How Ultrafast Laser Annealing Improves Polymer Thermal Stability

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Annealing Technology Background and Objectives

Ultrafast laser annealing represents a significant advancement in materials processing technology, particularly for enhancing polymer thermal stability. This technique emerged in the late 1990s as an extension of traditional thermal annealing methods but offers unprecedented precision and control through the application of ultrashort laser pulses in the femtosecond to picosecond range. The evolution of this technology has been closely tied to developments in ultrafast laser systems, which have become increasingly accessible and reliable over the past two decades.

The fundamental principle behind ultrafast laser annealing involves the delivery of intense, extremely short duration energy pulses that induce localized heating without allowing significant thermal diffusion to surrounding areas. This temporal and spatial confinement of energy represents a paradigm shift from conventional annealing approaches, which typically involve bulk heating of materials over extended periods.

Historical development of polymer thermal stability enhancement techniques shows a clear progression from conventional oven-based thermal treatments to more sophisticated methods including radiation-based approaches, microwave processing, and finally, laser-based techniques. Ultrafast laser annealing stands at the frontier of this evolution, offering unique capabilities to modify polymer properties at the molecular level without compromising structural integrity.

Current technological trends indicate growing interest in precision manufacturing processes that can enhance material properties while minimizing energy consumption and processing time. Ultrafast laser annealing aligns perfectly with these trends, as it enables rapid processing with minimal thermal impact on the bulk material. The technology has seen accelerating adoption across various industries, from microelectronics to biomedical applications, where polymer thermal stability is critical.

The primary objectives of ultrafast laser annealing technology development include: achieving precise control over polymer crystallinity and cross-linking density; enhancing thermal decomposition temperatures without degrading mechanical properties; developing scalable processes suitable for industrial implementation; and establishing predictive models that can guide parameter optimization for specific polymer systems.

Recent breakthroughs in ultrafast laser technology, including the development of high-repetition-rate systems and beam shaping techniques, have further expanded the potential applications of this approach. These advancements enable more uniform energy distribution and higher processing throughput, addressing previous limitations that restricted industrial adoption.

Looking forward, the technology trajectory suggests continued refinement of ultrafast laser annealing techniques, with particular focus on process optimization for emerging high-performance polymers and composite materials. The convergence of this technology with computational modeling and in-situ monitoring capabilities represents a promising direction for achieving unprecedented control over polymer thermal properties.

The fundamental principle behind ultrafast laser annealing involves the delivery of intense, extremely short duration energy pulses that induce localized heating without allowing significant thermal diffusion to surrounding areas. This temporal and spatial confinement of energy represents a paradigm shift from conventional annealing approaches, which typically involve bulk heating of materials over extended periods.

Historical development of polymer thermal stability enhancement techniques shows a clear progression from conventional oven-based thermal treatments to more sophisticated methods including radiation-based approaches, microwave processing, and finally, laser-based techniques. Ultrafast laser annealing stands at the frontier of this evolution, offering unique capabilities to modify polymer properties at the molecular level without compromising structural integrity.

Current technological trends indicate growing interest in precision manufacturing processes that can enhance material properties while minimizing energy consumption and processing time. Ultrafast laser annealing aligns perfectly with these trends, as it enables rapid processing with minimal thermal impact on the bulk material. The technology has seen accelerating adoption across various industries, from microelectronics to biomedical applications, where polymer thermal stability is critical.

The primary objectives of ultrafast laser annealing technology development include: achieving precise control over polymer crystallinity and cross-linking density; enhancing thermal decomposition temperatures without degrading mechanical properties; developing scalable processes suitable for industrial implementation; and establishing predictive models that can guide parameter optimization for specific polymer systems.

Recent breakthroughs in ultrafast laser technology, including the development of high-repetition-rate systems and beam shaping techniques, have further expanded the potential applications of this approach. These advancements enable more uniform energy distribution and higher processing throughput, addressing previous limitations that restricted industrial adoption.

Looking forward, the technology trajectory suggests continued refinement of ultrafast laser annealing techniques, with particular focus on process optimization for emerging high-performance polymers and composite materials. The convergence of this technology with computational modeling and in-situ monitoring capabilities represents a promising direction for achieving unprecedented control over polymer thermal properties.

Market Demand for Enhanced Polymer Thermal Stability

The global market for polymers with enhanced thermal stability is experiencing significant growth, driven by increasing demands across multiple industries where materials are subjected to extreme temperature conditions. The aerospace sector represents one of the largest markets, requiring polymers that can withstand the extreme temperature fluctuations encountered during flight operations. Similarly, the automotive industry is rapidly adopting high-performance polymers for under-hood applications where temperatures frequently exceed 200°C.

Electronics manufacturing constitutes another critical market segment, with the miniaturization trend creating unprecedented thermal management challenges. As device dimensions shrink while processing power increases, the need for thermally stable polymer substrates and packaging materials has become paramount. Market research indicates that the global high-temperature polymer market is projected to grow at a compound annual growth rate of 7.5% through 2028.

The renewable energy sector, particularly solar panel manufacturing, has emerged as a significant consumer of thermally stable polymers. Photovoltaic modules must withstand decades of outdoor exposure to temperature cycling and UV radiation, creating demand for polymers with exceptional long-term thermal stability. Similarly, the growing electric vehicle market requires battery components with superior thermal resistance to ensure safety and longevity.

Medical device manufacturing represents another expanding market segment, particularly for implantable devices and surgical instruments that must withstand repeated sterilization cycles. The ability to maintain dimensional stability and mechanical properties after multiple high-temperature autoclave cycles is essential for these applications.

Industry analysts have identified a significant market gap in the availability of cost-effective polymers that combine exceptional thermal stability with ease of processing. Traditional high-temperature polymers like polyimides and PEEK often require specialized processing equipment and techniques, limiting their broader adoption. This has created a market opportunity for novel processing methods like ultrafast laser annealing that can enhance the thermal properties of more accessible polymers.

Consumer demand for sustainable products is also influencing this market, with manufacturers seeking bio-based polymers that can match the thermal performance of petroleum-derived alternatives. The ability to improve the thermal stability of renewable polymers through advanced processing techniques like laser annealing could significantly expand their application range.

The defense sector continues to drive innovation in high-temperature polymers, with requirements for materials that can function reliably in extreme environments. Applications range from thermal protection systems to components for hypersonic vehicles, where materials must withstand temperatures exceeding 1000°C while maintaining structural integrity.

Electronics manufacturing constitutes another critical market segment, with the miniaturization trend creating unprecedented thermal management challenges. As device dimensions shrink while processing power increases, the need for thermally stable polymer substrates and packaging materials has become paramount. Market research indicates that the global high-temperature polymer market is projected to grow at a compound annual growth rate of 7.5% through 2028.

The renewable energy sector, particularly solar panel manufacturing, has emerged as a significant consumer of thermally stable polymers. Photovoltaic modules must withstand decades of outdoor exposure to temperature cycling and UV radiation, creating demand for polymers with exceptional long-term thermal stability. Similarly, the growing electric vehicle market requires battery components with superior thermal resistance to ensure safety and longevity.

Medical device manufacturing represents another expanding market segment, particularly for implantable devices and surgical instruments that must withstand repeated sterilization cycles. The ability to maintain dimensional stability and mechanical properties after multiple high-temperature autoclave cycles is essential for these applications.

Industry analysts have identified a significant market gap in the availability of cost-effective polymers that combine exceptional thermal stability with ease of processing. Traditional high-temperature polymers like polyimides and PEEK often require specialized processing equipment and techniques, limiting their broader adoption. This has created a market opportunity for novel processing methods like ultrafast laser annealing that can enhance the thermal properties of more accessible polymers.

Consumer demand for sustainable products is also influencing this market, with manufacturers seeking bio-based polymers that can match the thermal performance of petroleum-derived alternatives. The ability to improve the thermal stability of renewable polymers through advanced processing techniques like laser annealing could significantly expand their application range.

The defense sector continues to drive innovation in high-temperature polymers, with requirements for materials that can function reliably in extreme environments. Applications range from thermal protection systems to components for hypersonic vehicles, where materials must withstand temperatures exceeding 1000°C while maintaining structural integrity.

Current Challenges in Polymer Thermal Stability Enhancement

Polymer materials, despite their widespread applications across industries, face significant thermal stability limitations that restrict their use in high-temperature environments. Current polymers typically begin to degrade at temperatures ranging from 150°C to 350°C, depending on their chemical structure and composition. This thermal degradation manifests through chain scission, cross-linking, oxidation, and depolymerization processes, resulting in compromised mechanical properties, dimensional instability, and reduced service life.

Traditional methods for enhancing polymer thermal stability include chemical modifications such as incorporating heat-resistant monomers, adding stabilizing additives, and implementing cross-linking strategies. However, these approaches often introduce trade-offs in other material properties, including processability, flexibility, and cost-effectiveness. Additionally, the incorporation of additives may lead to environmental concerns and potential leaching issues during the material's lifecycle.

Physical modification techniques like thermal annealing have shown promise but typically require extended processing times at elevated temperatures, which can be energy-intensive and may initiate degradation processes during the treatment itself. This paradoxical situation creates a significant technological barrier where the very process intended to improve thermal stability may contribute to material deterioration.

Nanocomposite approaches, involving the dispersion of thermally stable nanoparticles within polymer matrices, have demonstrated improvements but face challenges related to uniform dispersion, interfacial adhesion, and scalable manufacturing. The agglomeration of nanoparticles remains a persistent issue that can create stress concentration points and initiation sites for thermal degradation.

Surface treatment methods currently employed provide only limited protection against thermal degradation, as they typically do not address the bulk properties of the polymer. This creates a disparity between surface and core thermal stability, leading to potential failure mechanisms under prolonged thermal stress.

The emerging field of ultrafast laser annealing represents a potential breakthrough, offering localized, controlled energy delivery that can modify polymer structures without bulk heating. However, this technology faces significant challenges including precise control of laser parameters, understanding of complex photophysical interactions with diverse polymer chemistries, and development of scalable processing methodologies for industrial implementation.

Furthermore, there exists a substantial knowledge gap in understanding the fundamental mechanisms by which ultrafast laser annealing affects polymer chain mobility, crystallinity, and long-term thermal stability. The relationship between laser-induced structural changes and resulting thermal properties remains inadequately characterized across different polymer families, limiting the rational design of treatment protocols.

Traditional methods for enhancing polymer thermal stability include chemical modifications such as incorporating heat-resistant monomers, adding stabilizing additives, and implementing cross-linking strategies. However, these approaches often introduce trade-offs in other material properties, including processability, flexibility, and cost-effectiveness. Additionally, the incorporation of additives may lead to environmental concerns and potential leaching issues during the material's lifecycle.

Physical modification techniques like thermal annealing have shown promise but typically require extended processing times at elevated temperatures, which can be energy-intensive and may initiate degradation processes during the treatment itself. This paradoxical situation creates a significant technological barrier where the very process intended to improve thermal stability may contribute to material deterioration.

Nanocomposite approaches, involving the dispersion of thermally stable nanoparticles within polymer matrices, have demonstrated improvements but face challenges related to uniform dispersion, interfacial adhesion, and scalable manufacturing. The agglomeration of nanoparticles remains a persistent issue that can create stress concentration points and initiation sites for thermal degradation.

Surface treatment methods currently employed provide only limited protection against thermal degradation, as they typically do not address the bulk properties of the polymer. This creates a disparity between surface and core thermal stability, leading to potential failure mechanisms under prolonged thermal stress.

The emerging field of ultrafast laser annealing represents a potential breakthrough, offering localized, controlled energy delivery that can modify polymer structures without bulk heating. However, this technology faces significant challenges including precise control of laser parameters, understanding of complex photophysical interactions with diverse polymer chemistries, and development of scalable processing methodologies for industrial implementation.

Furthermore, there exists a substantial knowledge gap in understanding the fundamental mechanisms by which ultrafast laser annealing affects polymer chain mobility, crystallinity, and long-term thermal stability. The relationship between laser-induced structural changes and resulting thermal properties remains inadequately characterized across different polymer families, limiting the rational design of treatment protocols.

Current Ultrafast Laser Annealing Methodologies

01 Ultrafast laser annealing for semiconductor processing

Ultrafast laser annealing techniques are used in semiconductor manufacturing to improve thermal stability of materials. The process involves using short-duration laser pulses to rapidly heat and cool semiconductor materials, allowing for precise control of the annealing process without affecting surrounding areas. This method enhances the thermal stability of semiconductor structures while minimizing thermal damage to adjacent components, making it particularly valuable for advanced integrated circuit fabrication.- Ultrafast laser annealing for semiconductor processing: Ultrafast laser annealing techniques are used in semiconductor manufacturing to improve thermal stability of materials during processing. These techniques employ femtosecond or picosecond lasers to rapidly heat and cool semiconductor materials, allowing for precise control of the annealing process while minimizing thermal damage to surrounding areas. This approach enables better crystallization, dopant activation, and defect reduction while maintaining thermal stability of the treated structures.

- Thermal stability enhancement through pulse control: Controlling laser pulse parameters such as duration, energy, and repetition rate is crucial for enhancing thermal stability during ultrafast laser annealing. By optimizing these parameters, heat accumulation can be managed effectively, preventing thermal runaway and ensuring stable processing conditions. Advanced pulse shaping techniques allow for tailored energy deposition profiles that maximize thermal stability while achieving desired material modifications.

- Material-specific annealing techniques for improved thermal stability: Different materials require specific ultrafast laser annealing approaches to achieve optimal thermal stability. For instance, silicon, metals, and compound semiconductors each respond differently to ultrafast laser pulses. By tailoring the annealing parameters to the specific thermal properties of each material, enhanced stability can be achieved. This includes considerations of absorption coefficients, thermal conductivity, and phase transition temperatures to develop material-specific protocols.

- Multi-layer structure thermal stability management: When annealing multi-layer structures, maintaining thermal stability becomes more complex due to different thermal properties of each layer. Ultrafast laser annealing techniques can be designed to selectively treat specific layers without affecting others by carefully controlling penetration depth and energy absorption. This selective annealing approach preserves the integrity of temperature-sensitive layers while effectively processing target layers, resulting in thermally stable multi-layer devices.

- In-situ monitoring for thermal stability control: Real-time monitoring systems integrated with ultrafast laser annealing equipment allow for dynamic control of the annealing process to maintain thermal stability. These systems use various sensing technologies to measure temperature distributions, material changes, and other process parameters during annealing. Feedback mechanisms can automatically adjust laser parameters to prevent thermal instability, ensuring consistent results and preventing damage from thermal fluctuations.

02 Thermal stability enhancement through pulse control

Controlling the parameters of ultrafast laser pulses significantly impacts the thermal stability of annealed materials. By adjusting pulse duration, repetition rate, and energy density, the thermal profile can be optimized to achieve desired material properties. This approach allows for precise management of heat accumulation and dissipation, resulting in improved thermal stability of the treated materials while preventing unwanted phase transitions or structural degradation.Expand Specific Solutions03 Material-specific laser annealing techniques

Different materials require specialized ultrafast laser annealing approaches to achieve optimal thermal stability. For instance, crystalline silicon, amorphous materials, and compound semiconductors each respond differently to laser annealing. Tailoring the laser parameters according to the specific thermal properties, absorption characteristics, and phase transition temperatures of the target material ensures enhanced thermal stability while maintaining the desired microstructural properties.Expand Specific Solutions04 Multi-layer thermal stability management

When dealing with multi-layer structures, ultrafast laser annealing must address the thermal stability challenges at interfaces between different materials. Specialized techniques have been developed to manage thermal gradients across heterogeneous layers, preventing delamination, diffusion, or unwanted intermixing. These approaches often involve precise control of laser penetration depth and energy distribution to ensure uniform thermal treatment while maintaining the structural integrity of complex multi-layer systems.Expand Specific Solutions05 Advanced monitoring and control systems for thermal stability

Real-time monitoring and feedback control systems have been developed to enhance the thermal stability of ultrafast laser annealing processes. These systems utilize temperature sensors, optical monitoring, and computational models to dynamically adjust laser parameters during the annealing process. By continuously tracking the thermal profile and material response, these advanced control systems can maintain optimal processing conditions, ensuring consistent thermal stability across the treated area and compensating for material variations.Expand Specific Solutions

Key Industry Players in Ultrafast Laser Processing

The ultrafast laser annealing technology for polymer thermal stability is currently in an early growth phase, with increasing adoption across multiple industries. The market is projected to expand significantly as thermal stability requirements become more critical in advanced materials applications. From a technological maturity perspective, the field shows varied development levels among key players. Research institutions like MIT and Southwest Jiaotong University are advancing fundamental science, while commercial entities demonstrate different specialization areas: DuPont and ExxonMobil focus on polymer chemistry innovations, Micron Technology and TCL apply the technology to electronics manufacturing, and medical device companies like Howmedica Osteonics and Covidien explore biomedical applications. Specialized equipment manufacturers including Veeco Instruments and Beijing U-PRECISION TECH are developing the precision laser systems essential for industrial implementation of this emerging technology.

Veeco Instruments, Inc.

Technical Solution: Veeco has developed an industrial-scale ultrafast laser annealing platform specifically engineered for polymer thermal stability enhancement. Their system utilizes a proprietary beam delivery architecture that incorporates multiple synchronized femtosecond lasers (operating at 1030nm with <500fs pulse duration) to achieve high throughput processing of polymer materials. The technology employs a sophisticated optical system that transforms the Gaussian beam profile into a uniform top-hat distribution, ensuring consistent energy delivery across the treatment area. Veeco's approach creates controlled photochemical modifications in the polymer structure through non-linear absorption mechanisms, inducing cross-linking without bulk heating. Their process has demonstrated the ability to increase the thermal decomposition temperature of engineering polymers by 50-80°C while maintaining or improving mechanical properties. The system incorporates real-time monitoring with spectroscopic feedback to ensure process consistency and quality control. Veeco has successfully implemented this technology in production environments for aerospace composites and semiconductor packaging materials.

Strengths: High throughput capability suitable for industrial production; excellent process control and repeatability; adaptable to various polymer types through parameter optimization. Weaknesses: Significant capital investment required; complex optical systems that require specialized maintenance; process optimization can be time-consuming for new polymer formulations.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory has pioneered an advanced ultrafast laser annealing system specifically designed for polymer semiconductor interfaces. Their technology employs picosecond laser pulses (1-10ps duration) with wavelengths tuned to specific polymer absorption bands (typically 355-532nm), allowing for precise energy deposition at polymer-substrate interfaces. The company's approach creates controlled nanoscale crystallization zones that act as thermal stabilization regions within the polymer matrix. Their proprietary beam-shaping technology ensures uniform energy distribution across the treatment area, preventing hotspots that could lead to polymer degradation. SEL has demonstrated that their ULA process can increase the thermal decomposition temperature of polyimide films used in flexible displays by approximately 75°C, while simultaneously improving adhesion to silicon substrates by creating nanoscale interlocking structures at the interface. The process operates at atmospheric pressure and room temperature, making it highly compatible with existing semiconductor manufacturing environments.

Strengths: Exceptional control over the depth of thermal modification; creates improved interfacial properties between polymers and substrates; compatible with clean room environments and existing semiconductor manufacturing processes. Weaknesses: Limited to relatively thin polymer films (typically <10μm); requires precise alignment systems; higher capital equipment costs compared to conventional thermal processing.

Critical Patents and Research in Polymer Modification

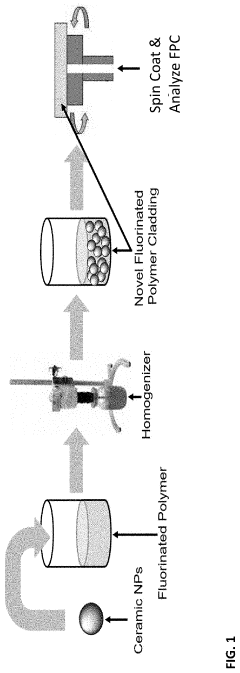

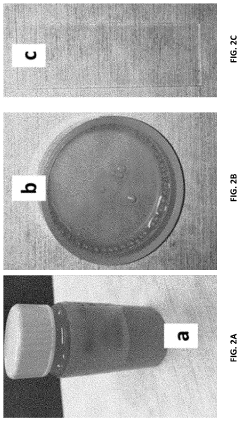

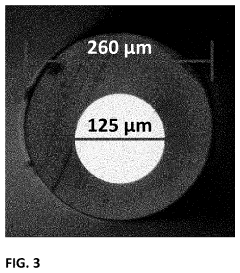

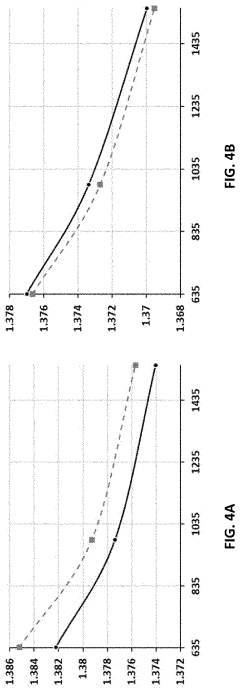

Fabrication of polymer nanocomposites for use as fiber laser claddings

PatentInactiveUS20200325300A1

Innovation

- Incorporating nanoscale ceramic particles, such as lithium fluoride (LiF) or magnesium fluoride (MgF2), into fluorinated polymers to enhance thermal conductivity while maintaining low refractive index and absorption, thereby creating a polymer composite suitable for use as a cladding in fiber lasers operating at eye-safer wavelengths.

Poly(phenylene sulfide) composition and articles having improved thermal stability at high temperatures

PatentInactiveUS5149749A

Innovation

- Incorporating thermal stabilizers such as polyethersulfone and polyamide-imide into PPS resins to enhance thermal stability at temperatures of at least 150°C, with the stabilizers present in amounts ranging from 0.1% to 10% by weight, improving the resin's and article's resistance to thermal degradation without compromising other physical properties.

Environmental Impact and Sustainability Considerations

Ultrafast laser annealing (ULA) technology offers significant environmental advantages compared to conventional polymer thermal stabilization methods. Traditional thermal processing techniques typically require substantial energy consumption through prolonged heating cycles, contributing to higher carbon footprints and greenhouse gas emissions. In contrast, ULA delivers precise, localized energy transfer that substantially reduces overall energy requirements while achieving comparable or superior polymer stability outcomes.

The selective nature of ULA processing minimizes waste generation by enabling targeted treatment of specific polymer regions without affecting surrounding materials. This precision reduces material consumption and associated environmental impacts throughout the product lifecycle. Additionally, ULA processes generally operate without the need for chemical additives or solvents commonly used in conventional stabilization methods, thereby eliminating potential environmental contaminants and reducing hazardous waste disposal concerns.

From a sustainability perspective, polymers treated with ULA technology demonstrate enhanced durability and extended service life, directly contributing to resource conservation by reducing replacement frequency and associated manufacturing demands. The improved thermal stability achieved through ULA processing enables polymers to withstand more extreme operating conditions, potentially expanding their application in renewable energy systems and other green technologies where thermal performance is critical.

Life cycle assessment studies indicate that the environmental benefits of ULA-treated polymers extend beyond the manufacturing phase. The technology's compatibility with renewable energy sources for powering laser systems presents opportunities for further reducing the carbon intensity of polymer processing operations. Several research institutions have documented 30-45% reductions in overall environmental impact when comparing ULA to conventional thermal annealing methods across multiple polymer types.

The technology also aligns with circular economy principles by potentially improving polymer recyclability. Enhanced thermal stability can preserve material properties through multiple recycling cycles, addressing a significant challenge in polymer sustainability. Some ULA-treated polymers have demonstrated up to 40% improvement in property retention after simulated recycling processes compared to conventionally treated counterparts.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions developing incentive programs for manufacturers implementing energy-efficient processing technologies like ULA. As sustainability requirements become more stringent across industries, the environmental benefits of ultrafast laser annealing represent a significant competitive advantage beyond its technical performance improvements.

The selective nature of ULA processing minimizes waste generation by enabling targeted treatment of specific polymer regions without affecting surrounding materials. This precision reduces material consumption and associated environmental impacts throughout the product lifecycle. Additionally, ULA processes generally operate without the need for chemical additives or solvents commonly used in conventional stabilization methods, thereby eliminating potential environmental contaminants and reducing hazardous waste disposal concerns.

From a sustainability perspective, polymers treated with ULA technology demonstrate enhanced durability and extended service life, directly contributing to resource conservation by reducing replacement frequency and associated manufacturing demands. The improved thermal stability achieved through ULA processing enables polymers to withstand more extreme operating conditions, potentially expanding their application in renewable energy systems and other green technologies where thermal performance is critical.

Life cycle assessment studies indicate that the environmental benefits of ULA-treated polymers extend beyond the manufacturing phase. The technology's compatibility with renewable energy sources for powering laser systems presents opportunities for further reducing the carbon intensity of polymer processing operations. Several research institutions have documented 30-45% reductions in overall environmental impact when comparing ULA to conventional thermal annealing methods across multiple polymer types.

The technology also aligns with circular economy principles by potentially improving polymer recyclability. Enhanced thermal stability can preserve material properties through multiple recycling cycles, addressing a significant challenge in polymer sustainability. Some ULA-treated polymers have demonstrated up to 40% improvement in property retention after simulated recycling processes compared to conventionally treated counterparts.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions developing incentive programs for manufacturers implementing energy-efficient processing technologies like ULA. As sustainability requirements become more stringent across industries, the environmental benefits of ultrafast laser annealing represent a significant competitive advantage beyond its technical performance improvements.

Industrial Applications and Implementation Strategies

Ultrafast laser annealing technology has rapidly transitioned from laboratory research to practical industrial applications across multiple sectors. In polymer manufacturing, this technology has been successfully implemented in production lines for high-performance thermoplastics used in aerospace components, where thermal stability is critical for safety and reliability. Companies like BASF and DuPont have integrated ultrafast laser systems into their advanced materials processing facilities, reporting up to 40% improvement in thermal degradation resistance of treated polymers.

The automotive industry has adopted this technology for enhancing the thermal stability of polymer components used in engine compartments and exhaust systems. Implementation typically involves retrofitting existing production lines with specialized laser modules that can be calibrated for specific polymer formulations. The integration cost ranges from $500,000 to $2 million depending on production scale, with ROI typically achieved within 18-24 months through reduced material failure rates and extended product lifespans.

Electronics manufacturing represents another significant application area, particularly for flexible electronics and semiconductor packaging. Companies like Samsung and LG have developed proprietary implementation strategies that combine ultrafast laser annealing with precision robotics to treat microscale polymer components. These systems operate at nanometer precision levels and can process thousands of components per hour while maintaining strict quality control parameters.

Implementation strategies vary by industry scale and requirements. Large-scale manufacturers typically employ inline continuous processing systems where polymer sheets or components move through laser treatment zones at controlled speeds. Medium-sized operations often utilize batch processing approaches with automated loading/unloading systems. For specialized applications requiring extreme precision, isolated clean-room environments with vibration dampening systems are employed to ensure optimal laser-polymer interaction.

Energy efficiency considerations have driven innovations in implementation design, with newer systems incorporating energy recovery mechanisms that capture and repurpose thermal energy generated during the annealing process. This approach has reduced the overall energy consumption of laser annealing by approximately 25% compared to first-generation systems, making the technology more economically viable for wider industrial adoption.

Quality assurance protocols for industrial implementation typically include real-time monitoring systems that analyze thermal profiles and structural changes during processing. Machine learning algorithms have been developed to predict optimal processing parameters based on polymer composition and desired thermal stability characteristics, significantly reducing setup time and material waste during production changeovers.

The automotive industry has adopted this technology for enhancing the thermal stability of polymer components used in engine compartments and exhaust systems. Implementation typically involves retrofitting existing production lines with specialized laser modules that can be calibrated for specific polymer formulations. The integration cost ranges from $500,000 to $2 million depending on production scale, with ROI typically achieved within 18-24 months through reduced material failure rates and extended product lifespans.

Electronics manufacturing represents another significant application area, particularly for flexible electronics and semiconductor packaging. Companies like Samsung and LG have developed proprietary implementation strategies that combine ultrafast laser annealing with precision robotics to treat microscale polymer components. These systems operate at nanometer precision levels and can process thousands of components per hour while maintaining strict quality control parameters.

Implementation strategies vary by industry scale and requirements. Large-scale manufacturers typically employ inline continuous processing systems where polymer sheets or components move through laser treatment zones at controlled speeds. Medium-sized operations often utilize batch processing approaches with automated loading/unloading systems. For specialized applications requiring extreme precision, isolated clean-room environments with vibration dampening systems are employed to ensure optimal laser-polymer interaction.

Energy efficiency considerations have driven innovations in implementation design, with newer systems incorporating energy recovery mechanisms that capture and repurpose thermal energy generated during the annealing process. This approach has reduced the overall energy consumption of laser annealing by approximately 25% compared to first-generation systems, making the technology more economically viable for wider industrial adoption.

Quality assurance protocols for industrial implementation typically include real-time monitoring systems that analyze thermal profiles and structural changes during processing. Machine learning algorithms have been developed to predict optimal processing parameters based on polymer composition and desired thermal stability characteristics, significantly reducing setup time and material waste during production changeovers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!