noisy environments.

Understanding these environmental factors and implementing appropriate mitigation strategies is essential for achieving reliable, accurate environmental sensing with thermopile technology. System designers must consider the specific environmental conditions of the intended application and incorporate suitable protective measures and compensation techniques accordingly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!