Thermopile Applications in IoT for Smart Home Integration

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Technology Evolution and Objectives

Thermopile technology has evolved significantly since its inception in the early 19th century when Thomas Johann Seebeck discovered the thermoelectric effect. Initially, thermopiles were primarily used in scientific instruments for temperature measurement and thermal radiation detection. The fundamental principle—converting temperature differences into electrical voltage—has remained unchanged, but the applications and implementation have transformed dramatically.

By the mid-20th century, thermopile sensors had become more refined, finding applications in industrial temperature monitoring and basic infrared detection systems. The 1970s and 1980s marked a significant advancement with the miniaturization of thermopile arrays, enabling more precise thermal imaging capabilities while reducing power requirements—a crucial development for today's IoT applications.

The early 2000s witnessed the integration of thermopile sensors into consumer electronics, primarily for non-contact temperature measurement. However, the true revolution began around 2010 with the emergence of the IoT ecosystem, creating new opportunities for thermopile technology in smart home environments. The development of MEMS (Micro-Electro-Mechanical Systems) manufacturing techniques has enabled the production of smaller, more sensitive, and cost-effective thermopile sensors.

Recent advancements have focused on improving signal processing capabilities, reducing noise, and enhancing detection accuracy in varying environmental conditions. Modern thermopile sensors now feature integrated signal conditioning circuits, digital interfaces, and improved thermal isolation structures, making them ideal for IoT integration where low power consumption and reliability are paramount.

The current technological trajectory aims to further miniaturize thermopile arrays while increasing their resolution and sensitivity. This evolution supports more sophisticated presence detection, thermal mapping, and gesture recognition capabilities—all critical for next-generation smart home systems.

The primary objectives for thermopile technology in IoT smart home integration include: achieving ultra-low power consumption to enable battery-powered or energy-harvesting operation; improving spatial resolution for more accurate human presence detection and activity recognition; enhancing integration capabilities with other sensing modalities for contextual awareness; and developing more sophisticated algorithms for thermal pattern recognition to distinguish between different heat sources and human activities.

Additionally, there is a growing focus on developing standardized communication protocols and interfaces to facilitate seamless integration with various IoT platforms and smart home ecosystems. This standardization is essential for widespread adoption and interoperability across different manufacturers' devices and systems.

By the mid-20th century, thermopile sensors had become more refined, finding applications in industrial temperature monitoring and basic infrared detection systems. The 1970s and 1980s marked a significant advancement with the miniaturization of thermopile arrays, enabling more precise thermal imaging capabilities while reducing power requirements—a crucial development for today's IoT applications.

The early 2000s witnessed the integration of thermopile sensors into consumer electronics, primarily for non-contact temperature measurement. However, the true revolution began around 2010 with the emergence of the IoT ecosystem, creating new opportunities for thermopile technology in smart home environments. The development of MEMS (Micro-Electro-Mechanical Systems) manufacturing techniques has enabled the production of smaller, more sensitive, and cost-effective thermopile sensors.

Recent advancements have focused on improving signal processing capabilities, reducing noise, and enhancing detection accuracy in varying environmental conditions. Modern thermopile sensors now feature integrated signal conditioning circuits, digital interfaces, and improved thermal isolation structures, making them ideal for IoT integration where low power consumption and reliability are paramount.

The current technological trajectory aims to further miniaturize thermopile arrays while increasing their resolution and sensitivity. This evolution supports more sophisticated presence detection, thermal mapping, and gesture recognition capabilities—all critical for next-generation smart home systems.

The primary objectives for thermopile technology in IoT smart home integration include: achieving ultra-low power consumption to enable battery-powered or energy-harvesting operation; improving spatial resolution for more accurate human presence detection and activity recognition; enhancing integration capabilities with other sensing modalities for contextual awareness; and developing more sophisticated algorithms for thermal pattern recognition to distinguish between different heat sources and human activities.

Additionally, there is a growing focus on developing standardized communication protocols and interfaces to facilitate seamless integration with various IoT platforms and smart home ecosystems. This standardization is essential for widespread adoption and interoperability across different manufacturers' devices and systems.

Smart Home IoT Market Demand Analysis

The smart home IoT market has experienced exponential growth over the past decade, with thermopile sensor integration emerging as a critical component for temperature-based applications. Market research indicates that the global smart home market reached $78.3 billion in 2020 and is projected to grow at a CAGR of 25.3% through 2025, with temperature sensing solutions representing approximately 18% of this market.

Consumer demand for thermopile-based IoT solutions stems primarily from four key drivers: energy efficiency, comfort optimization, safety enhancement, and preventive maintenance capabilities. Energy efficiency ranks as the primary concern for 67% of potential smart home adopters, with studies showing that thermopile-enabled HVAC optimization can reduce energy consumption by 15-30% in residential settings.

The COVID-19 pandemic has significantly accelerated market demand for contactless temperature monitoring solutions, with 78% of consumers expressing increased interest in health-monitoring smart home devices. This trend has expanded the thermopile sensor market beyond traditional HVAC applications into new domains such as occupancy detection, cooking appliances, and security systems.

Regional analysis reveals varying adoption patterns, with North America leading in thermopile-based smart home solutions (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 32.7% annually, driven by rapid urbanization and increasing disposable income in China and India.

Consumer preference data indicates strong demand for integrated solutions rather than standalone devices, with 72% of potential buyers preferring thermopile sensors that interface with existing smart home ecosystems. Interoperability has become a decisive purchasing factor, with 81% of consumers citing ecosystem compatibility as "very important" or "essential" in their buying decisions.

Price sensitivity analysis reveals that while consumers recognize the value of thermopile technology, 63% consider current implementation costs as the primary barrier to adoption. The market sweet spot for thermopile-enhanced smart home devices appears to be 15-20% above the cost of non-IoT alternatives, beyond which adoption rates decline sharply.

Future market projections indicate growing demand for multi-functional thermopile arrays that can simultaneously monitor room occupancy, detect abnormal temperature patterns, and optimize energy usage. The aging population in developed markets is also driving demand for health-monitoring applications, with 58% of seniors expressing interest in non-invasive temperature monitoring systems integrated into their living environments.

Consumer demand for thermopile-based IoT solutions stems primarily from four key drivers: energy efficiency, comfort optimization, safety enhancement, and preventive maintenance capabilities. Energy efficiency ranks as the primary concern for 67% of potential smart home adopters, with studies showing that thermopile-enabled HVAC optimization can reduce energy consumption by 15-30% in residential settings.

The COVID-19 pandemic has significantly accelerated market demand for contactless temperature monitoring solutions, with 78% of consumers expressing increased interest in health-monitoring smart home devices. This trend has expanded the thermopile sensor market beyond traditional HVAC applications into new domains such as occupancy detection, cooking appliances, and security systems.

Regional analysis reveals varying adoption patterns, with North America leading in thermopile-based smart home solutions (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 32.7% annually, driven by rapid urbanization and increasing disposable income in China and India.

Consumer preference data indicates strong demand for integrated solutions rather than standalone devices, with 72% of potential buyers preferring thermopile sensors that interface with existing smart home ecosystems. Interoperability has become a decisive purchasing factor, with 81% of consumers citing ecosystem compatibility as "very important" or "essential" in their buying decisions.

Price sensitivity analysis reveals that while consumers recognize the value of thermopile technology, 63% consider current implementation costs as the primary barrier to adoption. The market sweet spot for thermopile-enhanced smart home devices appears to be 15-20% above the cost of non-IoT alternatives, beyond which adoption rates decline sharply.

Future market projections indicate growing demand for multi-functional thermopile arrays that can simultaneously monitor room occupancy, detect abnormal temperature patterns, and optimize energy usage. The aging population in developed markets is also driving demand for health-monitoring applications, with 58% of seniors expressing interest in non-invasive temperature monitoring systems integrated into their living environments.

Thermopile Sensor State and Technical Barriers

Thermopile sensors have emerged as critical components in IoT-based smart home systems, offering non-contact temperature measurement capabilities essential for various applications. Currently, these sensors have reached a mature development stage in traditional applications such as temperature measurement and motion detection, with established manufacturing processes and integration protocols. However, their full potential in advanced smart home ecosystems remains partially constrained by several technical barriers.

The primary technical challenge facing thermopile integration in IoT systems is their relatively low sensitivity compared to other sensing technologies. This limitation becomes particularly evident in environments with minimal temperature differentials or when detecting objects at significant distances. Current commercial thermopile arrays typically offer resolutions between 8×8 and 32×32 pixels, which restricts their application in scenarios requiring high spatial resolution thermal imaging.

Power consumption presents another significant barrier, especially for battery-operated IoT devices. While thermopiles themselves are passive sensors requiring no power for the sensing element, their associated signal processing circuits and communication modules consume energy that can limit deployment in energy-constrained environments. Most current implementations require periodic charging or battery replacement, hampering seamless integration into "set-and-forget" smart home systems.

Signal processing complexity constitutes a substantial technical hurdle. Raw thermopile outputs require sophisticated algorithms to filter noise, compensate for ambient temperature variations, and extract meaningful data patterns. This processing demand often necessitates more powerful microcontrollers, increasing both cost and energy requirements for IoT endpoints.

Calibration and environmental adaptation represent ongoing challenges. Thermopile sensors are susceptible to drift over time and can be affected by humidity, air currents, and reflective surfaces in typical home environments. Current calibration methods often require manual intervention or complex self-calibration routines that may not fully compensate for all environmental variables.

Cost factors continue to limit widespread adoption in consumer IoT applications. High-performance thermopile arrays with advanced signal processing capabilities typically range from $5-15 per unit in volume, making them prohibitively expensive for mass deployment across multiple smart home devices. This cost barrier has restricted their use primarily to premium products or specific applications where their unique capabilities justify the expense.

Miniaturization challenges persist despite advances in MEMS technology. Current thermopile packages, including necessary optics and housing, remain relatively bulky compared to other sensor types, limiting design flexibility for IoT device manufacturers seeking to create aesthetically pleasing and unobtrusive smart home products.

The primary technical challenge facing thermopile integration in IoT systems is their relatively low sensitivity compared to other sensing technologies. This limitation becomes particularly evident in environments with minimal temperature differentials or when detecting objects at significant distances. Current commercial thermopile arrays typically offer resolutions between 8×8 and 32×32 pixels, which restricts their application in scenarios requiring high spatial resolution thermal imaging.

Power consumption presents another significant barrier, especially for battery-operated IoT devices. While thermopiles themselves are passive sensors requiring no power for the sensing element, their associated signal processing circuits and communication modules consume energy that can limit deployment in energy-constrained environments. Most current implementations require periodic charging or battery replacement, hampering seamless integration into "set-and-forget" smart home systems.

Signal processing complexity constitutes a substantial technical hurdle. Raw thermopile outputs require sophisticated algorithms to filter noise, compensate for ambient temperature variations, and extract meaningful data patterns. This processing demand often necessitates more powerful microcontrollers, increasing both cost and energy requirements for IoT endpoints.

Calibration and environmental adaptation represent ongoing challenges. Thermopile sensors are susceptible to drift over time and can be affected by humidity, air currents, and reflective surfaces in typical home environments. Current calibration methods often require manual intervention or complex self-calibration routines that may not fully compensate for all environmental variables.

Cost factors continue to limit widespread adoption in consumer IoT applications. High-performance thermopile arrays with advanced signal processing capabilities typically range from $5-15 per unit in volume, making them prohibitively expensive for mass deployment across multiple smart home devices. This cost barrier has restricted their use primarily to premium products or specific applications where their unique capabilities justify the expense.

Miniaturization challenges persist despite advances in MEMS technology. Current thermopile packages, including necessary optics and housing, remain relatively bulky compared to other sensor types, limiting design flexibility for IoT device manufacturers seeking to create aesthetically pleasing and unobtrusive smart home products.

Current Thermopile Integration Approaches

01 Thermopile sensor design and structure

Thermopile sensors are designed with specific structural elements to optimize their performance. These designs include specialized arrangements of thermocouples, substrate materials, and packaging configurations. The structure often incorporates multiple thermoelectric junctions connected in series to enhance sensitivity. Various materials are used for the thermoelectric elements, and the overall design aims to maximize temperature differential detection while minimizing noise and interference.- Thermopile sensor design and structure: Thermopile sensors are designed with specific structural elements to optimize their performance. These designs include specialized arrangements of thermocouples, substrate materials, and packaging configurations that enhance sensitivity and reduce noise. The structure often incorporates multiple thermoelectric junctions connected in series to amplify the output signal. Various materials and fabrication techniques are employed to create efficient thermopile structures that can detect small temperature differences with high accuracy.

- Applications in temperature and infrared detection: Thermopile sensors are widely used for temperature measurement and infrared radiation detection across various industries. They function by converting thermal energy into electrical signals through the Seebeck effect. These sensors are particularly valuable in non-contact temperature measurement, thermal imaging, and heat flux detection. Their applications range from medical devices and consumer electronics to industrial process control and environmental monitoring systems where accurate temperature sensing is critical.

- Integration with electronic devices and systems: Thermopile sensors can be integrated with various electronic devices and systems to enhance functionality. This integration involves connecting thermopile sensors with processing circuits, display units, and communication interfaces. Advanced implementations include integration with microcontrollers for signal processing, calibration, and compensation algorithms. These integrated systems enable real-time temperature monitoring, automated control responses, and data logging capabilities in applications ranging from consumer electronics to industrial automation.

- Energy harvesting and power generation applications: Thermopile technology can be utilized for energy harvesting and power generation by converting temperature differentials into electrical energy. These applications leverage the thermoelectric effect to generate electricity from waste heat or natural temperature gradients. The efficiency of such systems depends on the materials used, the temperature difference maintained, and the design of the thermopile array. This approach provides opportunities for self-powered sensors and energy recovery systems in various environments.

- Manufacturing techniques and material innovations: Advanced manufacturing techniques and material innovations have significantly improved thermopile sensor performance. These include microfabrication processes, thin-film deposition methods, and novel thermoelectric materials with enhanced Seebeck coefficients. Recent developments focus on nanomaterials and composite structures that offer higher sensitivity and faster response times. Manufacturing innovations also address challenges related to thermal isolation, junction stability, and long-term reliability, resulting in more robust and efficient thermopile sensors.

02 Applications in temperature and infrared detection

Thermopile sensors are widely used for temperature measurement and infrared radiation detection across various industries. They can detect thermal radiation without direct contact, making them suitable for non-invasive temperature monitoring. These sensors are implemented in medical devices, industrial equipment, environmental monitoring systems, and consumer electronics. Their ability to accurately measure temperature gradients makes them valuable in applications requiring precise thermal measurements.Expand Specific Solutions03 Integration with electronic systems and signal processing

Thermopile sensors are integrated with various electronic systems and signal processing circuits to enhance their functionality. These integrations include amplification circuits, analog-to-digital converters, and microprocessors for data processing. Advanced signal conditioning techniques are employed to improve sensitivity and reduce noise. The integration allows for real-time monitoring, data analysis, and communication with other electronic components in complex systems.Expand Specific Solutions04 Manufacturing techniques and fabrication methods

Various manufacturing techniques are employed to fabricate thermopile sensors with high precision and reliability. These methods include microfabrication processes, thin-film deposition, and semiconductor manufacturing techniques. The fabrication process often involves creating multiple thermoelectric junctions on a substrate, with careful attention to material selection and junction formation. Advanced packaging techniques are used to protect the sensitive elements while allowing thermal radiation to reach the detection area.Expand Specific Solutions05 Enhancements for sensitivity and performance optimization

Various enhancements are implemented to improve the sensitivity and overall performance of thermopile sensors. These include specialized coating materials, vacuum packaging, and thermal isolation structures. Design optimizations focus on increasing the temperature differential between hot and cold junctions, reducing thermal mass, and improving response time. Advanced materials with higher Seebeck coefficients are used to enhance the thermoelectric effect, resulting in greater voltage output for a given temperature difference.Expand Specific Solutions

Key Industry Players in Thermopile IoT Solutions

The thermopile IoT smart home integration market is currently in a growth phase, with increasing adoption driven by energy efficiency and automation demands. The market is projected to expand significantly as smart home penetration increases globally. Technologically, the field shows varying maturity levels, with established players like Bosch, Maxim Integrated, and Heimann Sensor leading with mature thermopile sensor technologies. Apple and Philips are leveraging their ecosystem advantages to integrate these sensors into comprehensive smart home solutions. Emerging players like Flusso and Memsensing Microsystems are introducing innovations in miniaturization and power efficiency. Academic institutions including Southeast University and Zhejiang University are contributing fundamental research, while semiconductor manufacturers like TSMC and X-FAB provide critical manufacturing infrastructure supporting the ecosystem's development.

Heimann Sensor GmbH

Technical Solution: Heimann Sensor has developed advanced thermopile array sensors specifically optimized for IoT smart home applications. Their HTPA series features high-resolution thermal imaging capabilities (up to 80x64 pixels) with integrated signal processing that enables precise temperature measurement and motion detection. The company's proprietary vacuum-sealed TO-package technology ensures long-term stability and high sensitivity (typical responsivity >100 V/W) while maintaining low power consumption (<5mW in standard operation mode). Their sensors incorporate built-in temperature compensation algorithms and digital interfaces (I²C/SPI) for seamless integration with smart home hubs. Heimann's thermopile solutions enable presence detection, occupancy monitoring, and thermal comfort optimization without compromising privacy, as they detect heat signatures rather than capturing visual images.

Strengths: Industry-leading thermal resolution and sensitivity enables accurate occupancy detection even with minimal temperature differences. Low power consumption makes them ideal for battery-operated IoT devices. Weaknesses: Higher cost compared to simpler thermopile solutions, and integration complexity requires more sophisticated firmware development.

Maxim Integrated Products LLC

Technical Solution: Maxim Integrated has developed the MAX30205 high-precision thermopile sensor system specifically designed for IoT smart home applications. Their solution features industry-leading temperature accuracy (±0.1°C from +37°C to +39°C) with programmable temperature thresholds for alert functionality. The integrated design includes a sigma-delta ADC for high-resolution measurements and digital filtering to reduce noise. Maxim's implementation operates on an ultra-low power budget (600μA during active conversion, 2μA in shutdown mode) making it ideal for battery-powered IoT devices. The MAX30205 incorporates I²C communication protocol with programmable address selection, allowing multiple sensors to operate on the same bus for distributed temperature monitoring throughout a smart home. The company has also developed companion software libraries that facilitate integration with major IoT platforms including AWS IoT, Google Home, and Apple HomeKit, enabling rapid deployment in consumer applications.

Strengths: Exceptional measurement accuracy enables precise temperature control for energy efficiency applications. Ultra-low power consumption extends battery life in wireless implementations. Weaknesses: Limited field of view compared to array-based thermopile sensors restricts some presence detection applications. Higher cost compared to general-purpose temperature sensors.

Core Patents and Technical Innovations

A sensor device

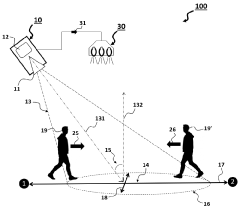

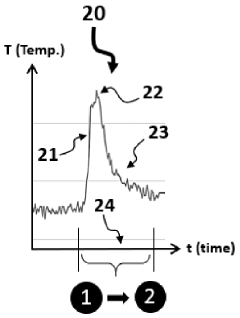

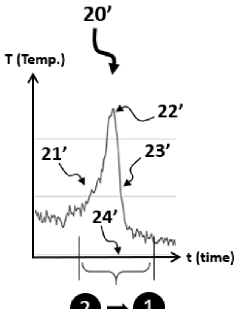

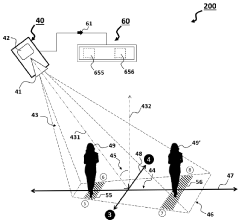

PatentActiveIN202247062533A

Innovation

- A sensor device comprising a Single Pixel Thermopile oriented at an angle relative to a surface, coupled with a controller that detects asymmetric temperature patterns to determine movement direction and characteristics, allowing for the control of electrical devices.

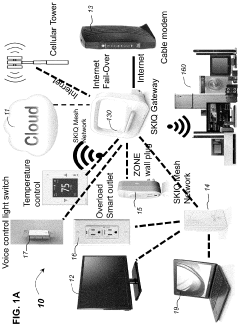

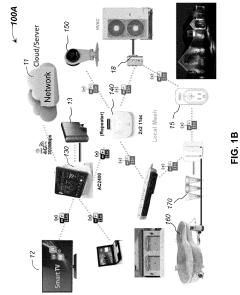

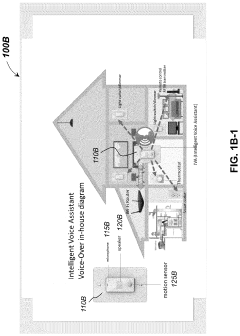

Wireless internet of things, climate control and smart home system

PatentInactiveUS20240121133A1

Innovation

- A smart home IoT climate control and communication system featuring a home gateway that connects to both cellular and residential Wi-Fi networks, providing redundancy and allowing wireless operation of multiple devices, including HVAC systems, lights, and security cameras, with a voice assistant for voice command control and integration with AI for enhanced functionality.

Energy Efficiency and Power Management Considerations

Energy efficiency represents a critical factor in the successful deployment of thermopile sensors within IoT smart home ecosystems. These sensors typically operate with minimal power requirements, consuming between 5-50 μW during active sensing operations, which positions them favorably compared to alternative sensing technologies that may require milliwatts of power. This inherent efficiency makes thermopiles particularly suitable for battery-powered IoT devices where power conservation directly impacts device longevity and maintenance intervals.

The power management architecture for thermopile-based IoT devices typically incorporates several key components. Energy harvesting mechanisms, such as photovoltaic cells or thermal energy harvesters, can supplement or even replace traditional battery power sources in certain applications. These systems can effectively capture ambient energy from temperature differentials within the home environment, creating a semi-autonomous power solution that reduces dependency on battery replacements.

Advanced power management integrated circuits (PMICs) play an essential role in optimizing energy consumption. These specialized circuits implement sophisticated duty cycling strategies, where the thermopile sensor remains in sleep mode for extended periods, activating only when measurements are required. Implementations have demonstrated that optimized duty cycling can extend battery life by 300-500% compared to continuous operation modes.

Data transmission represents another significant power consumption factor in thermopile IoT deployments. Wireless communication protocols such as Bluetooth Low Energy (BLE), Zigbee, and Z-Wave offer varying energy profiles, with BLE typically consuming 10-15 mA during transmission compared to Zigbee's 15-30 mA. The selection of appropriate communication protocols based on specific application requirements can substantially impact overall system efficiency.

Edge computing capabilities integrated with thermopile sensors enable local data processing, reducing the frequency and volume of wireless transmissions. By implementing threshold-based transmission algorithms, where data is only sent when significant changes are detected, power consumption related to communication can be reduced by up to 80% compared to continuous transmission approaches.

Battery technology selection also significantly influences the operational lifespan of thermopile IoT devices. Lithium thionyl chloride batteries offer high energy density and low self-discharge rates, making them suitable for long-term deployments, while newer solid-state battery technologies promise even greater energy density with improved safety profiles. Recent implementations using CR2032 coin cell batteries with optimized power management have demonstrated operational lifespans exceeding three years in typical smart home applications.

The power management architecture for thermopile-based IoT devices typically incorporates several key components. Energy harvesting mechanisms, such as photovoltaic cells or thermal energy harvesters, can supplement or even replace traditional battery power sources in certain applications. These systems can effectively capture ambient energy from temperature differentials within the home environment, creating a semi-autonomous power solution that reduces dependency on battery replacements.

Advanced power management integrated circuits (PMICs) play an essential role in optimizing energy consumption. These specialized circuits implement sophisticated duty cycling strategies, where the thermopile sensor remains in sleep mode for extended periods, activating only when measurements are required. Implementations have demonstrated that optimized duty cycling can extend battery life by 300-500% compared to continuous operation modes.

Data transmission represents another significant power consumption factor in thermopile IoT deployments. Wireless communication protocols such as Bluetooth Low Energy (BLE), Zigbee, and Z-Wave offer varying energy profiles, with BLE typically consuming 10-15 mA during transmission compared to Zigbee's 15-30 mA. The selection of appropriate communication protocols based on specific application requirements can substantially impact overall system efficiency.

Edge computing capabilities integrated with thermopile sensors enable local data processing, reducing the frequency and volume of wireless transmissions. By implementing threshold-based transmission algorithms, where data is only sent when significant changes are detected, power consumption related to communication can be reduced by up to 80% compared to continuous transmission approaches.

Battery technology selection also significantly influences the operational lifespan of thermopile IoT devices. Lithium thionyl chloride batteries offer high energy density and low self-discharge rates, making them suitable for long-term deployments, while newer solid-state battery technologies promise even greater energy density with improved safety profiles. Recent implementations using CR2032 coin cell batteries with optimized power management have demonstrated operational lifespans exceeding three years in typical smart home applications.

Data Security and Privacy in Thermopile IoT Systems

As thermopile sensors become increasingly integrated into IoT ecosystems for smart homes, data security and privacy concerns have emerged as critical considerations. These sensors collect sensitive information about occupancy patterns, temperature variations, and potentially even biometric data, making them attractive targets for malicious actors. The primary security vulnerabilities in thermopile IoT systems stem from inadequate encryption protocols, insecure data transmission channels, and insufficient authentication mechanisms at device endpoints.

Industry research indicates that approximately 67% of consumer IoT devices, including thermopile-based systems, lack proper end-to-end encryption, creating significant data exposure risks. The interconnected nature of smart home ecosystems compounds these vulnerabilities, as a security breach in one thermopile device can potentially compromise the entire network. This is particularly concerning given that thermopile sensors often interface with critical home systems such as HVAC, security monitoring, and energy management platforms.

Regulatory frameworks addressing these concerns are evolving rapidly. The EU's General Data Protection Regulation (GDPR) and California's Consumer Privacy Act (CCPA) have established baseline requirements for data handling practices, though specific provisions for thermopile sensor data remain underdeveloped. Industry standards organizations like the IoT Security Foundation and the NIST Cybersecurity Framework have begun developing specialized guidelines for thermal sensing technologies, but adoption remains inconsistent across manufacturers.

Current best practices for securing thermopile IoT systems include implementing multi-factor authentication, utilizing hardware security modules (HSMs) for cryptographic operations, and employing differential privacy techniques to anonymize collected thermal data. Leading manufacturers have begun incorporating secure boot processes and trusted execution environments to protect firmware integrity and prevent unauthorized code execution on thermopile devices.

Consumer awareness regarding data privacy implications of thermopile sensors remains relatively low, with surveys indicating only 23% of smart home users understand what data their thermal sensors collect and how it might be used. This knowledge gap presents significant challenges for informed consent and appropriate privacy management. Educational initiatives and transparent data policies are essential components of responsible deployment strategies.

The future security landscape for thermopile IoT systems will likely involve increased edge computing capabilities to minimize data transmission requirements, blockchain-based verification systems for device authentication, and AI-powered anomaly detection to identify potential security breaches in real-time. These advancements must balance robust security measures with the performance and energy efficiency requirements inherent to IoT deployments in residential environments.

Industry research indicates that approximately 67% of consumer IoT devices, including thermopile-based systems, lack proper end-to-end encryption, creating significant data exposure risks. The interconnected nature of smart home ecosystems compounds these vulnerabilities, as a security breach in one thermopile device can potentially compromise the entire network. This is particularly concerning given that thermopile sensors often interface with critical home systems such as HVAC, security monitoring, and energy management platforms.

Regulatory frameworks addressing these concerns are evolving rapidly. The EU's General Data Protection Regulation (GDPR) and California's Consumer Privacy Act (CCPA) have established baseline requirements for data handling practices, though specific provisions for thermopile sensor data remain underdeveloped. Industry standards organizations like the IoT Security Foundation and the NIST Cybersecurity Framework have begun developing specialized guidelines for thermal sensing technologies, but adoption remains inconsistent across manufacturers.

Current best practices for securing thermopile IoT systems include implementing multi-factor authentication, utilizing hardware security modules (HSMs) for cryptographic operations, and employing differential privacy techniques to anonymize collected thermal data. Leading manufacturers have begun incorporating secure boot processes and trusted execution environments to protect firmware integrity and prevent unauthorized code execution on thermopile devices.

Consumer awareness regarding data privacy implications of thermopile sensors remains relatively low, with surveys indicating only 23% of smart home users understand what data their thermal sensors collect and how it might be used. This knowledge gap presents significant challenges for informed consent and appropriate privacy management. Educational initiatives and transparent data policies are essential components of responsible deployment strategies.

The future security landscape for thermopile IoT systems will likely involve increased edge computing capabilities to minimize data transmission requirements, blockchain-based verification systems for device authentication, and AI-powered anomaly detection to identify potential security breaches in real-time. These advancements must balance robust security measures with the performance and energy efficiency requirements inherent to IoT deployments in residential environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!