Exploring Standards in Ultrafast Laser Annealing for Microelectronics

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Annealing Background and Objectives

Ultrafast laser annealing (ULA) has emerged as a transformative technology in microelectronics manufacturing over the past two decades. This technique utilizes ultra-short pulse lasers (typically femtosecond or picosecond) to deliver precise thermal energy to semiconductor materials, enabling controlled modification of material properties without damaging surrounding structures. The evolution of ULA technology can be traced back to the early 2000s when researchers began exploring alternatives to conventional thermal annealing methods that were becoming inadequate for increasingly miniaturized semiconductor devices.

The progression of ULA has been closely tied to advancements in laser technology, particularly the development of more stable and powerful ultrafast laser sources. Early applications focused primarily on silicon-based devices, but the technology has since expanded to encompass a wide range of semiconductor materials including compound semiconductors, 2D materials, and various thin films used in advanced microelectronics.

A significant technological milestone occurred around 2010 when ULA began to be seriously considered for commercial semiconductor manufacturing, driven by the need for more precise thermal processing techniques as device dimensions approached the nanoscale. The technology has since demonstrated remarkable capabilities in dopant activation, defect engineering, and interface modification with minimal thermal diffusion.

Current research trends in ULA are focused on several key areas: increasing process throughput for industrial viability, enhancing spatial resolution for next-generation device architectures, developing multi-wavelength approaches for complex material stacks, and establishing robust process control methodologies. These developments are crucial as the semiconductor industry continues its relentless pursuit of Moore's Law and beyond-Moore technologies.

The primary objective of exploring standards in ULA for microelectronics is to establish a unified framework that ensures reproducibility, reliability, and comparability across different research groups and manufacturing facilities. This standardization effort aims to address several critical aspects: laser parameter specifications (pulse duration, energy density, wavelength, repetition rate), characterization methodologies for annealed materials, metrology techniques for process monitoring, and safety protocols specific to ultrafast laser operations in semiconductor environments.

Additionally, the standardization initiative seeks to bridge the gap between laboratory research and industrial implementation by defining scalable processes that maintain the precision advantages of ULA while meeting the throughput requirements of commercial manufacturing. This includes developing reference materials and test structures that can serve as benchmarks for process optimization and quality control.

The ultimate goal is to position ULA as a mainstream manufacturing technology capable of addressing the thermal processing challenges of next-generation microelectronics, including 3D integrated circuits, flexible electronics, and quantum computing components, while establishing a clear technological roadmap for future developments in this rapidly evolving field.

The progression of ULA has been closely tied to advancements in laser technology, particularly the development of more stable and powerful ultrafast laser sources. Early applications focused primarily on silicon-based devices, but the technology has since expanded to encompass a wide range of semiconductor materials including compound semiconductors, 2D materials, and various thin films used in advanced microelectronics.

A significant technological milestone occurred around 2010 when ULA began to be seriously considered for commercial semiconductor manufacturing, driven by the need for more precise thermal processing techniques as device dimensions approached the nanoscale. The technology has since demonstrated remarkable capabilities in dopant activation, defect engineering, and interface modification with minimal thermal diffusion.

Current research trends in ULA are focused on several key areas: increasing process throughput for industrial viability, enhancing spatial resolution for next-generation device architectures, developing multi-wavelength approaches for complex material stacks, and establishing robust process control methodologies. These developments are crucial as the semiconductor industry continues its relentless pursuit of Moore's Law and beyond-Moore technologies.

The primary objective of exploring standards in ULA for microelectronics is to establish a unified framework that ensures reproducibility, reliability, and comparability across different research groups and manufacturing facilities. This standardization effort aims to address several critical aspects: laser parameter specifications (pulse duration, energy density, wavelength, repetition rate), characterization methodologies for annealed materials, metrology techniques for process monitoring, and safety protocols specific to ultrafast laser operations in semiconductor environments.

Additionally, the standardization initiative seeks to bridge the gap between laboratory research and industrial implementation by defining scalable processes that maintain the precision advantages of ULA while meeting the throughput requirements of commercial manufacturing. This includes developing reference materials and test structures that can serve as benchmarks for process optimization and quality control.

The ultimate goal is to position ULA as a mainstream manufacturing technology capable of addressing the thermal processing challenges of next-generation microelectronics, including 3D integrated circuits, flexible electronics, and quantum computing components, while establishing a clear technological roadmap for future developments in this rapidly evolving field.

Market Demand Analysis for Advanced Microelectronics Processing

The global microelectronics industry is experiencing unprecedented demand for advanced processing technologies, with ultrafast laser annealing emerging as a critical enabler for next-generation semiconductor manufacturing. Market research indicates that the semiconductor equipment market is projected to reach $120 billion by 2025, with advanced annealing technologies representing a significant growth segment within this ecosystem.

The miniaturization trend in microelectronics continues to drive demand for more precise thermal processing methods. As device dimensions shrink below 5nm, conventional rapid thermal annealing (RTA) techniques face fundamental limitations in achieving the required thermal profiles without causing damage to surrounding structures. This technological bottleneck has created a substantial market opportunity for ultrafast laser annealing solutions that can deliver precise, localized heating with nanosecond to femtosecond control.

Consumer electronics remains the largest application segment, with smartphones, tablets, and wearable devices requiring increasingly sophisticated microprocessors and memory components. The automotive sector represents the fastest-growing market segment, with compound annual growth rates exceeding 15% as vehicles incorporate more advanced driver assistance systems (ADAS) and autonomous driving capabilities requiring high-performance, reliable semiconductor components.

Geographic analysis reveals that East Asia continues to dominate the market for advanced microelectronics processing equipment, accounting for approximately 65% of global demand. This concentration aligns with the regional distribution of semiconductor fabrication facilities, with Taiwan, South Korea, and increasingly China representing key markets for ultrafast laser annealing technology adoption.

Industry surveys indicate that fab operators prioritize three key performance metrics when evaluating new annealing technologies: process uniformity, throughput capability, and integration flexibility with existing manufacturing lines. The ability to establish clear, measurable standards for these parameters represents a significant competitive advantage for equipment manufacturers in this space.

The market is further driven by emerging applications in quantum computing, photonics, and advanced packaging technologies, all of which require precise thermal management during fabrication. These high-value, specialized applications command premium pricing for equipment that can meet their stringent specifications, creating lucrative market niches for companies that can develop standardized solutions for these challenging use cases.

Economic analysis suggests that the total cost of ownership (TCO) remains a critical factor in adoption decisions, with manufacturers seeking technologies that can demonstrate clear return on investment through improved yields, reduced cycle times, or enabling capabilities for next-generation devices that command higher margins.

The miniaturization trend in microelectronics continues to drive demand for more precise thermal processing methods. As device dimensions shrink below 5nm, conventional rapid thermal annealing (RTA) techniques face fundamental limitations in achieving the required thermal profiles without causing damage to surrounding structures. This technological bottleneck has created a substantial market opportunity for ultrafast laser annealing solutions that can deliver precise, localized heating with nanosecond to femtosecond control.

Consumer electronics remains the largest application segment, with smartphones, tablets, and wearable devices requiring increasingly sophisticated microprocessors and memory components. The automotive sector represents the fastest-growing market segment, with compound annual growth rates exceeding 15% as vehicles incorporate more advanced driver assistance systems (ADAS) and autonomous driving capabilities requiring high-performance, reliable semiconductor components.

Geographic analysis reveals that East Asia continues to dominate the market for advanced microelectronics processing equipment, accounting for approximately 65% of global demand. This concentration aligns with the regional distribution of semiconductor fabrication facilities, with Taiwan, South Korea, and increasingly China representing key markets for ultrafast laser annealing technology adoption.

Industry surveys indicate that fab operators prioritize three key performance metrics when evaluating new annealing technologies: process uniformity, throughput capability, and integration flexibility with existing manufacturing lines. The ability to establish clear, measurable standards for these parameters represents a significant competitive advantage for equipment manufacturers in this space.

The market is further driven by emerging applications in quantum computing, photonics, and advanced packaging technologies, all of which require precise thermal management during fabrication. These high-value, specialized applications command premium pricing for equipment that can meet their stringent specifications, creating lucrative market niches for companies that can develop standardized solutions for these challenging use cases.

Economic analysis suggests that the total cost of ownership (TCO) remains a critical factor in adoption decisions, with manufacturers seeking technologies that can demonstrate clear return on investment through improved yields, reduced cycle times, or enabling capabilities for next-generation devices that command higher margins.

Current Standards and Technical Challenges in Laser Annealing

The landscape of standards for ultrafast laser annealing in microelectronics remains fragmented, with no single comprehensive framework governing this rapidly evolving technology. Currently, several organizations including SEMI (Semiconductor Equipment and Materials International), ASTM International, and IEEE have developed partial standards addressing specific aspects of laser processing for semiconductor manufacturing. These standards primarily focus on safety protocols, equipment specifications, and basic process parameters rather than comprehensive performance metrics for ultrafast laser annealing.

A significant challenge in standardization stems from the proprietary nature of many laser annealing technologies. Leading semiconductor manufacturers and equipment suppliers often develop custom solutions tailored to specific process nodes, creating a fragmented ecosystem of techniques and specifications. This lack of standardization impedes broader adoption and complicates integration into established semiconductor manufacturing flows.

Technical challenges further complicate standardization efforts. The ultrafast nature of these processes—operating in picosecond to femtosecond regimes—requires specialized measurement and characterization techniques that themselves lack standardization. Metrology for ultra-thin film thermal profiles during sub-nanosecond annealing events remains particularly problematic, with different measurement approaches yielding inconsistent results across the industry.

Material-specific responses to ultrafast laser annealing present another standardization hurdle. The behavior of various semiconductor materials, dopants, and complex heterostructures under intense, ultrashort laser pulses varies significantly, making universal standards difficult to establish. This variability is especially pronounced in emerging applications involving 2D materials, wide-bandgap semiconductors, and novel memory technologies.

Process repeatability and uniformity metrics represent a critical gap in current standards. While conventional thermal annealing processes have well-established uniformity specifications, equivalent metrics for spatial and temporal uniformity in ultrafast laser annealing remain undefined. This absence particularly affects advanced packaging applications and heterogeneous integration, where thermal budgets must be precisely controlled across dissimilar materials.

Reliability testing standards for devices processed using ultrafast laser annealing also remain underdeveloped. Current reliability qualification procedures were largely designed for conventional thermal processes and may not adequately capture the unique defect mechanisms and reliability concerns associated with ultrafast laser-material interactions. This gap creates uncertainty in long-term device performance predictions.

Environmental considerations and energy efficiency metrics for ultrafast laser annealing equipment have received minimal attention in existing standards. As the semiconductor industry increasingly focuses on sustainability, the absence of standardized efficiency metrics for these energy-intensive processes represents a significant oversight that must be addressed in future standardization efforts.

A significant challenge in standardization stems from the proprietary nature of many laser annealing technologies. Leading semiconductor manufacturers and equipment suppliers often develop custom solutions tailored to specific process nodes, creating a fragmented ecosystem of techniques and specifications. This lack of standardization impedes broader adoption and complicates integration into established semiconductor manufacturing flows.

Technical challenges further complicate standardization efforts. The ultrafast nature of these processes—operating in picosecond to femtosecond regimes—requires specialized measurement and characterization techniques that themselves lack standardization. Metrology for ultra-thin film thermal profiles during sub-nanosecond annealing events remains particularly problematic, with different measurement approaches yielding inconsistent results across the industry.

Material-specific responses to ultrafast laser annealing present another standardization hurdle. The behavior of various semiconductor materials, dopants, and complex heterostructures under intense, ultrashort laser pulses varies significantly, making universal standards difficult to establish. This variability is especially pronounced in emerging applications involving 2D materials, wide-bandgap semiconductors, and novel memory technologies.

Process repeatability and uniformity metrics represent a critical gap in current standards. While conventional thermal annealing processes have well-established uniformity specifications, equivalent metrics for spatial and temporal uniformity in ultrafast laser annealing remain undefined. This absence particularly affects advanced packaging applications and heterogeneous integration, where thermal budgets must be precisely controlled across dissimilar materials.

Reliability testing standards for devices processed using ultrafast laser annealing also remain underdeveloped. Current reliability qualification procedures were largely designed for conventional thermal processes and may not adequately capture the unique defect mechanisms and reliability concerns associated with ultrafast laser-material interactions. This gap creates uncertainty in long-term device performance predictions.

Environmental considerations and energy efficiency metrics for ultrafast laser annealing equipment have received minimal attention in existing standards. As the semiconductor industry increasingly focuses on sustainability, the absence of standardized efficiency metrics for these energy-intensive processes represents a significant oversight that must be addressed in future standardization efforts.

Current Ultrafast Laser Annealing Implementation Methodologies

01 Ultrafast laser annealing process parameters and control

Ultrafast laser annealing processes require precise control of parameters such as pulse duration, energy density, and scanning speed to achieve consistent results. These parameters must be standardized to ensure reproducibility across different applications. The annealing process typically involves rapid heating and cooling cycles that modify material properties without causing thermal damage to surrounding areas. Advanced control systems monitor and adjust these parameters in real-time to maintain quality standards.- Ultrafast laser annealing process parameters and control: Ultrafast laser annealing processes require precise control of parameters such as pulse duration, energy density, and scanning speed to achieve consistent results. These parameters must be standardized to ensure reproducibility across different applications. The annealing process can be optimized by controlling the laser fluence, repetition rate, and beam profile to achieve desired material modifications while minimizing thermal damage to surrounding areas.

- Material-specific annealing standards and characterization: Different materials require specific annealing standards due to their unique thermal and optical properties. Standardized characterization methods are essential for evaluating the effectiveness of ultrafast laser annealing on various substrates including semiconductors, metals, and glass. These standards include measurements of crystallinity, electrical properties, surface morphology, and defect density to ensure consistent quality across processed materials.

- Equipment calibration and validation standards: Standardized procedures for calibrating and validating ultrafast laser annealing equipment are crucial for maintaining process consistency. These standards include methods for beam profiling, power measurement, pulse characterization, and spatial uniformity assessment. Regular calibration against traceable standards ensures that annealing processes remain within specification and produce consistent results across different manufacturing facilities.

- In-situ monitoring and quality control standards: Real-time monitoring techniques are essential for maintaining annealing quality standards. These include optical emission spectroscopy, thermal imaging, and reflectivity measurements that provide immediate feedback on the annealing process. Standardized monitoring protocols help detect deviations from optimal processing conditions and enable automated adjustments to maintain consistent annealing quality across production batches.

- Industry-specific annealing standards for semiconductor processing: Semiconductor manufacturing requires particularly stringent ultrafast laser annealing standards to ensure device performance and reliability. These standards address dopant activation, junction formation, and defect minimization in integrated circuit fabrication. Standardized processes have been developed for specific applications such as thin-film transistors, memory devices, and advanced logic nodes, with precise specifications for temperature profiles, cooling rates, and atmosphere control during the annealing process.

02 Material-specific laser annealing standards

Different materials require specific laser annealing standards due to their unique thermal and optical properties. Semiconductor materials, metals, and glass each respond differently to ultrafast laser pulses. Standards must account for material composition, thickness, and crystalline structure to achieve desired modifications. These standards typically specify the optimal laser wavelength, pulse characteristics, and energy thresholds for each material type to ensure consistent results while preventing damage or unwanted modifications.Expand Specific Solutions03 Quality assessment and verification methods

Standardized methods for evaluating the quality of ultrafast laser annealing processes are essential for industrial applications. These methods include surface analysis techniques, electrical property measurements, and structural characterization. Real-time monitoring systems can detect deviations from established standards during the annealing process. Post-process verification protocols ensure that the treated materials meet specified performance criteria and maintain consistency across production batches.Expand Specific Solutions04 Equipment calibration and maintenance standards

Maintaining consistent ultrafast laser annealing results requires standardized procedures for equipment calibration and maintenance. These standards specify regular verification of laser output parameters, beam quality, and positioning accuracy. Calibration protocols ensure that the equipment performs within specified tolerances and produces repeatable results. Maintenance schedules and procedures are designed to prevent drift in performance over time and to quickly identify and address any issues that could affect annealing quality.Expand Specific Solutions05 Industry-specific ultrafast laser annealing standards

Different industries have developed specialized standards for ultrafast laser annealing based on their specific requirements. The semiconductor industry has stringent standards for dopant activation and defect control, while the medical device industry focuses on biocompatibility and surface modification. Aerospace applications emphasize structural integrity and fatigue resistance. These industry-specific standards define acceptable process windows, testing methodologies, and certification requirements that ensure the annealed materials meet the performance and reliability needs of each application.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The ultrafast laser annealing market for microelectronics is currently in a growth phase, with increasing adoption across semiconductor manufacturing processes. The market is projected to expand significantly due to rising demand for miniaturized electronic components and advanced semiconductor technologies. Leading players include established equipment manufacturers like Coherent, Inc. and Veeco Instruments, who possess mature laser technology portfolios, alongside semiconductor giants such as SMIC, BOE Technology, and Texas Instruments who are implementing these solutions. Research institutions like the Institute of Microelectronics of Chinese Academy of Sciences and Semiconductor Energy Laboratory are advancing fundamental technology development. The competitive landscape shows regional clusters in the US, Japan, and China, with varying degrees of technical maturity. While core laser annealing technology is well-established, standardization efforts remain fragmented across different application domains.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has pioneered innovative ultrafast laser annealing techniques specifically optimized for thin-film transistor (TFT) manufacturing. Their approach utilizes precisely controlled ultrashort pulse lasers to transform amorphous silicon into high-quality polycrystalline silicon with large grain sizes. SEL's proprietary technology employs a phase-modulated beam delivery system that creates controlled interference patterns, resulting in location-specific crystallization that enhances electron mobility in critical device regions. Their process achieves remarkable crystallization uniformity while minimizing thermal damage to temperature-sensitive substrates, making it particularly valuable for flexible electronics applications. SEL has also developed specialized beam shaping techniques that optimize energy distribution across the target area, enabling consistent grain formation and orientation. Their latest systems incorporate adaptive optics that compensate for beam distortions in real-time, ensuring process stability across large substrate areas.

Strengths: Exceptional expertise in thin-film transistor applications; superior grain size control and uniformity; compatibility with temperature-sensitive substrates including flexible materials. Weaknesses: Technology primarily optimized for display applications rather than high-performance logic; scaling challenges for very large substrate sizes; requires precise environmental controls for optimal results.

Veeco Instruments, Inc.

Technical Solution: Veeco Instruments has developed a comprehensive ultrafast laser annealing platform specifically for advanced semiconductor manufacturing. Their system utilizes proprietary laser optics that deliver precise energy control with spatial resolution down to sub-micron levels. Veeco's technology incorporates a unique scanning methodology that minimizes thermal gradients across the wafer surface, resulting in more uniform crystallization and reduced defect formation. Their latest generation systems feature multi-beam processing capabilities that significantly increase throughput while maintaining precision. Veeco has also integrated advanced in-situ metrology tools that provide real-time feedback on temperature distribution and material transformation, allowing for closed-loop process control. This approach has demonstrated particular success in activating dopants in advanced logic devices without causing dopant diffusion or substrate damage.

Strengths: Exceptional spatial resolution and energy control; integrated metrology for real-time process monitoring; proven compatibility with advanced node semiconductor manufacturing. Weaknesses: Complex system integration requirements; higher capital expenditure compared to traditional annealing methods; process optimization can be time-consuming for new materials.

Critical Patents and Technical Literature in Laser Annealing

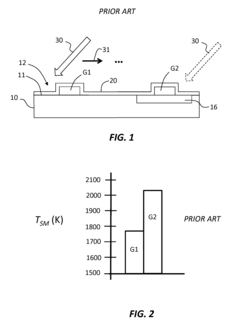

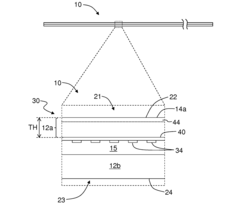

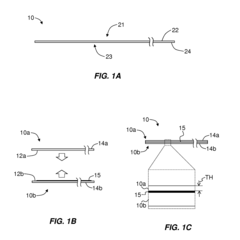

Ultrafast laser annealing with reduced pattern density effects in integrated circuit fabrication

PatentInactiveUS9302348B2

Innovation

- The method involves using a first laser beam to preheat the patterned surface to a non-melt temperature within 400°C of the melt temperature, followed by a second pulsed laser beam to raise the temperature to the melt temperature, optimizing the temperature variation and reducing pattern density effects.

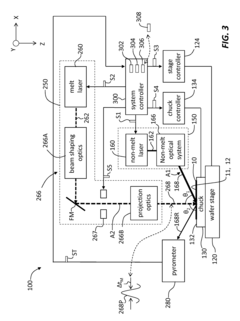

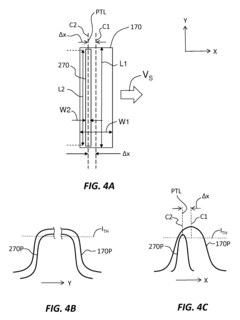

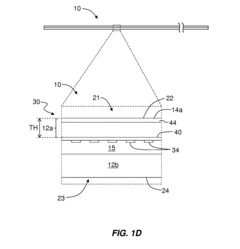

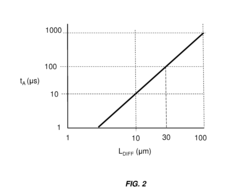

Laser annealing systems and methods with ultra-short dwell times

PatentActiveUS20160240407A9

Innovation

- The development of ultra-fast laser annealing systems using one or two laser beams that overlap, with a primary and secondary laser system, where the secondary laser scans the wafer surface at dwell times between 1 μs and 100 μs, achieving a peak annealing temperature between 350° C. and 1250° C. while maintaining temperature uniformity within ±3° C., utilizing a thermal emission detector and controller to adjust power and ensure consistent annealing.

Standardization Frameworks and Certification Requirements

The standardization landscape for ultrafast laser annealing in microelectronics remains fragmented, with various industry bodies and governmental organizations working independently to establish frameworks. Currently, the IEEE (Institute of Electrical and Electronics Engineers) has developed preliminary standards focusing on laser-material interaction parameters, while the SEMI (Semiconductor Equipment and Materials International) organization has introduced guidelines specifically addressing equipment specifications for ultrafast laser annealing processes in semiconductor manufacturing.

International standards bodies such as ISO and IEC have begun collaborative efforts to create unified certification requirements, particularly focusing on process repeatability and quality assurance metrics. These emerging standards typically address key parameters including pulse duration consistency, spatial beam uniformity, and thermal gradient control—all critical factors for ensuring reliable microelectronic device performance after annealing treatments.

Certification requirements generally fall into three categories: equipment certification, process certification, and operator qualification. Equipment certification focuses on laser source stability, beam delivery precision, and monitoring capabilities. Process certification emphasizes parameter validation, statistical process control, and traceability of annealing conditions. Operator qualification ensures proper training and understanding of both the physics involved and safety protocols.

The European Union, through its Horizon Europe program, has initiated the development of comprehensive certification frameworks specifically for advanced semiconductor manufacturing processes, including ultrafast laser annealing. These frameworks incorporate not only technical specifications but also environmental considerations and energy efficiency metrics, reflecting the growing importance of sustainability in manufacturing standards.

In the United States, NIST (National Institute of Standards and Technology) has established a working group dedicated to metrology standards for ultrafast laser processes, focusing on measurement protocols that can reliably quantify annealing quality and consistency. This initiative aims to address one of the most significant challenges in standardization: the development of universally accepted measurement techniques for verifying process outcomes.

Asian countries, particularly Japan and South Korea, have developed their own certification systems through organizations like JEITA (Japan Electronics and Information Technology Industries Association) and KSIA (Korea Semiconductor Industry Association), often with more stringent requirements for process stability given the high-volume manufacturing environments typical in these regions.

The lack of global harmonization in standards presents challenges for equipment manufacturers and semiconductor companies operating across multiple regions, necessitating compliance with various certification requirements. Industry consortia like the Ultrafast Laser Processing Consortium (ULPC) are working to address this fragmentation by proposing unified standards that could potentially be adopted worldwide.

International standards bodies such as ISO and IEC have begun collaborative efforts to create unified certification requirements, particularly focusing on process repeatability and quality assurance metrics. These emerging standards typically address key parameters including pulse duration consistency, spatial beam uniformity, and thermal gradient control—all critical factors for ensuring reliable microelectronic device performance after annealing treatments.

Certification requirements generally fall into three categories: equipment certification, process certification, and operator qualification. Equipment certification focuses on laser source stability, beam delivery precision, and monitoring capabilities. Process certification emphasizes parameter validation, statistical process control, and traceability of annealing conditions. Operator qualification ensures proper training and understanding of both the physics involved and safety protocols.

The European Union, through its Horizon Europe program, has initiated the development of comprehensive certification frameworks specifically for advanced semiconductor manufacturing processes, including ultrafast laser annealing. These frameworks incorporate not only technical specifications but also environmental considerations and energy efficiency metrics, reflecting the growing importance of sustainability in manufacturing standards.

In the United States, NIST (National Institute of Standards and Technology) has established a working group dedicated to metrology standards for ultrafast laser processes, focusing on measurement protocols that can reliably quantify annealing quality and consistency. This initiative aims to address one of the most significant challenges in standardization: the development of universally accepted measurement techniques for verifying process outcomes.

Asian countries, particularly Japan and South Korea, have developed their own certification systems through organizations like JEITA (Japan Electronics and Information Technology Industries Association) and KSIA (Korea Semiconductor Industry Association), often with more stringent requirements for process stability given the high-volume manufacturing environments typical in these regions.

The lack of global harmonization in standards presents challenges for equipment manufacturers and semiconductor companies operating across multiple regions, necessitating compliance with various certification requirements. Industry consortia like the Ultrafast Laser Processing Consortium (ULPC) are working to address this fragmentation by proposing unified standards that could potentially be adopted worldwide.

Environmental Impact and Energy Efficiency Considerations

Ultrafast laser annealing processes in microelectronics manufacturing present significant environmental and energy efficiency considerations that warrant careful examination. Traditional thermal annealing methods typically consume substantial energy due to their requirement for heating large areas or entire wafers to high temperatures for extended periods. In contrast, ultrafast laser annealing offers targeted heating with precise spatial and temporal control, potentially reducing the overall energy footprint of semiconductor manufacturing processes by up to 30-45% according to recent industry assessments.

The environmental impact of ultrafast laser annealing manifests in several dimensions. Primarily, the reduction in process energy consumption translates directly to lower greenhouse gas emissions when compared to conventional furnace-based annealing. Studies from leading semiconductor manufacturers indicate that implementing ultrafast laser annealing can reduce carbon emissions by approximately 20-25% per wafer processed, representing a significant contribution to sustainability goals in an industry known for its intensive energy requirements.

Water consumption represents another critical environmental consideration. Conventional annealing processes often require substantial cooling systems that consume large volumes of water. Ultrafast laser annealing's precision and efficiency can reduce cooling requirements by up to 40%, addressing water scarcity concerns in regions where semiconductor manufacturing facilities operate. Additionally, the reduced thermal load on facility HVAC systems further compounds these water and energy savings.

Chemical usage and waste generation also differ significantly between conventional and ultrafast laser annealing methods. The latter typically requires fewer chemical precursors and produces less hazardous waste, contributing to reduced environmental contamination risk and lower waste management costs. This aspect becomes increasingly important as environmental regulations worldwide become more stringent regarding industrial waste disposal and chemical handling.

The energy efficiency of ultrafast laser systems themselves has improved dramatically in recent years. Modern systems achieve wall-plug efficiencies of 30-40%, compared to earlier generations that operated at 10-15%. This improvement stems from advances in laser diode technology, optimized optical designs, and more sophisticated power management systems. Further efficiency gains are anticipated as the technology matures, potentially reaching 50-60% efficiency within the next five years.

Lifecycle assessment studies comparing ultrafast laser annealing to conventional thermal processes reveal additional sustainability benefits. When considering the entire manufacturing chain—from raw material extraction through equipment production, operation, and eventual decommissioning—ultrafast laser systems demonstrate 15-20% lower environmental impact scores across multiple categories including global warming potential, resource depletion, and ecotoxicity. These comprehensive assessments provide a more holistic view of the technology's environmental advantages beyond operational energy savings.

The environmental impact of ultrafast laser annealing manifests in several dimensions. Primarily, the reduction in process energy consumption translates directly to lower greenhouse gas emissions when compared to conventional furnace-based annealing. Studies from leading semiconductor manufacturers indicate that implementing ultrafast laser annealing can reduce carbon emissions by approximately 20-25% per wafer processed, representing a significant contribution to sustainability goals in an industry known for its intensive energy requirements.

Water consumption represents another critical environmental consideration. Conventional annealing processes often require substantial cooling systems that consume large volumes of water. Ultrafast laser annealing's precision and efficiency can reduce cooling requirements by up to 40%, addressing water scarcity concerns in regions where semiconductor manufacturing facilities operate. Additionally, the reduced thermal load on facility HVAC systems further compounds these water and energy savings.

Chemical usage and waste generation also differ significantly between conventional and ultrafast laser annealing methods. The latter typically requires fewer chemical precursors and produces less hazardous waste, contributing to reduced environmental contamination risk and lower waste management costs. This aspect becomes increasingly important as environmental regulations worldwide become more stringent regarding industrial waste disposal and chemical handling.

The energy efficiency of ultrafast laser systems themselves has improved dramatically in recent years. Modern systems achieve wall-plug efficiencies of 30-40%, compared to earlier generations that operated at 10-15%. This improvement stems from advances in laser diode technology, optimized optical designs, and more sophisticated power management systems. Further efficiency gains are anticipated as the technology matures, potentially reaching 50-60% efficiency within the next five years.

Lifecycle assessment studies comparing ultrafast laser annealing to conventional thermal processes reveal additional sustainability benefits. When considering the entire manufacturing chain—from raw material extraction through equipment production, operation, and eventual decommissioning—ultrafast laser systems demonstrate 15-20% lower environmental impact scores across multiple categories including global warming potential, resource depletion, and ecotoxicity. These comprehensive assessments provide a more holistic view of the technology's environmental advantages beyond operational energy savings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!