Evaluating Polysilane's Role in Waste Reduction Technologies

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Background

Polysilanes, a class of silicon-based polymers, have emerged as a promising material in various technological applications, including waste reduction technologies. These polymers consist of a backbone of silicon atoms bonded to organic side groups, resulting in unique properties that make them suitable for environmental applications.

The development of polysilanes can be traced back to the 1920s when early research focused on their synthesis and characterization. However, it wasn't until the 1980s that significant advancements were made in understanding their structure-property relationships and potential applications. Since then, polysilanes have garnered increasing attention in the scientific community due to their versatile properties and potential for addressing environmental challenges.

One of the key features of polysilanes is their high thermal stability, which allows them to withstand extreme temperatures without degradation. This property makes them particularly useful in waste reduction technologies, where they can be employed in high-temperature processes such as waste incineration or pyrolysis. Additionally, polysilanes exhibit excellent chemical resistance, enabling their use in harsh chemical environments often encountered in waste treatment facilities.

The unique electronic properties of polysilanes, stemming from their silicon-silicon backbone, have also contributed to their potential in waste reduction technologies. These materials possess a delocalized σ-electron system along the polymer chain, resulting in interesting optical and electronic characteristics. This property has led to their exploration in photocatalytic applications for water purification and the degradation of organic pollutants.

In recent years, research has focused on developing functionalized polysilanes with specific properties tailored for waste reduction applications. For instance, the incorporation of metal nanoparticles into polysilane matrices has shown promise in enhancing their catalytic activity for the breakdown of harmful pollutants. Furthermore, the ability to modify the side groups of polysilanes allows for the fine-tuning of their properties, such as solubility and reactivity, making them adaptable to various waste treatment scenarios.

The biodegradability of certain polysilane derivatives has also attracted attention in the context of sustainable waste management. Some polysilanes can be designed to degrade into environmentally benign products under specific conditions, potentially offering a solution to the persistent problem of plastic waste accumulation.

As environmental concerns continue to grow globally, the role of polysilanes in waste reduction technologies is expected to expand. Ongoing research aims to optimize their synthesis, improve their performance in various applications, and explore new avenues for their integration into existing waste management systems. The versatility and unique properties of polysilanes position them as a promising material for addressing the complex challenges of waste reduction and environmental protection in the coming years.

The development of polysilanes can be traced back to the 1920s when early research focused on their synthesis and characterization. However, it wasn't until the 1980s that significant advancements were made in understanding their structure-property relationships and potential applications. Since then, polysilanes have garnered increasing attention in the scientific community due to their versatile properties and potential for addressing environmental challenges.

One of the key features of polysilanes is their high thermal stability, which allows them to withstand extreme temperatures without degradation. This property makes them particularly useful in waste reduction technologies, where they can be employed in high-temperature processes such as waste incineration or pyrolysis. Additionally, polysilanes exhibit excellent chemical resistance, enabling their use in harsh chemical environments often encountered in waste treatment facilities.

The unique electronic properties of polysilanes, stemming from their silicon-silicon backbone, have also contributed to their potential in waste reduction technologies. These materials possess a delocalized σ-electron system along the polymer chain, resulting in interesting optical and electronic characteristics. This property has led to their exploration in photocatalytic applications for water purification and the degradation of organic pollutants.

In recent years, research has focused on developing functionalized polysilanes with specific properties tailored for waste reduction applications. For instance, the incorporation of metal nanoparticles into polysilane matrices has shown promise in enhancing their catalytic activity for the breakdown of harmful pollutants. Furthermore, the ability to modify the side groups of polysilanes allows for the fine-tuning of their properties, such as solubility and reactivity, making them adaptable to various waste treatment scenarios.

The biodegradability of certain polysilane derivatives has also attracted attention in the context of sustainable waste management. Some polysilanes can be designed to degrade into environmentally benign products under specific conditions, potentially offering a solution to the persistent problem of plastic waste accumulation.

As environmental concerns continue to grow globally, the role of polysilanes in waste reduction technologies is expected to expand. Ongoing research aims to optimize their synthesis, improve their performance in various applications, and explore new avenues for their integration into existing waste management systems. The versatility and unique properties of polysilanes position them as a promising material for addressing the complex challenges of waste reduction and environmental protection in the coming years.

Waste Reduction Market

The waste reduction market has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations aimed at minimizing waste generation and promoting sustainable practices. This market encompasses a wide range of technologies, products, and services designed to reduce, reuse, and recycle waste materials across various industries and sectors.

The global waste reduction market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. This growth is fueled by several factors, including rising awareness of environmental issues, government initiatives to promote circular economy principles, and the increasing adoption of sustainable business practices by corporations worldwide.

One of the key segments within the waste reduction market is waste-to-energy technologies, which convert waste materials into usable forms of energy. This sector has seen substantial investment and innovation, particularly in developed countries seeking to reduce landfill usage and generate renewable energy simultaneously. Additionally, the market for recycling technologies and equipment has expanded rapidly, with advancements in sorting, processing, and material recovery techniques driving efficiency and profitability.

The industrial sector represents a significant portion of the waste reduction market, as manufacturers seek to minimize waste generation, improve resource efficiency, and comply with environmental regulations. This has led to the development of specialized waste reduction solutions tailored to specific industries, such as automotive, electronics, and construction.

In the consumer goods sector, there is a growing demand for products made from recycled materials and those designed for easy recyclability or biodegradability. This trend has spurred innovation in packaging design and material science, creating new opportunities for companies operating in the waste reduction space.

Emerging economies are becoming increasingly important players in the waste reduction market, as rapid urbanization and industrialization drive the need for more effective waste management solutions. This presents both challenges and opportunities for market participants, as these regions often require tailored approaches to waste reduction that consider local infrastructure, regulations, and cultural factors.

The role of technology in the waste reduction market cannot be overstated, with digital solutions such as IoT-enabled waste management systems, AI-powered sorting technologies, and blockchain-based tracking systems gaining traction. These innovations are enhancing the efficiency and transparency of waste reduction processes, opening up new avenues for market growth and differentiation.

As the waste reduction market continues to evolve, there is a growing focus on developing holistic, circular economy solutions that address the entire lifecycle of products and materials. This approach is driving collaboration between different sectors and stakeholders, fostering innovation, and creating new business models centered around waste reduction and resource efficiency.

The global waste reduction market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. This growth is fueled by several factors, including rising awareness of environmental issues, government initiatives to promote circular economy principles, and the increasing adoption of sustainable business practices by corporations worldwide.

One of the key segments within the waste reduction market is waste-to-energy technologies, which convert waste materials into usable forms of energy. This sector has seen substantial investment and innovation, particularly in developed countries seeking to reduce landfill usage and generate renewable energy simultaneously. Additionally, the market for recycling technologies and equipment has expanded rapidly, with advancements in sorting, processing, and material recovery techniques driving efficiency and profitability.

The industrial sector represents a significant portion of the waste reduction market, as manufacturers seek to minimize waste generation, improve resource efficiency, and comply with environmental regulations. This has led to the development of specialized waste reduction solutions tailored to specific industries, such as automotive, electronics, and construction.

In the consumer goods sector, there is a growing demand for products made from recycled materials and those designed for easy recyclability or biodegradability. This trend has spurred innovation in packaging design and material science, creating new opportunities for companies operating in the waste reduction space.

Emerging economies are becoming increasingly important players in the waste reduction market, as rapid urbanization and industrialization drive the need for more effective waste management solutions. This presents both challenges and opportunities for market participants, as these regions often require tailored approaches to waste reduction that consider local infrastructure, regulations, and cultural factors.

The role of technology in the waste reduction market cannot be overstated, with digital solutions such as IoT-enabled waste management systems, AI-powered sorting technologies, and blockchain-based tracking systems gaining traction. These innovations are enhancing the efficiency and transparency of waste reduction processes, opening up new avenues for market growth and differentiation.

As the waste reduction market continues to evolve, there is a growing focus on developing holistic, circular economy solutions that address the entire lifecycle of products and materials. This approach is driving collaboration between different sectors and stakeholders, fostering innovation, and creating new business models centered around waste reduction and resource efficiency.

Polysilane Challenges

Despite the promising potential of polysilane in waste reduction technologies, several significant challenges hinder its widespread adoption and implementation. One of the primary obstacles is the high production cost associated with polysilane synthesis. The current manufacturing processes require expensive precursors and energy-intensive reactions, making large-scale production economically unfeasible for many applications in waste management.

Another major challenge lies in the stability and durability of polysilane-based materials. When exposed to certain environmental conditions, such as moisture or UV radiation, polysilanes can undergo rapid degradation, limiting their long-term effectiveness in waste reduction applications. This instability necessitates the development of protective measures or modified formulations to enhance the material's resilience in diverse waste management scenarios.

The environmental impact of polysilane production and disposal presents an additional hurdle. While polysilanes offer potential benefits in waste reduction, the synthesis of these materials often involves the use of toxic precursors and generates hazardous by-products. Addressing these environmental concerns requires the development of greener synthesis routes and improved waste management strategies for polysilane-based products at the end of their lifecycle.

Scalability remains a significant challenge in the application of polysilane technologies for waste reduction. Many promising polysilane-based solutions have been demonstrated at laboratory scales, but translating these successes to industrial-scale operations presents numerous engineering and logistical difficulties. Overcoming these scaling issues is crucial for the practical implementation of polysilane technologies in real-world waste management systems.

Furthermore, the lack of standardization and regulatory frameworks specific to polysilane-based waste reduction technologies poses challenges for industry adoption. The absence of clear guidelines and performance standards makes it difficult for stakeholders to assess the efficacy and safety of polysilane solutions, potentially slowing down their integration into existing waste management infrastructures.

Lastly, the limited understanding of polysilane behavior in complex waste matrices presents a significant research challenge. The interaction between polysilanes and various waste components, including organic pollutants, heavy metals, and microorganisms, requires extensive study to optimize the performance of polysilane-based waste reduction technologies. This knowledge gap necessitates comprehensive research efforts to elucidate the fundamental mechanisms underlying polysilane's waste reduction capabilities in diverse environmental conditions.

Another major challenge lies in the stability and durability of polysilane-based materials. When exposed to certain environmental conditions, such as moisture or UV radiation, polysilanes can undergo rapid degradation, limiting their long-term effectiveness in waste reduction applications. This instability necessitates the development of protective measures or modified formulations to enhance the material's resilience in diverse waste management scenarios.

The environmental impact of polysilane production and disposal presents an additional hurdle. While polysilanes offer potential benefits in waste reduction, the synthesis of these materials often involves the use of toxic precursors and generates hazardous by-products. Addressing these environmental concerns requires the development of greener synthesis routes and improved waste management strategies for polysilane-based products at the end of their lifecycle.

Scalability remains a significant challenge in the application of polysilane technologies for waste reduction. Many promising polysilane-based solutions have been demonstrated at laboratory scales, but translating these successes to industrial-scale operations presents numerous engineering and logistical difficulties. Overcoming these scaling issues is crucial for the practical implementation of polysilane technologies in real-world waste management systems.

Furthermore, the lack of standardization and regulatory frameworks specific to polysilane-based waste reduction technologies poses challenges for industry adoption. The absence of clear guidelines and performance standards makes it difficult for stakeholders to assess the efficacy and safety of polysilane solutions, potentially slowing down their integration into existing waste management infrastructures.

Lastly, the limited understanding of polysilane behavior in complex waste matrices presents a significant research challenge. The interaction between polysilanes and various waste components, including organic pollutants, heavy metals, and microorganisms, requires extensive study to optimize the performance of polysilane-based waste reduction technologies. This knowledge gap necessitates comprehensive research efforts to elucidate the fundamental mechanisms underlying polysilane's waste reduction capabilities in diverse environmental conditions.

Current Applications

01 Recycling and reuse of polysilane waste

Methods for recycling and reusing polysilane waste materials to reduce environmental impact and improve resource efficiency. This includes processes for recovering and purifying polysilanes from waste streams, as well as techniques for converting waste polysilanes into useful products or precursors for other materials.- Recycling and reuse of polysilane waste: Methods for recycling and reusing polysilane waste materials to reduce environmental impact and improve resource efficiency. This includes processes for recovering and purifying polysilanes from waste streams, as well as techniques for incorporating recycled polysilanes into new products or applications.

- Optimization of polysilane synthesis processes: Improved synthesis methods for polysilanes that minimize waste generation and increase yield. This involves developing more efficient reaction pathways, optimizing reaction conditions, and using catalysts or additives to enhance selectivity and reduce byproduct formation.

- Waste reduction in polysilane-based coating applications: Techniques for reducing waste in the application of polysilane-based coatings, including improved formulation strategies, more efficient application methods, and the development of low-waste or solvent-free coating systems. This also encompasses methods for recovering and reusing excess coating materials.

- Polysilane waste treatment and disposal methods: Development of environmentally friendly methods for treating and disposing of polysilane waste that cannot be recycled or reused. This includes chemical, physical, or biological treatment processes to render the waste less harmful, as well as safe disposal techniques that minimize environmental impact.

- Alternative materials and processes to reduce polysilane waste: Research into alternative materials or processes that can replace or reduce the use of polysilanes in certain applications, thereby minimizing waste generation. This may include the development of new silicon-based polymers with improved properties or the exploration of entirely different material systems that can serve similar functions with less waste.

02 Optimization of polysilane synthesis processes

Improved synthesis methods for polysilanes that minimize waste generation and increase yield. This involves developing more efficient catalysts, optimizing reaction conditions, and implementing continuous flow processes to reduce the formation of byproducts and unwanted side reactions.Expand Specific Solutions03 Waste reduction in polysilane-based thin film production

Techniques for reducing waste in the production of polysilane-based thin films, including improved deposition methods, more efficient use of precursor materials, and strategies for recovering and reusing excess polysilane during the film formation process.Expand Specific Solutions04 Environmentally friendly polysilane disposal methods

Development of safe and environmentally friendly methods for disposing of polysilane waste that cannot be recycled or reused. This includes chemical treatments to render polysilanes less harmful, as well as controlled degradation processes that minimize the release of toxic substances.Expand Specific Solutions05 Polysilane waste reduction in semiconductor manufacturing

Strategies specifically tailored to reduce polysilane waste in semiconductor manufacturing processes. This involves optimizing lithography techniques, improving resist formulations, and implementing more efficient cleaning and etching processes that minimize the consumption and disposal of polysilane-based materials.Expand Specific Solutions

Key Industry Players

The polysilane waste reduction technology market is in its early growth stage, characterized by increasing research and development efforts across various industries. The market size is expanding as environmental regulations drive demand for innovative waste management solutions. Technologically, the field is rapidly evolving, with companies like Air Liquide, Osaka Gas, and Nippon Shokubai leading in research and development. These firms, along with others such as Wacker Chemie and Evonik Operations, are investing in advanced polysilane-based technologies to improve waste reduction efficiency. While the technology is promising, it is still maturing, with ongoing efforts to enhance scalability and cost-effectiveness for widespread industrial adoption.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed innovative polysilane-based technologies for waste reduction. Their approach involves using polysilanes as precursors for silicon-based materials in various applications. The company has created a process that utilizes polysilanes to produce high-purity silicon for solar cells, reducing waste in semiconductor manufacturing[1]. Additionally, Wacker has developed polysilane-based coatings that enhance the durability and recyclability of materials, contributing to waste reduction in industries such as construction and automotive[2]. Their research also focuses on using polysilanes in advanced polymer composites, which can lead to lighter and more recyclable materials for packaging and consumer goods[3].

Strengths: Extensive experience in silicon chemistry, established production capabilities, and a strong research focus on sustainable materials. Weaknesses: Potential high costs associated with polysilane production and implementation in waste reduction technologies.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has made significant strides in utilizing polysilanes for waste reduction technologies. The company has developed a proprietary process that employs polysilanes as precursors for silicon carbide ceramics, which are used in high-temperature waste treatment applications[4]. This technology allows for more efficient incineration of hazardous waste, reducing overall waste volume and toxicity. Evonik has also explored the use of polysilanes in advanced filtration membranes, capable of removing contaminants from industrial wastewater with higher efficiency than traditional methods[5]. Furthermore, their research extends to using polysilane-derived materials in catalytic converters, potentially reducing harmful emissions from various industrial processes[6].

Strengths: Strong expertise in specialty chemicals, diverse application portfolio, and a focus on sustainable solutions. Weaknesses: Relatively new to polysilane-specific applications, which may require significant investment in R&D and production scaling.

Polysilane Innovations

Polysilane production process

PatentInactiveUS20110158886A1

Innovation

- A polysilane production process using a binuclear metal complex catalyst at room temperature and 1 atm to polymerize silane compounds, eliminating the need for large-scale equipment and enabling efficient polysilane synthesis under mild conditions.

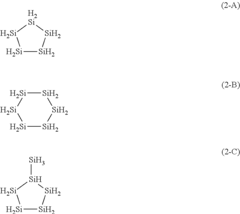

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Environmental Impact

Polysilane's potential role in waste reduction technologies has significant environmental implications that warrant careful consideration. The use of polysilane-based materials in waste management processes could lead to substantial reductions in environmental pollution and resource depletion. One of the primary benefits is the potential for improved recycling efficiency, particularly in the treatment of plastic waste. Polysilane-based additives have shown promise in enhancing the degradability of certain plastics, potentially accelerating their breakdown in landfills or composting facilities.

Furthermore, polysilane compounds may contribute to more effective filtration systems for wastewater treatment. Their unique chemical properties allow for the development of advanced membranes that can remove a wider range of contaminants, including microplastics and certain chemical pollutants. This could result in cleaner water discharge from treatment plants, reducing the environmental burden on aquatic ecosystems.

In the realm of air pollution control, polysilane-derived materials are being explored for their potential in capturing and converting harmful emissions. Preliminary studies suggest that these materials could be incorporated into catalytic converters or industrial scrubbers, potentially improving the efficiency of air purification processes. This could lead to reduced greenhouse gas emissions and improved air quality in urban and industrial areas.

The production of polysilane itself, however, raises some environmental concerns. The synthesis process typically involves energy-intensive steps and the use of potentially hazardous chemicals. As such, the overall environmental impact of polysilane-based waste reduction technologies must be assessed through comprehensive life cycle analyses. These studies should consider the energy consumption, raw material sourcing, and potential emissions associated with polysilane production, as well as the long-term benefits of its application in waste management.

Another important aspect to consider is the end-of-life management of polysilane-containing products. While these materials may offer benefits in waste reduction, their own disposal or recycling must be carefully planned to prevent the introduction of new environmental challenges. Research into the biodegradability and recyclability of polysilane-based materials is crucial to ensure that their use does not simply shift the environmental burden to a different stage of the product lifecycle.

In conclusion, the environmental impact of polysilane in waste reduction technologies is multifaceted. While it offers promising solutions for enhancing recycling, water treatment, and air purification processes, careful consideration must be given to the full lifecycle environmental costs and benefits. Ongoing research and development efforts should focus on optimizing the production of polysilane and its derivatives to minimize negative environmental impacts while maximizing its potential for waste reduction and environmental protection.

Furthermore, polysilane compounds may contribute to more effective filtration systems for wastewater treatment. Their unique chemical properties allow for the development of advanced membranes that can remove a wider range of contaminants, including microplastics and certain chemical pollutants. This could result in cleaner water discharge from treatment plants, reducing the environmental burden on aquatic ecosystems.

In the realm of air pollution control, polysilane-derived materials are being explored for their potential in capturing and converting harmful emissions. Preliminary studies suggest that these materials could be incorporated into catalytic converters or industrial scrubbers, potentially improving the efficiency of air purification processes. This could lead to reduced greenhouse gas emissions and improved air quality in urban and industrial areas.

The production of polysilane itself, however, raises some environmental concerns. The synthesis process typically involves energy-intensive steps and the use of potentially hazardous chemicals. As such, the overall environmental impact of polysilane-based waste reduction technologies must be assessed through comprehensive life cycle analyses. These studies should consider the energy consumption, raw material sourcing, and potential emissions associated with polysilane production, as well as the long-term benefits of its application in waste management.

Another important aspect to consider is the end-of-life management of polysilane-containing products. While these materials may offer benefits in waste reduction, their own disposal or recycling must be carefully planned to prevent the introduction of new environmental challenges. Research into the biodegradability and recyclability of polysilane-based materials is crucial to ensure that their use does not simply shift the environmental burden to a different stage of the product lifecycle.

In conclusion, the environmental impact of polysilane in waste reduction technologies is multifaceted. While it offers promising solutions for enhancing recycling, water treatment, and air purification processes, careful consideration must be given to the full lifecycle environmental costs and benefits. Ongoing research and development efforts should focus on optimizing the production of polysilane and its derivatives to minimize negative environmental impacts while maximizing its potential for waste reduction and environmental protection.

Regulatory Framework

The regulatory framework surrounding polysilane's application in waste reduction technologies is complex and multifaceted, involving various levels of governance and environmental protection standards. At the international level, the United Nations Environment Programme (UNEP) has established guidelines for sustainable waste management, which indirectly influence the development and adoption of innovative materials like polysilane. These guidelines emphasize the importance of circular economy principles and the reduction of harmful emissions, aligning with polysilane's potential benefits in waste reduction.

In the European Union, the Waste Framework Directive (2008/98/EC) sets the overarching legal framework for waste management. This directive prioritizes waste prevention, reuse, and recycling, creating a favorable environment for technologies that can contribute to these goals. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also plays a crucial role in governing the use of new materials like polysilane, ensuring their safety for human health and the environment.

In the United States, the Environmental Protection Agency (EPA) oversees waste management regulations under the Resource Conservation and Recovery Act (RCRA). The EPA's focus on promoting sustainable materials management aligns with the potential applications of polysilane in waste reduction. Additionally, individual states often have their own regulations that may impact the adoption of new waste reduction technologies.

Japan, known for its advanced waste management practices, has implemented the Basic Act on Establishing a Sound Material-Cycle Society. This legislation promotes the development of technologies that contribute to resource efficiency and waste reduction, potentially creating opportunities for polysilane-based solutions.

Emerging economies, such as China and India, are rapidly evolving their regulatory frameworks to address growing waste management challenges. China's recent ban on certain types of waste imports has accelerated the need for innovative waste reduction technologies, potentially opening new markets for polysilane applications.

As the regulatory landscape continues to evolve, it is crucial for stakeholders in the polysilane industry to actively engage with policymakers and regulatory bodies. This engagement can help shape future regulations that support the adoption of innovative waste reduction technologies while ensuring appropriate safety and environmental standards are maintained.

In the European Union, the Waste Framework Directive (2008/98/EC) sets the overarching legal framework for waste management. This directive prioritizes waste prevention, reuse, and recycling, creating a favorable environment for technologies that can contribute to these goals. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also plays a crucial role in governing the use of new materials like polysilane, ensuring their safety for human health and the environment.

In the United States, the Environmental Protection Agency (EPA) oversees waste management regulations under the Resource Conservation and Recovery Act (RCRA). The EPA's focus on promoting sustainable materials management aligns with the potential applications of polysilane in waste reduction. Additionally, individual states often have their own regulations that may impact the adoption of new waste reduction technologies.

Japan, known for its advanced waste management practices, has implemented the Basic Act on Establishing a Sound Material-Cycle Society. This legislation promotes the development of technologies that contribute to resource efficiency and waste reduction, potentially creating opportunities for polysilane-based solutions.

Emerging economies, such as China and India, are rapidly evolving their regulatory frameworks to address growing waste management challenges. China's recent ban on certain types of waste imports has accelerated the need for innovative waste reduction technologies, potentially opening new markets for polysilane applications.

As the regulatory landscape continues to evolve, it is crucial for stakeholders in the polysilane industry to actively engage with policymakers and regulatory bodies. This engagement can help shape future regulations that support the adoption of innovative waste reduction technologies while ensuring appropriate safety and environmental standards are maintained.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!