Explore Thermopile Role in Enhanced Infrared Vision Systems

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile Technology Background and Objectives

Thermopile sensors have evolved significantly since their inception in the early 19th century, transforming from simple thermoelectric devices into sophisticated infrared detection systems. The fundamental principle behind thermopile technology—the Seebeck effect—was discovered in 1821 by Thomas Johann Seebeck, who observed that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This discovery laid the groundwork for thermopile development, which has accelerated dramatically in recent decades.

The evolution of thermopile technology has been driven by increasing demands for non-contact temperature measurement and thermal imaging across various industries. Early applications were limited to basic temperature sensing, but modern thermopiles have expanded into complex infrared vision systems with enhanced sensitivity, resolution, and response times. This progression has been facilitated by advancements in semiconductor manufacturing, materials science, and signal processing techniques.

Current thermopile-based infrared vision systems represent a critical technology in the broader thermal imaging landscape, positioned between simple pyroelectric sensors and more sophisticated microbolometer arrays. Their unique value proposition lies in their ability to provide reliable temperature measurement without requiring cooling systems, offering a balance of performance, power efficiency, and cost-effectiveness that makes them suitable for numerous applications.

The primary objective of exploring thermopile technology in enhanced infrared vision systems is to overcome existing limitations while capitalizing on inherent advantages. Key technical goals include improving spatial resolution to detect finer thermal details, enhancing temperature sensitivity to identify smaller temperature differentials, reducing response time for real-time applications, and minimizing power consumption for portable and IoT implementations.

Another crucial objective is to develop more integrated solutions that combine thermopile arrays with advanced signal processing algorithms and machine learning capabilities. This integration aims to enable more intelligent thermal imaging systems capable of not just detecting temperature variations but interpreting thermal patterns for automated decision-making processes.

The long-term technological trajectory points toward miniaturization and integration with other sensing modalities, creating multi-spectral imaging systems that provide more comprehensive environmental data. Research is also focused on developing flexible thermopile arrays that can conform to non-planar surfaces, opening new application possibilities in wearable technology, automotive systems, and structural health monitoring.

As infrared sensing becomes increasingly important in emerging fields like autonomous vehicles, smart buildings, and healthcare diagnostics, thermopile technology stands at a pivotal point in its evolution, with significant potential for innovation and market expansion in the coming decade.

The evolution of thermopile technology has been driven by increasing demands for non-contact temperature measurement and thermal imaging across various industries. Early applications were limited to basic temperature sensing, but modern thermopiles have expanded into complex infrared vision systems with enhanced sensitivity, resolution, and response times. This progression has been facilitated by advancements in semiconductor manufacturing, materials science, and signal processing techniques.

Current thermopile-based infrared vision systems represent a critical technology in the broader thermal imaging landscape, positioned between simple pyroelectric sensors and more sophisticated microbolometer arrays. Their unique value proposition lies in their ability to provide reliable temperature measurement without requiring cooling systems, offering a balance of performance, power efficiency, and cost-effectiveness that makes them suitable for numerous applications.

The primary objective of exploring thermopile technology in enhanced infrared vision systems is to overcome existing limitations while capitalizing on inherent advantages. Key technical goals include improving spatial resolution to detect finer thermal details, enhancing temperature sensitivity to identify smaller temperature differentials, reducing response time for real-time applications, and minimizing power consumption for portable and IoT implementations.

Another crucial objective is to develop more integrated solutions that combine thermopile arrays with advanced signal processing algorithms and machine learning capabilities. This integration aims to enable more intelligent thermal imaging systems capable of not just detecting temperature variations but interpreting thermal patterns for automated decision-making processes.

The long-term technological trajectory points toward miniaturization and integration with other sensing modalities, creating multi-spectral imaging systems that provide more comprehensive environmental data. Research is also focused on developing flexible thermopile arrays that can conform to non-planar surfaces, opening new application possibilities in wearable technology, automotive systems, and structural health monitoring.

As infrared sensing becomes increasingly important in emerging fields like autonomous vehicles, smart buildings, and healthcare diagnostics, thermopile technology stands at a pivotal point in its evolution, with significant potential for innovation and market expansion in the coming decade.

Market Analysis for Infrared Vision Applications

The global market for infrared vision systems has experienced substantial growth, driven by increasing applications across multiple sectors. The infrared vision technology market was valued at approximately $6.8 billion in 2022 and is projected to reach $12.5 billion by 2028, representing a compound annual growth rate of 10.7%. This growth trajectory is primarily fueled by rising demand in security and surveillance, automotive safety systems, and industrial process monitoring applications.

Thermopile-based infrared vision systems occupy a significant segment within this market, particularly in the mid-to-low price range applications. These systems offer a compelling value proposition by providing adequate thermal detection capabilities at a fraction of the cost of more advanced technologies like microbolometers or quantum detectors. The thermopile segment currently accounts for about 24% of the total infrared vision market, with particularly strong adoption in consumer electronics, building automation, and medical diagnostics.

In the consumer electronics sector, thermopile sensors are increasingly integrated into smartphones and smart home devices for temperature sensing and basic thermal imaging. This segment is growing at approximately 15% annually, driven by consumer interest in affordable thermal imaging capabilities for home inspection, energy efficiency monitoring, and basic security applications.

The automotive industry represents another high-growth area for thermopile-based infrared systems. With the advancement of advanced driver-assistance systems (ADAS) and autonomous driving technologies, infrared vision has become crucial for enhancing night driving safety and pedestrian detection. The automotive thermopile sensor market is expected to grow at 18% annually through 2028, as manufacturers increasingly adopt these sensors for entry and mid-level vehicle models.

Industrial applications constitute the largest market segment for thermopile infrared systems, accounting for approximately 32% of total thermopile sensor deployments. These applications include preventive maintenance, process monitoring, and quality control across manufacturing facilities. The industrial segment is projected to maintain steady growth at 9% annually, driven by Industry 4.0 initiatives and increasing focus on predictive maintenance.

Geographically, North America and Europe currently lead in thermopile infrared system adoption, collectively accounting for 58% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 16% annually, primarily driven by rapid industrialization in China and India, along with strong consumer electronics manufacturing sectors.

The healthcare sector represents an emerging opportunity for thermopile-based infrared vision systems, particularly for applications in fever detection, patient monitoring, and medical imaging. This segment has seen accelerated growth following the COVID-19 pandemic, with an annual growth rate of approximately 14%, as healthcare facilities worldwide have recognized the value of non-contact temperature measurement systems.

Thermopile-based infrared vision systems occupy a significant segment within this market, particularly in the mid-to-low price range applications. These systems offer a compelling value proposition by providing adequate thermal detection capabilities at a fraction of the cost of more advanced technologies like microbolometers or quantum detectors. The thermopile segment currently accounts for about 24% of the total infrared vision market, with particularly strong adoption in consumer electronics, building automation, and medical diagnostics.

In the consumer electronics sector, thermopile sensors are increasingly integrated into smartphones and smart home devices for temperature sensing and basic thermal imaging. This segment is growing at approximately 15% annually, driven by consumer interest in affordable thermal imaging capabilities for home inspection, energy efficiency monitoring, and basic security applications.

The automotive industry represents another high-growth area for thermopile-based infrared systems. With the advancement of advanced driver-assistance systems (ADAS) and autonomous driving technologies, infrared vision has become crucial for enhancing night driving safety and pedestrian detection. The automotive thermopile sensor market is expected to grow at 18% annually through 2028, as manufacturers increasingly adopt these sensors for entry and mid-level vehicle models.

Industrial applications constitute the largest market segment for thermopile infrared systems, accounting for approximately 32% of total thermopile sensor deployments. These applications include preventive maintenance, process monitoring, and quality control across manufacturing facilities. The industrial segment is projected to maintain steady growth at 9% annually, driven by Industry 4.0 initiatives and increasing focus on predictive maintenance.

Geographically, North America and Europe currently lead in thermopile infrared system adoption, collectively accounting for 58% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 16% annually, primarily driven by rapid industrialization in China and India, along with strong consumer electronics manufacturing sectors.

The healthcare sector represents an emerging opportunity for thermopile-based infrared vision systems, particularly for applications in fever detection, patient monitoring, and medical imaging. This segment has seen accelerated growth following the COVID-19 pandemic, with an annual growth rate of approximately 14%, as healthcare facilities worldwide have recognized the value of non-contact temperature measurement systems.

Current Thermopile Technology Landscape and Challenges

Thermopile technology has evolved significantly over the past decade, establishing itself as a cornerstone in modern infrared vision systems. Currently, thermopile sensors operate on the principle of thermoelectric effect, converting thermal radiation into measurable electrical signals without requiring cooling mechanisms. This fundamental advantage has positioned thermopiles as cost-effective alternatives to more complex infrared detection technologies in various applications ranging from industrial monitoring to consumer electronics.

The global landscape of thermopile technology reveals a mature yet actively developing field. Market leaders including Excelitas Technologies, Heimann Sensor, Melexis, and FLIR Systems have established robust manufacturing capabilities, primarily concentrated in North America, Europe, and East Asia. These regions demonstrate advanced research infrastructure and production facilities that continue to push the boundaries of thermopile performance metrics.

Despite significant progress, thermopile technology faces several critical challenges that limit its broader adoption in high-performance infrared vision systems. The foremost technical limitation remains the relatively low sensitivity compared to microbolometer and quantum detector technologies. Current commercial thermopile arrays typically achieve temperature resolution between 0.1°C to 0.5°C, which falls short of the requirements for advanced applications such as long-range surveillance or precise medical diagnostics.

Spatial resolution presents another significant hurdle, with most commercially available thermopile arrays limited to pixel counts below 32×32, substantially lower than competing technologies. This limitation stems from difficulties in miniaturizing thermopile elements while maintaining thermal isolation between adjacent pixels. The resulting trade-off between pixel size and thermal sensitivity continues to challenge manufacturers seeking higher resolution capabilities.

Response time constraints further impact thermopile applications in dynamic environments. Typical response times range from 10-30 milliseconds, significantly slower than alternative technologies, which limits their effectiveness in tracking rapidly moving objects or capturing transient thermal events. This temporal limitation derives from the inherent thermal mass of the sensing elements and the time required for temperature equilibration.

Power consumption, while generally favorable compared to cooled infrared detectors, remains an obstacle for ultra-low-power applications such as battery-operated devices and IoT sensors. Current thermopile arrays typically consume 5-15 mW during operation, necessitating further optimization for truly autonomous deployment scenarios.

Manufacturing scalability also presents challenges, particularly in achieving consistent performance across large production volumes. The complex multi-material structures required for thermopile fabrication introduce yield issues that impact production economics and ultimately affect market penetration in cost-sensitive applications.

The global landscape of thermopile technology reveals a mature yet actively developing field. Market leaders including Excelitas Technologies, Heimann Sensor, Melexis, and FLIR Systems have established robust manufacturing capabilities, primarily concentrated in North America, Europe, and East Asia. These regions demonstrate advanced research infrastructure and production facilities that continue to push the boundaries of thermopile performance metrics.

Despite significant progress, thermopile technology faces several critical challenges that limit its broader adoption in high-performance infrared vision systems. The foremost technical limitation remains the relatively low sensitivity compared to microbolometer and quantum detector technologies. Current commercial thermopile arrays typically achieve temperature resolution between 0.1°C to 0.5°C, which falls short of the requirements for advanced applications such as long-range surveillance or precise medical diagnostics.

Spatial resolution presents another significant hurdle, with most commercially available thermopile arrays limited to pixel counts below 32×32, substantially lower than competing technologies. This limitation stems from difficulties in miniaturizing thermopile elements while maintaining thermal isolation between adjacent pixels. The resulting trade-off between pixel size and thermal sensitivity continues to challenge manufacturers seeking higher resolution capabilities.

Response time constraints further impact thermopile applications in dynamic environments. Typical response times range from 10-30 milliseconds, significantly slower than alternative technologies, which limits their effectiveness in tracking rapidly moving objects or capturing transient thermal events. This temporal limitation derives from the inherent thermal mass of the sensing elements and the time required for temperature equilibration.

Power consumption, while generally favorable compared to cooled infrared detectors, remains an obstacle for ultra-low-power applications such as battery-operated devices and IoT sensors. Current thermopile arrays typically consume 5-15 mW during operation, necessitating further optimization for truly autonomous deployment scenarios.

Manufacturing scalability also presents challenges, particularly in achieving consistent performance across large production volumes. The complex multi-material structures required for thermopile fabrication introduce yield issues that impact production economics and ultimately affect market penetration in cost-sensitive applications.

Current Thermopile Integration Solutions for IR Vision

01 Thermopile sensor design for enhanced infrared detection

Thermopile sensors are designed with specific structures to enhance infrared detection capabilities. These designs include specialized junction arrangements, improved thermal isolation, and optimized absorption layers that increase sensitivity to infrared radiation. Advanced thermopile configurations can detect subtle temperature differences and convert them into electrical signals more efficiently, making them ideal for infrared vision applications.- Thermopile sensor design for enhanced infrared detection: Thermopile sensors can be designed with specific structures to enhance infrared vision capabilities. These designs include optimized thermal isolation, specialized junction arrangements, and improved thermal response characteristics. Advanced thermopile configurations allow for better sensitivity to infrared radiation, enabling clearer thermal imaging and enhanced detection of heat signatures across various applications.

- Integration of thermopiles in infrared imaging arrays: Thermopile elements can be arranged in array configurations to create comprehensive infrared imaging systems. These arrays allow for pixel-by-pixel thermal detection across a field of view, enabling detailed infrared vision capabilities. The integration includes specialized readout circuitry, signal processing, and array architectures that maximize thermal resolution while minimizing cross-talk between adjacent thermopile elements.

- Thermopile-based infrared vision systems for specific applications: Thermopile technology can be adapted for specialized infrared vision applications including night vision, surveillance, automotive safety systems, and medical diagnostics. These systems incorporate application-specific filters, optics, and processing algorithms to enhance the infrared vision capabilities for particular use cases. The adaptations allow thermopiles to provide reliable infrared detection in various environmental conditions and operational scenarios.

- Signal processing techniques for thermopile infrared vision: Advanced signal processing methods can significantly enhance the performance of thermopile-based infrared vision systems. These techniques include noise reduction algorithms, temperature compensation, calibration methods, and image enhancement processing. By implementing sophisticated signal processing, thermopile infrared vision systems can achieve improved thermal sensitivity, better image quality, and more accurate temperature measurements.

- Miniaturization and integration of thermopile infrared vision systems: Advancements in manufacturing techniques have enabled the miniaturization and integration of thermopile-based infrared vision systems. These developments include MEMS fabrication processes, system-on-chip designs, and compact packaging solutions. Miniaturized thermopile systems can be integrated into portable devices, wearable technology, and embedded systems while maintaining high performance infrared vision capabilities.

02 Integration of thermopiles in infrared imaging arrays

Thermopile sensors can be arranged in arrays to create comprehensive infrared imaging systems. These arrays allow for pixel-by-pixel temperature detection across a field of view, enabling detailed thermal imaging. The integration includes readout circuitry, signal processing components, and addressing mechanisms that work together to produce enhanced infrared vision capabilities with improved resolution and sensitivity.Expand Specific Solutions03 Miniaturization and packaging of thermopile-based infrared systems

Advancements in miniaturization techniques have enabled the development of compact thermopile-based infrared vision systems. These innovations include wafer-level packaging, MEMS fabrication processes, and integrated circuit designs that reduce the overall size while maintaining or improving performance. Miniaturized thermopile systems can be incorporated into portable devices, wearable technology, and space-constrained applications.Expand Specific Solutions04 Signal processing techniques for thermopile output enhancement

Various signal processing methods are employed to enhance the output from thermopile sensors in infrared vision systems. These techniques include noise reduction algorithms, temperature compensation, signal amplification, and digital filtering. Advanced processing approaches can extract meaningful thermal information from raw sensor data, improving contrast, reducing artifacts, and enhancing the overall quality of infrared images.Expand Specific Solutions05 Application-specific thermopile configurations for specialized infrared vision

Thermopile sensors can be specifically configured for different infrared vision applications. These specialized designs may include customized spectral responses, field-of-view optimizations, or integration with complementary sensors. Application-specific configurations enable enhanced performance in areas such as night vision, thermal surveillance, medical diagnostics, and industrial monitoring by tailoring the thermopile characteristics to the particular requirements of each use case.Expand Specific Solutions

Critical Patents and Innovations in Thermopile Technology

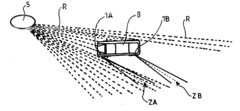

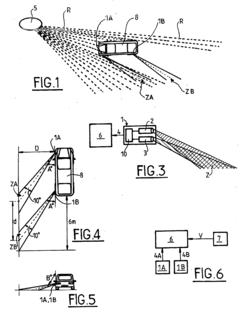

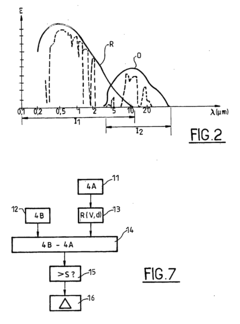

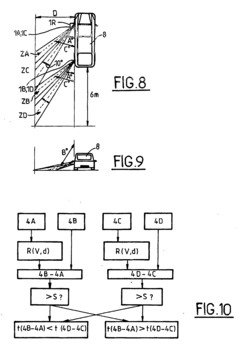

Optical exploration device and vehicle comprising said device

PatentInactiveUS20060072223A1

Innovation

- The device employs both thermopile and photodiode/phototransistor sensors with overlapping wavelength sensitivity ranges, oriented to aim at the same detection zone, allowing for signal subtraction and comparison to differentiate between solar radiation and object radiation, thereby reducing false positives and ensuring reliable detection.

Thermal Imaging Performance Metrics and Standards

Thermal imaging systems require standardized metrics and benchmarks to evaluate performance across different applications and environments. The International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) have established key performance metrics that specifically apply to thermopile-based infrared vision systems.

Noise Equivalent Temperature Difference (NETD) represents the minimum temperature difference a thermal imaging system can detect above the noise floor. For thermopile arrays in enhanced vision systems, competitive NETD values range from 50mK to 200mK, with high-end systems achieving sub-50mK sensitivity. This metric directly impacts the system's ability to detect subtle temperature variations in challenging environmental conditions.

Spatial resolution, measured in pixels or as Modulation Transfer Function (MTF), determines the system's ability to distinguish between closely positioned objects with different temperatures. Modern thermopile arrays for enhanced vision applications typically offer resolutions from 32×32 to 160×120 pixels, with advanced systems pushing toward 384×288 configurations.

Response time constitutes another critical performance parameter, particularly for dynamic applications. Standard thermopile sensors exhibit response times between 10-50ms, while specialized fast-response variants can achieve 5-10ms response times, enabling more effective real-time monitoring and detection capabilities.

Field of View (FOV) specifications typically range from 20° to 90° for standard thermopile-based systems, with specialized wide-angle configurations extending beyond 120°. The FOV directly influences detection range and area coverage capabilities in surveillance and automotive applications.

Temperature measurement accuracy standards generally require ±2°C or ±2% of reading for industrial and commercial applications, with high-precision systems achieving ±1°C accuracy across their operating range. This accuracy must be maintained across the system's specified operating temperature range, typically -20°C to +50°C for outdoor applications.

Durability standards for thermopile-based systems include IP67 rating for dust and water resistance in outdoor deployments, and operational stability requirements of less than 1% drift over 1000 hours of continuous operation. Military and automotive applications impose additional requirements for vibration resistance (MIL-STD-810 or ISO 16750) and extended temperature operation (-40°C to +85°C).

Power consumption metrics are increasingly important, with current standards expecting thermopile array systems to operate below 100mW for portable applications and under 500mW for fixed installations. This enables extended battery life in mobile applications and reduces thermal management requirements.

Noise Equivalent Temperature Difference (NETD) represents the minimum temperature difference a thermal imaging system can detect above the noise floor. For thermopile arrays in enhanced vision systems, competitive NETD values range from 50mK to 200mK, with high-end systems achieving sub-50mK sensitivity. This metric directly impacts the system's ability to detect subtle temperature variations in challenging environmental conditions.

Spatial resolution, measured in pixels or as Modulation Transfer Function (MTF), determines the system's ability to distinguish between closely positioned objects with different temperatures. Modern thermopile arrays for enhanced vision applications typically offer resolutions from 32×32 to 160×120 pixels, with advanced systems pushing toward 384×288 configurations.

Response time constitutes another critical performance parameter, particularly for dynamic applications. Standard thermopile sensors exhibit response times between 10-50ms, while specialized fast-response variants can achieve 5-10ms response times, enabling more effective real-time monitoring and detection capabilities.

Field of View (FOV) specifications typically range from 20° to 90° for standard thermopile-based systems, with specialized wide-angle configurations extending beyond 120°. The FOV directly influences detection range and area coverage capabilities in surveillance and automotive applications.

Temperature measurement accuracy standards generally require ±2°C or ±2% of reading for industrial and commercial applications, with high-precision systems achieving ±1°C accuracy across their operating range. This accuracy must be maintained across the system's specified operating temperature range, typically -20°C to +50°C for outdoor applications.

Durability standards for thermopile-based systems include IP67 rating for dust and water resistance in outdoor deployments, and operational stability requirements of less than 1% drift over 1000 hours of continuous operation. Military and automotive applications impose additional requirements for vibration resistance (MIL-STD-810 or ISO 16750) and extended temperature operation (-40°C to +85°C).

Power consumption metrics are increasingly important, with current standards expecting thermopile array systems to operate below 100mW for portable applications and under 500mW for fixed installations. This enables extended battery life in mobile applications and reduces thermal management requirements.

Environmental and Power Efficiency Considerations

Thermopile sensors in infrared vision systems demonstrate remarkable environmental adaptability across diverse operating conditions. These sensors maintain consistent performance in temperature ranges from -40°C to +85°C, making them suitable for applications from arctic monitoring to industrial environments. Unlike competing technologies such as microbolometers, thermopiles require no temperature stabilization mechanisms, significantly reducing system complexity and environmental footprint.

Power efficiency represents a critical advantage of thermopile-based infrared systems. Operating with power consumption typically between 5-15mW during active sensing—approximately 60-80% less than comparable microbolometer arrays—thermopiles enable extended battery life in portable applications. This efficiency derives from their fundamental operating principle: thermopiles generate voltage directly from temperature differentials without requiring external bias currents, resulting in near-zero standby power consumption.

Environmental sustainability considerations further enhance thermopile appeal in modern infrared vision systems. The manufacturing process for thermopile sensors utilizes fewer toxic materials compared to alternative infrared sensing technologies. Most thermopile arrays employ silicon-based MEMS fabrication techniques compatible with established semiconductor manufacturing standards, minimizing specialized waste streams. Additionally, their longer operational lifespan—typically exceeding 10 years without performance degradation—reduces electronic waste compared to technologies requiring more frequent replacement.

Deployment flexibility represents another environmental advantage. Thermopile-based systems can operate effectively in challenging environments including high humidity, dusty conditions, and areas with electromagnetic interference. Their sealed packaging prevents contamination of the sensing elements, eliminating maintenance requirements in field deployments. This robustness translates to reduced service visits and associated transportation emissions for remote monitoring applications.

Recent advancements in thermopile array design have further improved their environmental profile. Integration of energy harvesting capabilities allows some next-generation thermopile systems to supplement their power requirements from ambient temperature differentials—particularly valuable in industrial monitoring applications where temperature gradients naturally exist. Combined with low-power wireless communication protocols like BLE 5.0 or Zigbee, these systems can operate semi-autonomously in environmental monitoring applications, reducing infrastructure requirements and associated environmental impacts.

Power efficiency represents a critical advantage of thermopile-based infrared systems. Operating with power consumption typically between 5-15mW during active sensing—approximately 60-80% less than comparable microbolometer arrays—thermopiles enable extended battery life in portable applications. This efficiency derives from their fundamental operating principle: thermopiles generate voltage directly from temperature differentials without requiring external bias currents, resulting in near-zero standby power consumption.

Environmental sustainability considerations further enhance thermopile appeal in modern infrared vision systems. The manufacturing process for thermopile sensors utilizes fewer toxic materials compared to alternative infrared sensing technologies. Most thermopile arrays employ silicon-based MEMS fabrication techniques compatible with established semiconductor manufacturing standards, minimizing specialized waste streams. Additionally, their longer operational lifespan—typically exceeding 10 years without performance degradation—reduces electronic waste compared to technologies requiring more frequent replacement.

Deployment flexibility represents another environmental advantage. Thermopile-based systems can operate effectively in challenging environments including high humidity, dusty conditions, and areas with electromagnetic interference. Their sealed packaging prevents contamination of the sensing elements, eliminating maintenance requirements in field deployments. This robustness translates to reduced service visits and associated transportation emissions for remote monitoring applications.

Recent advancements in thermopile array design have further improved their environmental profile. Integration of energy harvesting capabilities allows some next-generation thermopile systems to supplement their power requirements from ambient temperature differentials—particularly valuable in industrial monitoring applications where temperature gradients naturally exist. Combined with low-power wireless communication protocols like BLE 5.0 or Zigbee, these systems can operate semi-autonomously in environmental monitoring applications, reducing infrastructure requirements and associated environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!