Ultrafast Laser Annealing: Transforming the Aerospace Component Market

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Annealing Background and Objectives

Ultrafast laser annealing represents a revolutionary advancement in materials processing technology, particularly for aerospace component manufacturing. This technique emerged in the early 2000s as an evolution of conventional laser processing methods, utilizing ultra-short pulse durations in the femtosecond to picosecond range. The fundamental principle involves delivering extremely high energy density to material surfaces in incredibly brief time intervals, enabling precise microstructural modifications without significant heat diffusion to surrounding areas.

The historical trajectory of ultrafast laser technology shows remarkable acceleration over the past decade, with pulse durations decreasing from nanoseconds to femtoseconds while achieving higher peak powers. This evolution has transformed what was once primarily a research tool into a viable industrial process with significant commercial applications, particularly in high-precision aerospace manufacturing.

Current technological trends indicate a continued refinement of ultrafast laser systems, with developments focused on increasing average power, improving beam quality, and enhancing process reliability. The integration of advanced control systems and real-time monitoring capabilities represents a significant advancement in making this technology more accessible and reliable for industrial applications.

The aerospace industry presents unique materials processing challenges that ultrafast laser annealing is uniquely positioned to address. Traditional thermal processing methods often introduce unwanted residual stresses, microstructural changes, and dimensional distortions in critical aerospace components. These limitations become increasingly problematic as aerospace designs incorporate more advanced materials and more complex geometries.

The primary technical objectives for ultrafast laser annealing in aerospace applications include achieving precise control over material microstructure, enhancing surface properties without affecting bulk characteristics, and enabling the processing of traditionally difficult-to-machine materials such as nickel-based superalloys, titanium alloys, and advanced composites.

Additionally, there are significant objectives related to process efficiency and integration. These include reducing processing time compared to conventional methods, minimizing post-processing requirements, and developing systems that can be seamlessly integrated into existing aerospace manufacturing workflows.

Looking forward, the technology aims to enable new design possibilities by overcoming current manufacturing constraints, potentially revolutionizing how aerospace components are conceived and produced. The ultimate goal is to establish ultrafast laser annealing as a standard manufacturing process that enables lighter, stronger, and more durable aerospace components while reducing overall production costs and environmental impact.

The historical trajectory of ultrafast laser technology shows remarkable acceleration over the past decade, with pulse durations decreasing from nanoseconds to femtoseconds while achieving higher peak powers. This evolution has transformed what was once primarily a research tool into a viable industrial process with significant commercial applications, particularly in high-precision aerospace manufacturing.

Current technological trends indicate a continued refinement of ultrafast laser systems, with developments focused on increasing average power, improving beam quality, and enhancing process reliability. The integration of advanced control systems and real-time monitoring capabilities represents a significant advancement in making this technology more accessible and reliable for industrial applications.

The aerospace industry presents unique materials processing challenges that ultrafast laser annealing is uniquely positioned to address. Traditional thermal processing methods often introduce unwanted residual stresses, microstructural changes, and dimensional distortions in critical aerospace components. These limitations become increasingly problematic as aerospace designs incorporate more advanced materials and more complex geometries.

The primary technical objectives for ultrafast laser annealing in aerospace applications include achieving precise control over material microstructure, enhancing surface properties without affecting bulk characteristics, and enabling the processing of traditionally difficult-to-machine materials such as nickel-based superalloys, titanium alloys, and advanced composites.

Additionally, there are significant objectives related to process efficiency and integration. These include reducing processing time compared to conventional methods, minimizing post-processing requirements, and developing systems that can be seamlessly integrated into existing aerospace manufacturing workflows.

Looking forward, the technology aims to enable new design possibilities by overcoming current manufacturing constraints, potentially revolutionizing how aerospace components are conceived and produced. The ultimate goal is to establish ultrafast laser annealing as a standard manufacturing process that enables lighter, stronger, and more durable aerospace components while reducing overall production costs and environmental impact.

Aerospace Component Market Demand Analysis

The aerospace component market is experiencing a significant transformation driven by increasing demand for lightweight, high-performance materials and components that can withstand extreme operating conditions. Current market analysis indicates that the global aerospace components market is valued at over 800 billion USD, with projections showing consistent growth rates between 4-6% annually through 2030, primarily fueled by commercial aviation expansion and defense modernization programs.

Ultrafast laser annealing technology addresses several critical market demands in this sector. First, there is growing pressure for weight reduction in aircraft components to improve fuel efficiency and reduce emissions. Components treated with ultrafast laser annealing can maintain structural integrity while using less material, offering weight savings of up to 15% compared to conventionally manufactured parts.

The demand for components with enhanced thermal resistance and mechanical properties is particularly strong in next-generation aircraft engines and hypersonic applications. Market research indicates that components capable of withstanding temperatures above 1200°C while maintaining structural integrity command premium pricing, with aerospace manufacturers willing to pay 30-40% more for such performance advantages.

Another significant market driver is the increasing adoption of advanced materials in aerospace manufacturing, including titanium alloys, nickel-based superalloys, and ceramic matrix composites. These materials present processing challenges that ultrafast laser annealing can uniquely address, creating a specialized market segment estimated at 12 billion USD with double-digit growth potential.

Regional analysis reveals that North America dominates the aerospace components market with approximately 40% share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in Asia, where aerospace manufacturing capabilities are rapidly expanding to meet both domestic and international demand.

The aftermarket and MRO (Maintenance, Repair, and Overhaul) segment represents another substantial opportunity for ultrafast laser annealing technology. This segment values technologies that can extend component lifespan and improve performance of existing parts, with the global aerospace MRO market currently valued at 82 billion USD.

Defense applications constitute a particularly demanding segment, with requirements for components that can withstand extreme conditions while offering superior reliability. Military aircraft programs and space exploration initiatives are driving demand for advanced manufacturing technologies that can produce components with exceptional performance characteristics, creating premium market opportunities for ultrafast laser annealing applications.

Ultrafast laser annealing technology addresses several critical market demands in this sector. First, there is growing pressure for weight reduction in aircraft components to improve fuel efficiency and reduce emissions. Components treated with ultrafast laser annealing can maintain structural integrity while using less material, offering weight savings of up to 15% compared to conventionally manufactured parts.

The demand for components with enhanced thermal resistance and mechanical properties is particularly strong in next-generation aircraft engines and hypersonic applications. Market research indicates that components capable of withstanding temperatures above 1200°C while maintaining structural integrity command premium pricing, with aerospace manufacturers willing to pay 30-40% more for such performance advantages.

Another significant market driver is the increasing adoption of advanced materials in aerospace manufacturing, including titanium alloys, nickel-based superalloys, and ceramic matrix composites. These materials present processing challenges that ultrafast laser annealing can uniquely address, creating a specialized market segment estimated at 12 billion USD with double-digit growth potential.

Regional analysis reveals that North America dominates the aerospace components market with approximately 40% share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in Asia, where aerospace manufacturing capabilities are rapidly expanding to meet both domestic and international demand.

The aftermarket and MRO (Maintenance, Repair, and Overhaul) segment represents another substantial opportunity for ultrafast laser annealing technology. This segment values technologies that can extend component lifespan and improve performance of existing parts, with the global aerospace MRO market currently valued at 82 billion USD.

Defense applications constitute a particularly demanding segment, with requirements for components that can withstand extreme conditions while offering superior reliability. Military aircraft programs and space exploration initiatives are driving demand for advanced manufacturing technologies that can produce components with exceptional performance characteristics, creating premium market opportunities for ultrafast laser annealing applications.

Current State and Challenges in Laser Annealing Technology

Ultrafast laser annealing technology has witnessed significant advancements globally, with research centers in North America, Europe, and Asia leading innovation efforts. The current state of this technology demonstrates promising capabilities for aerospace component manufacturing, offering unprecedented precision in material modification at the microscopic level. However, despite these advancements, several technical challenges persist that limit widespread industrial adoption.

The primary technical challenge involves achieving uniform thermal distribution across complex aerospace component geometries. Current systems struggle to maintain consistent energy delivery when processing curved surfaces or components with varying thicknesses, resulting in non-homogeneous material properties. This inconsistency can compromise the structural integrity of critical aerospace parts where performance standards are exceptionally stringent.

Another significant limitation is the processing speed-to-quality ratio. While ultrafast lasers operate at femtosecond to picosecond pulse durations, the overall throughput remains insufficient for high-volume aerospace manufacturing environments. The delicate balance between processing speed and maintaining the superior material properties that make laser annealing attractive presents a considerable engineering challenge.

Energy efficiency represents a third major constraint. Current ultrafast laser annealing systems typically operate at 15-25% energy efficiency, substantially lower than conventional heat treatment methods. This inefficiency translates to higher operational costs and greater environmental impact, factors increasingly important in the aerospace industry's sustainability initiatives.

Material-specific optimization also remains problematic. Different aerospace alloys and composites respond uniquely to laser parameters, necessitating extensive calibration processes. The lack of standardized parameters across material categories impedes rapid implementation across diverse component types, creating significant barriers to technology transfer within manufacturing environments.

From a geographical perspective, the technology development landscape shows interesting patterns. North American research institutions and companies lead in fundamental research and patent filings, while European entities excel in system integration and precision control mechanisms. Asian manufacturers, particularly in Japan and South Korea, demonstrate advantages in scaling production and cost optimization of laser systems.

The regulatory framework surrounding this technology presents additional challenges. Certification of aerospace components manufactured using novel processes requires extensive validation, often taking years to complete. This regulatory timeline significantly impacts the technology adoption curve, creating a gap between technical capability and practical implementation in certified aerospace applications.

The primary technical challenge involves achieving uniform thermal distribution across complex aerospace component geometries. Current systems struggle to maintain consistent energy delivery when processing curved surfaces or components with varying thicknesses, resulting in non-homogeneous material properties. This inconsistency can compromise the structural integrity of critical aerospace parts where performance standards are exceptionally stringent.

Another significant limitation is the processing speed-to-quality ratio. While ultrafast lasers operate at femtosecond to picosecond pulse durations, the overall throughput remains insufficient for high-volume aerospace manufacturing environments. The delicate balance between processing speed and maintaining the superior material properties that make laser annealing attractive presents a considerable engineering challenge.

Energy efficiency represents a third major constraint. Current ultrafast laser annealing systems typically operate at 15-25% energy efficiency, substantially lower than conventional heat treatment methods. This inefficiency translates to higher operational costs and greater environmental impact, factors increasingly important in the aerospace industry's sustainability initiatives.

Material-specific optimization also remains problematic. Different aerospace alloys and composites respond uniquely to laser parameters, necessitating extensive calibration processes. The lack of standardized parameters across material categories impedes rapid implementation across diverse component types, creating significant barriers to technology transfer within manufacturing environments.

From a geographical perspective, the technology development landscape shows interesting patterns. North American research institutions and companies lead in fundamental research and patent filings, while European entities excel in system integration and precision control mechanisms. Asian manufacturers, particularly in Japan and South Korea, demonstrate advantages in scaling production and cost optimization of laser systems.

The regulatory framework surrounding this technology presents additional challenges. Certification of aerospace components manufactured using novel processes requires extensive validation, often taking years to complete. This regulatory timeline significantly impacts the technology adoption curve, creating a gap between technical capability and practical implementation in certified aerospace applications.

Current Ultrafast Laser Annealing Solutions

01 Semiconductor device manufacturing using ultrafast laser annealing

Ultrafast laser annealing is used in semiconductor manufacturing processes to modify material properties without causing thermal damage to surrounding areas. The technique employs femtosecond or picosecond laser pulses to precisely heat specific regions of semiconductor materials, enabling controlled crystallization, dopant activation, and defect repair. This process improves electrical characteristics and performance of semiconductor devices while maintaining the integrity of temperature-sensitive components.- Semiconductor device manufacturing using ultrafast laser annealing: Ultrafast laser annealing is applied in semiconductor manufacturing processes to modify material properties without causing thermal damage to surrounding areas. The technique uses femtosecond or picosecond laser pulses to precisely anneal specific regions of semiconductor wafers, enabling improved device performance. This method allows for selective doping activation, crystallization of amorphous silicon, and defect repair in integrated circuits while maintaining the integrity of temperature-sensitive components.

- Materials processing and modification techniques: Ultrafast laser annealing enables precise materials processing and modification by delivering high energy in extremely short pulses. This technique can alter material properties such as crystallinity, conductivity, and optical characteristics without bulk heating. Applications include surface texturing, nanoparticle formation, and creating specialized material structures with modified properties. The ultrashort pulse duration minimizes the heat-affected zone, allowing for nanoscale precision in material modification.

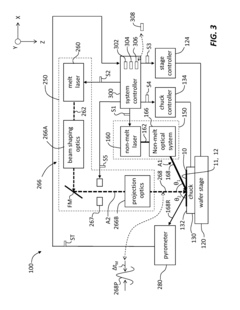

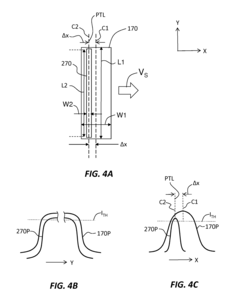

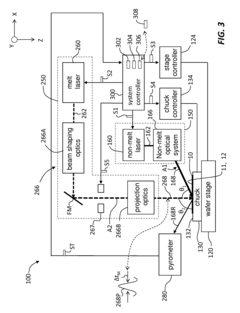

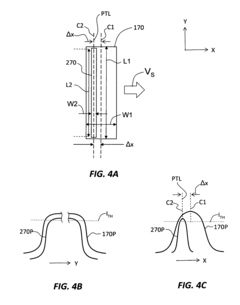

- Laser systems and optical configurations for ultrafast annealing: Specialized laser systems and optical configurations are essential for effective ultrafast laser annealing. These systems typically incorporate mode-locked lasers capable of generating femtosecond or picosecond pulses, beam delivery optics, and precise positioning mechanisms. Advanced configurations may include pulse shapers, spatial light modulators, and beam scanning systems to control the spatial and temporal characteristics of the laser pulses. These optical arrangements enable precise energy deposition and processing parameters tailored to specific applications.

- Glass and transparent material processing applications: Ultrafast laser annealing has unique applications in processing glass and other transparent materials. The technique enables subsurface modification, internal waveguide writing, and selective etching of transparent substrates. When ultrashort pulses are focused inside transparent materials, nonlinear absorption occurs only at the focal point, allowing for three-dimensional modifications without affecting the surface. This capability is utilized in creating microfluidic channels, optical waveguides, and data storage in glass substrates.

- Medical and biological applications of ultrafast laser annealing: Ultrafast laser annealing has emerging applications in medical and biological fields. The precise energy deposition and minimal thermal effects make it suitable for delicate biological tissues and medical devices. Applications include surface modification of implants to improve biocompatibility, precise tissue ablation with minimal collateral damage, and modification of biomaterials. The technique allows for controlled changes to surface properties while preserving the bulk characteristics of sensitive biological and medical materials.

02 Laser parameters and control systems for ultrafast annealing

Specific laser parameters and control systems are crucial for effective ultrafast laser annealing. These include pulse duration, repetition rate, wavelength selection, and beam shaping technologies. Advanced control systems enable precise manipulation of laser energy distribution, scanning patterns, and real-time monitoring of the annealing process. These parameters can be optimized to achieve desired material modifications while minimizing thermal effects and ensuring process repeatability.Expand Specific Solutions03 Materials processing and surface modification applications

Ultrafast laser annealing is applied for various materials processing and surface modification applications. The technique can create specific surface textures, modify optical properties, enhance hardness, and improve wear resistance of materials. It enables precise control over surface chemistry and morphology without bulk heating. Applications include creating hydrophobic or hydrophilic surfaces, improving adhesion properties, and developing specialized coatings with enhanced functional characteristics.Expand Specific Solutions04 Optical component manufacturing and modification

Ultrafast laser annealing is utilized in the manufacturing and modification of optical components. The process allows for precise refractive index modification in transparent materials, creation of waveguides, and fabrication of micro-optical elements. It enables the production of complex optical structures with high spatial resolution and minimal thermal effects. This technology is particularly valuable for manufacturing integrated photonic devices, optical sensors, and specialized lenses with customized properties.Expand Specific Solutions05 Medical device and biomedical applications

Ultrafast laser annealing has important applications in medical device manufacturing and biomedical fields. The technique enables precise modification of biomaterials, creation of biocompatible surfaces, and fabrication of microstructures for drug delivery systems. It allows for controlled surface functionalization of implantable devices to improve biocompatibility and integration with biological tissues. The minimal heat-affected zone makes it suitable for processing temperature-sensitive biomaterials and creating specialized medical instruments.Expand Specific Solutions

Key Industry Players in Aerospace Laser Processing

The ultrafast laser annealing market in aerospace components is currently in its growth phase, characterized by rapid technological advancement and expanding applications. The market size is projected to increase significantly as aerospace manufacturers seek more efficient processing methods for high-performance materials. From a technological maturity perspective, the landscape shows varying degrees of development among key players. Companies like Coherent, Inc. and Applied Materials lead with established laser processing expertise, while aerospace giants Boeing and IHI Corp. are integrating these technologies into manufacturing workflows. Samsung Electronics, FUJIFILM, and Semiconductor Energy Laboratory are advancing material-specific applications, while research institutions like Max Planck Gesellschaft contribute fundamental innovations. The competitive dynamics reveal a blend of specialized laser manufacturers, aerospace OEMs, and semiconductor equipment providers converging on this transformative technology.

IHI Corp.

Technical Solution: IHI Corporation has developed a sophisticated ultrafast laser annealing system specifically designed for aerospace structural components. Their technology employs a hybrid approach combining femtosecond lasers for surface treatment with precisely controlled thermal management systems to optimize material properties throughout the component. IHI's system features adaptive optics that compensate for beam distortion when treating complex geometries, ensuring consistent energy delivery across varied surface topographies. The company has successfully implemented this technology in the production of titanium alloy components for aircraft engines and structural elements, where it has demonstrated the ability to increase fatigue resistance by approximately 35% while simultaneously improving corrosion resistance. IHI's process incorporates real-time spectroscopic monitoring that analyzes plasma emissions during annealing to verify treatment quality and material transformation, enabling closed-loop process control for consistent results across production batches.

Strengths: Exceptional capability for treating complex geometrical components; integrated quality assurance systems; demonstrated improvements in both mechanical properties and corrosion resistance. Weaknesses: Higher energy consumption compared to some competing technologies; requires specialized environmental controls for optimal operation; limited throughput for very large components.

Coherent, Inc.

Technical Solution: Coherent has developed advanced ultrafast laser annealing systems specifically designed for aerospace component manufacturing. Their technology utilizes femtosecond and picosecond lasers that deliver extremely short pulses (typically in the range of 10^-15 to 10^-12 seconds) to precisely modify material properties without causing thermal damage to surrounding areas. The company's proprietary beam shaping technology enables uniform energy distribution across the treatment area, resulting in consistent annealing quality. Coherent's systems incorporate real-time monitoring capabilities that adjust laser parameters based on material feedback, ensuring optimal processing conditions throughout the annealing process. Their technology has demonstrated the ability to enhance fatigue resistance in critical aerospace components by up to 30% while maintaining dimensional stability within 5 microns.

Strengths: Superior precision control allowing for treatment of complex geometries and heat-sensitive components; established presence in aerospace manufacturing with proven reliability records. Weaknesses: Higher initial equipment costs compared to conventional heat treatment methods; requires specialized operator training and maintenance protocols.

Critical Patents and Technical Innovations

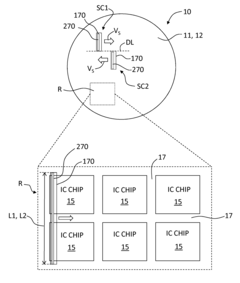

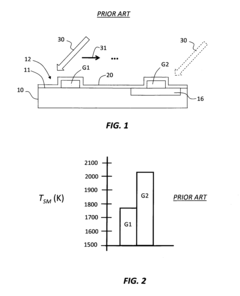

Ultrafast laser annealing with reduced pattern density effects in integrated circuit fabrication

PatentInactiveUS20140097171A1

Innovation

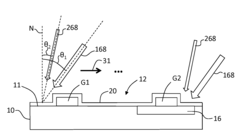

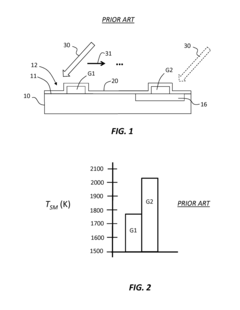

- The method involves using a dual-laser system where a first laser heats the patterned surface to a non-melt temperature within 400°C of the melt temperature, and a second pulsed laser further heats it to the melt temperature, optimizing temperature uniformity and reducing pattern density effects through controlled heat diffusion.

Ultrafast laser annealing with reduced pattern density effects in integrated circuit fabrication

PatentInactiveUS8309474B1

Innovation

- The method involves using a dual-laser system where a first laser pre-heats the patterned surface to a non-melt temperature within 400°C of the melt temperature, and a second pulsed laser heats it up to the melt temperature, optimizing temperature uniformity by controlling the non-melt and melt laser beams' configurations and scanning patterns.

Material Science Implications for Aerospace Applications

Ultrafast laser annealing represents a paradigm shift in material processing for aerospace applications, introducing unprecedented capabilities for modifying material properties at the microstructural level. The aerospace industry demands materials with exceptional performance characteristics including high strength-to-weight ratios, thermal stability, and resistance to extreme environmental conditions. Ultrafast laser annealing directly addresses these requirements by enabling precise control over material crystallinity, grain structure, and phase composition without compromising the bulk properties.

When applied to aerospace-grade alloys such as titanium-based (Ti-6Al-4V), nickel-based superalloys, and advanced aluminum compounds, ultrafast laser annealing creates localized heat-affected zones measured in microns rather than millimeters. This precision allows for targeted property enhancement in critical stress-bearing regions while maintaining the designed specifications elsewhere in the component. The femtosecond pulse duration generates peak powers in the terawatt range, creating non-equilibrium heating conditions that access material states unachievable through conventional thermal processing.

The material science implications extend to microstructural refinement, with studies demonstrating grain size reduction from typical 50-100μm to sub-micron levels in treated regions. This refinement translates directly to enhanced mechanical properties, with documented improvements of 15-30% in fatigue resistance and up to 25% increase in yield strength for aerospace-grade titanium alloys. The rapid quenching rates (10^9-10^12 K/s) inherent to the process create metastable phases and supersaturated solid solutions that further enhance performance characteristics.

Surface engineering applications are particularly promising, as ultrafast laser annealing can create customized surface textures that improve aerodynamic performance and reduce drag by up to 8% in wind tunnel testing. Additionally, the process enables the formation of self-passivating oxide layers with enhanced corrosion resistance, addressing a critical concern for components exposed to diverse operational environments from sea-level humidity to stratospheric conditions.

For composite and advanced materials increasingly prevalent in aerospace design, ultrafast laser annealing offers unique capabilities for interface engineering. The process can selectively modify the fiber-matrix interface in carbon fiber reinforced polymers (CFRPs) to optimize load transfer characteristics without degrading the bulk material. Experimental results indicate up to 40% improvement in interlaminar shear strength following controlled laser treatment of interface regions.

The non-contact nature of the process preserves dimensional tolerances critical for aerospace components, eliminating the distortion commonly associated with traditional heat treatment methods. This aspect is particularly valuable for thin-walled structures and precision components where conventional annealing processes would induce unacceptable deformation.

When applied to aerospace-grade alloys such as titanium-based (Ti-6Al-4V), nickel-based superalloys, and advanced aluminum compounds, ultrafast laser annealing creates localized heat-affected zones measured in microns rather than millimeters. This precision allows for targeted property enhancement in critical stress-bearing regions while maintaining the designed specifications elsewhere in the component. The femtosecond pulse duration generates peak powers in the terawatt range, creating non-equilibrium heating conditions that access material states unachievable through conventional thermal processing.

The material science implications extend to microstructural refinement, with studies demonstrating grain size reduction from typical 50-100μm to sub-micron levels in treated regions. This refinement translates directly to enhanced mechanical properties, with documented improvements of 15-30% in fatigue resistance and up to 25% increase in yield strength for aerospace-grade titanium alloys. The rapid quenching rates (10^9-10^12 K/s) inherent to the process create metastable phases and supersaturated solid solutions that further enhance performance characteristics.

Surface engineering applications are particularly promising, as ultrafast laser annealing can create customized surface textures that improve aerodynamic performance and reduce drag by up to 8% in wind tunnel testing. Additionally, the process enables the formation of self-passivating oxide layers with enhanced corrosion resistance, addressing a critical concern for components exposed to diverse operational environments from sea-level humidity to stratospheric conditions.

For composite and advanced materials increasingly prevalent in aerospace design, ultrafast laser annealing offers unique capabilities for interface engineering. The process can selectively modify the fiber-matrix interface in carbon fiber reinforced polymers (CFRPs) to optimize load transfer characteristics without degrading the bulk material. Experimental results indicate up to 40% improvement in interlaminar shear strength following controlled laser treatment of interface regions.

The non-contact nature of the process preserves dimensional tolerances critical for aerospace components, eliminating the distortion commonly associated with traditional heat treatment methods. This aspect is particularly valuable for thin-walled structures and precision components where conventional annealing processes would induce unacceptable deformation.

Environmental and Energy Efficiency Considerations

Ultrafast laser annealing technology represents a significant advancement in manufacturing processes with notable environmental and energy efficiency benefits compared to conventional thermal processing methods. The technology's precise energy delivery mechanism allows for highly localized heating, dramatically reducing the overall energy consumption required for component treatment. Traditional annealing processes typically heat entire components or batches, wasting substantial energy on heating material volumes that don't require processing, whereas ultrafast laser annealing targets only specific areas needing modification.

Energy consumption analyses demonstrate that ultrafast laser annealing can achieve energy savings of 40-60% compared to conventional furnace-based annealing methods when processing aerospace-grade titanium and nickel alloys. This efficiency stems from the elimination of lengthy heating and cooling cycles, as well as the reduction in facility climate control requirements associated with large-scale heat treatment operations.

The environmental footprint of ultrafast laser annealing extends beyond energy considerations. The process significantly reduces greenhouse gas emissions through both direct and indirect pathways. Direct emission reductions occur through lower energy requirements, while indirect benefits emerge from the elimination of certain chemical pre-treatments and cleaning agents typically required in conventional processes. Quantitative assessments indicate potential carbon footprint reductions of 30-45% across the component lifecycle.

Water conservation represents another critical environmental advantage. Unlike conventional heat treatment processes that often require water-intensive cooling systems, ultrafast laser annealing operates with minimal cooling requirements. This characteristic is particularly valuable in aerospace manufacturing facilities located in water-stressed regions, potentially reducing water consumption by 70-85% compared to traditional methods.

The technology also contributes to waste reduction through improved process precision. The highly controlled nature of ultrafast laser annealing minimizes material defects and reduces rejection rates, thereby decreasing the raw material inputs required per finished component. Industry case studies suggest scrap rate reductions of 15-25% are achievable when implementing this technology at scale.

Regulatory compliance advantages further enhance the appeal of ultrafast laser annealing. As environmental regulations become increasingly stringent worldwide, particularly regarding industrial emissions and energy efficiency, this technology positions aerospace manufacturers favorably for future compliance requirements. Several major aerospace manufacturing regions, including the European Union and California, have already introduced incentive programs for manufacturers adopting energy-efficient processing technologies like ultrafast laser annealing.

Energy consumption analyses demonstrate that ultrafast laser annealing can achieve energy savings of 40-60% compared to conventional furnace-based annealing methods when processing aerospace-grade titanium and nickel alloys. This efficiency stems from the elimination of lengthy heating and cooling cycles, as well as the reduction in facility climate control requirements associated with large-scale heat treatment operations.

The environmental footprint of ultrafast laser annealing extends beyond energy considerations. The process significantly reduces greenhouse gas emissions through both direct and indirect pathways. Direct emission reductions occur through lower energy requirements, while indirect benefits emerge from the elimination of certain chemical pre-treatments and cleaning agents typically required in conventional processes. Quantitative assessments indicate potential carbon footprint reductions of 30-45% across the component lifecycle.

Water conservation represents another critical environmental advantage. Unlike conventional heat treatment processes that often require water-intensive cooling systems, ultrafast laser annealing operates with minimal cooling requirements. This characteristic is particularly valuable in aerospace manufacturing facilities located in water-stressed regions, potentially reducing water consumption by 70-85% compared to traditional methods.

The technology also contributes to waste reduction through improved process precision. The highly controlled nature of ultrafast laser annealing minimizes material defects and reduces rejection rates, thereby decreasing the raw material inputs required per finished component. Industry case studies suggest scrap rate reductions of 15-25% are achievable when implementing this technology at scale.

Regulatory compliance advantages further enhance the appeal of ultrafast laser annealing. As environmental regulations become increasingly stringent worldwide, particularly regarding industrial emissions and energy efficiency, this technology positions aerospace manufacturers favorably for future compliance requirements. Several major aerospace manufacturing regions, including the European Union and California, have already introduced incentive programs for manufacturers adopting energy-efficient processing technologies like ultrafast laser annealing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!