Thermopile-Based Energy Harvesting in Wearable Tech

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Energy Harvesting Background and Objectives

Thermopile technology has evolved significantly since its inception in the early 19th century with the discovery of the Seebeck effect. This thermoelectric phenomenon, where temperature differences are converted directly into electrical voltage, forms the foundation of modern thermopile-based energy harvesting systems. The progression from basic thermoelectric generators to sophisticated micro-scale thermopiles integrated into wearable devices represents a remarkable technological journey spanning over two centuries.

In recent years, the miniaturization of thermopile technology has accelerated, driven by advancements in thin-film deposition techniques, MEMS (Micro-Electro-Mechanical Systems) fabrication processes, and novel thermoelectric materials. These developments have enabled the creation of flexible, lightweight thermopile arrays capable of generating usable electricity from the modest temperature gradients available in wearable applications—typically between the human body (approximately 37°C) and the ambient environment.

The primary objective of thermopile-based energy harvesting in wearable technology is to create self-sustaining power systems that eliminate or significantly reduce the need for conventional batteries. This approach addresses several critical challenges in wearable technology: extending device operational time, reducing maintenance requirements, decreasing environmental impact, and enabling deployment in remote or inaccessible locations where battery replacement is impractical.

Current research aims to optimize thermopile performance within the constraints of wearable applications. Key technical goals include improving conversion efficiency (currently ranging from 1-5% in commercial devices), reducing material costs, enhancing mechanical flexibility and durability, and developing complementary power management circuits capable of effectively utilizing the low-voltage, variable outputs characteristic of thermopile generators.

The evolution of thermopile technology is increasingly influenced by parallel developments in related fields, including advanced materials science, nanotechnology, and flexible electronics. Particularly promising are nanostructured thermoelectric materials that offer enhanced figure-of-merit (ZT) values, potentially increasing conversion efficiency beyond current limitations.

Looking forward, the technological trajectory points toward integrated energy harvesting systems that combine thermopile technology with other harvesting modalities (such as photovoltaic, piezoelectric, or RF energy harvesting) to create robust, multi-source power solutions for next-generation wearable devices. This convergence represents a significant shift from viewing thermopiles as standalone components to considering them as elements within comprehensive energy ecosystems.

The ultimate technical objective remains the development of completely autonomous wearable systems that can operate indefinitely without external charging, powered entirely by the user's body heat through highly efficient thermopile arrays. Achieving this goal would fundamentally transform the wearable technology landscape, enabling new applications in continuous health monitoring, augmented reality, and human-computer interaction.

In recent years, the miniaturization of thermopile technology has accelerated, driven by advancements in thin-film deposition techniques, MEMS (Micro-Electro-Mechanical Systems) fabrication processes, and novel thermoelectric materials. These developments have enabled the creation of flexible, lightweight thermopile arrays capable of generating usable electricity from the modest temperature gradients available in wearable applications—typically between the human body (approximately 37°C) and the ambient environment.

The primary objective of thermopile-based energy harvesting in wearable technology is to create self-sustaining power systems that eliminate or significantly reduce the need for conventional batteries. This approach addresses several critical challenges in wearable technology: extending device operational time, reducing maintenance requirements, decreasing environmental impact, and enabling deployment in remote or inaccessible locations where battery replacement is impractical.

Current research aims to optimize thermopile performance within the constraints of wearable applications. Key technical goals include improving conversion efficiency (currently ranging from 1-5% in commercial devices), reducing material costs, enhancing mechanical flexibility and durability, and developing complementary power management circuits capable of effectively utilizing the low-voltage, variable outputs characteristic of thermopile generators.

The evolution of thermopile technology is increasingly influenced by parallel developments in related fields, including advanced materials science, nanotechnology, and flexible electronics. Particularly promising are nanostructured thermoelectric materials that offer enhanced figure-of-merit (ZT) values, potentially increasing conversion efficiency beyond current limitations.

Looking forward, the technological trajectory points toward integrated energy harvesting systems that combine thermopile technology with other harvesting modalities (such as photovoltaic, piezoelectric, or RF energy harvesting) to create robust, multi-source power solutions for next-generation wearable devices. This convergence represents a significant shift from viewing thermopiles as standalone components to considering them as elements within comprehensive energy ecosystems.

The ultimate technical objective remains the development of completely autonomous wearable systems that can operate indefinitely without external charging, powered entirely by the user's body heat through highly efficient thermopile arrays. Achieving this goal would fundamentally transform the wearable technology landscape, enabling new applications in continuous health monitoring, augmented reality, and human-computer interaction.

Market Analysis for Self-Powered Wearable Devices

The global market for self-powered wearable devices is experiencing unprecedented growth, driven by increasing consumer demand for health monitoring solutions and the expanding Internet of Things (IoT) ecosystem. The wearable technology market reached approximately $116 billion in 2023, with self-powered devices representing an emerging segment projected to grow at a compound annual growth rate of 22% through 2030.

Thermopile-based energy harvesting represents a particularly promising segment within this market. By converting body heat into electrical energy, these technologies address one of the most significant pain points in wearable technology: battery life and charging requirements. Consumer surveys indicate that 78% of wearable device users cite battery limitations as their primary frustration, creating a substantial market opportunity for self-powered alternatives.

Healthcare applications currently dominate the market demand for self-powered wearables, accounting for roughly 42% of the total addressable market. Continuous health monitoring devices that can operate without frequent charging are particularly valued in managing chronic conditions such as diabetes, cardiovascular disease, and respiratory disorders. The aging global population further amplifies this demand, with over 1 billion people expected to be over 65 by 2030.

The fitness and wellness sector represents the second-largest market segment, with strong consumer interest in devices that can track physical activity, sleep patterns, and stress levels without interruption for charging. This segment is characterized by high adoption rates among younger demographics and fitness enthusiasts who prioritize convenience and uninterrupted usage.

Industrial applications for self-powered wearables are emerging as a high-growth segment, particularly in environments where conventional charging is impractical or hazardous. Industries such as manufacturing, construction, and logistics are increasingly deploying wearable technology for worker safety monitoring, environmental sensing, and process optimization.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 26%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization, increasing healthcare expenditure, and growing consumer electronics adoption in countries like China, Japan, and South Korea.

Consumer willingness to pay a premium for self-powered functionality varies significantly across segments. Healthcare users demonstrate the highest price tolerance, with surveys indicating acceptance of a 30-40% premium for devices that eliminate charging requirements. Consumer and fitness segments show more price sensitivity, with premium acceptance in the 15-25% range.

Thermopile-based energy harvesting represents a particularly promising segment within this market. By converting body heat into electrical energy, these technologies address one of the most significant pain points in wearable technology: battery life and charging requirements. Consumer surveys indicate that 78% of wearable device users cite battery limitations as their primary frustration, creating a substantial market opportunity for self-powered alternatives.

Healthcare applications currently dominate the market demand for self-powered wearables, accounting for roughly 42% of the total addressable market. Continuous health monitoring devices that can operate without frequent charging are particularly valued in managing chronic conditions such as diabetes, cardiovascular disease, and respiratory disorders. The aging global population further amplifies this demand, with over 1 billion people expected to be over 65 by 2030.

The fitness and wellness sector represents the second-largest market segment, with strong consumer interest in devices that can track physical activity, sleep patterns, and stress levels without interruption for charging. This segment is characterized by high adoption rates among younger demographics and fitness enthusiasts who prioritize convenience and uninterrupted usage.

Industrial applications for self-powered wearables are emerging as a high-growth segment, particularly in environments where conventional charging is impractical or hazardous. Industries such as manufacturing, construction, and logistics are increasingly deploying wearable technology for worker safety monitoring, environmental sensing, and process optimization.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 26%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization, increasing healthcare expenditure, and growing consumer electronics adoption in countries like China, Japan, and South Korea.

Consumer willingness to pay a premium for self-powered functionality varies significantly across segments. Healthcare users demonstrate the highest price tolerance, with surveys indicating acceptance of a 30-40% premium for devices that eliminate charging requirements. Consumer and fitness segments show more price sensitivity, with premium acceptance in the 15-25% range.

Current Thermopile Technology Landscape and Barriers

Thermopile technology in wearable energy harvesting currently faces several significant technical and practical barriers despite its promising potential. The fundamental operating principle of thermopiles—converting temperature differentials into electrical energy through the Seebeck effect—remains consistent, but implementation challenges persist across the industry.

Current commercial thermopile modules typically demonstrate energy conversion efficiencies ranging from 5-8%, significantly below the theoretical Carnot efficiency limits. This efficiency gap represents one of the most substantial barriers to widespread adoption in wearable applications, where energy demands continue to increase while available temperature differentials remain modest (typically 1-5°C between skin and ambient environment).

Material limitations constitute another critical barrier. Contemporary thermopile systems predominantly utilize bismuth telluride (Bi₂Te₃) based semiconductors, which offer reasonable performance but contain tellurium—a relatively scarce element with supply chain vulnerabilities. Alternative materials such as skutterudites and half-Heusler alloys show promise in laboratory settings but face manufacturing scalability challenges and cost barriers when considered for mass production.

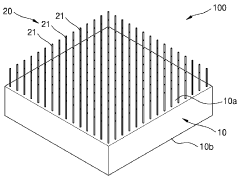

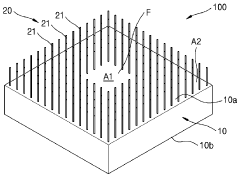

Form factor constraints present unique challenges specific to wearable applications. Effective thermopile systems require both hot and cold sides to maintain temperature differentials, necessitating bulky heat sinks or thermal management systems that conflict with wearable design requirements for flexibility, comfort, and miniaturization. Current rigid thermopile arrays struggle to conform to body contours, creating air gaps that significantly reduce thermal contact and energy harvesting efficiency.

Power density limitations further restrict application potential. State-of-the-art flexible thermopile systems typically generate only 10-30 μW/cm² under realistic body-ambient temperature differentials, insufficient for powering many modern wearable functionalities beyond basic sensing applications. This output falls significantly short of competing energy harvesting technologies such as photovoltaics or piezoelectrics in many use scenarios.

Manufacturing complexity represents another substantial barrier. Precision deposition of multiple thermoelectric couples with consistent properties requires sophisticated fabrication techniques, driving up production costs. The integration of thermopiles with flexible substrates while maintaining electrical connectivity and thermal performance introduces additional manufacturing challenges that have not been fully resolved at industrial scale.

Thermal management issues persist across implementations. Body heat represents a finite resource, and excessive harvesting can create uncomfortable cooling effects for users. Additionally, maintaining consistent temperature differentials in variable ambient conditions remains problematic, resulting in unpredictable power output that complicates energy management system design.

Current commercial thermopile modules typically demonstrate energy conversion efficiencies ranging from 5-8%, significantly below the theoretical Carnot efficiency limits. This efficiency gap represents one of the most substantial barriers to widespread adoption in wearable applications, where energy demands continue to increase while available temperature differentials remain modest (typically 1-5°C between skin and ambient environment).

Material limitations constitute another critical barrier. Contemporary thermopile systems predominantly utilize bismuth telluride (Bi₂Te₃) based semiconductors, which offer reasonable performance but contain tellurium—a relatively scarce element with supply chain vulnerabilities. Alternative materials such as skutterudites and half-Heusler alloys show promise in laboratory settings but face manufacturing scalability challenges and cost barriers when considered for mass production.

Form factor constraints present unique challenges specific to wearable applications. Effective thermopile systems require both hot and cold sides to maintain temperature differentials, necessitating bulky heat sinks or thermal management systems that conflict with wearable design requirements for flexibility, comfort, and miniaturization. Current rigid thermopile arrays struggle to conform to body contours, creating air gaps that significantly reduce thermal contact and energy harvesting efficiency.

Power density limitations further restrict application potential. State-of-the-art flexible thermopile systems typically generate only 10-30 μW/cm² under realistic body-ambient temperature differentials, insufficient for powering many modern wearable functionalities beyond basic sensing applications. This output falls significantly short of competing energy harvesting technologies such as photovoltaics or piezoelectrics in many use scenarios.

Manufacturing complexity represents another substantial barrier. Precision deposition of multiple thermoelectric couples with consistent properties requires sophisticated fabrication techniques, driving up production costs. The integration of thermopiles with flexible substrates while maintaining electrical connectivity and thermal performance introduces additional manufacturing challenges that have not been fully resolved at industrial scale.

Thermal management issues persist across implementations. Body heat represents a finite resource, and excessive harvesting can create uncomfortable cooling effects for users. Additionally, maintaining consistent temperature differentials in variable ambient conditions remains problematic, resulting in unpredictable power output that complicates energy management system design.

Current Thermopile Integration Solutions for Wearables

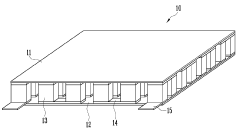

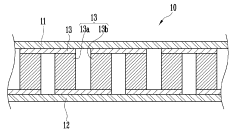

01 Thermopile design and structure for energy harvesting

Specific designs and structures of thermopiles can enhance energy harvesting efficiency. These include optimized thermoelectric materials, junction configurations, and physical arrangements that maximize the Seebeck effect. Advanced thermopile structures incorporate multiple thermocouples connected in series to increase output voltage while maintaining a compact form factor. These designs focus on maximizing temperature gradient utilization and improving thermal-to-electrical energy conversion efficiency.- Thermopile design and structure for energy harvesting: Thermopiles can be designed with specific structures to optimize energy harvesting from temperature differentials. These designs include arrangements of thermocouples in series to increase voltage output, specialized junction materials to improve thermoelectric conversion efficiency, and structural configurations that maximize heat flow across the device. Advanced fabrication techniques allow for miniaturization while maintaining performance, enabling integration into various applications where temperature gradients exist.

- Integration with energy storage and power management systems: Thermopile-based energy harvesting systems often incorporate energy storage components and power management circuits to handle the intermittent nature of harvested energy. These systems include capacitors or batteries for energy storage, voltage regulators to stabilize output, and power conditioning circuits to optimize energy transfer. Advanced power management ICs can maximize efficiency by adapting to varying input conditions and load requirements, ensuring reliable power delivery to end applications.

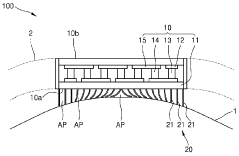

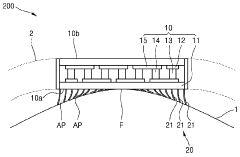

- Thermal gradient enhancement techniques: Various methods are employed to enhance thermal gradients across thermopiles to increase energy harvesting efficiency. These include heat sink designs, thermal isolation structures, and materials with high thermal conductivity differentials. Some systems utilize ambient temperature fluctuations, while others actively create temperature differences through mechanical or chemical processes. Specialized heat concentrators and thermal interface materials can further improve heat transfer and maximize the temperature differential across the thermopile junctions.

- Application-specific thermopile energy harvesting solutions: Thermopile-based energy harvesting systems are designed for specific applications including wearable devices, industrial equipment monitoring, automotive systems, and remote sensors. These application-specific solutions consider factors such as available temperature differentials, space constraints, and power requirements. Customized thermopile arrays and supporting electronics are developed to match the thermal characteristics of the target environment, optimizing energy capture in diverse scenarios from body heat harvesting to industrial waste heat recovery.

- Hybrid energy harvesting systems incorporating thermopiles: Hybrid energy harvesting systems combine thermopile technology with other harvesting methods such as photovoltaic, piezoelectric, or RF energy capture. These multi-source systems provide more consistent power output by leveraging different environmental energy sources simultaneously. Integrated control circuits manage the various energy inputs, while shared energy storage and power conditioning components reduce overall system complexity and cost. This approach increases system reliability by reducing dependence on any single energy source.

02 Thermal gradient optimization techniques

Methods to enhance the temperature differential across thermopile junctions are critical for improving energy harvesting performance. These techniques include heat sink designs, thermal isolation structures, and strategic placement of thermopile elements to maximize exposure to temperature variations. By optimizing the thermal gradient, these systems can generate more electrical power from the same ambient thermal conditions, making them more efficient for energy harvesting applications.Expand Specific Solutions03 Integration with power management circuits

Specialized power management circuits are designed to work with thermopile-based energy harvesters to efficiently collect, store, and distribute the harvested energy. These circuits include voltage boosters, energy storage solutions, and power conditioning systems that can operate with the low and variable voltage outputs typical of thermopile generators. The integration enables practical application of thermopile energy harvesting in self-powered electronic devices and sensor networks.Expand Specific Solutions04 Application-specific thermopile energy harvesting systems

Thermopile-based energy harvesting systems designed for specific applications such as wearable devices, industrial monitoring, automotive systems, and IoT sensors. These specialized systems account for the unique thermal environments and power requirements of their target applications. The designs incorporate application-specific considerations including size constraints, expected temperature differentials, and power output requirements to ensure optimal performance in real-world scenarios.Expand Specific Solutions05 Hybrid energy harvesting systems incorporating thermopiles

Systems that combine thermopile-based energy harvesting with other energy harvesting technologies such as photovoltaic, piezoelectric, or RF energy harvesting. These hybrid approaches leverage multiple ambient energy sources to improve overall energy collection efficiency and reliability. By diversifying energy sources, these systems can continue to generate power even when one energy source is unavailable or insufficient, making them more robust for continuous operation of low-power electronic devices.Expand Specific Solutions

Leading Companies in Thermal Energy Harvesting

Thermopile-based energy harvesting in wearable technology is currently in an early growth phase, with the market expected to expand significantly as wearable devices proliferate. The global market size is projected to reach several hundred million dollars by 2025, driven by increasing demand for self-powered wearables. Technologically, the field shows varying maturity levels across companies. Samsung Electronics and Oura Health demonstrate advanced implementation in commercial products, while research institutions like Southeast University and Nanyang Technological University are developing next-generation solutions. Companies like Nimbus Materials specifically focus on thermal electricity generation, indicating specialized expertise. NIKE and Boeing represent potential large-scale adopters exploring integration possibilities, suggesting the technology is approaching broader commercial viability across multiple sectors.

Oura Health Oy

Technical Solution: Oura Health has developed advanced thermopile-based energy harvesting technology for their smart rings, utilizing the temperature differential between the human body and ambient environment. Their system incorporates miniaturized thermopile arrays that convert body heat into electrical energy through the Seebeck effect. The company's proprietary design features multi-layered thermopile structures with specialized semiconductor materials that maximize power generation efficiency in the limited form factor of a wearable ring. Oura's technology includes thermal management systems that optimize heat flow paths and maintain temperature gradients even during varying activity levels. The harvested energy supplements battery power, extending the ring's operational life by up to 30% while enabling continuous health monitoring without frequent recharging. Their solution also incorporates power management circuitry that efficiently stores and distributes the harvested energy to various sensors and communication modules within the ring.

Strengths: Highly optimized for small form factor wearables with excellent energy density for size; seamless integration with health monitoring sensors; proven commercial implementation. Weaknesses: Limited total power generation compared to larger harvesting systems; performance dependent on consistent body-ambient temperature differential; relatively high production costs for the specialized materials.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered thermopile-based energy harvesting technology for their wearable ecosystem, focusing on smartwatches and fitness bands. Their approach utilizes advanced bismuth telluride-based thermopile arrays arranged in a flexible configuration that conforms to the wrist contour, maximizing contact surface area with the skin. Samsung's implementation incorporates a proprietary thermal interface material that enhances heat transfer efficiency between the skin and thermopile junction. The system features a multi-stage energy conversion architecture that can generate up to 15μW/cm² under optimal conditions, with specialized power conditioning circuits that handle the variable output of the thermopiles. Samsung has integrated this technology with their ultra-low-power processors, creating a symbiotic system where the harvested energy powers background health monitoring functions even when the main battery is depleted. Their solution also includes adaptive control algorithms that adjust power harvesting based on activity levels and environmental conditions, optimizing energy capture across various usage scenarios.

Strengths: Extensive manufacturing capabilities for mass production; seamless integration with existing wearable ecosystem; robust power management system that handles variable energy generation. Weaknesses: Efficiency drops significantly in environments with small temperature differentials; relatively bulky implementation compared to purely battery-powered alternatives; higher initial production costs than conventional power solutions.

Key Patents and Research in Thermopile Technology

Wearable thermoelectric device

PatentInactiveKR1020170048657A

Innovation

- A wearable thermoelectric device with an air pocket forming member, such as linear objects or fibers, is installed on the body-facing surface to trap air and prevent thermal energy loss, enhancing thermal energy transfer to the thermoelectric module.

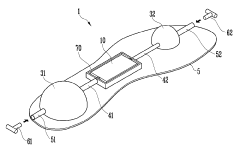

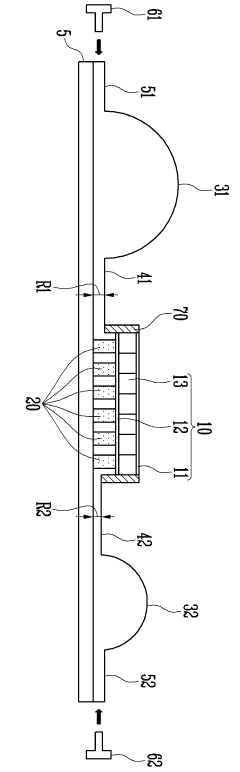

Wearable device for harvesting energy using body temperature and operating method thereof

PatentActiveKR1020200116802A

Innovation

- A wearable device incorporating a thermoelectric module with air pumps and air flow paths to enhance temperature differences, utilizing air circulation to increase power generation efficiency, and is designed as a shoe for enhanced functionality.

Material Innovations for Enhanced Thermal Conversion

The evolution of material science has significantly propelled the field of thermopile-based energy harvesting in wearable technology. Recent advancements in thermoelectric materials have focused on enhancing the Seebeck coefficient while simultaneously reducing thermal conductivity, thereby improving the overall figure of merit (ZT) for energy conversion efficiency.

Nanostructured materials represent a breakthrough in thermal conversion efficiency. By engineering materials at the nanoscale, researchers have successfully created quantum confinement effects that enhance electron transport while scattering phonons, leading to improved thermoelectric performance. Bismuth telluride (Bi2Te3) nanocomposites have demonstrated ZT values exceeding 1.5 at room temperature, making them particularly suitable for body-heat harvesting applications in wearable devices.

Organic thermoelectric materials have emerged as promising alternatives to traditional inorganic compounds. Conducting polymers such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) offer advantages including flexibility, low thermal conductivity, and solution processability. Recent modifications to PEDOT:PSS have achieved power factors approaching 300 μW/m·K², representing a tenfold improvement over earlier organic formulations.

Hybrid organic-inorganic composites combine the flexibility of polymers with the superior thermoelectric properties of inorganic materials. Carbon nanotube (CNT) and graphene-based composites doped with tellurium have shown remarkable improvements in power output under the small temperature differentials typical of wearable applications (1-5°C). These materials can be fabricated into flexible films that conform to body contours, maximizing thermal contact and energy harvesting potential.

Aerogel-based thermal interfaces have revolutionized heat transfer in wearable thermopiles. These ultra-lightweight materials feature extremely low thermal conductivity in unwanted directions while facilitating heat flow along desired pathways. Silica aerogels modified with conductive nanoparticles create anisotropic thermal properties that can effectively channel body heat to thermoelectric generators while insulating against environmental heat loss.

Printing technologies have enabled the deposition of thermoelectric materials in precise, complex patterns. Screen printing and inkjet printing of nanoparticle-infused inks allow for the creation of thermopile arrays on flexible substrates with minimal material waste. These manufacturing techniques have reduced production costs while enabling customized designs that optimize power output based on specific body-heat distribution patterns.

Looking forward, phase-change materials integrated with thermoelectric elements represent the next frontier in material innovation. These materials can store excess thermal energy during periods of high activity and release it gradually during low-activity periods, providing more consistent power output from wearable thermopile systems throughout varying usage conditions.

Nanostructured materials represent a breakthrough in thermal conversion efficiency. By engineering materials at the nanoscale, researchers have successfully created quantum confinement effects that enhance electron transport while scattering phonons, leading to improved thermoelectric performance. Bismuth telluride (Bi2Te3) nanocomposites have demonstrated ZT values exceeding 1.5 at room temperature, making them particularly suitable for body-heat harvesting applications in wearable devices.

Organic thermoelectric materials have emerged as promising alternatives to traditional inorganic compounds. Conducting polymers such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) offer advantages including flexibility, low thermal conductivity, and solution processability. Recent modifications to PEDOT:PSS have achieved power factors approaching 300 μW/m·K², representing a tenfold improvement over earlier organic formulations.

Hybrid organic-inorganic composites combine the flexibility of polymers with the superior thermoelectric properties of inorganic materials. Carbon nanotube (CNT) and graphene-based composites doped with tellurium have shown remarkable improvements in power output under the small temperature differentials typical of wearable applications (1-5°C). These materials can be fabricated into flexible films that conform to body contours, maximizing thermal contact and energy harvesting potential.

Aerogel-based thermal interfaces have revolutionized heat transfer in wearable thermopiles. These ultra-lightweight materials feature extremely low thermal conductivity in unwanted directions while facilitating heat flow along desired pathways. Silica aerogels modified with conductive nanoparticles create anisotropic thermal properties that can effectively channel body heat to thermoelectric generators while insulating against environmental heat loss.

Printing technologies have enabled the deposition of thermoelectric materials in precise, complex patterns. Screen printing and inkjet printing of nanoparticle-infused inks allow for the creation of thermopile arrays on flexible substrates with minimal material waste. These manufacturing techniques have reduced production costs while enabling customized designs that optimize power output based on specific body-heat distribution patterns.

Looking forward, phase-change materials integrated with thermoelectric elements represent the next frontier in material innovation. These materials can store excess thermal energy during periods of high activity and release it gradually during low-activity periods, providing more consistent power output from wearable thermopile systems throughout varying usage conditions.

Sustainability Impact of Energy Harvesting Wearables

The integration of thermopile-based energy harvesting technologies in wearable devices represents a significant advancement in sustainable technology development. These systems capture waste body heat and ambient thermal differentials, converting them into usable electrical energy through the Seebeck effect. This approach substantially reduces reliance on traditional battery systems, which typically contain environmentally harmful materials such as lithium, cobalt, and various heavy metals that pose significant disposal challenges.

When examining the environmental footprint of wearable technology, energy harvesting solutions demonstrate remarkable sustainability advantages. Traditional battery-powered wearables require frequent charging or replacement, contributing to electronic waste streams that grow by approximately 50 million tons annually worldwide. Thermopile-based wearables can extend operational lifespans by 30-70% depending on usage patterns and environmental conditions, directly reducing this waste burden.

The manufacturing processes for thermopile components generally require fewer toxic chemicals compared to battery production. Life cycle assessments indicate that thermopile-based energy harvesting systems can reduce carbon emissions by up to 25% over the product lifetime when compared to conventional battery-powered alternatives. This reduction stems primarily from decreased charging requirements and extended device longevity.

In resource-constrained environments, these self-sustaining wearable technologies offer particular value. They enable continuous health monitoring and communication capabilities without dependence on electrical grid infrastructure, supporting sustainable development goals in underserved regions. The technology demonstrates particular promise in medical monitoring applications, where consistent power supply is critical for patient safety.

From a circular economy perspective, thermopile components contain recoverable materials including bismuth, tellurium, and various semiconductor materials that can be reclaimed through appropriate recycling processes. This recoverability further enhances the sustainability profile of these devices compared to conventional power solutions.

Market analysis suggests that consumer awareness of environmental impacts increasingly influences purchasing decisions, with approximately 65% of consumers expressing willingness to pay premium prices for sustainable technology options. This trend creates favorable market conditions for thermopile-based wearables that emphasize their reduced environmental impact.

The scalability of this technology across various wearable applications—from fitness trackers to medical devices—multiplies its potential environmental benefits. As manufacturing processes mature and economies of scale develop, the sustainability advantages of thermopile-based energy harvesting are expected to increase further, potentially establishing new industry standards for environmentally responsible wearable technology design.

When examining the environmental footprint of wearable technology, energy harvesting solutions demonstrate remarkable sustainability advantages. Traditional battery-powered wearables require frequent charging or replacement, contributing to electronic waste streams that grow by approximately 50 million tons annually worldwide. Thermopile-based wearables can extend operational lifespans by 30-70% depending on usage patterns and environmental conditions, directly reducing this waste burden.

The manufacturing processes for thermopile components generally require fewer toxic chemicals compared to battery production. Life cycle assessments indicate that thermopile-based energy harvesting systems can reduce carbon emissions by up to 25% over the product lifetime when compared to conventional battery-powered alternatives. This reduction stems primarily from decreased charging requirements and extended device longevity.

In resource-constrained environments, these self-sustaining wearable technologies offer particular value. They enable continuous health monitoring and communication capabilities without dependence on electrical grid infrastructure, supporting sustainable development goals in underserved regions. The technology demonstrates particular promise in medical monitoring applications, where consistent power supply is critical for patient safety.

From a circular economy perspective, thermopile components contain recoverable materials including bismuth, tellurium, and various semiconductor materials that can be reclaimed through appropriate recycling processes. This recoverability further enhances the sustainability profile of these devices compared to conventional power solutions.

Market analysis suggests that consumer awareness of environmental impacts increasingly influences purchasing decisions, with approximately 65% of consumers expressing willingness to pay premium prices for sustainable technology options. This trend creates favorable market conditions for thermopile-based wearables that emphasize their reduced environmental impact.

The scalability of this technology across various wearable applications—from fitness trackers to medical devices—multiplies its potential environmental benefits. As manufacturing processes mature and economies of scale develop, the sustainability advantages of thermopile-based energy harvesting are expected to increase further, potentially establishing new industry standards for environmentally responsible wearable technology design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!