Environmental Safety Protocols for Industrial Isobutane Usage

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Safety Background and Objectives

Isobutane, a highly flammable hydrocarbon, has been widely used in various industrial applications for decades. Its properties make it valuable in refrigeration, aerosol propellants, and as a raw material in petrochemical processes. However, the inherent risks associated with its use have necessitated the development of comprehensive environmental safety protocols.

The evolution of isobutane safety measures can be traced back to the mid-20th century when its industrial applications began to expand. Initially, safety concerns primarily focused on fire and explosion risks. As environmental awareness grew in the latter part of the century, attention shifted to include the potential impacts of isobutane on air quality and climate change.

Recent technological advancements have led to more sophisticated safety systems and monitoring techniques. These developments aim to minimize the risks associated with isobutane handling, storage, and use in industrial settings. The current objective is to establish a robust framework of environmental safety protocols that address both immediate hazards and long-term environmental considerations.

Key goals in developing these protocols include preventing accidental releases, reducing emissions during normal operations, and ensuring proper disposal or recycling of isobutane-containing products. Additionally, there is a growing emphasis on improving energy efficiency in processes that utilize isobutane, thereby reducing overall environmental impact.

The regulatory landscape surrounding isobutane usage has also evolved significantly. International agreements and national regulations now set stringent standards for its handling and emissions. These regulations aim to protect workers, surrounding communities, and the broader environment from potential harm.

As industries continue to rely on isobutane, the objectives of safety protocols are expanding beyond mere compliance. There is an increasing focus on proactive risk management, continuous improvement of safety systems, and the integration of sustainable practices in isobutane-related processes.

The development of environmental safety protocols for industrial isobutane usage represents a convergence of technological innovation, regulatory requirements, and environmental stewardship. Future objectives in this field are likely to include the exploration of safer alternatives, the implementation of more advanced leak detection and prevention systems, and the development of closed-loop systems that minimize environmental impact throughout the isobutane lifecycle.

The evolution of isobutane safety measures can be traced back to the mid-20th century when its industrial applications began to expand. Initially, safety concerns primarily focused on fire and explosion risks. As environmental awareness grew in the latter part of the century, attention shifted to include the potential impacts of isobutane on air quality and climate change.

Recent technological advancements have led to more sophisticated safety systems and monitoring techniques. These developments aim to minimize the risks associated with isobutane handling, storage, and use in industrial settings. The current objective is to establish a robust framework of environmental safety protocols that address both immediate hazards and long-term environmental considerations.

Key goals in developing these protocols include preventing accidental releases, reducing emissions during normal operations, and ensuring proper disposal or recycling of isobutane-containing products. Additionally, there is a growing emphasis on improving energy efficiency in processes that utilize isobutane, thereby reducing overall environmental impact.

The regulatory landscape surrounding isobutane usage has also evolved significantly. International agreements and national regulations now set stringent standards for its handling and emissions. These regulations aim to protect workers, surrounding communities, and the broader environment from potential harm.

As industries continue to rely on isobutane, the objectives of safety protocols are expanding beyond mere compliance. There is an increasing focus on proactive risk management, continuous improvement of safety systems, and the integration of sustainable practices in isobutane-related processes.

The development of environmental safety protocols for industrial isobutane usage represents a convergence of technological innovation, regulatory requirements, and environmental stewardship. Future objectives in this field are likely to include the exploration of safer alternatives, the implementation of more advanced leak detection and prevention systems, and the development of closed-loop systems that minimize environmental impact throughout the isobutane lifecycle.

Industrial Demand for Isobutane Usage

The industrial demand for isobutane has been steadily increasing over the past decade, driven by its versatile applications across various sectors. Primarily, the petrochemical industry utilizes isobutane as a key feedstock in the production of high-octane gasoline components, synthetic rubber, and other chemical intermediates. This sector alone accounts for a significant portion of the global isobutane consumption, with demand projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2025.

In the refrigeration and air conditioning industry, isobutane has gained traction as an environmentally friendly alternative to traditional hydrofluorocarbon (HFC) refrigerants. Its low global warming potential (GWP) and zero ozone depletion potential (ODP) make it an attractive option for manufacturers seeking to comply with stringent environmental regulations. The shift towards isobutane-based cooling systems has been particularly pronounced in Europe and Asia, where regulatory pressures are driving the adoption of more sustainable refrigerants.

The aerosol industry represents another substantial market for isobutane, where it serves as a propellant in various consumer and industrial products. The personal care and household cleaning sectors have seen a notable increase in isobutane usage, as manufacturers move away from chlorofluorocarbon (CFC) propellants. This trend is expected to continue, with the aerosol market forecasted to expand at a CAGR of 3.8% from 2020 to 2027.

Emerging applications in the energy sector are also contributing to the growing demand for isobutane. Its use in the production of synthetic fuels and as a component in liquefied petroleum gas (LPG) blends is becoming more prevalent. Additionally, research into isobutane's potential as a working fluid in organic Rankine cycle (ORC) systems for waste heat recovery is opening up new avenues for industrial utilization.

Despite the positive growth outlook, the isobutane market faces challenges related to supply volatility and price fluctuations. These factors are closely tied to the dynamics of the global oil and gas industry, as isobutane is primarily derived from natural gas processing and petroleum refining. Consequently, industrial consumers are increasingly focusing on securing stable supply chains and exploring alternative production methods to mitigate these risks.

The geographical distribution of isobutane demand reflects the global industrial landscape, with North America, Europe, and Asia-Pacific emerging as key consumption hubs. The Asia-Pacific region, in particular, is expected to witness the highest growth rate in isobutane demand, driven by rapid industrialization and urbanization in countries like China and India. This regional shift is prompting major isobutane producers to reassess their global production and distribution strategies to better serve emerging markets.

In the refrigeration and air conditioning industry, isobutane has gained traction as an environmentally friendly alternative to traditional hydrofluorocarbon (HFC) refrigerants. Its low global warming potential (GWP) and zero ozone depletion potential (ODP) make it an attractive option for manufacturers seeking to comply with stringent environmental regulations. The shift towards isobutane-based cooling systems has been particularly pronounced in Europe and Asia, where regulatory pressures are driving the adoption of more sustainable refrigerants.

The aerosol industry represents another substantial market for isobutane, where it serves as a propellant in various consumer and industrial products. The personal care and household cleaning sectors have seen a notable increase in isobutane usage, as manufacturers move away from chlorofluorocarbon (CFC) propellants. This trend is expected to continue, with the aerosol market forecasted to expand at a CAGR of 3.8% from 2020 to 2027.

Emerging applications in the energy sector are also contributing to the growing demand for isobutane. Its use in the production of synthetic fuels and as a component in liquefied petroleum gas (LPG) blends is becoming more prevalent. Additionally, research into isobutane's potential as a working fluid in organic Rankine cycle (ORC) systems for waste heat recovery is opening up new avenues for industrial utilization.

Despite the positive growth outlook, the isobutane market faces challenges related to supply volatility and price fluctuations. These factors are closely tied to the dynamics of the global oil and gas industry, as isobutane is primarily derived from natural gas processing and petroleum refining. Consequently, industrial consumers are increasingly focusing on securing stable supply chains and exploring alternative production methods to mitigate these risks.

The geographical distribution of isobutane demand reflects the global industrial landscape, with North America, Europe, and Asia-Pacific emerging as key consumption hubs. The Asia-Pacific region, in particular, is expected to witness the highest growth rate in isobutane demand, driven by rapid industrialization and urbanization in countries like China and India. This regional shift is prompting major isobutane producers to reassess their global production and distribution strategies to better serve emerging markets.

Current Safety Challenges in Isobutane Handling

The handling of isobutane in industrial settings presents several significant safety challenges that require careful consideration and management. One of the primary concerns is the highly flammable nature of isobutane, which can form explosive mixtures with air. This necessitates stringent controls on potential ignition sources and the implementation of robust fire prevention and suppression systems throughout facilities where isobutane is used or stored.

Another critical challenge is the potential for leaks and releases. Isobutane is a gas at room temperature and pressure, making it prone to escape through small openings or faulty equipment. Even minor leaks can quickly create hazardous atmospheres, particularly in enclosed spaces. This requires continuous monitoring of air quality, installation of leak detection systems, and regular maintenance of all equipment and piping to ensure integrity.

Asphyxiation risk is a further concern in isobutane handling. As a simple asphyxiant, isobutane can displace oxygen in confined spaces, leading to potentially fatal consequences for workers. This necessitates strict protocols for confined space entry, including proper ventilation, atmospheric testing, and the use of appropriate personal protective equipment (PPE).

The storage and transportation of isobutane also present unique challenges. Pressure vessels used for storage must be designed to withstand the vapor pressure of isobutane at varying temperatures, and transportation containers must meet specific regulatory requirements to prevent accidental releases during transit. Additionally, the expansion properties of isobutane when transitioning from liquid to gas state must be accounted for in all storage and handling systems to prevent overpressurization.

Worker training and awareness represent another crucial aspect of isobutane safety. Employees must be thoroughly educated on the properties of isobutane, proper handling procedures, emergency response protocols, and the correct use of safety equipment. This includes regular drills and refresher courses to maintain a high level of safety consciousness among all personnel.

Environmental concerns also factor into the safety challenges of isobutane usage. While not directly toxic, isobutane is a volatile organic compound (VOC) and a greenhouse gas. Minimizing emissions through proper handling, storage, and disposal practices is essential to comply with environmental regulations and reduce the ecological impact of industrial operations.

Lastly, the regulatory landscape surrounding isobutane usage is complex and evolving. Staying compliant with local, national, and international safety standards and environmental regulations requires ongoing vigilance and adaptation of safety protocols. This includes regular audits, documentation of safety procedures, and proactive engagement with regulatory bodies to ensure all operations meet or exceed current safety requirements.

Another critical challenge is the potential for leaks and releases. Isobutane is a gas at room temperature and pressure, making it prone to escape through small openings or faulty equipment. Even minor leaks can quickly create hazardous atmospheres, particularly in enclosed spaces. This requires continuous monitoring of air quality, installation of leak detection systems, and regular maintenance of all equipment and piping to ensure integrity.

Asphyxiation risk is a further concern in isobutane handling. As a simple asphyxiant, isobutane can displace oxygen in confined spaces, leading to potentially fatal consequences for workers. This necessitates strict protocols for confined space entry, including proper ventilation, atmospheric testing, and the use of appropriate personal protective equipment (PPE).

The storage and transportation of isobutane also present unique challenges. Pressure vessels used for storage must be designed to withstand the vapor pressure of isobutane at varying temperatures, and transportation containers must meet specific regulatory requirements to prevent accidental releases during transit. Additionally, the expansion properties of isobutane when transitioning from liquid to gas state must be accounted for in all storage and handling systems to prevent overpressurization.

Worker training and awareness represent another crucial aspect of isobutane safety. Employees must be thoroughly educated on the properties of isobutane, proper handling procedures, emergency response protocols, and the correct use of safety equipment. This includes regular drills and refresher courses to maintain a high level of safety consciousness among all personnel.

Environmental concerns also factor into the safety challenges of isobutane usage. While not directly toxic, isobutane is a volatile organic compound (VOC) and a greenhouse gas. Minimizing emissions through proper handling, storage, and disposal practices is essential to comply with environmental regulations and reduce the ecological impact of industrial operations.

Lastly, the regulatory landscape surrounding isobutane usage is complex and evolving. Staying compliant with local, national, and international safety standards and environmental regulations requires ongoing vigilance and adaptation of safety protocols. This includes regular audits, documentation of safety procedures, and proactive engagement with regulatory bodies to ensure all operations meet or exceed current safety requirements.

Existing Isobutane Safety Protocols

01 Production and purification of isobutane

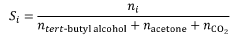

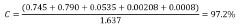

Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.- Production and purification of isobutane: Various methods for producing and purifying isobutane are described, including catalytic processes, distillation techniques, and separation from other hydrocarbons. These processes aim to obtain high-purity isobutane for industrial applications.

- Isobutane as a refrigerant: Isobutane is utilized as an environmentally friendly refrigerant in cooling systems and heat pumps. Its properties make it suitable for replacing traditional refrigerants with high global warming potential.

- Isobutane in chemical reactions: Isobutane is used as a reactant or intermediate in various chemical processes, including alkylation, dehydrogenation, and isomerization reactions. These processes are important in the production of high-octane fuels and petrochemicals.

- Isobutane in aerosol formulations: Isobutane is employed as a propellant in aerosol formulations for various applications, including personal care products, paints, and industrial sprays. Its low boiling point and vapor pressure make it suitable for this purpose.

- Safety and handling of isobutane: Due to its flammability and potential explosion hazards, specific safety measures and handling procedures are required for isobutane. This includes proper storage, transportation, and use in industrial settings to minimize risks associated with its volatile nature.

02 Isobutane as a refrigerant

Isobutane is utilized as a refrigerant in various cooling systems. Its properties make it suitable for use in refrigeration and air conditioning applications. The patents describe different formulations and systems that incorporate isobutane as a key component in refrigeration cycles.Expand Specific Solutions03 Isobutane in fuel compositions

Isobutane is used as a component in various fuel compositions. These formulations are designed to improve the performance and efficiency of internal combustion engines. The patents describe different fuel blends that incorporate isobutane to enhance combustion properties.Expand Specific Solutions04 Chemical reactions involving isobutane

Several chemical reactions and processes involving isobutane are described. These include oxidation, dehydrogenation, and isomerization reactions. The patents detail various catalysts, reaction conditions, and methods for carrying out these transformations to produce valuable chemical products.Expand Specific Solutions05 Isobutane in aerosol propellants

Isobutane is used as a propellant in aerosol formulations. The patents describe various compositions and methods for incorporating isobutane into aerosol products. These formulations are designed to improve the spray characteristics and stability of aerosol products in different applications.Expand Specific Solutions

Key Players in Industrial Isobutane Safety

The environmental safety protocols for industrial isobutane usage are in a mature stage of development, with a well-established market and robust technological solutions. The global market for isobutane safety systems is substantial, driven by increasing industrial applications and stringent regulatory requirements. Key players like China Petroleum & Chemical Corp., DuPont de Nemours, Inc., and Evonik Operations GmbH have developed advanced safety technologies and protocols. These companies, along with others such as Wanhua Chemical Group Co., Ltd. and Braskem SA, are continuously innovating to improve safety measures, efficiency, and environmental performance in isobutane handling and usage across various industries.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced environmental safety protocols for industrial isobutane usage. Their approach includes a multi-layered safety system incorporating real-time monitoring, automated shut-off mechanisms, and advanced leak detection technologies[1]. Sinopec has implemented a closed-loop isobutane recovery system that minimizes emissions and reduces environmental impact[2]. The company has also invested in employee training programs focused on isobutane handling and emergency response procedures. Additionally, Sinopec has developed specialized storage facilities with enhanced fire suppression systems and explosion-proof designs to mitigate risks associated with isobutane's flammability[3]. Their protocols also include regular maintenance schedules and integrity checks for all equipment in contact with isobutane.

Strengths: Comprehensive safety approach, advanced monitoring systems, and efficient isobutane recovery. Weaknesses: High implementation costs and potential complexity in retrofitting existing facilities.

UOP LLC

Technical Solution: UOP LLC, a Honeywell company, has pioneered innovative environmental safety protocols for industrial isobutane usage. Their approach focuses on process intensification and inherently safer design principles. UOP has developed a proprietary isobutane handling system that incorporates advanced process control algorithms to maintain optimal operating conditions and prevent potential hazards[4]. The system includes smart sensors that continuously monitor pressure, temperature, and flow rates, triggering automatic safety responses when deviations occur. UOP's protocols also emphasize the use of corrosion-resistant materials and double-walled piping systems to minimize the risk of leaks. Furthermore, they have implemented a comprehensive risk assessment methodology specifically tailored for isobutane-related processes, which helps identify and mitigate potential hazards throughout the facility[5].

Strengths: Cutting-edge process control technology, tailored risk assessment methodology. Weaknesses: Potentially high initial investment costs, may require significant modifications to existing infrastructure.

Innovative Safety Technologies for Isobutane

Hydroxylation of alkanes using ozone

PatentWO2022192866A1

Innovation

- Combining an alkane with ozone in a liquid phase medium containing a protic additive, such as water or alcohols, at mild temperatures and pressures, which stabilizes hydrotrioxide intermediates and maximizes ozone utilization, thereby enhancing the selectivity of hydroxylate products like tert-butyl alcohol.

Regulatory Framework for Isobutane Use

The regulatory framework for isobutane use in industrial settings is a complex and multifaceted system designed to ensure the safe handling, storage, and utilization of this flammable hydrocarbon. At the international level, organizations such as the United Nations and the International Organization for Standardization (ISO) provide overarching guidelines that inform national and regional regulations.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a pivotal role in establishing and enforcing safety standards for isobutane use in industrial environments. OSHA's Process Safety Management (PSM) standard (29 CFR 1910.119) is particularly relevant, as it covers the management of highly hazardous chemicals, including isobutane. This standard mandates comprehensive safety programs, risk assessments, and emergency response planning for facilities handling isobutane above certain threshold quantities.

The Environmental Protection Agency (EPA) also contributes to the regulatory landscape through its Risk Management Program (RMP) rule (40 CFR Part 68). This regulation requires facilities using isobutane to develop and implement risk management plans, conduct hazard assessments, and establish accident prevention programs. The EPA's regulations focus on preventing and mitigating the environmental impacts of potential isobutane releases.

At the state and local levels, additional regulations may apply, often building upon federal standards to address specific regional concerns. For instance, California's Accidental Release Prevention (CalARP) Program imposes stricter requirements than the federal RMP, reflecting the state's commitment to enhanced environmental and safety protections.

In the European Union, the regulatory framework is primarily shaped by the ATEX Directives (2014/34/EU and 1999/92/EC), which govern equipment and protective systems intended for use in potentially explosive atmospheres. These directives are complemented by the Seveso III Directive (2012/18/EU), which aims to prevent major accidents involving dangerous substances and limit their consequences for human health and the environment.

Industry-specific standards and best practices also form an integral part of the regulatory framework. Organizations such as the American Petroleum Institute (API) and the National Fire Protection Association (NFPA) develop guidelines that often become de facto standards for isobutane handling in various industrial applications.

Compliance with these regulations typically involves implementing robust safety management systems, conducting regular risk assessments, providing comprehensive employee training, and maintaining detailed documentation of safety procedures and incident response plans. As the regulatory landscape continues to evolve, companies must stay abreast of changes and adapt their practices accordingly to ensure ongoing compliance and safety in isobutane usage.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a pivotal role in establishing and enforcing safety standards for isobutane use in industrial environments. OSHA's Process Safety Management (PSM) standard (29 CFR 1910.119) is particularly relevant, as it covers the management of highly hazardous chemicals, including isobutane. This standard mandates comprehensive safety programs, risk assessments, and emergency response planning for facilities handling isobutane above certain threshold quantities.

The Environmental Protection Agency (EPA) also contributes to the regulatory landscape through its Risk Management Program (RMP) rule (40 CFR Part 68). This regulation requires facilities using isobutane to develop and implement risk management plans, conduct hazard assessments, and establish accident prevention programs. The EPA's regulations focus on preventing and mitigating the environmental impacts of potential isobutane releases.

At the state and local levels, additional regulations may apply, often building upon federal standards to address specific regional concerns. For instance, California's Accidental Release Prevention (CalARP) Program imposes stricter requirements than the federal RMP, reflecting the state's commitment to enhanced environmental and safety protections.

In the European Union, the regulatory framework is primarily shaped by the ATEX Directives (2014/34/EU and 1999/92/EC), which govern equipment and protective systems intended for use in potentially explosive atmospheres. These directives are complemented by the Seveso III Directive (2012/18/EU), which aims to prevent major accidents involving dangerous substances and limit their consequences for human health and the environment.

Industry-specific standards and best practices also form an integral part of the regulatory framework. Organizations such as the American Petroleum Institute (API) and the National Fire Protection Association (NFPA) develop guidelines that often become de facto standards for isobutane handling in various industrial applications.

Compliance with these regulations typically involves implementing robust safety management systems, conducting regular risk assessments, providing comprehensive employee training, and maintaining detailed documentation of safety procedures and incident response plans. As the regulatory landscape continues to evolve, companies must stay abreast of changes and adapt their practices accordingly to ensure ongoing compliance and safety in isobutane usage.

Environmental Impact Assessment

The environmental impact assessment of industrial isobutane usage is a critical component in ensuring sustainable and responsible operations. Isobutane, a highly flammable hydrocarbon, poses significant environmental risks if not properly managed. Its release into the atmosphere can contribute to air pollution and the formation of ground-level ozone, a major component of smog. Additionally, isobutane is a potent greenhouse gas with a global warming potential significantly higher than carbon dioxide.

When assessing the environmental impact of industrial isobutane usage, it is essential to consider both direct and indirect effects. Direct impacts include potential leaks or accidental releases during storage, transportation, and handling processes. These events can lead to localized air quality degradation and potential soil or water contamination. Indirect impacts encompass the broader ecological consequences, such as the contribution to climate change and the potential disruption of ecosystems due to long-term exposure.

The assessment should also evaluate the lifecycle environmental footprint of isobutane production and use. This includes examining the energy consumption and emissions associated with its extraction, refinement, and transportation. Furthermore, the end-of-life disposal or recycling of isobutane-containing products must be considered, as improper disposal can lead to environmental contamination.

To mitigate these environmental risks, industries must implement robust safety protocols and best practices. This includes regular equipment maintenance, leak detection systems, and proper training for personnel handling isobutane. The use of closed-loop systems and vapor recovery technologies can significantly reduce emissions during industrial processes. Additionally, implementing energy-efficient practices in isobutane production and utilization can help minimize the overall environmental impact.

Regulatory compliance is another crucial aspect of the environmental impact assessment. Industries must adhere to local, national, and international environmental regulations governing the use of volatile organic compounds and greenhouse gases. This may involve obtaining necessary permits, conducting regular environmental audits, and reporting emissions data to regulatory authorities.

In conclusion, a comprehensive environmental impact assessment for industrial isobutane usage should address air quality, climate change implications, ecosystem effects, and regulatory compliance. By thoroughly evaluating these factors and implementing appropriate mitigation strategies, industries can minimize the environmental footprint of isobutane usage while maintaining operational efficiency.

When assessing the environmental impact of industrial isobutane usage, it is essential to consider both direct and indirect effects. Direct impacts include potential leaks or accidental releases during storage, transportation, and handling processes. These events can lead to localized air quality degradation and potential soil or water contamination. Indirect impacts encompass the broader ecological consequences, such as the contribution to climate change and the potential disruption of ecosystems due to long-term exposure.

The assessment should also evaluate the lifecycle environmental footprint of isobutane production and use. This includes examining the energy consumption and emissions associated with its extraction, refinement, and transportation. Furthermore, the end-of-life disposal or recycling of isobutane-containing products must be considered, as improper disposal can lead to environmental contamination.

To mitigate these environmental risks, industries must implement robust safety protocols and best practices. This includes regular equipment maintenance, leak detection systems, and proper training for personnel handling isobutane. The use of closed-loop systems and vapor recovery technologies can significantly reduce emissions during industrial processes. Additionally, implementing energy-efficient practices in isobutane production and utilization can help minimize the overall environmental impact.

Regulatory compliance is another crucial aspect of the environmental impact assessment. Industries must adhere to local, national, and international environmental regulations governing the use of volatile organic compounds and greenhouse gases. This may involve obtaining necessary permits, conducting regular environmental audits, and reporting emissions data to regulatory authorities.

In conclusion, a comprehensive environmental impact assessment for industrial isobutane usage should address air quality, climate change implications, ecosystem effects, and regulatory compliance. By thoroughly evaluating these factors and implementing appropriate mitigation strategies, industries can minimize the environmental footprint of isobutane usage while maintaining operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!