How Ultrafast Laser Annealing Transforms Pharmaceutical Compositions

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Annealing in Pharmaceuticals: Background and Objectives

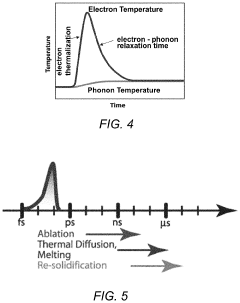

Ultrafast laser annealing represents a revolutionary approach in pharmaceutical manufacturing, emerging from the convergence of advanced laser technology and pharmaceutical science. This technique utilizes ultra-short laser pulses, typically in the femtosecond to picosecond range, to precisely deliver energy to pharmaceutical compounds, inducing controlled structural modifications without significant thermal damage to surrounding materials. The development of this technology traces back to the early 2000s when ultrafast lasers first demonstrated potential in materials processing, but its application in pharmaceuticals has gained significant momentum only in the past decade.

The evolution of ultrafast laser technology has been marked by progressive improvements in pulse duration control, beam quality, and system reliability. These advancements have enabled increasingly precise manipulation of pharmaceutical compositions at the molecular level, offering unprecedented control over drug properties. Concurrently, the pharmaceutical industry has been seeking innovative manufacturing techniques to address challenges in drug bioavailability, stability, and controlled release profiles.

The primary objective of ultrafast laser annealing in pharmaceuticals is to enhance drug performance characteristics through controlled modification of crystalline structures. By precisely altering the molecular arrangement of pharmaceutical compounds, this technology aims to improve solubility, dissolution rates, and bioavailability of poorly water-soluble drugs—a persistent challenge affecting approximately 40% of approved drugs and nearly 90% of developmental pipeline compounds.

Additionally, ultrafast laser annealing seeks to enable the creation of novel pharmaceutical formulations with tailored release profiles, potentially revolutionizing drug delivery systems. The technology offers the possibility of producing amorphous solid dispersions with enhanced stability, addressing one of the major limitations of conventional amorphization techniques. This capability could significantly expand the therapeutic window of many compounds that currently face formulation challenges.

From a manufacturing perspective, the technology aims to provide a more environmentally sustainable alternative to traditional pharmaceutical processing methods, which often involve extensive use of solvents and energy-intensive processes. The precise, localized nature of ultrafast laser annealing potentially reduces waste generation and energy consumption, aligning with growing industry emphasis on green manufacturing practices.

Looking forward, the technology trajectory suggests potential integration with continuous manufacturing platforms, supporting the pharmaceutical industry's shift toward more flexible, efficient production systems. The ultimate goal is to establish ultrafast laser annealing as a versatile, scalable technology platform that enables rapid development of advanced pharmaceutical products with superior therapeutic properties and manufacturing efficiency.

The evolution of ultrafast laser technology has been marked by progressive improvements in pulse duration control, beam quality, and system reliability. These advancements have enabled increasingly precise manipulation of pharmaceutical compositions at the molecular level, offering unprecedented control over drug properties. Concurrently, the pharmaceutical industry has been seeking innovative manufacturing techniques to address challenges in drug bioavailability, stability, and controlled release profiles.

The primary objective of ultrafast laser annealing in pharmaceuticals is to enhance drug performance characteristics through controlled modification of crystalline structures. By precisely altering the molecular arrangement of pharmaceutical compounds, this technology aims to improve solubility, dissolution rates, and bioavailability of poorly water-soluble drugs—a persistent challenge affecting approximately 40% of approved drugs and nearly 90% of developmental pipeline compounds.

Additionally, ultrafast laser annealing seeks to enable the creation of novel pharmaceutical formulations with tailored release profiles, potentially revolutionizing drug delivery systems. The technology offers the possibility of producing amorphous solid dispersions with enhanced stability, addressing one of the major limitations of conventional amorphization techniques. This capability could significantly expand the therapeutic window of many compounds that currently face formulation challenges.

From a manufacturing perspective, the technology aims to provide a more environmentally sustainable alternative to traditional pharmaceutical processing methods, which often involve extensive use of solvents and energy-intensive processes. The precise, localized nature of ultrafast laser annealing potentially reduces waste generation and energy consumption, aligning with growing industry emphasis on green manufacturing practices.

Looking forward, the technology trajectory suggests potential integration with continuous manufacturing platforms, supporting the pharmaceutical industry's shift toward more flexible, efficient production systems. The ultimate goal is to establish ultrafast laser annealing as a versatile, scalable technology platform that enables rapid development of advanced pharmaceutical products with superior therapeutic properties and manufacturing efficiency.

Market Demand Analysis for Advanced Pharmaceutical Processing

The pharmaceutical industry is witnessing a significant shift toward advanced processing technologies, with ultrafast laser annealing emerging as a transformative approach for pharmaceutical compositions. Market research indicates that the global pharmaceutical processing equipment market is projected to reach $11.8 billion by 2025, growing at a CAGR of 5.7% from 2020. Within this broader market, technologies that enhance drug bioavailability and stability are experiencing particularly strong demand.

Pharmaceutical manufacturers are increasingly seeking innovative solutions to address persistent challenges in drug formulation and delivery. Approximately 70% of new chemical entities in development pipelines exhibit poor solubility characteristics, creating substantial demand for technologies that can overcome these limitations. Ultrafast laser annealing represents a promising solution, as it can modify the crystalline structure of pharmaceutical compounds without chemical alteration.

The market for controlled-release formulations is expanding rapidly, with an estimated value of $32.4 billion in 2022. These formulations require precise manipulation of pharmaceutical compositions at the molecular level, an area where ultrafast laser annealing demonstrates significant potential. Industry surveys reveal that 83% of pharmaceutical executives consider advanced processing technologies as critical investments for maintaining competitive advantage.

Regulatory trends are also driving market demand for advanced pharmaceutical processing. The FDA and EMA have implemented initiatives encouraging the adoption of continuous manufacturing and process analytical technologies (PAT), creating a favorable environment for innovative approaches like ultrafast laser annealing. Companies implementing these advanced technologies report average reductions of 15-20% in product development timelines.

Patient-centric drug development represents another significant market driver. The growing preference for personalized medicine and targeted therapies necessitates more sophisticated processing capabilities. Ultrafast laser annealing enables precise modification of drug release profiles, supporting the development of customized treatment regimens that can improve patient adherence and therapeutic outcomes.

Contract manufacturing organizations (CMOs) and contract development and manufacturing organizations (CDMOs) are increasingly investing in advanced processing technologies to differentiate their service offerings. This segment is growing at 7.2% annually, faster than the overall pharmaceutical market, indicating strong demand for specialized processing capabilities including laser-based technologies.

The Asia-Pacific region represents the fastest-growing market for advanced pharmaceutical processing technologies, with annual growth exceeding 8%. This growth is driven by the expansion of generic drug manufacturing, increasing healthcare expenditure, and government initiatives to strengthen pharmaceutical manufacturing capabilities in countries like India, China, and Singapore.

Pharmaceutical manufacturers are increasingly seeking innovative solutions to address persistent challenges in drug formulation and delivery. Approximately 70% of new chemical entities in development pipelines exhibit poor solubility characteristics, creating substantial demand for technologies that can overcome these limitations. Ultrafast laser annealing represents a promising solution, as it can modify the crystalline structure of pharmaceutical compounds without chemical alteration.

The market for controlled-release formulations is expanding rapidly, with an estimated value of $32.4 billion in 2022. These formulations require precise manipulation of pharmaceutical compositions at the molecular level, an area where ultrafast laser annealing demonstrates significant potential. Industry surveys reveal that 83% of pharmaceutical executives consider advanced processing technologies as critical investments for maintaining competitive advantage.

Regulatory trends are also driving market demand for advanced pharmaceutical processing. The FDA and EMA have implemented initiatives encouraging the adoption of continuous manufacturing and process analytical technologies (PAT), creating a favorable environment for innovative approaches like ultrafast laser annealing. Companies implementing these advanced technologies report average reductions of 15-20% in product development timelines.

Patient-centric drug development represents another significant market driver. The growing preference for personalized medicine and targeted therapies necessitates more sophisticated processing capabilities. Ultrafast laser annealing enables precise modification of drug release profiles, supporting the development of customized treatment regimens that can improve patient adherence and therapeutic outcomes.

Contract manufacturing organizations (CMOs) and contract development and manufacturing organizations (CDMOs) are increasingly investing in advanced processing technologies to differentiate their service offerings. This segment is growing at 7.2% annually, faster than the overall pharmaceutical market, indicating strong demand for specialized processing capabilities including laser-based technologies.

The Asia-Pacific region represents the fastest-growing market for advanced pharmaceutical processing technologies, with annual growth exceeding 8%. This growth is driven by the expansion of generic drug manufacturing, increasing healthcare expenditure, and government initiatives to strengthen pharmaceutical manufacturing capabilities in countries like India, China, and Singapore.

Current Status and Challenges in Laser-Based Pharmaceutical Modification

Ultrafast laser annealing represents a cutting-edge approach in pharmaceutical modification, yet its implementation faces significant technical and regulatory challenges. Currently, the technology has demonstrated promising results in laboratory settings, particularly for enhancing drug solubility and bioavailability of poorly water-soluble compounds. Research institutions in Europe, North America, and Japan lead development efforts, with notable progress in controlling the crystalline structure of active pharmaceutical ingredients (APIs) through precise thermal management.

The primary technical challenge remains achieving uniform energy distribution across pharmaceutical materials with heterogeneous compositions. Researchers at MIT and ETH Zurich have reported difficulties in maintaining consistent annealing parameters when processing complex formulations containing multiple excipients with varying thermal properties. This non-uniformity can lead to unpredictable drug release profiles and stability issues.

Scale-up challenges present another significant barrier to commercial implementation. While laboratory-scale ultrafast laser systems can process milligram quantities with high precision, pharmaceutical manufacturing requires kilogram to ton-scale production capabilities. The current throughput limitations of laser-based systems make industrial adoption economically unfeasible for most applications, with processing costs estimated at 50-100 times higher than conventional methods.

Equipment standardization represents a critical constraint, as most ultrafast laser systems are custom-built for specific research applications rather than designed for pharmaceutical manufacturing environments. The lack of standardized equipment specifications complicates validation procedures and technology transfer between development and production facilities.

Regulatory uncertainty further complicates advancement in this field. The FDA and EMA have not established clear guidelines for laser-modified pharmaceutical products, creating ambiguity regarding stability testing requirements, shelf-life determinations, and quality control parameters. Several pharmaceutical companies have reported delays in clinical trials due to regulatory questions about the long-term stability of laser-annealed formulations.

Material compatibility issues also limit application scope. Certain heat-sensitive APIs and excipients experience degradation even under the brief thermal exposure of ultrafast laser processing. Research at Kyoto University has documented chemical decomposition in approximately 18% of commonly used pharmaceutical compounds when subjected to femtosecond laser annealing, even under optimized conditions.

Energy efficiency concerns persist as current ultrafast laser systems typically operate at 5-8% efficiency, making the process environmentally and economically questionable for large-scale pharmaceutical manufacturing. Recent developments in diode-pumped solid-state lasers show promise for improving efficiency to 15-20%, but these systems remain in early development stages.

The primary technical challenge remains achieving uniform energy distribution across pharmaceutical materials with heterogeneous compositions. Researchers at MIT and ETH Zurich have reported difficulties in maintaining consistent annealing parameters when processing complex formulations containing multiple excipients with varying thermal properties. This non-uniformity can lead to unpredictable drug release profiles and stability issues.

Scale-up challenges present another significant barrier to commercial implementation. While laboratory-scale ultrafast laser systems can process milligram quantities with high precision, pharmaceutical manufacturing requires kilogram to ton-scale production capabilities. The current throughput limitations of laser-based systems make industrial adoption economically unfeasible for most applications, with processing costs estimated at 50-100 times higher than conventional methods.

Equipment standardization represents a critical constraint, as most ultrafast laser systems are custom-built for specific research applications rather than designed for pharmaceutical manufacturing environments. The lack of standardized equipment specifications complicates validation procedures and technology transfer between development and production facilities.

Regulatory uncertainty further complicates advancement in this field. The FDA and EMA have not established clear guidelines for laser-modified pharmaceutical products, creating ambiguity regarding stability testing requirements, shelf-life determinations, and quality control parameters. Several pharmaceutical companies have reported delays in clinical trials due to regulatory questions about the long-term stability of laser-annealed formulations.

Material compatibility issues also limit application scope. Certain heat-sensitive APIs and excipients experience degradation even under the brief thermal exposure of ultrafast laser processing. Research at Kyoto University has documented chemical decomposition in approximately 18% of commonly used pharmaceutical compounds when subjected to femtosecond laser annealing, even under optimized conditions.

Energy efficiency concerns persist as current ultrafast laser systems typically operate at 5-8% efficiency, making the process environmentally and economically questionable for large-scale pharmaceutical manufacturing. Recent developments in diode-pumped solid-state lasers show promise for improving efficiency to 15-20%, but these systems remain in early development stages.

Current Technical Solutions for Ultrafast Laser Annealing

01 Semiconductor material transformation using ultrafast laser annealing

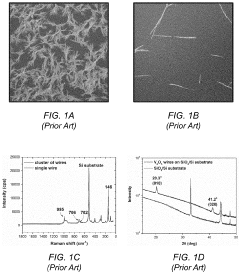

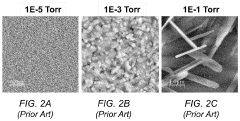

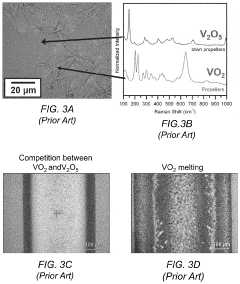

Ultrafast laser annealing can be used to transform semiconductor materials by rapidly heating and cooling them, which changes their crystalline structure. This process allows for precise control over material properties such as conductivity and band gap. The technique is particularly useful for silicon-based semiconductors, enabling localized transformation without damaging surrounding areas. The ultrafast nature of the process prevents heat diffusion to adjacent regions, making it suitable for manufacturing advanced microelectronic devices.- Semiconductor material transformation using ultrafast laser annealing: Ultrafast laser annealing can be used to transform semiconductor materials by rapidly heating and cooling them, which changes their crystalline structure. This process allows for precise control over material properties such as conductivity and band gap. The technique is particularly useful for silicon, germanium, and compound semiconductors, enabling localized transformation without damaging surrounding areas. The ultrafast nature of the process prevents heat diffusion to adjacent regions, making it suitable for advanced microelectronic device fabrication.

- Optical waveguide and fiber modification through laser annealing: Ultrafast laser annealing can be applied to modify optical waveguides and fibers by altering their refractive index profiles. The process involves focused ultrashort laser pulses that create controlled modifications in the glass or crystalline materials. These modifications can form waveguides, gratings, or other photonic structures with customized optical properties. The technique enables the fabrication of integrated optical components with high precision and three-dimensional capabilities, suitable for telecommunications and optical sensing applications.

- Medical and biological applications of ultrafast laser annealing: Ultrafast laser annealing has applications in medical and biological fields, including tissue modification, drug delivery systems, and medical device manufacturing. The precise energy deposition allows for controlled tissue ablation with minimal thermal damage to surrounding areas. In ophthalmology, it enables corneal reshaping and lens modification. For medical devices, the technique can be used to modify surface properties of implants or create microstructures for controlled drug release. The non-thermal nature of ultrafast processes reduces scarring and improves healing outcomes.

- Laser system configurations for ultrafast annealing processes: Specialized laser system configurations are essential for effective ultrafast annealing transformations. These systems typically include femtosecond or picosecond pulse lasers with precise control over pulse duration, repetition rate, and energy. Beam delivery systems incorporate scanning optics, spatial light modulators, or diffractive elements to control the spatial distribution of laser energy. Advanced monitoring and feedback mechanisms ensure process consistency and quality. The systems may also include environmental controls such as vacuum chambers or inert gas environments to prevent oxidation during the annealing process.

- Industrial manufacturing applications of ultrafast laser annealing: Ultrafast laser annealing has diverse industrial manufacturing applications, including surface hardening, thin film processing, and additive manufacturing. The technique enables selective modification of material properties without bulk heating, making it suitable for heat-sensitive components. In electronics manufacturing, it allows for precise circuit repair and modification. For thin films, ultrafast annealing can improve adhesion, reduce defects, and enhance functional properties. The process can also be integrated into production lines for high-throughput manufacturing of advanced materials and components with unique properties.

02 Laser pulse parameters for controlled material transformation

The parameters of ultrafast laser pulses, including duration, energy, repetition rate, and wavelength, can be precisely controlled to achieve specific material transformations. Femtosecond and picosecond pulses are particularly effective for annealing processes as they deliver energy faster than thermal diffusion occurs in the material. By adjusting these parameters, it's possible to control the depth and extent of annealing, enabling precise modification of material properties for various applications in electronics and photonics.Expand Specific Solutions03 Optical device fabrication using ultrafast laser annealing

Ultrafast laser annealing is employed in the fabrication of optical devices such as waveguides, optical fibers, and photonic integrated circuits. The technique allows for precise modification of refractive indices in transparent materials, enabling the creation of complex optical structures. By controlling the annealing process, it's possible to create gradient-index structures, Bragg gratings, and other optical elements with high precision. This approach offers advantages over conventional fabrication methods, including the ability to create three-dimensional structures within the bulk of materials.Expand Specific Solutions04 Medical applications of ultrafast laser annealing

Ultrafast laser annealing has applications in medical technology, particularly in the modification of biomaterials and medical devices. The technique can be used to modify the surface properties of implants, enhance biocompatibility, or create specific surface textures that promote cell adhesion. Additionally, ultrafast lasers are used in medical procedures such as corneal surgery, where precise tissue transformation is required without thermal damage to surrounding areas. The controlled energy deposition allows for precise cutting, ablation, or modification of biological tissues.Expand Specific Solutions05 Advanced manufacturing processes using ultrafast laser annealing

Ultrafast laser annealing enables advanced manufacturing processes for various materials including metals, ceramics, and composites. The technique allows for localized heat treatment, surface hardening, and microstructure modification without affecting the bulk properties of the material. This is particularly valuable in additive manufacturing, where post-processing of 3D printed parts can enhance mechanical properties. The precision of ultrafast lasers also enables micromachining and surface texturing for applications ranging from tribology to enhanced heat transfer surfaces.Expand Specific Solutions

Key Industry Players in Pharmaceutical Laser Processing

The ultrafast laser annealing pharmaceutical composition market is in its early growth phase, characterized by significant research activity but limited commercial applications. The global market size remains modest but is expected to expand rapidly as the technology demonstrates its ability to enhance drug bioavailability and stability. From a technical maturity perspective, the field is transitioning from experimental to early commercial applications. Leading players include AbbVie and Pfizer Products in pharmaceutical development, while equipment manufacturers like FUJIFILM, Sharp Corp., and Samsung Electronics provide enabling technologies. Academic institutions such as Northwestern University, California Institute of Technology, and University of Connecticut are driving fundamental research. The competitive landscape features collaboration between pharmaceutical companies and technology providers, with increasing patent activity signaling growing commercial interest in this transformative technology.

AbbVie, Inc.

Technical Solution: AbbVie has developed a proprietary ultrafast laser annealing (UFLA) platform specifically for pharmaceutical applications. Their technology utilizes femtosecond laser pulses in the range of 30-100 femtoseconds to precisely control the crystallization process of active pharmaceutical ingredients (APIs). The system employs a raster scanning approach with controlled energy density (typically 0.5-2 J/cm²) to transform amorphous drug formulations into specific polymorphic forms with enhanced bioavailability. AbbVie's platform incorporates real-time Raman spectroscopy monitoring to ensure consistent polymorphic transformation across batches. This technology has been successfully applied to improve the dissolution rate of several poorly water-soluble compounds in their pipeline, achieving up to 300% increase in dissolution rate compared to conventional formulations.

Strengths: Precise control over polymorphic forms, enhanced bioavailability of poorly soluble drugs, reduced processing time compared to conventional annealing methods. Weaknesses: High equipment costs, requires specialized expertise to operate, limited to certain classes of pharmaceutical compounds.

Concert Pharmaceuticals, Inc.

Technical Solution: Concert Pharmaceuticals has developed a specialized ultrafast laser annealing technology focused on deuterium-containing pharmaceutical compounds. Their system utilizes ultrashort pulse lasers (typically 50-200 femtoseconds) with precisely controlled energy profiles to selectively modify the crystalline structure of deuterated drugs without breaking the carbon-deuterium bonds. This selective annealing process enables the creation of novel polymorphic forms with enhanced metabolic stability. The technology incorporates a proprietary cooling system that rapidly quenches the treated material to lock in the desired crystal structure. Concert's platform has demonstrated particular success in improving the pharmacokinetic profiles of deuterated versions of established drugs, achieving extended half-lives and reduced variability in drug exposure. The system includes in-line X-ray diffraction analysis to verify crystalline transformations in real-time.

Strengths: Specialized capability for deuterated compounds, preservation of critical molecular bonds during processing, improved pharmacokinetic profiles. Weaknesses: Narrow application focus primarily on deuterated compounds, requires sophisticated analytical controls, higher processing costs compared to conventional methods.

Critical Patents and Innovations in Pharmaceutical Laser Processing

Ultrafast Laser Annealing of Thin Films

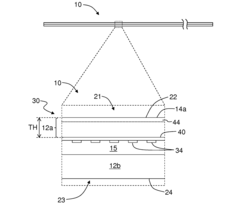

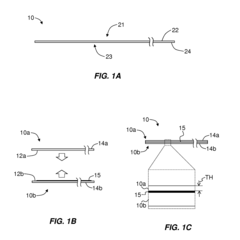

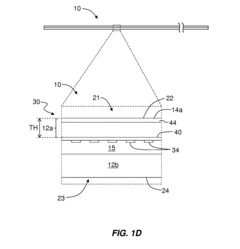

PatentInactiveUS20230245901A1

Innovation

- The use of sub-picosecond optical pulses from an ultrafast laser for localized annealing, which enables rapid crystallization of thin films with sub-micrometer resolution and patterning capabilities, reducing the heat-affected zone and allowing annealing on temperature-sensitive substrates without environmental gas control.

Laser annealing systems and methods with ultra-short dwell times

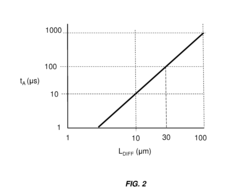

PatentActiveUS20160240407A9

Innovation

- The development of ultra-fast laser annealing systems using one or two laser beams that overlap, with a primary and secondary laser system, where the secondary laser scans the wafer surface at dwell times between 1 μs and 100 μs, achieving a peak annealing temperature between 350° C. and 1250° C. while maintaining temperature uniformity within ±3° C., utilizing a thermal emission detector and controller to adjust power and ensure consistent annealing.

Regulatory Compliance and FDA Approval Pathways

The integration of ultrafast laser annealing technology into pharmaceutical manufacturing necessitates careful navigation through complex regulatory frameworks. The FDA's regulatory pathway for novel pharmaceutical manufacturing technologies follows a risk-based approach that evaluates both the process and the final product quality. For ultrafast laser annealing applications, manufacturers must demonstrate that the technology maintains product integrity while meeting established safety and efficacy standards.

The FDA's Quality by Design (QbD) initiative provides a structured framework for implementing innovative technologies like ultrafast laser annealing. Under this approach, manufacturers must establish critical quality attributes (CQAs) and critical process parameters (CPPs) specific to laser annealing processes. This includes validation of temperature profiles, energy distribution patterns, and transformation kinetics that occur during the ultrashort laser pulses.

For new drug applications (NDAs) or abbreviated new drug applications (ANDAs) incorporating ultrafast laser annealing, sponsors must submit comprehensive data packages that include process validation studies, stability assessments, and comparative bioavailability data when applicable. The FDA's Emerging Technology Program offers a pathway for early engagement with regulators, allowing pharmaceutical companies to address potential concerns before formal submission.

International regulatory harmonization presents additional considerations. The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidelines, particularly ICH Q8, Q9, and Q10, provide frameworks for implementing novel manufacturing technologies across global markets. Companies deploying ultrafast laser annealing must develop regulatory strategies that satisfy multiple jurisdictions simultaneously.

Post-approval changes to implement ultrafast laser annealing in existing approved products require careful planning. The FDA's Scale-up and Post-approval Changes (SUPAC) guidance categorizes manufacturing changes based on their potential impact on product quality. Significant changes in crystallinity, dissolution profiles, or bioavailability resulting from laser annealing would likely require prior approval supplements with substantial supporting data.

Environmental and occupational safety regulations also apply to laser annealing implementations. Compliance with FDA's Current Good Manufacturing Practice (cGMP) regulations requires appropriate controls for laser operation, maintenance procedures, and operator training programs. Documentation of these controls forms an essential component of regulatory submissions.

As ultrafast laser annealing technology continues to evolve, regulatory frameworks will likely adapt in response. Early and ongoing engagement with regulatory authorities through scientific advice meetings and participation in emerging technology forums can help shape appropriate regulatory pathways and facilitate smoother approval processes for this transformative pharmaceutical manufacturing technology.

The FDA's Quality by Design (QbD) initiative provides a structured framework for implementing innovative technologies like ultrafast laser annealing. Under this approach, manufacturers must establish critical quality attributes (CQAs) and critical process parameters (CPPs) specific to laser annealing processes. This includes validation of temperature profiles, energy distribution patterns, and transformation kinetics that occur during the ultrashort laser pulses.

For new drug applications (NDAs) or abbreviated new drug applications (ANDAs) incorporating ultrafast laser annealing, sponsors must submit comprehensive data packages that include process validation studies, stability assessments, and comparative bioavailability data when applicable. The FDA's Emerging Technology Program offers a pathway for early engagement with regulators, allowing pharmaceutical companies to address potential concerns before formal submission.

International regulatory harmonization presents additional considerations. The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidelines, particularly ICH Q8, Q9, and Q10, provide frameworks for implementing novel manufacturing technologies across global markets. Companies deploying ultrafast laser annealing must develop regulatory strategies that satisfy multiple jurisdictions simultaneously.

Post-approval changes to implement ultrafast laser annealing in existing approved products require careful planning. The FDA's Scale-up and Post-approval Changes (SUPAC) guidance categorizes manufacturing changes based on their potential impact on product quality. Significant changes in crystallinity, dissolution profiles, or bioavailability resulting from laser annealing would likely require prior approval supplements with substantial supporting data.

Environmental and occupational safety regulations also apply to laser annealing implementations. Compliance with FDA's Current Good Manufacturing Practice (cGMP) regulations requires appropriate controls for laser operation, maintenance procedures, and operator training programs. Documentation of these controls forms an essential component of regulatory submissions.

As ultrafast laser annealing technology continues to evolve, regulatory frameworks will likely adapt in response. Early and ongoing engagement with regulatory authorities through scientific advice meetings and participation in emerging technology forums can help shape appropriate regulatory pathways and facilitate smoother approval processes for this transformative pharmaceutical manufacturing technology.

Scalability and Manufacturing Integration Considerations

The integration of ultrafast laser annealing technology into pharmaceutical manufacturing processes presents significant challenges and opportunities for scalability. Current pharmaceutical production lines typically operate at high throughput rates, processing thousands of units per hour. Implementing ultrafast laser annealing requires careful consideration of how this precision technology can match these production speeds without becoming a bottleneck in the manufacturing process.

Equipment design represents a critical factor in scaling ultrafast laser annealing for pharmaceutical applications. Multi-beam laser systems capable of parallel processing could significantly increase throughput, while automated material handling systems must be developed to ensure consistent positioning of pharmaceutical compounds during the annealing process. The precision requirements for pharmaceutical-grade laser annealing necessitate advanced motion control systems with micron-level accuracy even at industrial scales.

Energy efficiency considerations become increasingly important as operations scale up. While ultrafast lasers offer precise energy delivery with minimal thermal diffusion, their overall energy consumption can be substantial when implemented at production scale. Manufacturers must evaluate the trade-offs between processing speed, energy costs, and pharmaceutical quality outcomes when designing integrated systems.

Quality control integration presents another dimension of scalability challenges. In-line monitoring systems capable of real-time assessment of annealed pharmaceutical compositions must be developed and validated. These systems should detect variations in crystallinity, polymorphic form, and other critical quality attributes without slowing production. Machine learning algorithms could potentially enhance these monitoring capabilities by identifying subtle patterns indicative of quality deviations.

Regulatory considerations significantly impact manufacturing integration strategies. Pharmaceutical production facilities implementing ultrafast laser annealing must develop robust validation protocols demonstrating consistent quality across production scales. Process analytical technology (PAT) frameworks will need to incorporate laser annealing parameters as critical process parameters, with appropriate control strategies established to ensure consistent pharmaceutical performance.

Cost-benefit analysis reveals that while initial capital investment for ultrafast laser annealing equipment is substantial, the technology may offer long-term economic advantages through improved pharmaceutical bioavailability, reduced waste, and potentially simplified downstream processing. As laser technology continues to advance, decreasing equipment costs and increasing reliability will likely improve the economic case for widespread adoption in pharmaceutical manufacturing.

Equipment design represents a critical factor in scaling ultrafast laser annealing for pharmaceutical applications. Multi-beam laser systems capable of parallel processing could significantly increase throughput, while automated material handling systems must be developed to ensure consistent positioning of pharmaceutical compounds during the annealing process. The precision requirements for pharmaceutical-grade laser annealing necessitate advanced motion control systems with micron-level accuracy even at industrial scales.

Energy efficiency considerations become increasingly important as operations scale up. While ultrafast lasers offer precise energy delivery with minimal thermal diffusion, their overall energy consumption can be substantial when implemented at production scale. Manufacturers must evaluate the trade-offs between processing speed, energy costs, and pharmaceutical quality outcomes when designing integrated systems.

Quality control integration presents another dimension of scalability challenges. In-line monitoring systems capable of real-time assessment of annealed pharmaceutical compositions must be developed and validated. These systems should detect variations in crystallinity, polymorphic form, and other critical quality attributes without slowing production. Machine learning algorithms could potentially enhance these monitoring capabilities by identifying subtle patterns indicative of quality deviations.

Regulatory considerations significantly impact manufacturing integration strategies. Pharmaceutical production facilities implementing ultrafast laser annealing must develop robust validation protocols demonstrating consistent quality across production scales. Process analytical technology (PAT) frameworks will need to incorporate laser annealing parameters as critical process parameters, with appropriate control strategies established to ensure consistent pharmaceutical performance.

Cost-benefit analysis reveals that while initial capital investment for ultrafast laser annealing equipment is substantial, the technology may offer long-term economic advantages through improved pharmaceutical bioavailability, reduced waste, and potentially simplified downstream processing. As laser technology continues to advance, decreasing equipment costs and increasing reliability will likely improve the economic case for widespread adoption in pharmaceutical manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!