How to Assemble Thermopile Arrays for Improved Outputs

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Array Technology Background and Objectives

Thermopile arrays have evolved significantly since their inception in the early 20th century, with major technological advancements occurring in the last three decades. Initially developed as simple thermoelectric devices based on the Seebeck effect discovered in 1821, thermopiles have transformed from single-junction devices to sophisticated multi-junction array configurations capable of detecting minute temperature differences with remarkable precision.

The evolution of thermopile technology has been driven by increasing demands for non-contact temperature measurement, thermal imaging, and energy harvesting applications. Early thermopile sensors were primarily used in specialized scientific instruments, but miniaturization and manufacturing improvements have expanded their application scope dramatically. The integration of semiconductor processing techniques in the 1990s marked a pivotal turning point, enabling mass production of thermopile arrays with consistent performance characteristics.

Current technological trends in thermopile arrays focus on improving three key performance metrics: sensitivity, response time, and signal-to-noise ratio. Recent innovations have explored novel materials beyond traditional bismuth-antimony and silicon-based thermocouples, including thin-film technologies and nanomaterials that offer superior thermoelectric properties. Additionally, advanced packaging techniques and MEMS (Micro-Electro-Mechanical Systems) integration have contributed to more compact and efficient array designs.

The primary objective of thermopile array assembly research is to develop methodologies that maximize output voltage while maintaining thermal isolation between hot and cold junctions. This involves optimizing the number of thermocouples, their spatial arrangement, and the thermal management strategies employed. Secondary objectives include reducing manufacturing costs, improving reliability, and enhancing compatibility with standard electronic interfaces.

Industry projections indicate growing demand for high-performance thermopile arrays in emerging applications such as autonomous vehicles, smart buildings, medical diagnostics, and IoT devices. The global market for thermal sensors, including thermopile arrays, is expected to reach $7.8 billion by 2026, with a compound annual growth rate of approximately 8.3%.

The technical roadmap for thermopile array development aims to achieve sensitivity improvements of 30-50% within the next five years through novel assembly techniques and materials engineering. Parallel efforts focus on reducing power consumption and form factor to enable integration into increasingly compact and energy-efficient devices. These advancements will be critical in meeting the requirements of next-generation sensing applications that demand higher resolution, faster response times, and greater measurement accuracy.

The evolution of thermopile technology has been driven by increasing demands for non-contact temperature measurement, thermal imaging, and energy harvesting applications. Early thermopile sensors were primarily used in specialized scientific instruments, but miniaturization and manufacturing improvements have expanded their application scope dramatically. The integration of semiconductor processing techniques in the 1990s marked a pivotal turning point, enabling mass production of thermopile arrays with consistent performance characteristics.

Current technological trends in thermopile arrays focus on improving three key performance metrics: sensitivity, response time, and signal-to-noise ratio. Recent innovations have explored novel materials beyond traditional bismuth-antimony and silicon-based thermocouples, including thin-film technologies and nanomaterials that offer superior thermoelectric properties. Additionally, advanced packaging techniques and MEMS (Micro-Electro-Mechanical Systems) integration have contributed to more compact and efficient array designs.

The primary objective of thermopile array assembly research is to develop methodologies that maximize output voltage while maintaining thermal isolation between hot and cold junctions. This involves optimizing the number of thermocouples, their spatial arrangement, and the thermal management strategies employed. Secondary objectives include reducing manufacturing costs, improving reliability, and enhancing compatibility with standard electronic interfaces.

Industry projections indicate growing demand for high-performance thermopile arrays in emerging applications such as autonomous vehicles, smart buildings, medical diagnostics, and IoT devices. The global market for thermal sensors, including thermopile arrays, is expected to reach $7.8 billion by 2026, with a compound annual growth rate of approximately 8.3%.

The technical roadmap for thermopile array development aims to achieve sensitivity improvements of 30-50% within the next five years through novel assembly techniques and materials engineering. Parallel efforts focus on reducing power consumption and form factor to enable integration into increasingly compact and energy-efficient devices. These advancements will be critical in meeting the requirements of next-generation sensing applications that demand higher resolution, faster response times, and greater measurement accuracy.

Market Demand Analysis for High-Performance Thermopile Arrays

The global market for high-performance thermopile arrays is experiencing robust growth driven by increasing demand across multiple sectors. The thermal sensing technology market, which includes thermopile arrays, was valued at approximately $5.2 billion in 2022 and is projected to reach $8.7 billion by 2028, representing a compound annual growth rate (CAGR) of 8.9%. This growth trajectory underscores the expanding applications and market potential for advanced thermopile array technologies.

Healthcare and medical diagnostics represent a primary market driver, with non-contact temperature measurement becoming essential in clinical settings. The COVID-19 pandemic significantly accelerated this trend, creating sustained demand for high-accuracy thermal measurement devices. Medical-grade thermopile arrays with improved outputs are particularly sought after for applications in fever screening systems, patient monitoring devices, and medical imaging equipment.

The industrial automation sector presents another substantial market opportunity. Manufacturing facilities increasingly deploy thermal sensing technologies for predictive maintenance, process monitoring, and quality control. High-performance thermopile arrays capable of detecting minute temperature variations across production lines can significantly reduce downtime and improve operational efficiency, delivering measurable return on investment for industrial users.

Consumer electronics represents a rapidly expanding market segment, with thermopile arrays being integrated into smartphones, wearable devices, and smart home systems. The miniaturization trend in consumer electronics has created demand for compact yet highly sensitive thermopile arrays that can deliver accurate temperature readings while consuming minimal power.

Automotive applications are emerging as a high-growth segment, particularly with the advancement of autonomous driving technologies. Thermopile arrays with enhanced outputs are increasingly utilized in driver monitoring systems, cabin comfort management, and engine diagnostics. The automotive-grade requirements for durability and reliability under extreme conditions are driving innovation in thermopile array assembly techniques.

Market analysis indicates a growing preference for thermopile arrays with higher pixel density, improved signal-to-noise ratios, and enhanced thermal sensitivity. End-users across industries are willing to pay premium prices for arrays that deliver superior performance metrics, particularly in terms of temperature resolution and measurement accuracy.

Regional market assessment shows North America and Europe leading in adoption of high-performance thermopile technologies, primarily in medical and industrial applications. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities and increasing implementation of automation technologies across China, Japan, South Korea, and Taiwan.

Healthcare and medical diagnostics represent a primary market driver, with non-contact temperature measurement becoming essential in clinical settings. The COVID-19 pandemic significantly accelerated this trend, creating sustained demand for high-accuracy thermal measurement devices. Medical-grade thermopile arrays with improved outputs are particularly sought after for applications in fever screening systems, patient monitoring devices, and medical imaging equipment.

The industrial automation sector presents another substantial market opportunity. Manufacturing facilities increasingly deploy thermal sensing technologies for predictive maintenance, process monitoring, and quality control. High-performance thermopile arrays capable of detecting minute temperature variations across production lines can significantly reduce downtime and improve operational efficiency, delivering measurable return on investment for industrial users.

Consumer electronics represents a rapidly expanding market segment, with thermopile arrays being integrated into smartphones, wearable devices, and smart home systems. The miniaturization trend in consumer electronics has created demand for compact yet highly sensitive thermopile arrays that can deliver accurate temperature readings while consuming minimal power.

Automotive applications are emerging as a high-growth segment, particularly with the advancement of autonomous driving technologies. Thermopile arrays with enhanced outputs are increasingly utilized in driver monitoring systems, cabin comfort management, and engine diagnostics. The automotive-grade requirements for durability and reliability under extreme conditions are driving innovation in thermopile array assembly techniques.

Market analysis indicates a growing preference for thermopile arrays with higher pixel density, improved signal-to-noise ratios, and enhanced thermal sensitivity. End-users across industries are willing to pay premium prices for arrays that deliver superior performance metrics, particularly in terms of temperature resolution and measurement accuracy.

Regional market assessment shows North America and Europe leading in adoption of high-performance thermopile technologies, primarily in medical and industrial applications. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding manufacturing capabilities and increasing implementation of automation technologies across China, Japan, South Korea, and Taiwan.

Current Challenges in Thermopile Array Assembly

Despite significant advancements in thermopile technology, the assembly of thermopile arrays continues to present several critical challenges that limit their performance and widespread adoption. One of the primary obstacles is the precise alignment of individual thermopile elements within the array. Even minor misalignments at the microscale can lead to substantial variations in thermal response across the array, resulting in non-uniform output signals and reduced overall sensitivity.

Manufacturing consistency represents another significant hurdle. Current production methods struggle to maintain uniform thermoelectric properties across all elements in larger arrays. This inconsistency stems from variations in material deposition thickness, doping concentrations, and junction quality during fabrication processes. These manufacturing discrepancies directly impact the voltage output homogeneity across the array, complicating signal processing and calibration.

Thermal crosstalk between adjacent thermopile elements presents a persistent challenge that degrades spatial resolution and measurement accuracy. As array density increases to improve resolution, the proximity between elements inevitably leads to thermal interference. Current isolation techniques often add complexity to the assembly process while simultaneously reducing the active sensing area, creating an unfavorable trade-off between resolution and sensitivity.

Interconnection reliability remains problematic, particularly for high-density arrays. The numerous electrical connections required between individual thermopile elements and readout circuitry create multiple potential failure points. Traditional wire bonding techniques introduce mechanical stress that can damage delicate thermoelectric materials, while alternative approaches like flip-chip bonding face challenges with thermal expansion mismatches that can lead to connection failures over time.

Packaging solutions for thermopile arrays face the contradictory requirements of providing excellent thermal isolation between hot and cold junctions while maintaining mechanical robustness. Current packaging approaches often compromise on one aspect to improve the other, resulting in either reduced sensitivity or decreased durability. Additionally, conventional packaging materials may introduce parasitic thermal paths that degrade the temperature differential necessary for optimal thermopile operation.

Cost-effective scaling represents perhaps the most significant barrier to widespread commercial implementation. Current assembly methods for high-performance thermopile arrays remain largely manual or semi-automated, requiring specialized equipment and skilled technicians. This labor-intensive process significantly increases production costs and limits manufacturing throughput, preventing thermopile arrays from reaching price points necessary for mass-market applications beyond specialized industrial and scientific instruments.

Manufacturing consistency represents another significant hurdle. Current production methods struggle to maintain uniform thermoelectric properties across all elements in larger arrays. This inconsistency stems from variations in material deposition thickness, doping concentrations, and junction quality during fabrication processes. These manufacturing discrepancies directly impact the voltage output homogeneity across the array, complicating signal processing and calibration.

Thermal crosstalk between adjacent thermopile elements presents a persistent challenge that degrades spatial resolution and measurement accuracy. As array density increases to improve resolution, the proximity between elements inevitably leads to thermal interference. Current isolation techniques often add complexity to the assembly process while simultaneously reducing the active sensing area, creating an unfavorable trade-off between resolution and sensitivity.

Interconnection reliability remains problematic, particularly for high-density arrays. The numerous electrical connections required between individual thermopile elements and readout circuitry create multiple potential failure points. Traditional wire bonding techniques introduce mechanical stress that can damage delicate thermoelectric materials, while alternative approaches like flip-chip bonding face challenges with thermal expansion mismatches that can lead to connection failures over time.

Packaging solutions for thermopile arrays face the contradictory requirements of providing excellent thermal isolation between hot and cold junctions while maintaining mechanical robustness. Current packaging approaches often compromise on one aspect to improve the other, resulting in either reduced sensitivity or decreased durability. Additionally, conventional packaging materials may introduce parasitic thermal paths that degrade the temperature differential necessary for optimal thermopile operation.

Cost-effective scaling represents perhaps the most significant barrier to widespread commercial implementation. Current assembly methods for high-performance thermopile arrays remain largely manual or semi-automated, requiring specialized equipment and skilled technicians. This labor-intensive process significantly increases production costs and limits manufacturing throughput, preventing thermopile arrays from reaching price points necessary for mass-market applications beyond specialized industrial and scientific instruments.

Current Assembly Techniques for Optimized Thermopile Outputs

01 Signal processing and output optimization for thermopile arrays

Various methods and systems for processing signals from thermopile arrays to optimize output quality and accuracy. These include signal amplification, filtering, and calibration techniques to enhance the sensitivity and reliability of thermopile array measurements. Advanced processing algorithms can compensate for environmental variations and noise, resulting in more precise temperature readings and thermal imaging capabilities.- Signal processing and output conversion for thermopile arrays: Thermopile arrays generate electrical signals that require processing to convert them into usable outputs. This involves amplification, filtering, and analog-to-digital conversion of the small voltage signals produced by the thermopile elements. Advanced signal processing techniques can enhance the sensitivity and accuracy of thermopile array measurements, allowing for better temperature detection and imaging capabilities.

- Thermopile array configurations for improved output performance: Various configurations of thermopile arrays can be designed to optimize output performance. This includes specific arrangements of thermocouples, the use of multiple junctions, and specialized array geometries. These configurations can enhance sensitivity, reduce noise, and improve the spatial resolution of temperature measurements, resulting in more accurate and reliable output signals.

- Temperature compensation techniques for thermopile array outputs: Temperature compensation is crucial for maintaining accurate outputs from thermopile arrays across varying ambient conditions. This involves implementing reference temperature sensors, differential measurement techniques, and calibration algorithms to correct for ambient temperature fluctuations. These methods help to minimize drift and ensure consistent performance of thermopile array systems in different environmental conditions.

- Integration of thermopile arrays with readout circuitry: The integration of thermopile arrays with specialized readout circuitry is essential for effective output signal management. This includes the development of application-specific integrated circuits (ASICs), multiplexing systems for array scanning, and interface electronics for communication with external systems. Proper integration enhances the functionality and usability of thermopile array outputs in various applications.

- Manufacturing techniques affecting thermopile array output quality: The manufacturing processes used to produce thermopile arrays significantly impact their output quality. This includes material selection for thermoelectric elements, deposition techniques, junction formation methods, and encapsulation approaches. Advanced manufacturing techniques can improve the uniformity, stability, and sensitivity of thermopile array outputs, leading to better performance in sensing applications.

02 Thermopile array design and configuration

Specific design considerations and configurations for thermopile arrays that affect their output characteristics. This includes the arrangement of thermocouples, junction density, and geometric patterns that optimize thermal sensitivity and spatial resolution. Various array architectures are employed to enhance detection capabilities for different applications, with considerations for size, power consumption, and response time.Expand Specific Solutions03 Integration of thermopile arrays with readout circuitry

Methods for integrating thermopile arrays with readout and interface circuitry to process and transmit output signals. These include analog-to-digital conversion techniques, multiplexing strategies for multi-element arrays, and interface protocols for connecting to external systems. The integration approaches focus on minimizing noise, reducing power consumption, and enabling real-time data acquisition from multiple thermopile elements.Expand Specific Solutions04 Calibration and compensation techniques for thermopile array outputs

Techniques for calibrating thermopile arrays and compensating for various factors that affect output accuracy. These include methods to account for ambient temperature variations, aging effects, and manufacturing inconsistencies. Compensation algorithms and reference temperature sensing are employed to maintain measurement accuracy across different operating conditions and throughout the device lifetime.Expand Specific Solutions05 Applications of thermopile array outputs in sensing systems

Various applications leveraging thermopile array outputs for sensing and detection purposes. These include non-contact temperature measurement, thermal imaging, motion detection, gas analysis, and presence sensing. The outputs from thermopile arrays are utilized in consumer electronics, industrial monitoring, medical diagnostics, and security systems, demonstrating their versatility across different fields.Expand Specific Solutions

Key Industry Players in Thermopile Sensor Manufacturing

The thermopile array assembly market is currently in a growth phase, with increasing demand driven by applications in thermal imaging, temperature sensing, and energy harvesting. The global market size is estimated to reach approximately $1.2 billion by 2025, with a CAGR of 8-10%. Technical maturity varies significantly among key players, with established semiconductor companies like Texas Instruments and LG Innotek leading in commercial applications. Research institutions such as IMEC Nederland and Southeast University are advancing fundamental innovations, while specialized manufacturers like Isabellenhütte Heusler and Tegway are developing novel flexible thermopile technologies. Asia Vital Components and ams Sensors UK are emerging as significant players in miniaturized thermopile arrays, particularly for consumer electronics and IoT applications.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed a comprehensive thermopile array assembly technology that focuses on maximizing output efficiency through innovative packaging and integration methods. Their approach utilizes a proprietary silicon-based micromachining process to create suspended thermopile structures with exceptional thermal isolation characteristics. TI's assembly technique incorporates vacuum packaging at the wafer level, which significantly reduces thermal conductance losses and improves sensitivity. The company has pioneered the use of specialized absorber materials with tailored spectral responses, allowing for customized wavelength sensitivity profiles. Their thermopile arrays feature integrated temperature reference sensors and precision analog front-end circuitry that provides temperature compensation, signal conditioning, and digital conversion capabilities. TI has also developed advanced calibration techniques that are implemented during the manufacturing process to ensure consistent performance across production batches.

Strengths: Excellent system integration capabilities that combine sensing elements with signal processing; superior thermal isolation resulting in higher sensitivity; advanced calibration techniques ensuring consistent performance. Weaknesses: Higher cost structure compared to simpler thermopile implementations; more complex manufacturing process requiring specialized equipment; potential challenges in extremely high-temperature applications.

Raytheon Co.

Technical Solution: Raytheon has developed sophisticated thermopile array assembly technologies primarily for defense and aerospace applications. Their approach focuses on high-reliability, high-performance arrays capable of operating in extreme environments. Raytheon's proprietary assembly process utilizes advanced materials science to create thermopile junctions with maximized Seebeck coefficients, significantly improving voltage output per temperature differential. Their manufacturing technique incorporates precision deposition of multiple thermoelectric materials in carefully controlled vacuum environments to ensure junction quality and consistency. The company has pioneered specialized membrane structures that provide superior thermal isolation while maintaining mechanical robustness, a critical factor for aerospace applications. Raytheon's thermopile arrays feature proprietary radiation absorber coatings with exceptionally high emissivity across broad wavelength ranges, optimizing energy capture. Their assembly process includes integration with custom-designed readout integrated circuits (ROICs) that provide advanced signal processing capabilities, including time-domain multiplexing and on-chip digitization.

Strengths: Exceptional reliability in extreme environments; superior thermal isolation techniques resulting in higher sensitivity; advanced integration with sophisticated signal processing. Weaknesses: Significantly higher cost structure compared to commercial solutions; highly specialized manufacturing requirements; primarily optimized for defense applications rather than commercial markets.

Critical Patents and Innovations in Thermopile Array Design

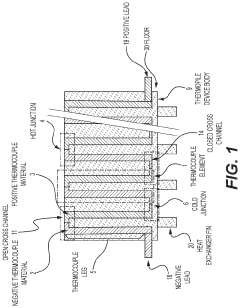

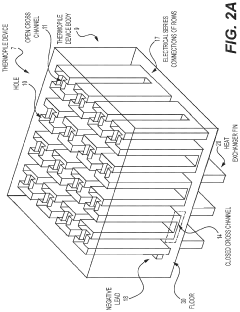

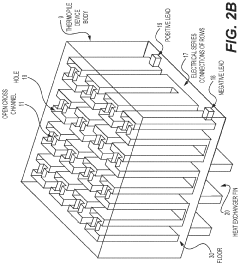

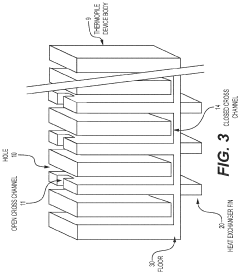

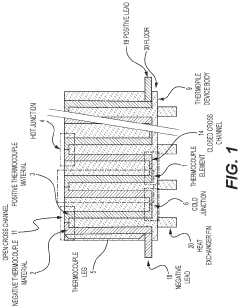

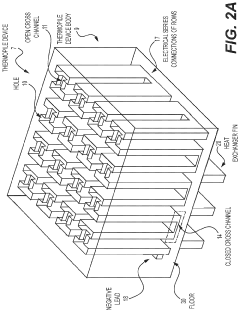

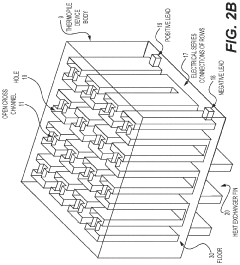

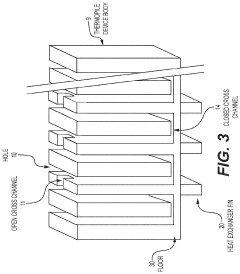

Thermopile Assembly Providing a Massive Electrical Series of Thermocouple Elements

PatentInactiveUS20200370965A1

Innovation

- A thermopile assembly using a heat-resistant, electrically-insulative container with cross-channels to form hot and cold junctions from common, stable thermocouple materials, allowing for the creation of a massive electrical series of thermocouples that can operate effectively at high temperatures through 3D printing and sintering processes.

Thermopile Assembly Providing a Massive Electrical Series of Wire Thermocouple Elements

PatentActiveUS20200256742A1

Innovation

- A thermopile assembly using a heat-resistant, electrically-insulative container with multiple rows of holes for wires and cross-channels to form thermocouple elements, allowing for the deposition of common, stable materials that can be sintered or melted to create a large number of thermocouples in series, enabling efficient power generation at high temperatures.

Materials Science Advancements for Thermopile Efficiency

Recent advancements in materials science have significantly contributed to improving thermopile efficiency. Traditional thermopile arrays have been limited by the thermoelectric properties of constituent materials, primarily relying on bismuth telluride and antimony telluride. However, the emergence of novel nanomaterials and composite structures has revolutionized the field, enabling higher Seebeck coefficients and reduced thermal conductivity.

Nanostructured materials represent a breakthrough in thermopile technology, as they can effectively scatter phonons while maintaining electron transport. Silicon-germanium nanowires, for instance, have demonstrated ZT values exceeding 2.0 at elevated temperatures, substantially higher than bulk materials. These improvements stem from quantum confinement effects and increased phonon scattering at interfaces, which collectively enhance the power factor while reducing thermal conductivity.

Thin-film deposition techniques have evolved to allow precise control over material composition and interface properties. Atomic layer deposition (ALD) and molecular beam epitaxy (MBE) enable the creation of superlattice structures with atomically sharp interfaces, maximizing the Seebeck effect while minimizing parasitic heat conduction. These techniques have facilitated the development of thermopile arrays with thickness uniformity variations below 2%, critical for consistent performance across large arrays.

Polymer-based thermoelectric materials represent another frontier, offering flexibility and cost advantages over traditional inorganic materials. PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) has emerged as a promising candidate, with recent modifications using ionic liquids pushing its ZT values to approximately 0.42 at room temperature. These materials enable conformal thermopile arrays that can be integrated into curved surfaces and flexible substrates.

Metal-organic frameworks (MOFs) are being explored for their unique thermal and electrical properties. By incorporating conductive fillers into the MOF structure, researchers have created hybrid materials with low thermal conductivity (< 0.3 W/mK) while maintaining reasonable electrical conductivity. This approach offers new possibilities for high-temperature thermopile applications where traditional materials suffer from performance degradation.

Surface engineering techniques have also contributed significantly to thermopile efficiency. Plasma treatment and chemical functionalization can modify carrier concentration and mobility at material interfaces, optimizing the power factor. Additionally, textured surfaces with micro and nano-scale features can scatter phonons more effectively, reducing thermal conductivity without compromising electrical performance.

The integration of 2D materials like graphene and transition metal dichalcogenides into thermopile structures has opened new avenues for ultra-thin, high-performance devices. These materials exhibit exceptional in-plane electrical conductivity while maintaining low cross-plane thermal conductivity, ideal properties for thermopile applications requiring high power density in limited spaces.

Nanostructured materials represent a breakthrough in thermopile technology, as they can effectively scatter phonons while maintaining electron transport. Silicon-germanium nanowires, for instance, have demonstrated ZT values exceeding 2.0 at elevated temperatures, substantially higher than bulk materials. These improvements stem from quantum confinement effects and increased phonon scattering at interfaces, which collectively enhance the power factor while reducing thermal conductivity.

Thin-film deposition techniques have evolved to allow precise control over material composition and interface properties. Atomic layer deposition (ALD) and molecular beam epitaxy (MBE) enable the creation of superlattice structures with atomically sharp interfaces, maximizing the Seebeck effect while minimizing parasitic heat conduction. These techniques have facilitated the development of thermopile arrays with thickness uniformity variations below 2%, critical for consistent performance across large arrays.

Polymer-based thermoelectric materials represent another frontier, offering flexibility and cost advantages over traditional inorganic materials. PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) has emerged as a promising candidate, with recent modifications using ionic liquids pushing its ZT values to approximately 0.42 at room temperature. These materials enable conformal thermopile arrays that can be integrated into curved surfaces and flexible substrates.

Metal-organic frameworks (MOFs) are being explored for their unique thermal and electrical properties. By incorporating conductive fillers into the MOF structure, researchers have created hybrid materials with low thermal conductivity (< 0.3 W/mK) while maintaining reasonable electrical conductivity. This approach offers new possibilities for high-temperature thermopile applications where traditional materials suffer from performance degradation.

Surface engineering techniques have also contributed significantly to thermopile efficiency. Plasma treatment and chemical functionalization can modify carrier concentration and mobility at material interfaces, optimizing the power factor. Additionally, textured surfaces with micro and nano-scale features can scatter phonons more effectively, reducing thermal conductivity without compromising electrical performance.

The integration of 2D materials like graphene and transition metal dichalcogenides into thermopile structures has opened new avenues for ultra-thin, high-performance devices. These materials exhibit exceptional in-plane electrical conductivity while maintaining low cross-plane thermal conductivity, ideal properties for thermopile applications requiring high power density in limited spaces.

Thermal Management Strategies in Array Configuration

Effective thermal management is critical when assembling thermopile arrays to achieve improved outputs. The configuration of thermopile elements within an array significantly impacts thermal gradients, which directly affects voltage generation efficiency. Implementing strategic thermal isolation between hot and cold junctions maximizes temperature differentials, thereby enhancing the Seebeck effect and overall array performance.

Heat dissipation mechanisms must be carefully engineered within thermopile array assemblies. Incorporating heat sinks at cold junctions facilitates rapid heat transfer away from these regions, maintaining lower temperatures and preserving the thermal gradient. Similarly, thermal concentrators at hot junctions can focus incoming thermal energy, intensifying the temperature at these points. This dual approach optimizes the temperature differential across the thermopile elements.

Material selection plays a crucial role in thermal management strategies. High thermal conductivity materials should be strategically placed to channel heat in desired directions, while thermal insulators must be positioned to prevent unwanted heat transfer between adjacent elements. This selective thermal routing prevents thermal crosstalk between array elements, which can otherwise diminish output performance through unwanted temperature equalization.

Geometric considerations in array configuration significantly impact thermal management effectiveness. Spacing between individual thermopile elements must be optimized to balance density requirements with thermal isolation needs. Three-dimensional array configurations can leverage vertical thermal gradients, potentially increasing output density per unit area while maintaining thermal separation between elements.

Advanced cooling techniques can further enhance thermopile array performance. Active cooling systems using microfluidic channels can provide precise temperature control at cold junctions. Meanwhile, phase-change materials incorporated into array structures can absorb excess thermal energy during peak operation, releasing it during low-demand periods to maintain stable thermal gradients.

Environmental encapsulation strategies must address both thermal management and long-term reliability concerns. Hermetic sealing protects sensitive thermopile elements while specialized thermal interface materials ensure efficient heat transfer at critical junctions. These encapsulation approaches must balance thermal conductivity requirements with mechanical protection needs to ensure sustained performance in various operating environments.

Thermal simulation and modeling tools have become essential for optimizing array configurations before physical prototyping. Computational fluid dynamics and finite element analysis enable precise prediction of thermal gradients across complex array geometries, allowing designers to identify and address potential hotspots or thermal bottlenecks that could compromise output performance.

Heat dissipation mechanisms must be carefully engineered within thermopile array assemblies. Incorporating heat sinks at cold junctions facilitates rapid heat transfer away from these regions, maintaining lower temperatures and preserving the thermal gradient. Similarly, thermal concentrators at hot junctions can focus incoming thermal energy, intensifying the temperature at these points. This dual approach optimizes the temperature differential across the thermopile elements.

Material selection plays a crucial role in thermal management strategies. High thermal conductivity materials should be strategically placed to channel heat in desired directions, while thermal insulators must be positioned to prevent unwanted heat transfer between adjacent elements. This selective thermal routing prevents thermal crosstalk between array elements, which can otherwise diminish output performance through unwanted temperature equalization.

Geometric considerations in array configuration significantly impact thermal management effectiveness. Spacing between individual thermopile elements must be optimized to balance density requirements with thermal isolation needs. Three-dimensional array configurations can leverage vertical thermal gradients, potentially increasing output density per unit area while maintaining thermal separation between elements.

Advanced cooling techniques can further enhance thermopile array performance. Active cooling systems using microfluidic channels can provide precise temperature control at cold junctions. Meanwhile, phase-change materials incorporated into array structures can absorb excess thermal energy during peak operation, releasing it during low-demand periods to maintain stable thermal gradients.

Environmental encapsulation strategies must address both thermal management and long-term reliability concerns. Hermetic sealing protects sensitive thermopile elements while specialized thermal interface materials ensure efficient heat transfer at critical junctions. These encapsulation approaches must balance thermal conductivity requirements with mechanical protection needs to ensure sustained performance in various operating environments.

Thermal simulation and modeling tools have become essential for optimizing array configurations before physical prototyping. Computational fluid dynamics and finite element analysis enable precise prediction of thermal gradients across complex array geometries, allowing designers to identify and address potential hotspots or thermal bottlenecks that could compromise output performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!