Measure Temperature Accuracy of Thermopile Sensors — Calibration

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Sensor Technology Evolution and Objectives

Thermopile sensors have evolved significantly since their inception in the early 20th century, transforming from rudimentary thermal detection devices to sophisticated temperature measurement instruments with applications across multiple industries. The fundamental operating principle, based on the Seebeck effect discovered in 1821, has remained consistent while the implementation technology has advanced dramatically.

The evolution of thermopile sensor technology can be traced through several distinct phases. Initially, these sensors were bulky, expensive, and limited to specialized laboratory applications. The 1970s marked a turning point with the introduction of thin-film technology, enabling miniaturization and cost reduction. By the 1990s, MEMS (Micro-Electro-Mechanical Systems) manufacturing techniques revolutionized thermopile production, allowing for mass production of highly sensitive sensors with integrated signal processing capabilities.

Recent advancements have focused on improving accuracy, reducing power consumption, and enhancing integration capabilities. Modern thermopile sensors now achieve temperature resolution as fine as 0.01°C with response times under 100 milliseconds. The integration of advanced materials such as bismuth-antimony and polysilicon has significantly improved thermal sensitivity while reducing noise levels.

Calibration technology has evolved in parallel, transitioning from manual, time-consuming processes to automated, algorithm-driven approaches. Early calibration methods relied on simple offset and gain adjustments, while contemporary techniques employ multi-point calibration, temperature cycling, and advanced mathematical models to compensate for non-linearities and environmental factors.

The primary objective in thermopile sensor development today is achieving laboratory-grade accuracy in field-deployable, cost-effective packages. This includes enhancing calibration methodologies to maintain accuracy across wider temperature ranges and varying environmental conditions. Specific goals include reducing calibration drift over time, minimizing hysteresis effects, and developing self-calibrating systems that can maintain accuracy without frequent recalibration.

Another critical objective is standardizing calibration protocols across the industry to ensure consistency and interoperability between different sensor manufacturers. This includes establishing traceable reference standards and developing universal calibration verification methods that can be implemented in various application environments.

Looking forward, the technology roadmap aims to achieve sub-millikelvin accuracy in commercial sensors while reducing power consumption to enable integration into energy-harvesting IoT devices. Advanced machine learning algorithms for adaptive calibration represent a promising frontier, potentially enabling sensors to self-adjust based on usage patterns and environmental conditions, further enhancing accuracy and reliability in real-world applications.

The evolution of thermopile sensor technology can be traced through several distinct phases. Initially, these sensors were bulky, expensive, and limited to specialized laboratory applications. The 1970s marked a turning point with the introduction of thin-film technology, enabling miniaturization and cost reduction. By the 1990s, MEMS (Micro-Electro-Mechanical Systems) manufacturing techniques revolutionized thermopile production, allowing for mass production of highly sensitive sensors with integrated signal processing capabilities.

Recent advancements have focused on improving accuracy, reducing power consumption, and enhancing integration capabilities. Modern thermopile sensors now achieve temperature resolution as fine as 0.01°C with response times under 100 milliseconds. The integration of advanced materials such as bismuth-antimony and polysilicon has significantly improved thermal sensitivity while reducing noise levels.

Calibration technology has evolved in parallel, transitioning from manual, time-consuming processes to automated, algorithm-driven approaches. Early calibration methods relied on simple offset and gain adjustments, while contemporary techniques employ multi-point calibration, temperature cycling, and advanced mathematical models to compensate for non-linearities and environmental factors.

The primary objective in thermopile sensor development today is achieving laboratory-grade accuracy in field-deployable, cost-effective packages. This includes enhancing calibration methodologies to maintain accuracy across wider temperature ranges and varying environmental conditions. Specific goals include reducing calibration drift over time, minimizing hysteresis effects, and developing self-calibrating systems that can maintain accuracy without frequent recalibration.

Another critical objective is standardizing calibration protocols across the industry to ensure consistency and interoperability between different sensor manufacturers. This includes establishing traceable reference standards and developing universal calibration verification methods that can be implemented in various application environments.

Looking forward, the technology roadmap aims to achieve sub-millikelvin accuracy in commercial sensors while reducing power consumption to enable integration into energy-harvesting IoT devices. Advanced machine learning algorithms for adaptive calibration represent a promising frontier, potentially enabling sensors to self-adjust based on usage patterns and environmental conditions, further enhancing accuracy and reliability in real-world applications.

Market Applications and Demand Analysis for Precision Temperature Measurement

The precision temperature measurement market is experiencing robust growth driven by increasing demands across multiple industries for accurate thermal monitoring solutions. The global market for temperature sensors, including thermopile technology, is projected to reach $7.88 billion by 2027, with a compound annual growth rate of 4.8% from 2020. This growth trajectory is primarily fueled by the expanding applications of high-precision temperature measurement in critical sectors.

Healthcare and medical diagnostics represent a significant market segment, where non-contact infrared thermometers utilizing thermopile sensors have seen unprecedented demand, particularly following the COVID-19 pandemic. The medical-grade temperature measurement devices market alone is expected to maintain a growth rate of 6.2% through 2025, with particular emphasis on devices achieving accuracy within ±0.1°C for clinical applications.

Industrial process control constitutes another major application area, where precise temperature monitoring directly impacts product quality and operational efficiency. Manufacturing sectors, particularly semiconductor fabrication, require temperature measurement accuracies of ±0.5°C or better, creating a specialized market segment valued at approximately $1.2 billion annually. The automotive industry similarly demands high-precision temperature sensors for engine management systems, battery thermal monitoring in electric vehicles, and climate control systems.

Consumer electronics represents a rapidly expanding market for miniaturized thermopile sensors, with applications in smartphones, smart home devices, and wearable technology. This segment is growing at 7.3% annually, driven by increasing consumer interest in health monitoring and environmental sensing capabilities in everyday devices.

The HVAC industry relies heavily on accurate temperature measurement for energy efficiency optimization, with building automation systems increasingly incorporating networks of precision temperature sensors. This market segment values calibration accuracy as a key differentiator, with premium solutions commanding price premiums of 30-40% over standard offerings.

Aerospace and defense applications demand the highest performance specifications, with temperature measurement systems required to maintain calibration accuracy across extreme environmental conditions. Though smaller in volume than consumer markets, this segment generates significant value due to stringent certification requirements and specialized calibration needs.

Emerging applications in environmental monitoring, agriculture, and food safety are creating new market opportunities for calibrated thermopile sensor systems. These sectors increasingly require distributed temperature monitoring networks with centralized calibration management, representing a growing market estimated at $650 million annually with double-digit growth rates.

Healthcare and medical diagnostics represent a significant market segment, where non-contact infrared thermometers utilizing thermopile sensors have seen unprecedented demand, particularly following the COVID-19 pandemic. The medical-grade temperature measurement devices market alone is expected to maintain a growth rate of 6.2% through 2025, with particular emphasis on devices achieving accuracy within ±0.1°C for clinical applications.

Industrial process control constitutes another major application area, where precise temperature monitoring directly impacts product quality and operational efficiency. Manufacturing sectors, particularly semiconductor fabrication, require temperature measurement accuracies of ±0.5°C or better, creating a specialized market segment valued at approximately $1.2 billion annually. The automotive industry similarly demands high-precision temperature sensors for engine management systems, battery thermal monitoring in electric vehicles, and climate control systems.

Consumer electronics represents a rapidly expanding market for miniaturized thermopile sensors, with applications in smartphones, smart home devices, and wearable technology. This segment is growing at 7.3% annually, driven by increasing consumer interest in health monitoring and environmental sensing capabilities in everyday devices.

The HVAC industry relies heavily on accurate temperature measurement for energy efficiency optimization, with building automation systems increasingly incorporating networks of precision temperature sensors. This market segment values calibration accuracy as a key differentiator, with premium solutions commanding price premiums of 30-40% over standard offerings.

Aerospace and defense applications demand the highest performance specifications, with temperature measurement systems required to maintain calibration accuracy across extreme environmental conditions. Though smaller in volume than consumer markets, this segment generates significant value due to stringent certification requirements and specialized calibration needs.

Emerging applications in environmental monitoring, agriculture, and food safety are creating new market opportunities for calibrated thermopile sensor systems. These sectors increasingly require distributed temperature monitoring networks with centralized calibration management, representing a growing market estimated at $650 million annually with double-digit growth rates.

Current Challenges in Thermopile Sensor Calibration

Despite significant advancements in thermopile sensor technology, calibration remains a critical challenge that impacts measurement accuracy across various applications. The non-linear response characteristics of thermopile sensors to temperature variations necessitate sophisticated calibration procedures that many manufacturers and end-users struggle to implement effectively. Current calibration methods often fail to account for the full range of environmental factors that influence sensor performance in real-world conditions.

One of the primary challenges is the inherent drift in sensor readings over time, which can lead to significant measurement errors if not properly compensated for. This drift is influenced by multiple factors including aging of materials, mechanical stress, and exposure to temperature extremes during operation. Traditional calibration approaches typically establish fixed correction parameters at the factory level, but these become increasingly inaccurate as the sensor ages.

Cross-sensitivity to non-target infrared radiation sources presents another substantial challenge. Thermopile sensors can be affected by nearby heat sources or reflective surfaces that are not part of the intended measurement target. Current calibration techniques often lack robust methodologies to differentiate between target and non-target radiation sources, leading to measurement inaccuracies in complex thermal environments.

The temperature dependency of the sensor's own cold junction compensation mechanism introduces additional complexity. As the ambient temperature around the sensor changes, the reference point for measurements shifts, requiring dynamic compensation algorithms. Many existing calibration approaches implement simplified linear compensation models that fail to address the non-linear nature of this relationship across wide temperature ranges.

Manufacturing variations between individual sensors, even within the same production batch, create inconsistencies that standard calibration protocols struggle to address. Each sensor may exhibit slightly different response characteristics, requiring individualized calibration parameters. However, the cost and time constraints of production often limit the feasibility of comprehensive individual sensor calibration.

Field recalibration represents another significant challenge, particularly for sensors deployed in remote or inaccessible locations. Current methods typically require specialized equipment and controlled environments, making in-situ recalibration impractical. This limitation results in degraded measurement accuracy over time for deployed sensors unless they are physically retrieved for laboratory recalibration.

The integration of thermopile sensors into increasingly miniaturized and complex systems introduces thermal management challenges that affect calibration stability. Heat generated by nearby electronic components can create thermal gradients across the sensor package, leading to measurement errors that are difficult to predict and compensate for using standard calibration techniques.

One of the primary challenges is the inherent drift in sensor readings over time, which can lead to significant measurement errors if not properly compensated for. This drift is influenced by multiple factors including aging of materials, mechanical stress, and exposure to temperature extremes during operation. Traditional calibration approaches typically establish fixed correction parameters at the factory level, but these become increasingly inaccurate as the sensor ages.

Cross-sensitivity to non-target infrared radiation sources presents another substantial challenge. Thermopile sensors can be affected by nearby heat sources or reflective surfaces that are not part of the intended measurement target. Current calibration techniques often lack robust methodologies to differentiate between target and non-target radiation sources, leading to measurement inaccuracies in complex thermal environments.

The temperature dependency of the sensor's own cold junction compensation mechanism introduces additional complexity. As the ambient temperature around the sensor changes, the reference point for measurements shifts, requiring dynamic compensation algorithms. Many existing calibration approaches implement simplified linear compensation models that fail to address the non-linear nature of this relationship across wide temperature ranges.

Manufacturing variations between individual sensors, even within the same production batch, create inconsistencies that standard calibration protocols struggle to address. Each sensor may exhibit slightly different response characteristics, requiring individualized calibration parameters. However, the cost and time constraints of production often limit the feasibility of comprehensive individual sensor calibration.

Field recalibration represents another significant challenge, particularly for sensors deployed in remote or inaccessible locations. Current methods typically require specialized equipment and controlled environments, making in-situ recalibration impractical. This limitation results in degraded measurement accuracy over time for deployed sensors unless they are physically retrieved for laboratory recalibration.

The integration of thermopile sensors into increasingly miniaturized and complex systems introduces thermal management challenges that affect calibration stability. Heat generated by nearby electronic components can create thermal gradients across the sensor package, leading to measurement errors that are difficult to predict and compensate for using standard calibration techniques.

Existing Calibration Methodologies and Standards

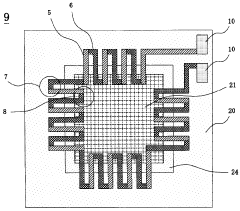

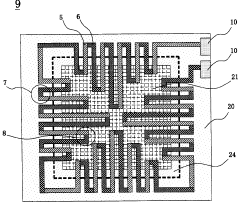

01 Thermopile sensor design optimization for accuracy

Optimizing the design of thermopile sensors can significantly improve temperature measurement accuracy. This includes using specialized materials, optimizing the thermocouple junction arrangement, and implementing advanced fabrication techniques. Design improvements focus on increasing the Seebeck coefficient, reducing thermal noise, and enhancing signal-to-noise ratio. These optimizations allow for more precise temperature readings across various applications.- Calibration techniques for thermopile sensors: Various calibration techniques can be employed to enhance the accuracy of thermopile sensors for temperature measurement. These include multi-point calibration methods, reference temperature comparison, and algorithmic compensation for environmental factors. Proper calibration can significantly reduce measurement errors and improve the overall accuracy of thermopile-based temperature sensing systems.

- Structural design improvements for accuracy enhancement: The physical design and structure of thermopile sensors play a crucial role in determining their temperature measurement accuracy. Innovations in thermopile array configurations, junction designs, and thermal isolation techniques can minimize thermal noise and drift. Advanced packaging methods and materials selection also contribute to improved stability and measurement precision.

- Signal processing and error compensation algorithms: Advanced signal processing techniques and error compensation algorithms are essential for improving the accuracy of thermopile sensor temperature measurements. These include digital filtering, noise reduction methods, and mathematical models that account for ambient temperature variations. Real-time compensation for thermal drift and environmental interference can significantly enhance measurement precision.

- Integration with complementary sensing technologies: Combining thermopile sensors with other sensing technologies can improve overall temperature measurement accuracy. Hybrid sensing approaches that incorporate reference temperature sensors, ambient condition monitors, or multi-spectral detection capabilities enable cross-validation and error correction. These integrated systems can achieve higher accuracy than standalone thermopile sensors.

- Application-specific optimization techniques: Thermopile sensor accuracy can be optimized for specific applications through targeted design modifications and specialized processing. For medical applications, body temperature compensation factors may be implemented, while industrial applications might focus on extended temperature range accuracy. Environmental monitoring applications may employ specific filtering techniques to account for atmospheric conditions that affect measurement accuracy.

02 Calibration methods for improved accuracy

Various calibration techniques can be employed to enhance the accuracy of thermopile sensors. These include multi-point calibration, temperature compensation algorithms, and reference temperature monitoring. Calibration processes account for environmental factors and sensor-specific characteristics that might affect readings. Advanced calibration methods can significantly reduce measurement errors and improve overall temperature sensing precision.Expand Specific Solutions03 Signal processing techniques for accuracy enhancement

Advanced signal processing techniques play a crucial role in improving thermopile sensor accuracy. These include digital filtering, signal amplification, noise reduction algorithms, and drift compensation. By implementing sophisticated processing methods, raw sensor data can be refined to eliminate interference and enhance measurement precision. Real-time signal processing allows for dynamic adjustment to changing environmental conditions.Expand Specific Solutions04 Environmental compensation for temperature accuracy

Environmental factors significantly impact thermopile sensor accuracy. Compensation techniques address influences such as ambient temperature fluctuations, humidity variations, and air flow disturbances. Methods include thermal isolation, protective housing designs, and algorithmic corrections. By accounting for environmental variables, these compensation approaches ensure consistent and reliable temperature measurements across diverse operating conditions.Expand Specific Solutions05 Integration with complementary sensors for enhanced accuracy

Combining thermopile sensors with complementary sensing technologies can significantly improve temperature measurement accuracy. Integration approaches include using reference temperature sensors, humidity sensors, or pressure sensors to provide contextual data for measurement correction. Fusion algorithms combine data from multiple sensor types to produce more accurate temperature readings. This multi-sensor approach compensates for individual sensor limitations and environmental variables.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermopile Sensors

The thermopile sensor calibration market is currently in a growth phase, with increasing demand driven by applications requiring precise temperature measurement across multiple industries. The global market size for thermal sensors is expanding at approximately 6-8% CAGR, valued at over $6 billion. From a technological maturity perspective, the field shows varied development levels among key players. Industry leaders like Melexis Technologies, Infineon Technologies, and NXP Semiconductors have established advanced calibration methodologies, while Apple and ABB Group are integrating these sensors into consumer and industrial applications with proprietary calibration techniques. Emerging players such as Ningbo Semiconductor and Suzhou Rongqi Sensor Technology are rapidly developing competitive solutions, particularly in cost-effective calibration processes. The competition is intensifying as manufacturers seek to improve accuracy while reducing calibration complexity and costs.

Maxim Integrated Products LLC

Technical Solution: Maxim Integrated has developed a comprehensive calibration approach for their thermopile sensor portfolio, centered around their MAX30205 medical-grade temperature sensors. Their calibration methodology employs a three-tier approach: factory calibration, system-level calibration, and adaptive runtime calibration. During manufacturing, each sensor undergoes precision calibration against NIST-traceable temperature references at multiple points across the operating range. Maxim's proprietary algorithm generates sensor-specific coefficients that are stored in non-volatile memory. Their system-level calibration framework allows integration of multiple temperature reference points within the final application to further enhance accuracy. The adaptive runtime calibration continuously monitors environmental conditions and sensor behavior patterns to apply dynamic compensation factors. This approach enables their medical-grade sensors to achieve clinical accuracy of ±0.1°C within the critical human body temperature range (35°C to 42°C). Maxim's sensors also incorporate drift compensation algorithms that analyze long-term behavior patterns to maintain calibration integrity throughout the product lifecycle.

Strengths: Exceptional accuracy in the medical temperature range; comprehensive calibration approach that addresses both manufacturing variations and environmental factors; low-power operation suitable for battery-powered devices. Weaknesses: Higher cost compared to industrial-grade alternatives; requires sophisticated integration to achieve maximum accuracy benefits; calibration optimization focused primarily on human body temperature range rather than wider industrial ranges.

Braun GmbH & Co. KG

Technical Solution: Braun has developed a highly specialized calibration system for their thermopile sensors used in medical thermometers, particularly their ThermoScan® product line. Their approach focuses on achieving clinical-grade accuracy in non-contact temperature measurement. Braun's calibration methodology employs a multi-stage process beginning with individual sensor characterization against medical-grade reference standards across the physiological temperature range (34°C to 43°C). Their proprietary Age Precision® technology incorporates age-specific calibration adjustments to account for physiological variations in skin temperature across different age groups. The calibration process generates sensor-specific coefficients that are stored in non-volatile memory and accessed by their signal processing algorithm during operation. Braun's approach uniquely addresses the challenge of measuring core body temperature from the tympanic membrane (eardrum) by incorporating anatomical compensation factors into their calibration model. Their latest generation sensors implement self-calibration routines that perform periodic verification against internal reference points to maintain accuracy over the product's lifetime. This comprehensive approach enables their medical thermometers to achieve clinical accuracy of ±0.2°C in the critical fever detection range, meeting both FDA and European medical device standards for temperature measurement accuracy.

Strengths: Exceptional accuracy in the clinical temperature range; specialized calibration optimized for human body temperature measurement; comprehensive age-specific adjustments for different patient populations. Weaknesses: Calibration highly specialized for medical applications with limited applicability to general industrial use; requires precise positioning and technique to achieve stated accuracy; higher cost compared to general-purpose temperature sensors.

Key Patents and Innovations in Thermopile Calibration

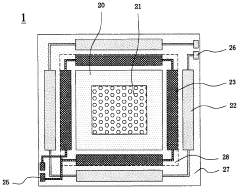

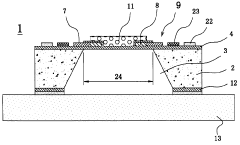

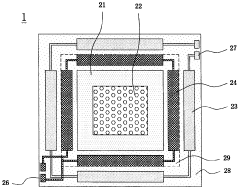

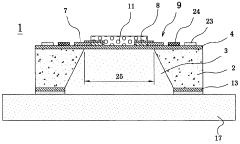

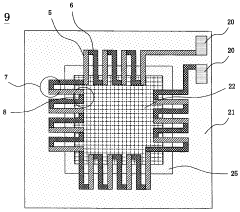

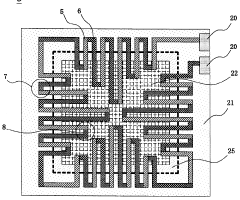

Thermopile sensor, and method of measuring temperature with infrared radiation

PatentWO2001061295A1

Innovation

- A thermopile sensor configuration where a heating element is directly connected to the cold junction region, allowing for synchronized temperature change measurement, and the output voltage is controlled to pass through zero at a constant gradient, reducing measurement time and improving accuracy by detecting phase reversal.

Thermopile sensor and temperature measuring method by infrared rays

PatentWO2001050102A1

Innovation

- Incorporating a resistor with a self-regulating positive temperature coefficient characteristic in the thermopile sensor, which maintains the cold junction at a constant bias temperature, synchronizing the thermal response speed with the thermopile output, and using a semiconductor heating element and thermistor for precise temperature measurement.

Environmental Factors Affecting Measurement Precision

Environmental factors play a critical role in determining the measurement precision of thermopile sensors during calibration processes. Temperature gradients within the testing environment represent one of the most significant challenges, as even minor variations can introduce substantial measurement errors. When ambient temperature fluctuates around the sensor, it creates thermal noise that directly impacts the sensor's output signal, potentially leading to inaccurate readings that deviate from true values by several degrees Celsius.

Humidity levels similarly affect thermopile performance by altering the thermal conductivity of the surrounding air. Research indicates that relative humidity variations between 20% and 80% can introduce measurement errors ranging from 0.1°C to 0.5°C, depending on the sensor design and protective housing. High humidity environments may also accelerate corrosion of sensor components, gradually degrading calibration stability over time.

Air movement and ventilation patterns create convective heat transfer effects that can significantly distort temperature readings. Studies have demonstrated that air currents as subtle as 0.5 m/s can produce measurement deviations exceeding 1.0°C in non-shielded thermopile configurations. This becomes particularly problematic in industrial settings where HVAC systems, equipment cooling fans, or personnel movement generate unpredictable airflow patterns.

Electromagnetic interference (EMI) from nearby electronic equipment constitutes another environmental challenge. Thermopile sensors with inadequate shielding may experience signal corruption when exposed to EMI sources such as power supplies, motors, or wireless communication devices. The resulting measurement errors typically manifest as random noise or systematic offsets that compromise calibration accuracy.

Dust, particulate matter, and other contaminants can physically obstruct the optical path of thermopile sensors, especially in infrared temperature measurement applications. Even microscopic particles deposited on sensor windows can absorb or scatter radiation, leading to attenuated signals and underestimated temperature readings. Regular cleaning protocols must be established to maintain calibration integrity in dusty environments.

Barometric pressure variations, while often overlooked, can influence thermopile measurements through changes in air density and thermal conductivity. This effect becomes particularly relevant in applications involving altitude changes or pressurized environments, where pressure differentials can introduce subtle but measurable calibration shifts that must be compensated for in high-precision applications.

Humidity levels similarly affect thermopile performance by altering the thermal conductivity of the surrounding air. Research indicates that relative humidity variations between 20% and 80% can introduce measurement errors ranging from 0.1°C to 0.5°C, depending on the sensor design and protective housing. High humidity environments may also accelerate corrosion of sensor components, gradually degrading calibration stability over time.

Air movement and ventilation patterns create convective heat transfer effects that can significantly distort temperature readings. Studies have demonstrated that air currents as subtle as 0.5 m/s can produce measurement deviations exceeding 1.0°C in non-shielded thermopile configurations. This becomes particularly problematic in industrial settings where HVAC systems, equipment cooling fans, or personnel movement generate unpredictable airflow patterns.

Electromagnetic interference (EMI) from nearby electronic equipment constitutes another environmental challenge. Thermopile sensors with inadequate shielding may experience signal corruption when exposed to EMI sources such as power supplies, motors, or wireless communication devices. The resulting measurement errors typically manifest as random noise or systematic offsets that compromise calibration accuracy.

Dust, particulate matter, and other contaminants can physically obstruct the optical path of thermopile sensors, especially in infrared temperature measurement applications. Even microscopic particles deposited on sensor windows can absorb or scatter radiation, leading to attenuated signals and underestimated temperature readings. Regular cleaning protocols must be established to maintain calibration integrity in dusty environments.

Barometric pressure variations, while often overlooked, can influence thermopile measurements through changes in air density and thermal conductivity. This effect becomes particularly relevant in applications involving altitude changes or pressurized environments, where pressure differentials can introduce subtle but measurable calibration shifts that must be compensated for in high-precision applications.

Traceability and Certification Requirements

Traceability and certification requirements form a critical foundation for ensuring the reliability and accuracy of thermopile sensor calibration processes. These requirements establish a formal connection between measurement results and recognized international standards, providing confidence in the accuracy of temperature readings across various applications. The International Temperature Scale of 1990 (ITS-90) serves as the primary reference standard for temperature measurements worldwide, establishing fixed points and interpolation methods that enable consistent temperature calibration across different laboratories and industries.

For thermopile sensor calibration, an unbroken chain of comparisons must link the sensor's measurements to primary standards maintained by national metrology institutes such as NIST (USA), PTB (Germany), or NPL (UK). This traceability chain typically involves several levels of reference standards, including primary standards (fixed-point cells), secondary standards (calibrated platinum resistance thermometers), and working standards used in manufacturing environments. Each transfer between standards introduces measurement uncertainty that must be quantified and documented.

Certification requirements for thermopile sensors vary by application domain, with medical and aerospace applications demanding the most stringent documentation. ISO/IEC 17025 accreditation is generally required for calibration laboratories performing thermopile sensor calibration, ensuring that the laboratory maintains appropriate quality management systems and technical competence. For medical applications, additional compliance with ISO 13485 may be necessary, while industrial applications often require adherence to industry-specific standards such as AMS2750 for aerospace thermal processing.

Documentation requirements include calibration certificates that must detail the measurement procedure, environmental conditions, reference standards used, and comprehensive uncertainty analysis. These certificates must clearly state the expanded measurement uncertainty (typically at 95% confidence level) and include information about the traceability chain. Many regulatory environments now require digital signatures and secure electronic records to prevent tampering with calibration data.

Recalibration intervals must be established based on stability analysis of the specific thermopile sensor technology, with typical intervals ranging from six months to two years depending on the application criticality and operating environment. Drift analysis should be performed to justify these intervals, particularly for sensors used in critical applications where temperature accuracy directly impacts product quality or safety.

International mutual recognition arrangements, such as the CIPM Mutual Recognition Arrangement, facilitate global acceptance of calibration certificates across national boundaries, reducing the need for redundant calibrations when thermopile sensors or instruments are used internationally. This harmonization of standards supports global trade while maintaining measurement integrity across diverse regulatory environments.

For thermopile sensor calibration, an unbroken chain of comparisons must link the sensor's measurements to primary standards maintained by national metrology institutes such as NIST (USA), PTB (Germany), or NPL (UK). This traceability chain typically involves several levels of reference standards, including primary standards (fixed-point cells), secondary standards (calibrated platinum resistance thermometers), and working standards used in manufacturing environments. Each transfer between standards introduces measurement uncertainty that must be quantified and documented.

Certification requirements for thermopile sensors vary by application domain, with medical and aerospace applications demanding the most stringent documentation. ISO/IEC 17025 accreditation is generally required for calibration laboratories performing thermopile sensor calibration, ensuring that the laboratory maintains appropriate quality management systems and technical competence. For medical applications, additional compliance with ISO 13485 may be necessary, while industrial applications often require adherence to industry-specific standards such as AMS2750 for aerospace thermal processing.

Documentation requirements include calibration certificates that must detail the measurement procedure, environmental conditions, reference standards used, and comprehensive uncertainty analysis. These certificates must clearly state the expanded measurement uncertainty (typically at 95% confidence level) and include information about the traceability chain. Many regulatory environments now require digital signatures and secure electronic records to prevent tampering with calibration data.

Recalibration intervals must be established based on stability analysis of the specific thermopile sensor technology, with typical intervals ranging from six months to two years depending on the application criticality and operating environment. Drift analysis should be performed to justify these intervals, particularly for sensors used in critical applications where temperature accuracy directly impacts product quality or safety.

International mutual recognition arrangements, such as the CIPM Mutual Recognition Arrangement, facilitate global acceptance of calibration certificates across national boundaries, reducing the need for redundant calibrations when thermopile sensors or instruments are used internationally. This harmonization of standards supports global trade while maintaining measurement integrity across diverse regulatory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!