How to Calibrate Thermopiles for Optimal Performance

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Calibration Background and Objectives

Thermopiles have evolved significantly since their inception in the early 19th century, originating from the fundamental principles of thermoelectric effects discovered by Thomas Johann Seebeck in 1821. These devices convert thermal energy into electrical energy based on the Seebeck effect, where a temperature difference between two dissimilar electrical conductors produces a voltage difference. The technology has progressed from simple thermocouples to sophisticated arrays of thermocouples connected in series, enabling enhanced sensitivity and performance characteristics.

In recent decades, thermopile technology has experienced accelerated development due to advancements in materials science, microfabrication techniques, and integrated circuit technology. Modern thermopiles incorporate thin-film technology, MEMS (Micro-Electro-Mechanical Systems) fabrication processes, and specialized semiconductor materials to achieve unprecedented levels of sensitivity, response time, and reliability. This evolution has expanded their application from traditional temperature measurement to diverse fields including infrared sensing, thermal imaging, energy harvesting, and medical diagnostics.

The calibration of thermopiles represents a critical aspect of their implementation, directly impacting measurement accuracy, reliability, and overall system performance. Historically, calibration methods have ranged from simple comparative techniques to sophisticated algorithmic approaches incorporating multiple reference points and environmental compensation factors. The trend in calibration technology has moved toward automated, intelligent systems that can adapt to changing environmental conditions and aging effects of the sensors themselves.

The primary objective of thermopile calibration is to establish a precise relationship between the output voltage of the device and the actual temperature differential being measured. This involves addressing various challenges including non-linearity in response curves, ambient temperature effects, thermal drift, aging-related parameter shifts, and manufacturing variations. Optimal calibration seeks to minimize measurement uncertainty while maximizing long-term stability across the device's operational lifetime.

Current technological goals in thermopile calibration focus on developing universal calibration methodologies that can be efficiently implemented across various device architectures and application environments. These include the development of self-calibrating systems, machine learning approaches for adaptive calibration, and standardized protocols that ensure consistency across different manufacturing batches and operational conditions. Additionally, there is significant interest in reducing calibration complexity and time requirements while improving the accuracy and reliability of the resulting measurements.

The evolution of calibration techniques is increasingly aligned with Industry 4.0 principles, incorporating IoT connectivity, cloud-based reference databases, and real-time adjustment capabilities. These advancements aim to transform thermopile calibration from a periodic maintenance requirement to a continuous optimization process, ultimately enhancing the performance and extending the functional lifespan of thermopile-based sensing systems across industrial, consumer, and scientific applications.

In recent decades, thermopile technology has experienced accelerated development due to advancements in materials science, microfabrication techniques, and integrated circuit technology. Modern thermopiles incorporate thin-film technology, MEMS (Micro-Electro-Mechanical Systems) fabrication processes, and specialized semiconductor materials to achieve unprecedented levels of sensitivity, response time, and reliability. This evolution has expanded their application from traditional temperature measurement to diverse fields including infrared sensing, thermal imaging, energy harvesting, and medical diagnostics.

The calibration of thermopiles represents a critical aspect of their implementation, directly impacting measurement accuracy, reliability, and overall system performance. Historically, calibration methods have ranged from simple comparative techniques to sophisticated algorithmic approaches incorporating multiple reference points and environmental compensation factors. The trend in calibration technology has moved toward automated, intelligent systems that can adapt to changing environmental conditions and aging effects of the sensors themselves.

The primary objective of thermopile calibration is to establish a precise relationship between the output voltage of the device and the actual temperature differential being measured. This involves addressing various challenges including non-linearity in response curves, ambient temperature effects, thermal drift, aging-related parameter shifts, and manufacturing variations. Optimal calibration seeks to minimize measurement uncertainty while maximizing long-term stability across the device's operational lifetime.

Current technological goals in thermopile calibration focus on developing universal calibration methodologies that can be efficiently implemented across various device architectures and application environments. These include the development of self-calibrating systems, machine learning approaches for adaptive calibration, and standardized protocols that ensure consistency across different manufacturing batches and operational conditions. Additionally, there is significant interest in reducing calibration complexity and time requirements while improving the accuracy and reliability of the resulting measurements.

The evolution of calibration techniques is increasingly aligned with Industry 4.0 principles, incorporating IoT connectivity, cloud-based reference databases, and real-time adjustment capabilities. These advancements aim to transform thermopile calibration from a periodic maintenance requirement to a continuous optimization process, ultimately enhancing the performance and extending the functional lifespan of thermopile-based sensing systems across industrial, consumer, and scientific applications.

Market Demand Analysis for Precision Temperature Sensing

The precision temperature sensing market is experiencing robust growth driven by increasing demand across multiple industries for accurate thermal measurement solutions. The global market for temperature sensors, including thermopiles, is projected to reach $7.88 billion by 2027, growing at a CAGR of 4.8% from 2020. This growth is particularly pronounced in sectors requiring non-contact temperature measurement capabilities that thermopiles excel at providing.

Healthcare applications represent a significant market driver, with demand for infrared thermometers and thermal imaging systems surging during the COVID-19 pandemic. This trend has established a new baseline for contactless temperature monitoring in clinical settings, with hospitals and healthcare facilities increasingly adopting advanced thermal sensing technologies for patient screening and monitoring.

Industrial automation constitutes another major market segment, where precise temperature control is critical for manufacturing processes, equipment monitoring, and predictive maintenance. The Industry 4.0 movement has accelerated adoption of smart sensors, including calibrated thermopiles, as manufacturers seek to optimize production efficiency and reduce downtime through accurate thermal monitoring.

Consumer electronics represents a rapidly expanding application area, with thermopile sensors being integrated into smartphones, wearables, and smart home devices. Market research indicates that consumer demand for health monitoring features in personal devices has grown by over 35% since 2019, creating new opportunities for miniaturized, calibrated thermopile solutions.

Automotive applications are showing particularly strong growth potential, with thermal sensors being deployed for battery management in electric vehicles, climate control systems, and advanced driver assistance systems. The electric vehicle market expansion, growing at approximately 21% annually, is creating substantial demand for high-precision temperature monitoring components.

Regional analysis reveals that Asia-Pacific currently dominates the temperature sensing market with approximately 38% share, followed by North America and Europe. China and India are emerging as key growth markets due to rapid industrialization and increasing healthcare infrastructure development.

Market surveys indicate that end-users prioritize measurement accuracy, reliability, and ease of calibration when selecting temperature sensing solutions. This underscores the importance of developing optimized calibration methodologies for thermopiles to meet these market requirements. Additionally, there is growing demand for self-calibrating systems that can maintain accuracy over extended operational periods without manual intervention.

Healthcare applications represent a significant market driver, with demand for infrared thermometers and thermal imaging systems surging during the COVID-19 pandemic. This trend has established a new baseline for contactless temperature monitoring in clinical settings, with hospitals and healthcare facilities increasingly adopting advanced thermal sensing technologies for patient screening and monitoring.

Industrial automation constitutes another major market segment, where precise temperature control is critical for manufacturing processes, equipment monitoring, and predictive maintenance. The Industry 4.0 movement has accelerated adoption of smart sensors, including calibrated thermopiles, as manufacturers seek to optimize production efficiency and reduce downtime through accurate thermal monitoring.

Consumer electronics represents a rapidly expanding application area, with thermopile sensors being integrated into smartphones, wearables, and smart home devices. Market research indicates that consumer demand for health monitoring features in personal devices has grown by over 35% since 2019, creating new opportunities for miniaturized, calibrated thermopile solutions.

Automotive applications are showing particularly strong growth potential, with thermal sensors being deployed for battery management in electric vehicles, climate control systems, and advanced driver assistance systems. The electric vehicle market expansion, growing at approximately 21% annually, is creating substantial demand for high-precision temperature monitoring components.

Regional analysis reveals that Asia-Pacific currently dominates the temperature sensing market with approximately 38% share, followed by North America and Europe. China and India are emerging as key growth markets due to rapid industrialization and increasing healthcare infrastructure development.

Market surveys indicate that end-users prioritize measurement accuracy, reliability, and ease of calibration when selecting temperature sensing solutions. This underscores the importance of developing optimized calibration methodologies for thermopiles to meet these market requirements. Additionally, there is growing demand for self-calibrating systems that can maintain accuracy over extended operational periods without manual intervention.

Current Thermopile Calibration Challenges

Despite significant advancements in thermopile technology, calibration remains a persistent challenge that impacts measurement accuracy and overall system performance. Current calibration methodologies face several critical limitations that hinder optimal thermopile operation across diverse applications ranging from medical devices to industrial process control systems.

Temperature dependency presents one of the most significant calibration challenges. Thermopiles exhibit non-linear response characteristics across different ambient temperature ranges, making it difficult to maintain consistent calibration across varying environmental conditions. This is particularly problematic in applications where temperature fluctuations are common, resulting in measurement drift and reduced accuracy.

Cross-sensitivity to non-target radiation sources constitutes another major calibration hurdle. Thermopiles can be influenced by electromagnetic interference, nearby heat sources, and reflected infrared radiation, all of which can contaminate measurements. Current calibration techniques struggle to effectively compensate for these external influences, especially in complex operational environments with multiple heat sources.

Aging and degradation effects further complicate calibration efforts. Over time, thermopile sensors experience material changes that alter their response characteristics. Existing calibration approaches typically establish parameters during initial setup but fail to account for long-term drift, resulting in gradually decreasing measurement accuracy throughout the sensor's operational lifetime.

Manufacturing variations between individual thermopile sensors create standardization difficulties. Even sensors from the same production batch can exhibit different response curves, requiring individual calibration procedures. This significantly increases production costs and complexity, particularly for high-volume applications where efficiency is paramount.

The trade-off between calibration accuracy and practical implementation represents a persistent industry challenge. Highly accurate calibration methods often require sophisticated equipment, controlled environments, and significant time investment, making them impractical for many real-world applications. Conversely, simplified calibration approaches sacrifice accuracy for convenience.

Reference temperature source limitations also impact calibration quality. Creating and maintaining precise reference temperature sources across wide measurement ranges is technically challenging and expensive. Many current calibration setups utilize reference sources with their own inherent uncertainties, which propagate through to the calibrated thermopile.

Digital signal processing constraints further limit calibration effectiveness. Many thermopile systems have restricted computational resources, limiting the complexity of calibration algorithms that can be implemented. This forces compromises in the sophistication of temperature compensation and error correction techniques that can be deployed in practical applications.

Temperature dependency presents one of the most significant calibration challenges. Thermopiles exhibit non-linear response characteristics across different ambient temperature ranges, making it difficult to maintain consistent calibration across varying environmental conditions. This is particularly problematic in applications where temperature fluctuations are common, resulting in measurement drift and reduced accuracy.

Cross-sensitivity to non-target radiation sources constitutes another major calibration hurdle. Thermopiles can be influenced by electromagnetic interference, nearby heat sources, and reflected infrared radiation, all of which can contaminate measurements. Current calibration techniques struggle to effectively compensate for these external influences, especially in complex operational environments with multiple heat sources.

Aging and degradation effects further complicate calibration efforts. Over time, thermopile sensors experience material changes that alter their response characteristics. Existing calibration approaches typically establish parameters during initial setup but fail to account for long-term drift, resulting in gradually decreasing measurement accuracy throughout the sensor's operational lifetime.

Manufacturing variations between individual thermopile sensors create standardization difficulties. Even sensors from the same production batch can exhibit different response curves, requiring individual calibration procedures. This significantly increases production costs and complexity, particularly for high-volume applications where efficiency is paramount.

The trade-off between calibration accuracy and practical implementation represents a persistent industry challenge. Highly accurate calibration methods often require sophisticated equipment, controlled environments, and significant time investment, making them impractical for many real-world applications. Conversely, simplified calibration approaches sacrifice accuracy for convenience.

Reference temperature source limitations also impact calibration quality. Creating and maintaining precise reference temperature sources across wide measurement ranges is technically challenging and expensive. Many current calibration setups utilize reference sources with their own inherent uncertainties, which propagate through to the calibrated thermopile.

Digital signal processing constraints further limit calibration effectiveness. Many thermopile systems have restricted computational resources, limiting the complexity of calibration algorithms that can be implemented. This forces compromises in the sophistication of temperature compensation and error correction techniques that can be deployed in practical applications.

Current Calibration Methodologies and Techniques

01 Thermopile design and structure optimization

Optimization of thermopile design and structure can significantly enhance performance. This includes improvements in thermoelectric materials, junction configurations, and overall device architecture. Advanced structural designs can minimize thermal losses, improve temperature gradient maintenance, and increase the voltage output per unit area. These optimizations focus on maximizing the Seebeck effect while reducing parasitic heat flows that diminish performance.- Thermopile design and structure optimization: Optimization of thermopile design and structure can significantly improve performance. This includes the arrangement of thermocouples, selection of materials with high Seebeck coefficients, and geometric configurations that maximize temperature gradients. Advanced designs incorporate specialized junction structures and optimized thermal paths to enhance sensitivity and response time.

- Temperature measurement and calibration techniques: Accurate temperature measurement and proper calibration are essential for thermopile performance. Various techniques have been developed to improve measurement accuracy, including reference junction compensation, signal processing algorithms, and calibration methods that account for ambient temperature variations. These approaches help minimize measurement errors and enhance overall system reliability.

- Thermal isolation and heat flow management: Effective thermal isolation and heat flow management are critical for thermopile performance. Techniques include using low thermal conductivity materials, creating vacuum or air gaps, implementing thermal barriers, and designing specialized heat sinks. These methods help maintain temperature differentials across the thermopile junctions, improving sensitivity and reducing response time.

- Integration with electronic systems and signal processing: Integration of thermopiles with electronic systems and advanced signal processing enhances overall performance. This includes amplification circuits, noise reduction techniques, digital signal processing, and integration with microcontrollers. These approaches improve signal-to-noise ratio, enable temperature compensation, and facilitate data interpretation for various applications.

- Application-specific thermopile optimizations: Thermopiles can be optimized for specific applications such as infrared detection, energy harvesting, or industrial temperature monitoring. These optimizations include specialized materials, custom geometries, and tailored packaging solutions. Application-specific designs consider factors like operating temperature range, response time requirements, and environmental conditions to maximize performance in particular use cases.

02 Thermal isolation and heat flow management

Effective thermal isolation and heat flow management are critical for thermopile performance. Techniques include using vacuum encapsulation, specialized insulating materials, and suspended membrane structures to minimize unwanted heat transfer. By controlling the heat flow paths and creating well-defined hot and cold junctions, the temperature differential across the thermopile can be maximized, resulting in higher output voltage and improved sensitivity for sensing applications.Expand Specific Solutions03 Material selection and composition for thermocouples

The selection of thermoelectric materials significantly impacts thermopile performance. Advanced semiconductor materials, metal alloys, and nanostructured composites can provide higher Seebeck coefficients and better electrical conductivity while maintaining low thermal conductivity. Material composition optimization focuses on increasing the figure of merit (ZT) through band structure engineering, carrier concentration control, and reducing phonon transport, leading to more efficient thermoelectric conversion.Expand Specific Solutions04 Integration with signal processing and calibration systems

Integration of thermopiles with advanced signal processing and calibration systems enhances overall performance. This includes on-chip amplification, digital signal processing, temperature compensation circuits, and self-calibration mechanisms. These integrated systems can correct for ambient temperature variations, aging effects, and other environmental factors that might otherwise degrade measurement accuracy and reliability in practical applications.Expand Specific Solutions05 Manufacturing techniques and fabrication processes

Advanced manufacturing techniques significantly impact thermopile performance. Microfabrication methods, including thin-film deposition, MEMS processing, and precision etching, enable the creation of thermopiles with optimized geometries and junction densities. Novel fabrication approaches such as wafer-level packaging, 3D integration, and nanoscale patterning allow for higher thermocouple density, better thermal isolation, and improved reliability, resulting in enhanced sensitivity and response time.Expand Specific Solutions

Key Industry Players in Thermopile Manufacturing

Thermopile calibration technology is currently in a mature growth phase, with an estimated global market size of $1.2-1.5 billion. The competitive landscape features established industrial leaders like Robert Bosch GmbH and Texas Instruments who dominate with comprehensive calibration solutions, alongside specialized players such as Exergen and Isabellenhütte Heusler focusing on niche applications. Technical maturity varies across sectors, with medical applications (led by Welch Allyn and Philips) showing high standardization, while industrial applications continue evolving. Academic institutions like Huazhong University and TU Delft are advancing next-generation calibration methodologies, while semiconductor manufacturers including NXP and Toshiba Materials are improving thermopile substrate technologies, driving performance improvements in temperature sensing applications across automotive, medical, and industrial sectors.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced thermopile calibration system for automotive and industrial applications, leveraging their extensive sensor manufacturing expertise. Their approach utilizes a comprehensive multi-point calibration process performed under controlled environmental conditions to establish baseline performance characteristics for each sensor. Bosch's methodology incorporates their proprietary "Adaptive Compensation" algorithms that dynamically adjust for ambient temperature variations and sensor aging effects. The calibration system employs precision reference temperature sources with traceability to international standards, ensuring measurement consistency across production batches. Their process includes specialized signal conditioning circuits that optimize the thermopile's output before digitization, significantly improving signal-to-noise ratio in challenging environments. Bosch's calibration parameters are stored in EEPROM and automatically applied by their sensor interface electronics, simplifying integration while maintaining measurement accuracy across the operating temperature range.

Strengths: Exceptional durability in harsh environments, high reliability in automotive applications, and comprehensive integration with vehicle systems. Weaknesses: Higher cost structure compared to consumer-grade solutions, calibration process requires specialized equipment, and system complexity necessitates technical expertise for implementation.

Welch Allyn, Inc.

Technical Solution: Welch Allyn has developed a specialized thermopile calibration system optimized for medical-grade temperature measurement devices. Their approach centers on a proprietary multi-stage calibration process that achieves clinical-grade accuracy across the physiological temperature range. The calibration methodology employs precision blackbody reference sources with NIST-traceable standards to establish baseline performance. Their SureTemp® technology incorporates adaptive calibration algorithms that compensate for variations in probe placement and environmental conditions. The system utilizes a mathematical model that accounts for both the thermopile's inherent non-linearity and the thermal transfer characteristics of the probe housing. Welch Allyn's calibration process includes extensive validation testing across thousands of clinical measurements to ensure statistical reliability. Their approach incorporates real-time drift compensation that continuously adjusts for sensor aging and environmental variations, maintaining measurement accuracy throughout the device lifecycle.

Strengths: Clinical-grade accuracy (±0.1°C in human temperature range), exceptional repeatability between measurements, and FDA-validated calibration protocols. Weaknesses: Calibration optimized primarily for human body temperature range rather than wider industrial applications, higher cost structure, and proprietary interfaces limiting third-party integration.

Critical Patents and Research in Thermopile Calibration

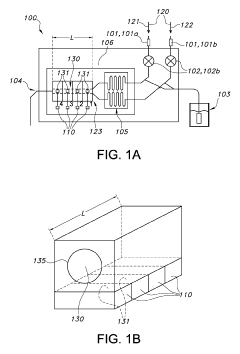

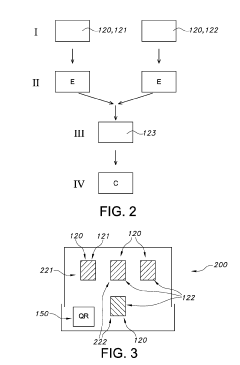

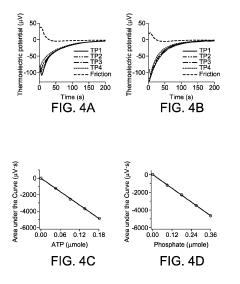

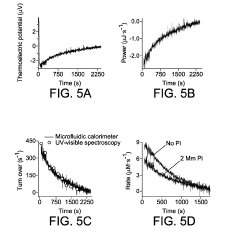

Calibration of a chip-based microfluidic calorimeter

PatentInactiveUS20190195701A1

Innovation

- A calibration method using the deprotonation reaction of a phosphate group is introduced, involving a buffer with a pH range of 7-9 and a compound with a phosphate group protonated in a pH range of 3-6, which generates heat measured by thermopiles, allowing for reliable calibration by relating thermopile signals to reference data from the deprotonating reaction.

Calibration of high-temperature thermocouples

PatentInactiveEP0697102A1

Innovation

- A method and device using a modulated light source to heat only the thermocouple tip, with precise IR radiation focusing and pyrometers to measure AC and DC components, allowing for accurate calibration up to 1800°C by determining emissivity and calculating the tip temperature, utilizing commercially available components.

Environmental Factors Affecting Calibration Accuracy

Environmental factors play a crucial role in thermopile calibration accuracy, often introducing significant measurement errors if not properly accounted for. Ambient temperature variations represent the most prominent environmental challenge, as they directly affect the reference junction temperature and can create thermal gradients across the sensor assembly. These gradients may lead to erroneous voltage readings that misrepresent the actual temperature differential being measured, particularly in applications requiring high precision.

Humidity levels similarly impact calibration quality by altering the thermal conductivity of the surrounding air and potentially causing condensation on sensor surfaces. When relative humidity exceeds 80%, moisture accumulation on thermopile components can create parasitic thermal paths that compromise measurement integrity. In industrial environments, this effect becomes particularly problematic during seasonal transitions or in facilities with inadequate climate control.

Air currents and ventilation patterns constitute another critical factor, as they can create uneven cooling effects across the thermopile sensor array. Even subtle air movements of 0.5 m/s or greater can introduce calibration errors exceeding 2% in sensitive applications. Testing has demonstrated that shielding techniques and strategic sensor positioning can mitigate these effects, though complete elimination remains challenging in dynamic environments.

Electromagnetic interference (EMI) from nearby equipment represents a non-thermal environmental factor that nonetheless significantly impacts calibration accuracy. Power supplies, motors, and wireless communication devices can induce voltage fluctuations in thermopile circuits that manifest as apparent temperature variations. Proper shielding and signal filtering become essential in environments with high electromagnetic noise floors.

Barometric pressure changes, while often overlooked, affect thermal conductivity and convection patterns around the sensor. This becomes particularly relevant in applications involving altitude variations or pressurized environments. Research indicates that pressure fluctuations of 10 kPa can alter calibration curves by up to 1.5% if not compensated for in the calibration algorithm.

Dust and particulate contamination gradually degrade calibration accuracy by altering the emissivity characteristics of thermopile surfaces. In industrial settings, even thin particulate films can shift spectral response patterns, necessitating more frequent recalibration or the implementation of protective measures such as purge air systems or optical filters with self-cleaning capabilities.

Addressing these environmental challenges requires a comprehensive approach combining physical shielding, environmental monitoring, mathematical compensation algorithms, and periodic verification procedures. Advanced calibration protocols now incorporate multi-variable correction factors that account for the complex interplay between these environmental parameters, significantly improving measurement stability across diverse operating conditions.

Humidity levels similarly impact calibration quality by altering the thermal conductivity of the surrounding air and potentially causing condensation on sensor surfaces. When relative humidity exceeds 80%, moisture accumulation on thermopile components can create parasitic thermal paths that compromise measurement integrity. In industrial environments, this effect becomes particularly problematic during seasonal transitions or in facilities with inadequate climate control.

Air currents and ventilation patterns constitute another critical factor, as they can create uneven cooling effects across the thermopile sensor array. Even subtle air movements of 0.5 m/s or greater can introduce calibration errors exceeding 2% in sensitive applications. Testing has demonstrated that shielding techniques and strategic sensor positioning can mitigate these effects, though complete elimination remains challenging in dynamic environments.

Electromagnetic interference (EMI) from nearby equipment represents a non-thermal environmental factor that nonetheless significantly impacts calibration accuracy. Power supplies, motors, and wireless communication devices can induce voltage fluctuations in thermopile circuits that manifest as apparent temperature variations. Proper shielding and signal filtering become essential in environments with high electromagnetic noise floors.

Barometric pressure changes, while often overlooked, affect thermal conductivity and convection patterns around the sensor. This becomes particularly relevant in applications involving altitude variations or pressurized environments. Research indicates that pressure fluctuations of 10 kPa can alter calibration curves by up to 1.5% if not compensated for in the calibration algorithm.

Dust and particulate contamination gradually degrade calibration accuracy by altering the emissivity characteristics of thermopile surfaces. In industrial settings, even thin particulate films can shift spectral response patterns, necessitating more frequent recalibration or the implementation of protective measures such as purge air systems or optical filters with self-cleaning capabilities.

Addressing these environmental challenges requires a comprehensive approach combining physical shielding, environmental monitoring, mathematical compensation algorithms, and periodic verification procedures. Advanced calibration protocols now incorporate multi-variable correction factors that account for the complex interplay between these environmental parameters, significantly improving measurement stability across diverse operating conditions.

Standardization and Quality Assurance Protocols

Standardization of thermopile calibration processes is essential for ensuring consistent performance across devices and applications. Establishing robust quality assurance protocols begins with the development of industry-wide calibration standards that define acceptable performance parameters, measurement methodologies, and verification procedures. These standards should address temperature ranges, response times, sensitivity thresholds, and output signal stability specific to different thermopile applications.

A comprehensive quality assurance framework for thermopile calibration must include detailed documentation requirements that track each device's calibration history, environmental conditions during testing, and performance metrics. This documentation serves as both a reference for future calibrations and evidence of compliance with industry standards, particularly important in regulated industries such as medical devices and aerospace.

Verification and validation procedures form the cornerstone of effective quality assurance protocols. These should include regular performance checks against certified reference standards, blind testing methodologies, and statistical analysis of calibration results to identify drift patterns or systematic errors. Implementation of statistical process control techniques enables early detection of calibration equipment degradation or procedural inconsistencies.

Traceability to national or international measurement standards is paramount in establishing credible calibration protocols. All reference instruments and calibration equipment should maintain documented traceability to standards maintained by organizations such as NIST, PTB, or other recognized metrology institutes. This chain of traceability ensures that thermopile measurements can be reliably compared across different facilities and time periods.

Uncertainty analysis must be incorporated into all calibration procedures, with clear methodologies for calculating and reporting measurement uncertainties. This analysis should account for all potential error sources including reference standard uncertainties, environmental variations, measurement system limitations, and operator influences. Properly quantified uncertainty values provide essential context for interpreting thermopile performance data.

Regular auditing of calibration facilities and procedures helps maintain quality standards over time. These audits should evaluate adherence to documented procedures, proper maintenance of calibration equipment, staff training and competency, and the integrity of calibration records. Third-party assessments can provide valuable objective evaluation of calibration quality systems.

Proficiency testing programs, where multiple laboratories calibrate identical thermopile samples, offer an effective mechanism for validating calibration procedures and identifying systematic biases between different facilities. Participation in such programs should be incorporated into quality assurance protocols, with results used to refine calibration methodologies and improve measurement consistency across the industry.

A comprehensive quality assurance framework for thermopile calibration must include detailed documentation requirements that track each device's calibration history, environmental conditions during testing, and performance metrics. This documentation serves as both a reference for future calibrations and evidence of compliance with industry standards, particularly important in regulated industries such as medical devices and aerospace.

Verification and validation procedures form the cornerstone of effective quality assurance protocols. These should include regular performance checks against certified reference standards, blind testing methodologies, and statistical analysis of calibration results to identify drift patterns or systematic errors. Implementation of statistical process control techniques enables early detection of calibration equipment degradation or procedural inconsistencies.

Traceability to national or international measurement standards is paramount in establishing credible calibration protocols. All reference instruments and calibration equipment should maintain documented traceability to standards maintained by organizations such as NIST, PTB, or other recognized metrology institutes. This chain of traceability ensures that thermopile measurements can be reliably compared across different facilities and time periods.

Uncertainty analysis must be incorporated into all calibration procedures, with clear methodologies for calculating and reporting measurement uncertainties. This analysis should account for all potential error sources including reference standard uncertainties, environmental variations, measurement system limitations, and operator influences. Properly quantified uncertainty values provide essential context for interpreting thermopile performance data.

Regular auditing of calibration facilities and procedures helps maintain quality standards over time. These audits should evaluate adherence to documented procedures, proper maintenance of calibration equipment, staff training and competency, and the integrity of calibration records. Third-party assessments can provide valuable objective evaluation of calibration quality systems.

Proficiency testing programs, where multiple laboratories calibrate identical thermopile samples, offer an effective mechanism for validating calibration procedures and identifying systematic biases between different facilities. Participation in such programs should be incorporated into quality assurance protocols, with results used to refine calibration methodologies and improve measurement consistency across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!