Enhance Thermopile Thermal Resistance using Insulation Techniques

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Thermal Resistance Background and Objectives

Thermopiles have evolved significantly since their inception in the early 19th century, originating from the Seebeck effect discovered in 1821. These devices convert thermal energy into electrical energy through the thermoelectric effect, making them valuable in various sensing and energy harvesting applications. The historical progression of thermopile technology has been marked by continuous improvements in materials, fabrication techniques, and thermal management strategies, with thermal resistance being a critical parameter affecting performance.

Thermal resistance in thermopiles represents the device's ability to maintain temperature differentials between hot and cold junctions, directly impacting voltage output and sensitivity. Higher thermal resistance generally yields better performance by preserving temperature gradients essential for thermoelectric conversion. The evolution of thermal resistance enhancement techniques has progressed from basic material selection to sophisticated micro and nanoscale engineering approaches.

Current industry trends indicate growing demand for thermopiles with enhanced thermal resistance in applications ranging from non-contact temperature measurement, infrared detection, and thermal imaging to energy harvesting systems. The miniaturization of devices and integration into IoT platforms has further accelerated the need for optimized thermal resistance characteristics while maintaining compact form factors.

The primary technical objective of this research is to systematically investigate and develop advanced insulation techniques that can significantly enhance the thermal resistance of thermopile sensors without compromising other performance parameters. Specifically, we aim to achieve a 30-50% improvement in thermal resistance compared to current commercial standards while maintaining or reducing manufacturing costs.

Secondary objectives include developing scalable fabrication methods for implementing these insulation techniques in mass production environments, creating simulation models that accurately predict thermal behavior of insulated thermopile structures, and establishing design guidelines for application-specific optimization of thermal resistance in various operating environments.

The long-term technological trajectory points toward integration of these enhanced thermopiles in next-generation sensing systems, particularly in medical diagnostics, automotive safety systems, and energy-efficient building management. Understanding the fundamental principles and practical implementation of thermal resistance enhancement will position organizations to capitalize on emerging market opportunities in these sectors.

This research addresses the growing technical challenge of balancing increased sensitivity requirements with miniaturization trends, where thermal crosstalk and parasitic heat paths increasingly limit device performance. By focusing on innovative insulation techniques, we aim to overcome these limitations and establish new performance benchmarks for thermopile technology.

Thermal resistance in thermopiles represents the device's ability to maintain temperature differentials between hot and cold junctions, directly impacting voltage output and sensitivity. Higher thermal resistance generally yields better performance by preserving temperature gradients essential for thermoelectric conversion. The evolution of thermal resistance enhancement techniques has progressed from basic material selection to sophisticated micro and nanoscale engineering approaches.

Current industry trends indicate growing demand for thermopiles with enhanced thermal resistance in applications ranging from non-contact temperature measurement, infrared detection, and thermal imaging to energy harvesting systems. The miniaturization of devices and integration into IoT platforms has further accelerated the need for optimized thermal resistance characteristics while maintaining compact form factors.

The primary technical objective of this research is to systematically investigate and develop advanced insulation techniques that can significantly enhance the thermal resistance of thermopile sensors without compromising other performance parameters. Specifically, we aim to achieve a 30-50% improvement in thermal resistance compared to current commercial standards while maintaining or reducing manufacturing costs.

Secondary objectives include developing scalable fabrication methods for implementing these insulation techniques in mass production environments, creating simulation models that accurately predict thermal behavior of insulated thermopile structures, and establishing design guidelines for application-specific optimization of thermal resistance in various operating environments.

The long-term technological trajectory points toward integration of these enhanced thermopiles in next-generation sensing systems, particularly in medical diagnostics, automotive safety systems, and energy-efficient building management. Understanding the fundamental principles and practical implementation of thermal resistance enhancement will position organizations to capitalize on emerging market opportunities in these sectors.

This research addresses the growing technical challenge of balancing increased sensitivity requirements with miniaturization trends, where thermal crosstalk and parasitic heat paths increasingly limit device performance. By focusing on innovative insulation techniques, we aim to overcome these limitations and establish new performance benchmarks for thermopile technology.

Market Analysis for Enhanced Thermal Sensors

The global thermal sensor market is experiencing robust growth, driven by increasing demand across multiple industries including automotive, consumer electronics, healthcare, and industrial applications. The market for enhanced thermal sensors, particularly those utilizing thermopile technology with improved thermal resistance through advanced insulation techniques, is projected to reach $7.5 billion by 2026, growing at a CAGR of 8.3% from 2021.

Consumer electronics represents the largest application segment, accounting for approximately 32% of the market share. The miniaturization trend in smartphones, wearables, and IoT devices has created significant demand for high-performance thermal sensors with enhanced sensitivity and reduced power consumption. Manufacturers are increasingly seeking thermopile sensors with superior thermal resistance to improve accuracy in compact form factors.

The automotive sector follows closely, constituting about 28% of the market. With the rise of electric vehicles and advanced driver-assistance systems (ADAS), the need for precise temperature monitoring has intensified. Enhanced thermopile sensors with improved insulation are critical for battery management systems, motor temperature monitoring, and cabin climate control applications.

Healthcare applications represent the fastest-growing segment with a CAGR of 11.2%. The COVID-19 pandemic has accelerated adoption of non-contact temperature measurement devices, creating unprecedented demand for high-precision thermal sensors. Medical device manufacturers are particularly interested in thermopile sensors with enhanced thermal resistance for applications ranging from clinical thermometers to advanced diagnostic equipment.

Regionally, Asia Pacific dominates the market with 42% share, driven by the strong presence of consumer electronics manufacturing and automotive production. North America and Europe follow with 27% and 23% respectively, with growth primarily fueled by healthcare and industrial applications.

Customer requirements are increasingly focused on three key performance metrics: measurement accuracy, response time, and power efficiency. Enhanced thermal resistance through advanced insulation techniques directly addresses these requirements by improving signal-to-noise ratio, reducing thermal leakage, and enabling more precise temperature readings with lower power consumption.

Market research indicates that customers are willing to pay a premium of 15-20% for thermal sensors that demonstrate superior thermal resistance properties. This price elasticity is particularly evident in high-value applications such as medical devices and industrial process control systems where measurement precision directly impacts operational outcomes.

The competitive landscape shows increasing investment in R&D focused on novel insulation materials and techniques. Companies that can successfully commercialize enhanced thermopile sensors with superior thermal resistance characteristics are positioned to capture significant market share in this growing segment.

Consumer electronics represents the largest application segment, accounting for approximately 32% of the market share. The miniaturization trend in smartphones, wearables, and IoT devices has created significant demand for high-performance thermal sensors with enhanced sensitivity and reduced power consumption. Manufacturers are increasingly seeking thermopile sensors with superior thermal resistance to improve accuracy in compact form factors.

The automotive sector follows closely, constituting about 28% of the market. With the rise of electric vehicles and advanced driver-assistance systems (ADAS), the need for precise temperature monitoring has intensified. Enhanced thermopile sensors with improved insulation are critical for battery management systems, motor temperature monitoring, and cabin climate control applications.

Healthcare applications represent the fastest-growing segment with a CAGR of 11.2%. The COVID-19 pandemic has accelerated adoption of non-contact temperature measurement devices, creating unprecedented demand for high-precision thermal sensors. Medical device manufacturers are particularly interested in thermopile sensors with enhanced thermal resistance for applications ranging from clinical thermometers to advanced diagnostic equipment.

Regionally, Asia Pacific dominates the market with 42% share, driven by the strong presence of consumer electronics manufacturing and automotive production. North America and Europe follow with 27% and 23% respectively, with growth primarily fueled by healthcare and industrial applications.

Customer requirements are increasingly focused on three key performance metrics: measurement accuracy, response time, and power efficiency. Enhanced thermal resistance through advanced insulation techniques directly addresses these requirements by improving signal-to-noise ratio, reducing thermal leakage, and enabling more precise temperature readings with lower power consumption.

Market research indicates that customers are willing to pay a premium of 15-20% for thermal sensors that demonstrate superior thermal resistance properties. This price elasticity is particularly evident in high-value applications such as medical devices and industrial process control systems where measurement precision directly impacts operational outcomes.

The competitive landscape shows increasing investment in R&D focused on novel insulation materials and techniques. Companies that can successfully commercialize enhanced thermopile sensors with superior thermal resistance characteristics are positioned to capture significant market share in this growing segment.

Current Insulation Techniques and Challenges

Thermopile sensors rely heavily on effective thermal insulation to maximize their sensitivity and performance. Current insulation techniques for thermopiles can be broadly categorized into material-based approaches and structural design strategies, each with specific advantages and limitations.

Traditional material-based insulation techniques include the use of low thermal conductivity materials such as silicon dioxide (SiO2), silicon nitride (Si3N4), and various polymers. SiO2 offers excellent electrical insulation properties with thermal conductivity around 1.4 W/m·K, while Si3N4 provides better mechanical strength with slightly higher thermal conductivity (15-30 W/m·K). Polymer-based insulators like polyimide and SU-8 photoresist deliver even lower thermal conductivity values (0.1-0.3 W/m·K) but often suffer from temperature stability issues at higher operating ranges.

Advanced materials such as aerogels and vacuum insulation panels represent cutting-edge solutions, offering extremely low thermal conductivity (0.01-0.03 W/m·K) but presenting significant manufacturing integration challenges in microscale thermopile devices. These materials often require specialized deposition techniques that may not be compatible with standard semiconductor fabrication processes.

Structural design approaches focus on creating physical barriers to heat flow through geometric optimization. Suspended membrane structures, where the thermopile is positioned on a thin membrane with minimal thermal connection to the substrate, have become industry standard. Micromachined cavities and trenches further reduce thermal conductance paths, while multi-layer insulation schemes create complex thermal resistance networks.

Despite these advancements, significant challenges persist in thermopile insulation technology. Thermal crosstalk between adjacent sensing elements remains problematic, particularly as device miniaturization continues. The trade-off between mechanical robustness and thermal isolation presents a fundamental engineering dilemma, as thinner structures with better insulation properties often lack durability.

Manufacturing scalability represents another major hurdle, with many advanced insulation techniques requiring complex, multi-step fabrication processes that increase production costs. Additionally, long-term stability and reliability of insulation materials under thermal cycling and environmental exposure conditions remain concerns, particularly for applications in harsh environments.

The integration of insulation materials with other device components presents compatibility challenges, especially regarding thermal expansion coefficient matching and adhesion properties. Furthermore, as devices continue to shrink, quantum effects and nanoscale heat transfer mechanisms become increasingly relevant, requiring new theoretical models and experimental approaches to optimize thermal resistance.

Traditional material-based insulation techniques include the use of low thermal conductivity materials such as silicon dioxide (SiO2), silicon nitride (Si3N4), and various polymers. SiO2 offers excellent electrical insulation properties with thermal conductivity around 1.4 W/m·K, while Si3N4 provides better mechanical strength with slightly higher thermal conductivity (15-30 W/m·K). Polymer-based insulators like polyimide and SU-8 photoresist deliver even lower thermal conductivity values (0.1-0.3 W/m·K) but often suffer from temperature stability issues at higher operating ranges.

Advanced materials such as aerogels and vacuum insulation panels represent cutting-edge solutions, offering extremely low thermal conductivity (0.01-0.03 W/m·K) but presenting significant manufacturing integration challenges in microscale thermopile devices. These materials often require specialized deposition techniques that may not be compatible with standard semiconductor fabrication processes.

Structural design approaches focus on creating physical barriers to heat flow through geometric optimization. Suspended membrane structures, where the thermopile is positioned on a thin membrane with minimal thermal connection to the substrate, have become industry standard. Micromachined cavities and trenches further reduce thermal conductance paths, while multi-layer insulation schemes create complex thermal resistance networks.

Despite these advancements, significant challenges persist in thermopile insulation technology. Thermal crosstalk between adjacent sensing elements remains problematic, particularly as device miniaturization continues. The trade-off between mechanical robustness and thermal isolation presents a fundamental engineering dilemma, as thinner structures with better insulation properties often lack durability.

Manufacturing scalability represents another major hurdle, with many advanced insulation techniques requiring complex, multi-step fabrication processes that increase production costs. Additionally, long-term stability and reliability of insulation materials under thermal cycling and environmental exposure conditions remain concerns, particularly for applications in harsh environments.

The integration of insulation materials with other device components presents compatibility challenges, especially regarding thermal expansion coefficient matching and adhesion properties. Furthermore, as devices continue to shrink, quantum effects and nanoscale heat transfer mechanisms become increasingly relevant, requiring new theoretical models and experimental approaches to optimize thermal resistance.

State-of-the-Art Thermal Insulation Solutions

01 Thermopile structure design for thermal resistance optimization

The design of thermopile structures can be optimized to manage thermal resistance effectively. This includes the arrangement of thermoelectric elements, junction configurations, and material selection to control heat flow paths. Proper structural design can minimize unwanted heat transfer, improve temperature gradient maintenance, and enhance overall thermal efficiency of the thermopile device.- Thermopile structure design for thermal resistance optimization: The design of thermopile structures significantly impacts thermal resistance. Various structural configurations, including membrane structures, suspended structures, and vacuum-sealed designs, can be implemented to optimize thermal isolation. These designs aim to reduce thermal conductivity pathways, thereby increasing temperature differentials across the thermopile junctions and improving sensitivity. Materials selection and junction geometry also play crucial roles in controlling thermal resistance properties.

- Thermal isolation techniques for thermopile sensors: Effective thermal isolation is essential for thermopile performance. Techniques include creating air gaps, using low thermal conductivity materials, implementing vacuum encapsulation, and designing thermal barriers. These methods prevent heat dissipation from the hot junction and maintain temperature gradients across the thermopile. Advanced isolation techniques can significantly reduce thermal crosstalk between adjacent sensing elements and improve the signal-to-noise ratio in thermopile-based sensing applications.

- Materials selection for thermopile thermal resistance control: The selection of materials for thermopile fabrication directly affects thermal resistance properties. Semiconductor materials with high Seebeck coefficients combined with low thermal conductivity are preferred. Materials such as polysilicon, bismuth telluride, antimony telluride, and various metal alloys are commonly used. Substrate materials with low thermal conductivity help maintain temperature differentials, while specialized coatings can enhance absorption or reflection properties to optimize thermal performance.

- Measurement and characterization of thermopile thermal resistance: Accurate measurement and characterization of thermal resistance in thermopiles is critical for performance evaluation. Various methods include transient thermal response testing, steady-state temperature differential measurements, and thermal imaging techniques. Advanced characterization approaches utilize finite element analysis and computational modeling to predict thermal behavior. These measurements help optimize design parameters and validate theoretical models for thermopile performance under different operating conditions.

- Applications leveraging thermopile thermal resistance properties: Thermopile thermal resistance properties are leveraged in various applications including infrared sensing, thermal imaging, temperature measurement, energy harvesting, and heat flux sensing. The controlled thermal resistance enables precise detection of temperature differentials in medical diagnostics, building energy management, automotive systems, and industrial process monitoring. Optimized thermal resistance characteristics allow for improved sensitivity, faster response times, and greater accuracy in these diverse application domains.

02 Thermal isolation techniques for thermopiles

Various thermal isolation techniques are employed to control the thermal resistance in thermopile devices. These include creating suspended structures, using vacuum or air gaps, implementing thermal barriers, and utilizing low thermal conductivity materials. Effective thermal isolation ensures that temperature differences are maintained across the thermopile junctions, improving sensitivity and performance of thermal sensing applications.Expand Specific Solutions03 Material selection for thermal resistance control

The selection of materials with specific thermal properties is crucial for controlling thermal resistance in thermopiles. Materials with high Seebeck coefficients combined with appropriate thermal conductivity characteristics are selected for thermoelectric elements. Substrate materials, interface layers, and packaging components are chosen to either promote or restrict heat flow depending on the application requirements.Expand Specific Solutions04 Thermal resistance measurement and characterization methods

Various methods are employed to measure and characterize the thermal resistance of thermopile devices. These include direct temperature measurement techniques, electrical response analysis, thermal imaging, and computational modeling. Accurate characterization of thermal resistance is essential for optimizing device performance, ensuring reliability, and validating design parameters for specific applications.Expand Specific Solutions05 Application-specific thermal resistance optimization

Thermal resistance in thermopiles is optimized differently based on specific applications. For energy harvesting applications, thermal resistance is managed to maximize temperature gradients and power output. In sensing applications, thermal resistance is controlled to enhance sensitivity and response time. For infrared detection, thermal isolation techniques are implemented to improve signal-to-noise ratio and detection capabilities.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The thermopile thermal resistance enhancement market is currently in a growth phase, with increasing demand driven by energy efficiency requirements across multiple industries. The market size is expanding at approximately 5-7% annually, particularly in automotive, aerospace, and semiconductor sectors. From a technological maturity perspective, established players like Siemens AG, Toshiba Corp., and LG Electronics have developed advanced commercial solutions, while specialized companies such as Hamamatsu Photonics and GlobalFoundries are focusing on semiconductor-specific applications. Aerospace leaders Boeing and Japan Aerospace Exploration Agency are advancing high-performance insulation techniques for extreme environments. The competitive landscape shows a mix of large conglomerates and specialized manufacturers, with innovation primarily focused on material science advancements and miniaturization capabilities for next-generation sensing applications.

Toshiba Corp.

Technical Solution: Toshiba has developed a comprehensive thermal insulation approach for thermopile sensors that combines multiple technologies to maximize thermal resistance. Their solution incorporates a suspended membrane structure fabricated using proprietary MEMS processes, creating an air gap with thermal conductivity as low as 0.026 W/mK. Toshiba employs specialized low-k dielectric materials with thermal conductivities below 0.15 W/mK as additional insulation layers. The company's advanced packaging technology includes vacuum sealing with specialized getter materials that maintain vacuum integrity over the product lifetime. Toshiba has also pioneered the use of aerogel-based insulation materials with extremely low thermal conductivity (0.013-0.020 W/mK) applied using proprietary deposition techniques that preserve the material's nanoporous structure. Their thermopile designs incorporate optimized thermal path geometries that minimize heat leakage through electrical connections.

Strengths: Comprehensive approach combining multiple insulation technologies; strong manufacturing capabilities for mass production; excellent thermal performance across wide temperature ranges. Weaknesses: Complex fabrication process requires specialized equipment; higher cost structure compared to simpler designs; potential reliability challenges with advanced materials in harsh environments.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has developed specialized thermopile insulation techniques focused on automotive applications that require exceptional durability and reliability. Their approach utilizes a multi-layer insulation system incorporating proprietary ceramic materials with extremely low thermal conductivity (0.05-0.10 W/mK). The company employs advanced MEMS fabrication techniques to create suspended membrane structures with optimized thermal bridges that minimize heat leakage while maintaining mechanical stability. Toyota's thermopile sensors feature specialized packaging with vacuum-sealed cavities that eliminate convective heat transfer, with reported thermal resistance improvements of up to 65% compared to conventional designs. Their technology incorporates specialized surface treatments that minimize radiative heat transfer across the sensor structure. Toyota has also developed proprietary composite insulation materials that maintain their thermal properties across the wide temperature ranges encountered in automotive environments (-40°C to +125°C).

Strengths: Exceptional durability and reliability suitable for harsh automotive environments; excellent thermal performance across wide temperature ranges; robust design withstands mechanical vibration and shock. Weaknesses: Higher production costs compared to consumer-grade solutions; larger physical size due to durability requirements; specialized automotive focus limits applicability in other markets.

Key Patents and Research in Thermopile Insulation

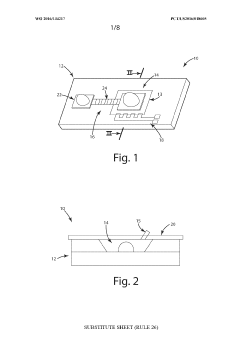

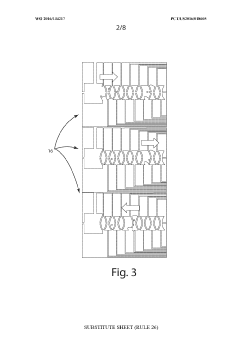

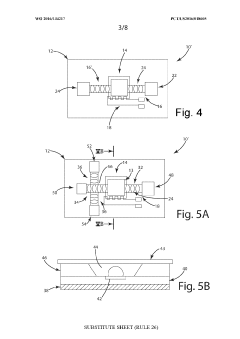

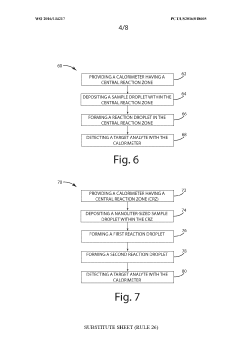

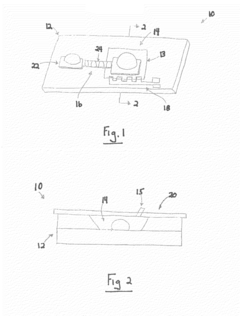

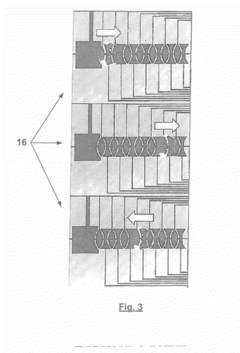

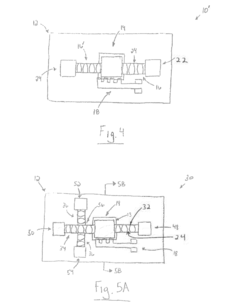

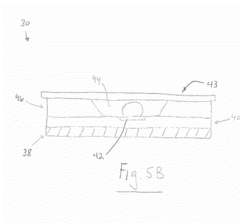

Device and method for detecting a target analyte

PatentWO2016134217A1

Innovation

- A nanocalorimetry-based device with a hermetically-sealed, thermally decoupled central reaction zone and functionalized surface for capturing analytes, combined with enzyme amplification strategies, allowing for rapid and sensitive detection of thermal signatures from binding events, enabling detection in minutes with minimal training and equipment.

Device And Method For Detecting A Target Analyte

PatentActiveUS20150160205A1

Innovation

- A nanocalorimetry-based diagnostic device with a hermetically-sealed, thermally decoupled central reaction zone and functionalized surfaces for capturing analytes, combined with enzyme amplification strategies, to enhance sensitivity and speed of detection.

Materials Science Advancements for Thermal Insulation

Recent advancements in materials science have revolutionized thermal insulation technologies, offering significant potential for enhancing thermopile thermal resistance. The development of aerogels represents one of the most promising breakthroughs, with silica aerogels demonstrating thermal conductivity values as low as 0.013 W/mK, approximately three times more effective than conventional fiberglass insulation. These ultra-lightweight materials, composed of up to 99.8% air, create nanoporous structures that severely restrict heat transfer pathways.

Ceramic-based insulation materials have also seen remarkable innovation, particularly with the introduction of multi-layered ceramic microspheres. These structures create numerous thermal boundary interfaces that effectively scatter phonons, reducing thermal conductivity while maintaining structural integrity at high temperatures up to 1600°C. This makes them particularly valuable for thermopile applications in extreme thermal environments.

Polymer-based nanocomposites represent another frontier in thermal insulation. By incorporating nanoparticles such as graphene oxide, boron nitride, or modified silica into polymer matrices, researchers have achieved thermal conductivity reductions of 25-40% compared to base polymers. These materials offer the additional advantages of flexibility, light weight, and compatibility with various manufacturing processes including 3D printing and injection molding.

Vacuum insulation panels (VIPs) have emerged as a high-performance solution, achieving thermal conductivity values below 0.004 W/mK. Modern VIPs utilize fumed silica cores with infrared opacifiers and getter materials, encapsulated in multi-layer barrier films. While offering exceptional performance, their implementation in thermopile applications requires careful consideration of edge effects and potential performance degradation over time.

Phase change materials (PCMs) integrated with traditional insulation offer dynamic thermal management capabilities. These materials absorb and release thermal energy during phase transitions, effectively dampening temperature fluctuations. Recent developments in microencapsulation techniques have addressed previous challenges related to containment and cycling stability, making PCMs increasingly viable for precision thermal management in thermopile systems.

Bio-based insulation materials derived from sustainable sources such as cellulose, hemp, and mycelium have demonstrated competitive thermal performance while offering environmental benefits. Advanced processing techniques have overcome traditional limitations related to moisture sensitivity and fire resistance, making these materials increasingly suitable for technical applications requiring precise thermal control.

Ceramic-based insulation materials have also seen remarkable innovation, particularly with the introduction of multi-layered ceramic microspheres. These structures create numerous thermal boundary interfaces that effectively scatter phonons, reducing thermal conductivity while maintaining structural integrity at high temperatures up to 1600°C. This makes them particularly valuable for thermopile applications in extreme thermal environments.

Polymer-based nanocomposites represent another frontier in thermal insulation. By incorporating nanoparticles such as graphene oxide, boron nitride, or modified silica into polymer matrices, researchers have achieved thermal conductivity reductions of 25-40% compared to base polymers. These materials offer the additional advantages of flexibility, light weight, and compatibility with various manufacturing processes including 3D printing and injection molding.

Vacuum insulation panels (VIPs) have emerged as a high-performance solution, achieving thermal conductivity values below 0.004 W/mK. Modern VIPs utilize fumed silica cores with infrared opacifiers and getter materials, encapsulated in multi-layer barrier films. While offering exceptional performance, their implementation in thermopile applications requires careful consideration of edge effects and potential performance degradation over time.

Phase change materials (PCMs) integrated with traditional insulation offer dynamic thermal management capabilities. These materials absorb and release thermal energy during phase transitions, effectively dampening temperature fluctuations. Recent developments in microencapsulation techniques have addressed previous challenges related to containment and cycling stability, making PCMs increasingly viable for precision thermal management in thermopile systems.

Bio-based insulation materials derived from sustainable sources such as cellulose, hemp, and mycelium have demonstrated competitive thermal performance while offering environmental benefits. Advanced processing techniques have overcome traditional limitations related to moisture sensitivity and fire resistance, making these materials increasingly suitable for technical applications requiring precise thermal control.

Energy Efficiency and Sustainability Considerations

Enhancing thermopile thermal resistance through insulation techniques offers significant energy efficiency and sustainability benefits across multiple applications. The improved thermal isolation directly translates to reduced energy consumption in sensing systems, as thermopiles with higher thermal resistance require less power to maintain temperature differentials necessary for accurate measurements. This energy optimization is particularly valuable in battery-powered devices and remote sensing applications where power resources are limited.

From a sustainability perspective, the materials selection for insulation technologies presents important environmental considerations. Advanced aerogels, vacuum insulation panels, and ceramic-based insulators must be evaluated not only for their thermal performance but also for their environmental footprint throughout their lifecycle. Manufacturers are increasingly adopting bio-based insulation materials and recycled content to reduce the carbon footprint associated with thermopile production.

The longevity of thermopile sensors directly impacts sustainability metrics. Enhanced thermal resistance through proper insulation extends device operational lifespans, reducing electronic waste generation and resource consumption associated with replacement manufacturing. This durability factor represents a key sustainability advantage that should be quantified when evaluating different insulation approaches.

Energy payback analysis reveals that the initial energy investment in manufacturing high-performance insulation materials is typically recovered multiple times over during the operational lifetime of thermopile devices. Studies indicate that advanced insulation techniques can improve energy efficiency by 30-45% compared to conventional approaches, with corresponding reductions in greenhouse gas emissions when deployed at scale.

In building applications, thermopiles with enhanced thermal resistance contribute to more precise HVAC control systems, potentially reducing building energy consumption by 8-12% according to recent field studies. Similar efficiency improvements have been documented in industrial process monitoring and automotive thermal management systems.

Regulatory frameworks increasingly incentivize energy-efficient sensing technologies through certification programs and energy standards. Manufacturers implementing advanced insulation techniques can leverage these frameworks to gain market advantage while contributing to national and global sustainability goals. The alignment of thermopile performance improvements with circular economy principles represents an emerging opportunity for technology developers seeking to differentiate their offerings in increasingly sustainability-conscious markets.

From a sustainability perspective, the materials selection for insulation technologies presents important environmental considerations. Advanced aerogels, vacuum insulation panels, and ceramic-based insulators must be evaluated not only for their thermal performance but also for their environmental footprint throughout their lifecycle. Manufacturers are increasingly adopting bio-based insulation materials and recycled content to reduce the carbon footprint associated with thermopile production.

The longevity of thermopile sensors directly impacts sustainability metrics. Enhanced thermal resistance through proper insulation extends device operational lifespans, reducing electronic waste generation and resource consumption associated with replacement manufacturing. This durability factor represents a key sustainability advantage that should be quantified when evaluating different insulation approaches.

Energy payback analysis reveals that the initial energy investment in manufacturing high-performance insulation materials is typically recovered multiple times over during the operational lifetime of thermopile devices. Studies indicate that advanced insulation techniques can improve energy efficiency by 30-45% compared to conventional approaches, with corresponding reductions in greenhouse gas emissions when deployed at scale.

In building applications, thermopiles with enhanced thermal resistance contribute to more precise HVAC control systems, potentially reducing building energy consumption by 8-12% according to recent field studies. Similar efficiency improvements have been documented in industrial process monitoring and automotive thermal management systems.

Regulatory frameworks increasingly incentivize energy-efficient sensing technologies through certification programs and energy standards. Manufacturers implementing advanced insulation techniques can leverage these frameworks to gain market advantage while contributing to national and global sustainability goals. The alignment of thermopile performance improvements with circular economy principles represents an emerging opportunity for technology developers seeking to differentiate their offerings in increasingly sustainability-conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!