Evaluating Process Efficiency in Direct Lithium Extraction Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. The evolution of DLE began in the early 2000s as researchers sought more sustainable alternatives to conventional evaporation ponds and hard-rock mining, which are characterized by extensive land use, high water consumption, and lengthy production timelines.

The technological trajectory of DLE has accelerated notably in the past five years, driven by the exponential growth in demand for lithium-ion batteries in electric vehicles and energy storage systems. This surge has created an urgent need for more efficient, environmentally responsible extraction methods capable of meeting global lithium demand, which is projected to increase by 400-500% by 2030.

DLE technologies encompass a diverse range of approaches, including adsorption, ion exchange, solvent extraction, and membrane processes. Each methodology offers distinct advantages in selectivity, recovery rates, and operational parameters, though they share the common objective of extracting lithium directly from brine resources with minimal environmental impact and reduced processing time.

The primary technical objectives of current DLE research and development efforts focus on several critical parameters: increasing lithium recovery rates beyond 90%, reducing energy consumption per ton of lithium carbonate equivalent (LCE), minimizing chemical reagent usage, and developing systems capable of processing diverse brine chemistries with varying lithium concentrations and impurity profiles.

A significant milestone in DLE development would be achieving commercial-scale operations with energy requirements below 5 GJ/ton LCE and water consumption less than 50 cubic meters per ton of product, representing substantial improvements over conventional methods. Additionally, reducing capital expenditure to levels competitive with traditional extraction methods remains a crucial goal for widespread industry adoption.

The technological evolution of DLE is increasingly influenced by interdisciplinary innovations, incorporating advances in materials science, particularly in the development of novel selective adsorbents and ion exchange materials with enhanced lithium selectivity and durability under repeated cycling conditions. Computational modeling and process intensification techniques are similarly contributing to optimizing system designs and operational parameters.

As the technology matures, standardized methodologies for evaluating process efficiency across different DLE systems have become essential for meaningful comparisons and investment decisions. These evaluation frameworks must account for multiple performance indicators, including lithium recovery rates, purity levels, operational costs, and environmental impacts, providing a comprehensive assessment of technology readiness and commercial viability.

The technological trajectory of DLE has accelerated notably in the past five years, driven by the exponential growth in demand for lithium-ion batteries in electric vehicles and energy storage systems. This surge has created an urgent need for more efficient, environmentally responsible extraction methods capable of meeting global lithium demand, which is projected to increase by 400-500% by 2030.

DLE technologies encompass a diverse range of approaches, including adsorption, ion exchange, solvent extraction, and membrane processes. Each methodology offers distinct advantages in selectivity, recovery rates, and operational parameters, though they share the common objective of extracting lithium directly from brine resources with minimal environmental impact and reduced processing time.

The primary technical objectives of current DLE research and development efforts focus on several critical parameters: increasing lithium recovery rates beyond 90%, reducing energy consumption per ton of lithium carbonate equivalent (LCE), minimizing chemical reagent usage, and developing systems capable of processing diverse brine chemistries with varying lithium concentrations and impurity profiles.

A significant milestone in DLE development would be achieving commercial-scale operations with energy requirements below 5 GJ/ton LCE and water consumption less than 50 cubic meters per ton of product, representing substantial improvements over conventional methods. Additionally, reducing capital expenditure to levels competitive with traditional extraction methods remains a crucial goal for widespread industry adoption.

The technological evolution of DLE is increasingly influenced by interdisciplinary innovations, incorporating advances in materials science, particularly in the development of novel selective adsorbents and ion exchange materials with enhanced lithium selectivity and durability under repeated cycling conditions. Computational modeling and process intensification techniques are similarly contributing to optimizing system designs and operational parameters.

As the technology matures, standardized methodologies for evaluating process efficiency across different DLE systems have become essential for meaningful comparisons and investment decisions. These evaluation frameworks must account for multiple performance indicators, including lithium recovery rates, purity levels, operational costs, and environmental impacts, providing a comprehensive assessment of technology readiness and commercial viability.

Market Analysis for Direct Lithium Extraction

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the global lithium market at approximately $7.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2030. Direct Lithium Extraction (DLE) technologies are positioned to capture a significant portion of this expanding market, with potential to revolutionize the supply chain dynamics.

Traditional lithium extraction methods, including hard rock mining and evaporation ponds, currently dominate the market with over 80% of global production. However, DLE technologies are gaining traction due to their potential for higher recovery rates, reduced environmental footprint, and faster production timelines. Market analysis indicates that DLE could potentially reduce extraction costs by 30-50% compared to conventional methods when operating at scale.

Regional market distribution shows significant concentration, with the "Lithium Triangle" of Argentina, Bolivia, and Chile holding approximately 58% of global lithium reserves. North America is emerging as a strategic market for DLE implementation, with the Salton Sea in California representing a potential production capacity of 600,000 tons of lithium carbonate equivalent annually. This regional diversification presents substantial opportunities for DLE technology providers to establish strategic partnerships with local operators.

Demand-side analysis reveals that battery manufacturers are increasingly prioritizing sustainable and ethically sourced lithium, creating a premium market segment for DLE-produced lithium. Major automotive manufacturers including Tesla, Volkswagen, and BMW have announced commitments to responsible sourcing practices, further strengthening market pull for DLE technologies.

Investment patterns demonstrate growing confidence in DLE technologies, with venture capital and corporate investment exceeding $1.2 billion between 2020-2022. This represents a 300% increase compared to the previous three-year period, indicating strong market confidence in the commercial viability of these emerging extraction methodologies.

Market barriers for DLE adoption include high initial capital expenditure requirements, technological uncertainties regarding long-term performance, and competition from established extraction methods with amortized infrastructure. Additionally, market penetration faces challenges from the conservative nature of the mining industry and regulatory uncertainties in key lithium-producing regions.

Future market projections suggest that DLE technologies could capture 25-30% of new lithium production capacity by 2030, representing a potential market value of $4-5 billion annually. This growth trajectory is contingent upon continued technological refinement, successful demonstration projects, and favorable regulatory frameworks in key markets.

Traditional lithium extraction methods, including hard rock mining and evaporation ponds, currently dominate the market with over 80% of global production. However, DLE technologies are gaining traction due to their potential for higher recovery rates, reduced environmental footprint, and faster production timelines. Market analysis indicates that DLE could potentially reduce extraction costs by 30-50% compared to conventional methods when operating at scale.

Regional market distribution shows significant concentration, with the "Lithium Triangle" of Argentina, Bolivia, and Chile holding approximately 58% of global lithium reserves. North America is emerging as a strategic market for DLE implementation, with the Salton Sea in California representing a potential production capacity of 600,000 tons of lithium carbonate equivalent annually. This regional diversification presents substantial opportunities for DLE technology providers to establish strategic partnerships with local operators.

Demand-side analysis reveals that battery manufacturers are increasingly prioritizing sustainable and ethically sourced lithium, creating a premium market segment for DLE-produced lithium. Major automotive manufacturers including Tesla, Volkswagen, and BMW have announced commitments to responsible sourcing practices, further strengthening market pull for DLE technologies.

Investment patterns demonstrate growing confidence in DLE technologies, with venture capital and corporate investment exceeding $1.2 billion between 2020-2022. This represents a 300% increase compared to the previous three-year period, indicating strong market confidence in the commercial viability of these emerging extraction methodologies.

Market barriers for DLE adoption include high initial capital expenditure requirements, technological uncertainties regarding long-term performance, and competition from established extraction methods with amortized infrastructure. Additionally, market penetration faces challenges from the conservative nature of the mining industry and regulatory uncertainties in key lithium-producing regions.

Future market projections suggest that DLE technologies could capture 25-30% of new lithium production capacity by 2030, representing a potential market value of $4-5 billion annually. This growth trajectory is contingent upon continued technological refinement, successful demonstration projects, and favorable regulatory frameworks in key markets.

Current Challenges in DLE Process Efficiency

Despite significant advancements in Direct Lithium Extraction (DLE) technologies, several critical efficiency challenges persist that hinder widespread commercial adoption. The primary challenge remains the selectivity of sorbents and membranes in complex brine environments. Current DLE systems struggle to maintain high lithium recovery rates when brines contain competing ions such as sodium, magnesium, and calcium, which often leads to co-extraction and reduced purity of the final product.

Energy consumption represents another major hurdle in DLE processes. Most systems require substantial energy inputs for pumping, heating, and regeneration cycles. This energy intensity directly impacts operational costs and carbon footprint, making some DLE approaches economically unviable when compared to traditional evaporation pond methods, particularly in regions with high energy costs or limited renewable energy access.

Water management efficiency remains problematic across various DLE technologies. Many systems require significant freshwater inputs for regeneration and washing cycles, creating a paradoxical situation where lithium extraction—critical for green energy transition—becomes water-intensive in often water-scarce regions. The water recovery and recycling capabilities of current systems frequently fall below optimal levels.

Process scalability presents ongoing challenges, with many promising laboratory-scale technologies failing to maintain efficiency metrics when scaled to commercial operations. The throughput limitations of current sorbent materials and membrane systems often necessitate larger physical footprints or multiple processing trains, increasing capital expenditure and operational complexity.

Sorbent and membrane durability under continuous operation conditions remains suboptimal. Most extraction media experience performance degradation over time due to fouling, physical breakdown, or chemical degradation. This necessitates frequent replacement cycles that increase operational costs and create additional waste streams requiring management.

Regeneration efficiency in DLE systems continues to be problematic, with many technologies requiring harsh chemical conditions, high temperatures, or energy-intensive processes to release captured lithium and prepare the extraction media for reuse. These regeneration steps often represent the most resource-intensive phase of the extraction cycle.

Process integration with downstream processing also presents efficiency challenges, as the lithium-rich solutions produced by DLE systems frequently require additional concentration and purification steps before conversion to battery-grade lithium compounds. These additional processing requirements can negate efficiency gains achieved in the primary extraction phase.

Energy consumption represents another major hurdle in DLE processes. Most systems require substantial energy inputs for pumping, heating, and regeneration cycles. This energy intensity directly impacts operational costs and carbon footprint, making some DLE approaches economically unviable when compared to traditional evaporation pond methods, particularly in regions with high energy costs or limited renewable energy access.

Water management efficiency remains problematic across various DLE technologies. Many systems require significant freshwater inputs for regeneration and washing cycles, creating a paradoxical situation where lithium extraction—critical for green energy transition—becomes water-intensive in often water-scarce regions. The water recovery and recycling capabilities of current systems frequently fall below optimal levels.

Process scalability presents ongoing challenges, with many promising laboratory-scale technologies failing to maintain efficiency metrics when scaled to commercial operations. The throughput limitations of current sorbent materials and membrane systems often necessitate larger physical footprints or multiple processing trains, increasing capital expenditure and operational complexity.

Sorbent and membrane durability under continuous operation conditions remains suboptimal. Most extraction media experience performance degradation over time due to fouling, physical breakdown, or chemical degradation. This necessitates frequent replacement cycles that increase operational costs and create additional waste streams requiring management.

Regeneration efficiency in DLE systems continues to be problematic, with many technologies requiring harsh chemical conditions, high temperatures, or energy-intensive processes to release captured lithium and prepare the extraction media for reuse. These regeneration steps often represent the most resource-intensive phase of the extraction cycle.

Process integration with downstream processing also presents efficiency challenges, as the lithium-rich solutions produced by DLE systems frequently require additional concentration and purification steps before conversion to battery-grade lithium compounds. These additional processing requirements can negate efficiency gains achieved in the primary extraction phase.

Current DLE Process Efficiency Solutions

01 Adsorption-based extraction technologies

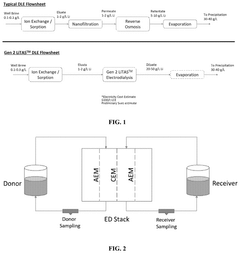

Direct Lithium Extraction (DLE) systems utilizing selective adsorption materials have shown significant improvements in process efficiency. These technologies employ specialized adsorbents that selectively capture lithium ions from brine solutions while rejecting competing ions. The adsorption process typically involves passing lithium-containing brines through columns packed with these materials, followed by desorption steps to recover concentrated lithium solutions. This approach reduces processing time compared to traditional evaporation methods and can achieve higher lithium recovery rates with lower environmental impact.- Adsorption-based extraction methods: Direct lithium extraction systems utilizing adsorption technologies employ selective adsorbents to capture lithium ions from brine solutions. These methods typically involve specialized ion exchange materials or lithium-selective sorbents that can efficiently separate lithium from other elements present in the brine. The process efficiency is enhanced through optimized contact time, regeneration cycles, and selective binding properties of the adsorbent materials, resulting in higher lithium recovery rates compared to traditional evaporation methods.

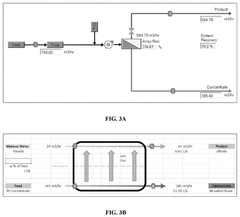

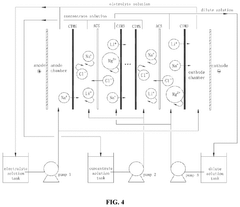

- Membrane and electrochemical separation techniques: Electrochemical separation techniques employ ion-selective membranes and electrical potential differences to extract lithium from brines. These systems utilize specialized membrane configurations that allow for selective transport of lithium ions while rejecting competing ions. The efficiency of these processes depends on membrane selectivity, applied voltage, and solution chemistry. Advanced electrochemical cells can significantly reduce processing time compared to conventional methods while maintaining high lithium recovery rates and purity levels.

- Process optimization and control systems: Advanced control systems and process optimization techniques significantly enhance the efficiency of direct lithium extraction operations. These include real-time monitoring of key parameters, automated adjustment of process conditions, and predictive analytics to maintain optimal extraction conditions. Machine learning algorithms can be employed to analyze operational data and suggest improvements to process parameters. Integration of digital twins and simulation models allows for virtual testing of process modifications before implementation, reducing downtime and increasing overall system efficiency.

- Brine pre-treatment and impurity management: Effective pre-treatment of lithium-containing brines is crucial for maximizing extraction efficiency. These processes involve the removal of interfering elements such as magnesium, calcium, and boron that can reduce the selectivity and capacity of extraction systems. Advanced filtration, precipitation, and selective removal techniques are employed to condition the brine before the main extraction process. Proper impurity management not only improves lithium recovery rates but also extends the operational lifetime of extraction media and reduces regeneration frequency.

- Regeneration and recovery systems: Efficient regeneration of extraction media is essential for continuous operation of direct lithium extraction systems. These processes involve the stripping of captured lithium from adsorbents or membranes and preparation of the media for subsequent extraction cycles. Advanced regeneration techniques minimize chemical consumption, reduce waste generation, and maintain the capacity of extraction media over multiple cycles. Closed-loop systems that recycle process water and reagents further enhance overall process efficiency while reducing environmental impact and operational costs.

02 Membrane and electrochemical separation systems

Membrane-based and electrochemical separation technologies represent advanced approaches to direct lithium extraction. These systems utilize ion-selective membranes or electrochemical cells to separate lithium from other elements in brine solutions. The technologies can include electrodialysis, electrochemical cells with lithium-selective membranes, or hybrid systems combining multiple separation principles. These methods typically consume less water than traditional processes, operate continuously rather than batch-wise, and can be more energy-efficient when properly optimized, leading to improved overall process efficiency.Expand Specific Solutions03 Process optimization and control systems

Advanced control systems and process optimization techniques have been developed to enhance the efficiency of direct lithium extraction operations. These innovations include real-time monitoring of extraction parameters, automated adjustment of process conditions, and integration of machine learning algorithms to optimize operational parameters. By implementing sophisticated control strategies, these systems can adapt to variations in feed composition, maximize lithium recovery rates, minimize reagent consumption, and reduce energy usage, thereby significantly improving overall process efficiency and economic viability.Expand Specific Solutions04 Integrated recovery and purification systems

Integrated systems that combine extraction, recovery, and purification steps have demonstrated enhanced efficiency in direct lithium extraction processes. These comprehensive solutions integrate multiple unit operations into cohesive systems that minimize intermediate handling and processing steps. The integration may include pre-treatment of brines, selective extraction of lithium, concentration of lithium-rich solutions, and final purification to battery-grade lithium compounds. By optimizing the interfaces between process steps and reducing material transfer operations, these integrated approaches achieve higher overall recovery rates and improved product quality with lower operational costs.Expand Specific Solutions05 Sustainable and energy-efficient extraction methods

Environmentally sustainable and energy-efficient extraction methods represent a significant advancement in direct lithium extraction technology. These approaches focus on minimizing water consumption, reducing chemical usage, utilizing renewable energy sources, and implementing closed-loop systems that recycle process streams. Some innovations include solar-powered extraction facilities, geothermal energy integration, and zero liquid discharge designs. By addressing environmental concerns while maintaining or improving extraction efficiency, these sustainable methods offer a pathway to more responsible lithium production with reduced carbon footprint and water usage compared to conventional extraction techniques.Expand Specific Solutions

Key Industry Players in DLE Systems

The direct lithium extraction (DLE) technology market is currently in a growth phase, characterized by increasing investments and technological advancements. The global market is projected to expand significantly as demand for lithium in battery applications surges. From a technological maturity perspective, the landscape shows varying degrees of development. Companies like Lilac Solutions, EnergyX, and Vulcan Energy are pioneering commercial-scale DLE implementations with innovative ion-exchange and membrane technologies. Koch Technology Solutions and Schlumberger are leveraging their industrial process expertise to enhance efficiency, while academic institutions such as the Chinese Academy of Sciences and The University of Manchester are advancing fundamental research. Newer entrants like Forager Station and Pure Lithium are introducing electrochemical approaches, indicating the technology's evolution toward more efficient extraction methods with reduced environmental impact.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced direct lithium extraction (DLE) process leveraging their expertise in separation technologies. Their approach utilizes a proprietary ion exchange system combined with specialized membrane filtration to selectively extract lithium from various brine sources. The process begins with pre-treatment to remove specific impurities, followed by a multi-stage ion exchange process where lithium ions are selectively captured while rejecting competing ions. The loaded ion exchange media is then regenerated using a carefully controlled chemical process, producing a concentrated lithium solution. Koch's system incorporates advanced process control and optimization algorithms that continuously adjust operating parameters based on incoming brine chemistry, maximizing efficiency[7]. Their technology achieves lithium recovery rates of approximately 85-90% while reducing water consumption by up to 90% compared to traditional evaporation methods. The modular design allows for scalable implementation, with processing times measured in hours rather than months. Koch has leveraged their extensive experience in large-scale industrial separations to address challenges in process efficiency, energy consumption, and operational reliability in DLE systems.

Strengths: Robust process design based on extensive industrial separation experience; advanced process control systems for optimized performance; modular and scalable architecture; high lithium selectivity across varying brine compositions; significant reduction in water usage. Weaknesses: Complex multi-stage process requiring careful integration of components; higher energy consumption compared to some competing technologies; regeneration chemicals add to operational costs; requires skilled operators for optimal performance; potential for fouling in certain brine conditions requiring additional maintenance.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an ion exchange technology for direct lithium extraction (DLE) that utilizes a novel ion exchange material specifically engineered to selectively capture lithium ions from brine resources. Their process employs ceramic beads containing lithium-selective active sites that can extract lithium from various brine sources with high efficiency. The system operates in a continuous flow process where brine passes through columns containing these beads, allowing for lithium adsorption while rejecting other elements. Once saturated, the beads are regenerated using a simple acid solution, producing a concentrated lithium solution ready for further processing. This approach significantly reduces processing time from months to hours compared to traditional evaporation ponds[1]. Lilac's technology can achieve lithium recovery rates of over 90% regardless of brine chemistry, whereas conventional methods typically recover only 40-50% of available lithium[2].

Strengths: High selectivity for lithium ions even in complex brines; rapid extraction timeframe (hours vs. months); water-efficient process with minimal environmental footprint; adaptable to various brine chemistries; high recovery rates exceeding 90%. Weaknesses: Requires specialized ion exchange materials that may have limited lifespan; regeneration process creates acidic waste streams requiring treatment; higher upfront capital costs compared to traditional evaporation methods.

Critical Technologies for Optimizing DLE Efficiency

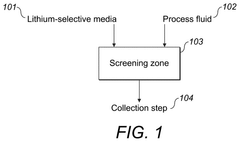

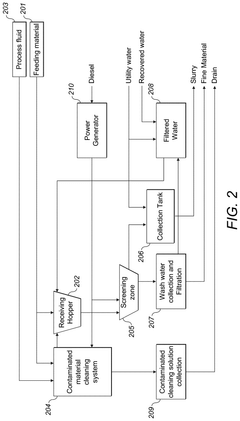

Method for improving lithium yield in a direct lithium extraction process

PatentPendingUS20250249465A1

Innovation

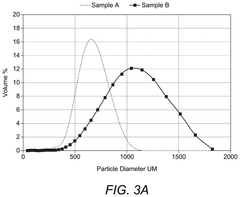

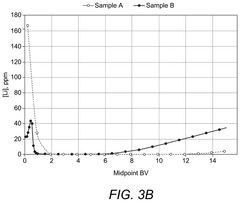

- A method involving a screening process using sieve elements with specific mesh sizes to separate lithium-selective media into desired particle sizes and remove contaminants, followed by dewatering and cleaning, to ensure optimal media performance in packed-bed columns.

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment of DLE Systems

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional lithium extraction methods, yet their environmental impacts require thorough assessment. DLE systems generally demonstrate reduced land footprint compared to evaporation ponds, with some technologies requiring up to 90% less land area for equivalent lithium production. This spatial efficiency translates to significantly lower habitat disruption in sensitive ecosystems where lithium resources are abundant.

Water consumption represents a critical environmental consideration, particularly in water-stressed regions. While conventional evaporation methods consume approximately 500,000 gallons of water per ton of lithium produced, advanced DLE systems have demonstrated potential reductions of 50-90% in water usage. Closed-loop systems that recycle process water show particular promise in minimizing freshwater withdrawals from local aquifers.

Chemical usage patterns in DLE operations present both challenges and opportunities. Most systems utilize selective adsorbents or ion exchange materials that require periodic regeneration with acids or bases. Environmental risk assessments indicate potential for localized soil and water contamination if proper containment systems are not implemented. However, quantitative analysis shows that chemical consumption per unit of lithium produced is typically lower than in traditional extraction processes.

Energy intensity varies significantly across DLE technologies, with electrical requirements ranging from 5 to 15 kWh per kilogram of lithium carbonate equivalent (LCE). Life cycle assessments reveal that the carbon footprint of DLE operations is heavily dependent on the regional electricity mix. Systems powered by renewable energy sources demonstrate carbon emissions reductions of up to 30% compared to conventional extraction methods.

Waste stream management represents another significant environmental consideration. DLE processes generate concentrated brine streams that require appropriate handling and disposal. Recent field trials indicate that selective recovery of additional valuable minerals from these streams (magnesium, potassium, boron) can transform waste management challenges into economic opportunities while reducing environmental liabilities.

Groundwater dynamics and subsurface impacts remain areas requiring further research. Preliminary hydrogeological modeling suggests that continuous brine extraction and reinjection can alter subsurface pressure gradients and potentially impact freshwater aquifers. Monitoring programs at pilot DLE facilities have documented localized changes in groundwater chemistry, though long-term ecosystem effects remain incompletely characterized.

Water consumption represents a critical environmental consideration, particularly in water-stressed regions. While conventional evaporation methods consume approximately 500,000 gallons of water per ton of lithium produced, advanced DLE systems have demonstrated potential reductions of 50-90% in water usage. Closed-loop systems that recycle process water show particular promise in minimizing freshwater withdrawals from local aquifers.

Chemical usage patterns in DLE operations present both challenges and opportunities. Most systems utilize selective adsorbents or ion exchange materials that require periodic regeneration with acids or bases. Environmental risk assessments indicate potential for localized soil and water contamination if proper containment systems are not implemented. However, quantitative analysis shows that chemical consumption per unit of lithium produced is typically lower than in traditional extraction processes.

Energy intensity varies significantly across DLE technologies, with electrical requirements ranging from 5 to 15 kWh per kilogram of lithium carbonate equivalent (LCE). Life cycle assessments reveal that the carbon footprint of DLE operations is heavily dependent on the regional electricity mix. Systems powered by renewable energy sources demonstrate carbon emissions reductions of up to 30% compared to conventional extraction methods.

Waste stream management represents another significant environmental consideration. DLE processes generate concentrated brine streams that require appropriate handling and disposal. Recent field trials indicate that selective recovery of additional valuable minerals from these streams (magnesium, potassium, boron) can transform waste management challenges into economic opportunities while reducing environmental liabilities.

Groundwater dynamics and subsurface impacts remain areas requiring further research. Preliminary hydrogeological modeling suggests that continuous brine extraction and reinjection can alter subsurface pressure gradients and potentially impact freshwater aquifers. Monitoring programs at pilot DLE facilities have documented localized changes in groundwater chemistry, though long-term ecosystem effects remain incompletely characterized.

Scalability and Economic Viability Analysis

The scalability of Direct Lithium Extraction (DLE) systems represents a critical factor in determining their commercial viability in the rapidly expanding lithium market. Current pilot-scale DLE operations demonstrate promising extraction efficiencies, but significant challenges emerge when considering industrial-scale implementation. Analysis indicates that most DLE technologies face diminishing efficiency returns when scaled beyond 20,000 metric tons of lithium carbonate equivalent (LCE) annually, primarily due to increased complexity in brine management and adsorbent regeneration cycles.

Economic modeling reveals that capital expenditure (CAPEX) requirements for DLE facilities range from $15,000-$30,000 per ton of annual LCE capacity, substantially higher than conventional evaporation pond methods ($10,000-$15,000). However, this initial investment disadvantage may be offset by DLE's accelerated production timeline, with full operational capacity achievable within 2-3 years compared to 5-7 years for traditional methods.

Operational expenditure (OPEX) analysis demonstrates significant variability across different DLE technologies. Ion-exchange based systems typically incur costs of $3,500-$5,000 per ton of LCE, while adsorption-based approaches range from $4,000-$6,500 per ton. These figures remain competitive with conventional methods ($3,000-$5,500) only when accounting for DLE's higher recovery rates (80-90% versus 40-50% for evaporation ponds).

Energy consumption represents a substantial component of operational costs, with most DLE systems requiring 2.5-4.0 MWh per ton of LCE produced. This energy intensity necessitates careful consideration of power source availability and cost when evaluating potential implementation sites. Renewable energy integration could significantly improve the economic profile of DLE operations, potentially reducing OPEX by 15-25% in optimal scenarios.

Water usage efficiency presents another critical economic consideration. While DLE systems generally return 80-90% of processed brine to aquifers, the remaining 10-20% represents a significant volume when operating at commercial scale. Water treatment and disposal costs can add $200-$600 per ton of LCE to operational expenses, depending on local environmental regulations and hydrogeological conditions.

Break-even analysis suggests that most current DLE technologies require lithium market prices above $12,000 per ton to achieve profitability at commercial scale. With recent market prices fluctuating between $15,000-$75,000 per ton, economic viability appears achievable but remains vulnerable to market volatility. Sensitivity analysis indicates that a 20% improvement in process efficiency could lower the break-even threshold to approximately $9,000 per ton, significantly enhancing long-term economic resilience.

Economic modeling reveals that capital expenditure (CAPEX) requirements for DLE facilities range from $15,000-$30,000 per ton of annual LCE capacity, substantially higher than conventional evaporation pond methods ($10,000-$15,000). However, this initial investment disadvantage may be offset by DLE's accelerated production timeline, with full operational capacity achievable within 2-3 years compared to 5-7 years for traditional methods.

Operational expenditure (OPEX) analysis demonstrates significant variability across different DLE technologies. Ion-exchange based systems typically incur costs of $3,500-$5,000 per ton of LCE, while adsorption-based approaches range from $4,000-$6,500 per ton. These figures remain competitive with conventional methods ($3,000-$5,500) only when accounting for DLE's higher recovery rates (80-90% versus 40-50% for evaporation ponds).

Energy consumption represents a substantial component of operational costs, with most DLE systems requiring 2.5-4.0 MWh per ton of LCE produced. This energy intensity necessitates careful consideration of power source availability and cost when evaluating potential implementation sites. Renewable energy integration could significantly improve the economic profile of DLE operations, potentially reducing OPEX by 15-25% in optimal scenarios.

Water usage efficiency presents another critical economic consideration. While DLE systems generally return 80-90% of processed brine to aquifers, the remaining 10-20% represents a significant volume when operating at commercial scale. Water treatment and disposal costs can add $200-$600 per ton of LCE to operational expenses, depending on local environmental regulations and hydrogeological conditions.

Break-even analysis suggests that most current DLE technologies require lithium market prices above $12,000 per ton to achieve profitability at commercial scale. With recent market prices fluctuating between $15,000-$75,000 per ton, economic viability appears achievable but remains vulnerable to market volatility. Sensitivity analysis indicates that a 20% improvement in process efficiency could lower the break-even threshold to approximately $9,000 per ton, significantly enhancing long-term economic resilience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!