The Impact of Ultrafast Laser Annealing on Energy Storage Solutions

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Annealing Technology Evolution and Objectives

Ultrafast laser annealing technology has evolved significantly over the past three decades, transforming from a niche laboratory technique to a commercially viable manufacturing process with profound implications for energy storage solutions. The technology originated in the 1990s when researchers first explored using ultrashort laser pulses for material modification, but remained largely experimental until the early 2000s when advances in laser systems enabled more precise control over pulse duration, energy, and repetition rates.

The evolution accelerated around 2010 when semiconductor manufacturers began adopting ultrafast laser annealing for specialized applications, demonstrating its potential for precise thermal processing without damaging surrounding materials. This capability proved crucial for developing next-generation energy storage materials, where nanoscale structural modifications can dramatically improve performance characteristics.

By 2015, researchers had established that ultrafast laser annealing could significantly enhance the electrochemical properties of various electrode materials, including lithium-ion battery components. The technique's ability to create controlled defects, increase crystallinity, and modify surface properties without bulk heating represented a paradigm shift in energy storage material processing.

The technology has since progressed through several key developmental phases: initial proof-of-concept demonstrations (2000-2010), early industrial adoption (2010-2015), optimization for energy storage applications (2015-2020), and current efforts toward scalable manufacturing integration (2020-present). Each phase has been characterized by increasing precision, processing speed, and energy efficiency of the laser systems themselves.

The primary objective of ultrafast laser annealing in energy storage applications is to overcome the fundamental limitations of conventional thermal processing methods. Specifically, the technology aims to enable selective modification of material properties at the nanoscale while maintaining overall structural integrity and avoiding thermal degradation of temperature-sensitive components.

Secondary objectives include developing scalable manufacturing processes that can transition from laboratory demonstrations to industrial production, reducing energy consumption in battery manufacturing, extending battery cycle life through improved electrode structures, and enabling the use of novel materials previously incompatible with conventional processing techniques.

Looking forward, the technology trajectory is focused on several ambitious goals: achieving precise control over phase transformations in complex multi-material systems, developing in-line process monitoring capabilities for quality control, reducing processing costs through higher throughput systems, and establishing standardized protocols for different energy storage chemistries. The ultimate aim is to enable a new generation of energy storage solutions with significantly higher energy density, faster charging capabilities, and longer operational lifetimes than currently possible with conventional manufacturing techniques.

The evolution accelerated around 2010 when semiconductor manufacturers began adopting ultrafast laser annealing for specialized applications, demonstrating its potential for precise thermal processing without damaging surrounding materials. This capability proved crucial for developing next-generation energy storage materials, where nanoscale structural modifications can dramatically improve performance characteristics.

By 2015, researchers had established that ultrafast laser annealing could significantly enhance the electrochemical properties of various electrode materials, including lithium-ion battery components. The technique's ability to create controlled defects, increase crystallinity, and modify surface properties without bulk heating represented a paradigm shift in energy storage material processing.

The technology has since progressed through several key developmental phases: initial proof-of-concept demonstrations (2000-2010), early industrial adoption (2010-2015), optimization for energy storage applications (2015-2020), and current efforts toward scalable manufacturing integration (2020-present). Each phase has been characterized by increasing precision, processing speed, and energy efficiency of the laser systems themselves.

The primary objective of ultrafast laser annealing in energy storage applications is to overcome the fundamental limitations of conventional thermal processing methods. Specifically, the technology aims to enable selective modification of material properties at the nanoscale while maintaining overall structural integrity and avoiding thermal degradation of temperature-sensitive components.

Secondary objectives include developing scalable manufacturing processes that can transition from laboratory demonstrations to industrial production, reducing energy consumption in battery manufacturing, extending battery cycle life through improved electrode structures, and enabling the use of novel materials previously incompatible with conventional processing techniques.

Looking forward, the technology trajectory is focused on several ambitious goals: achieving precise control over phase transformations in complex multi-material systems, developing in-line process monitoring capabilities for quality control, reducing processing costs through higher throughput systems, and establishing standardized protocols for different energy storage chemistries. The ultimate aim is to enable a new generation of energy storage solutions with significantly higher energy density, faster charging capabilities, and longer operational lifetimes than currently possible with conventional manufacturing techniques.

Market Demand Analysis for Advanced Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the pressing need for more efficient and sustainable energy management solutions. Current market projections indicate that the global energy storage market will reach approximately $546 billion by 2035, with a compound annual growth rate of 20-25% over the next decade. This remarkable growth trajectory underscores the critical importance of advanced energy storage technologies in the modern energy landscape.

Ultrafast laser annealing technology is emerging as a transformative innovation in the energy storage sector, particularly for enhancing battery performance and manufacturing efficiency. Market research indicates that industries are actively seeking solutions that can improve energy density, charging speeds, and overall battery lifespan - precisely the areas where ultrafast laser annealing shows significant promise.

The electric vehicle (EV) market represents one of the most substantial demand drivers for advanced energy storage solutions. With global EV sales projected to constitute over 30% of new vehicle sales by 2030, manufacturers are urgently seeking battery technologies that offer higher energy density, faster charging capabilities, and improved safety profiles. Ultrafast laser annealing processes can potentially address these requirements by enabling more precise control over electrode microstructure and interfaces.

Consumer electronics manufacturers are similarly expressing strong interest in next-generation energy storage solutions. The demand for longer-lasting, faster-charging, and more compact batteries continues to grow as devices become more powerful and feature-rich. Market surveys indicate that consumers consistently rank battery performance among their top three considerations when purchasing new electronic devices.

The renewable energy sector presents another significant market opportunity. As solar and wind power generation continues to expand globally, the need for efficient, large-scale energy storage solutions becomes increasingly critical. Grid-scale storage systems that can effectively manage intermittent renewable energy sources are projected to see demand growth exceeding 35% annually through 2030.

Industrial applications represent an often overlooked but substantial market segment. Manufacturing facilities, data centers, and telecommunications infrastructure all require reliable, high-performance energy storage solutions. The industrial sector's demand for advanced energy storage is expected to grow at 18% annually, driven by increasing electricity costs and the need for operational resilience.

Geographically, Asia-Pacific currently leads the market demand for advanced energy storage solutions, followed by North America and Europe. However, emerging markets in Latin America and Africa are showing accelerated growth rates as they invest in modernizing their energy infrastructure and leapfrogging to renewable energy technologies.

Ultrafast laser annealing technology is emerging as a transformative innovation in the energy storage sector, particularly for enhancing battery performance and manufacturing efficiency. Market research indicates that industries are actively seeking solutions that can improve energy density, charging speeds, and overall battery lifespan - precisely the areas where ultrafast laser annealing shows significant promise.

The electric vehicle (EV) market represents one of the most substantial demand drivers for advanced energy storage solutions. With global EV sales projected to constitute over 30% of new vehicle sales by 2030, manufacturers are urgently seeking battery technologies that offer higher energy density, faster charging capabilities, and improved safety profiles. Ultrafast laser annealing processes can potentially address these requirements by enabling more precise control over electrode microstructure and interfaces.

Consumer electronics manufacturers are similarly expressing strong interest in next-generation energy storage solutions. The demand for longer-lasting, faster-charging, and more compact batteries continues to grow as devices become more powerful and feature-rich. Market surveys indicate that consumers consistently rank battery performance among their top three considerations when purchasing new electronic devices.

The renewable energy sector presents another significant market opportunity. As solar and wind power generation continues to expand globally, the need for efficient, large-scale energy storage solutions becomes increasingly critical. Grid-scale storage systems that can effectively manage intermittent renewable energy sources are projected to see demand growth exceeding 35% annually through 2030.

Industrial applications represent an often overlooked but substantial market segment. Manufacturing facilities, data centers, and telecommunications infrastructure all require reliable, high-performance energy storage solutions. The industrial sector's demand for advanced energy storage is expected to grow at 18% annually, driven by increasing electricity costs and the need for operational resilience.

Geographically, Asia-Pacific currently leads the market demand for advanced energy storage solutions, followed by North America and Europe. However, emerging markets in Latin America and Africa are showing accelerated growth rates as they invest in modernizing their energy infrastructure and leapfrogging to renewable energy technologies.

Current State and Challenges in Laser Annealing for Energy Storage

Laser annealing technology has evolved significantly over the past decade, with ultrafast laser systems emerging as a transformative tool in energy storage material processing. Currently, the global landscape shows varying levels of technological maturity, with North America, Europe, and East Asia leading research and commercial applications. The United States and Germany dominate patent filings for ultrafast laser annealing techniques, while China has rapidly increased its research output in this domain over the past five years.

The primary technical challenges facing laser annealing for energy storage applications center around precision control, scalability, and material-specific optimization. Achieving uniform thermal distribution during the annealing process remains difficult, particularly for complex three-dimensional electrode structures and composite materials commonly used in advanced batteries. Temperature gradients can lead to inconsistent material properties and reduced performance in the final energy storage devices.

Another significant hurdle is the integration of ultrafast laser annealing into existing manufacturing processes. Current production lines for lithium-ion batteries and supercapacitors are optimized for conventional thermal treatment methods, making the transition to laser-based processes capital-intensive and technically complex. This integration challenge is compounded by the need for real-time monitoring systems capable of providing feedback during the ultrafast annealing process.

Material-specific challenges also persist, particularly for next-generation energy storage materials. Silicon anodes, solid-state electrolytes, and novel cathode materials each require tailored laser parameters, and the optimization process remains largely empirical rather than theoretical. The lack of comprehensive modeling tools that can accurately predict material behavior under ultrafast laser exposure limits systematic advancement in this field.

Energy efficiency presents another constraint, as high-power ultrafast laser systems consume significant electricity, potentially offsetting some of the sustainability benefits of improved energy storage devices. Current systems typically operate at 15-30% wall-plug efficiency, leaving substantial room for improvement.

Geographically, research centers in Massachusetts, California, Bavaria, and Shanghai have established specialized facilities for energy storage laser processing, creating regional clusters of expertise. However, knowledge transfer between academic research and industrial implementation remains fragmented, slowing the broader adoption of these advanced techniques.

Regulatory considerations also pose challenges, particularly regarding safety protocols for high-power laser systems in manufacturing environments and potential environmental impacts of laser-processed materials. These factors collectively contribute to the complex landscape of ultrafast laser annealing in energy storage applications, necessitating multidisciplinary approaches to overcome current limitations.

The primary technical challenges facing laser annealing for energy storage applications center around precision control, scalability, and material-specific optimization. Achieving uniform thermal distribution during the annealing process remains difficult, particularly for complex three-dimensional electrode structures and composite materials commonly used in advanced batteries. Temperature gradients can lead to inconsistent material properties and reduced performance in the final energy storage devices.

Another significant hurdle is the integration of ultrafast laser annealing into existing manufacturing processes. Current production lines for lithium-ion batteries and supercapacitors are optimized for conventional thermal treatment methods, making the transition to laser-based processes capital-intensive and technically complex. This integration challenge is compounded by the need for real-time monitoring systems capable of providing feedback during the ultrafast annealing process.

Material-specific challenges also persist, particularly for next-generation energy storage materials. Silicon anodes, solid-state electrolytes, and novel cathode materials each require tailored laser parameters, and the optimization process remains largely empirical rather than theoretical. The lack of comprehensive modeling tools that can accurately predict material behavior under ultrafast laser exposure limits systematic advancement in this field.

Energy efficiency presents another constraint, as high-power ultrafast laser systems consume significant electricity, potentially offsetting some of the sustainability benefits of improved energy storage devices. Current systems typically operate at 15-30% wall-plug efficiency, leaving substantial room for improvement.

Geographically, research centers in Massachusetts, California, Bavaria, and Shanghai have established specialized facilities for energy storage laser processing, creating regional clusters of expertise. However, knowledge transfer between academic research and industrial implementation remains fragmented, slowing the broader adoption of these advanced techniques.

Regulatory considerations also pose challenges, particularly regarding safety protocols for high-power laser systems in manufacturing environments and potential environmental impacts of laser-processed materials. These factors collectively contribute to the complex landscape of ultrafast laser annealing in energy storage applications, necessitating multidisciplinary approaches to overcome current limitations.

Current Ultrafast Laser Annealing Implementation Methodologies

01 Ultrafast laser annealing for energy storage materials

Ultrafast laser annealing techniques are applied to energy storage materials to enhance their properties. This process involves using short-duration laser pulses to rapidly heat and cool materials used in batteries, supercapacitors, and other energy storage devices. The annealing process can improve crystallinity, reduce defects, and enhance the electrochemical performance of these materials, leading to higher energy density, faster charging rates, and longer cycle life.- Ultrafast laser annealing for energy storage materials: Ultrafast laser annealing techniques can be applied to energy storage materials to enhance their properties. This process involves using short-duration laser pulses to rapidly heat and cool materials used in batteries, supercapacitors, and other energy storage devices. The controlled thermal treatment can improve crystallinity, reduce defects, and enhance the electrochemical performance of active materials, resulting in higher energy density and longer cycle life.

- Laser processing for semiconductor energy storage applications: Ultrafast laser annealing can be used to modify semiconductor materials for energy storage applications. The technique allows for precise control over the thermal treatment of semiconductor layers, enabling the formation of specific crystal structures and interfaces. This approach is particularly valuable for thin-film energy storage devices, where the quality of semiconductor junctions directly impacts charge storage capacity and transfer efficiency.

- Pulse control and energy management in laser annealing systems: Advanced control systems for ultrafast laser annealing enable precise energy delivery and management. These systems regulate pulse duration, frequency, and energy distribution to optimize the annealing process for different materials. By carefully controlling the laser parameters, it's possible to achieve uniform heating, prevent thermal damage, and ensure consistent material properties across the treated area, which is crucial for high-performance energy storage devices.

- Novel material structures created by ultrafast laser annealing: Ultrafast laser annealing can create unique material structures that enhance energy storage capabilities. The rapid heating and cooling rates achievable with ultrafast lasers allow for the formation of metastable phases and nanostructures that would be impossible to create using conventional heating methods. These novel structures can provide increased surface area, improved ion transport pathways, and enhanced electrical conductivity, all of which contribute to superior energy storage performance.

- Manufacturing processes integrating ultrafast laser annealing for energy devices: Manufacturing processes that incorporate ultrafast laser annealing can improve the production efficiency and quality of energy storage devices. These integrated approaches allow for selective treatment of specific components or layers within a device structure. The precision and speed of ultrafast laser processing make it compatible with roll-to-roll manufacturing and other high-throughput production methods, enabling cost-effective fabrication of advanced energy storage solutions.

02 Laser processing for semiconductor energy storage applications

Ultrafast laser annealing is utilized in semiconductor processing for energy storage applications. This technique enables precise modification of semiconductor materials used in energy storage devices, such as silicon anodes for lithium-ion batteries. The laser treatment can create nanostructures, modify surface properties, and improve the interface between different materials, resulting in enhanced charge storage capacity and improved electrical conductivity without causing thermal damage to surrounding areas.Expand Specific Solutions03 Pulsed laser annealing for thin film energy storage devices

Pulsed laser annealing is employed in the fabrication of thin film energy storage devices. This method uses ultrafast laser pulses to selectively anneal thin film materials without affecting the underlying substrate. The process enables the creation of high-quality thin film electrodes and electrolytes with improved crystallinity and reduced interfacial resistance. This technique is particularly valuable for flexible and miniaturized energy storage devices where conventional high-temperature annealing methods cannot be used.Expand Specific Solutions04 Laser-induced structural modifications for enhanced energy storage

Ultrafast laser annealing induces specific structural modifications in materials to enhance energy storage capabilities. The high-intensity, short-duration laser pulses can create controlled defects, phase transformations, and unique microstructures that are beneficial for energy storage. These structural changes can lead to increased surface area, improved ion diffusion pathways, and enhanced electron transport properties, resulting in superior energy storage performance compared to conventionally processed materials.Expand Specific Solutions05 Laser annealing systems for energy storage manufacturing

Specialized laser annealing systems are developed for the manufacturing of energy storage devices. These systems incorporate ultrafast lasers with precise control over pulse duration, energy, and beam characteristics to optimize the annealing process for different energy storage materials. Advanced features such as beam shaping, scanning patterns, and real-time monitoring enable scalable and efficient production of high-performance energy storage components with consistent quality and reduced processing time.Expand Specific Solutions

Key Industry Players in Ultrafast Laser and Energy Storage Sectors

The ultrafast laser annealing market for energy storage solutions is in a growth phase, characterized by increasing adoption across semiconductor and display industries. The market is expanding rapidly with projections indicating significant growth as energy storage technologies become more critical in renewable energy integration. Technologically, the field shows varying maturity levels, with established players like Applied Materials, Veeco Instruments, and Coherent leading commercial applications, while companies such as Semiconductor Energy Laboratory, Gigaphoton, and Shanghai Micro Electronics Equipment are advancing specialized implementations. Japanese and American firms currently dominate the landscape, though Chinese companies are making substantial investments to close the technology gap. The integration of ultrafast laser annealing with next-generation battery and capacitor manufacturing represents a promising frontier for further development.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has developed a proprietary ultrafast laser annealing technology called "Flash Crystal" specifically designed for energy storage applications. Their approach utilizes femtosecond laser pulses with precisely controlled energy distribution to selectively modify the crystalline structure of battery electrode materials without causing thermal damage to surrounding components. SEL's technology enables the creation of highly ordered nanostructures within electrode materials that significantly enhance ion diffusion pathways and electrical conductivity. Their process has demonstrated the ability to increase the capacity of silicon-based anodes by up to 40% while improving cycling stability through controlled formation of stress-relief microstructures. SEL has successfully implemented this technology in pilot production lines, achieving processing speeds of approximately 0.5 m²/min with exceptional uniformity. The company has also developed specialized beam delivery systems that enable annealing of complex three-dimensional electrode structures, opening new possibilities for advanced battery architectures.

Strengths: Exceptional precision in controlling crystallization processes at the nanoscale, enabling tailored material properties for specific energy storage requirements. Their technology allows for processing temperature-sensitive materials that cannot withstand conventional thermal annealing. Weaknesses: Currently limited to smaller production scales compared to some competitors, and requires highly specialized equipment that may present integration challenges for existing manufacturing lines.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced ultrafast laser annealing (ULA) technology specifically designed for energy storage applications. Their proprietary Precision Materials Engineering platform integrates femtosecond laser systems that deliver precisely controlled thermal energy to modify electrode materials at the nanoscale. This technology enables selective annealing of battery electrode materials, creating optimized crystalline structures and interfaces that enhance ion transport pathways. Their process can increase lithium-ion battery capacity by up to 30% while reducing charging times by 40% compared to conventional thermal annealing methods. Applied Materials' ULA systems operate at processing speeds exceeding 1 m²/min, making them viable for high-volume manufacturing environments. The company has demonstrated particular success in silicon-based anode materials, where ultrafast laser treatment creates controlled porosity that accommodates volume expansion during charging cycles, significantly extending battery lifespan.

Strengths: Industry-leading precision in thermal control allows for targeted material modification without damaging surrounding components. Their established semiconductor equipment expertise enables rapid scaling to production volumes. Weaknesses: The high capital equipment costs may limit adoption by smaller manufacturers, and the technology requires specialized expertise to optimize process parameters for different battery chemistries.

Critical Patents and Research in Ultrafast Laser Energy Applications

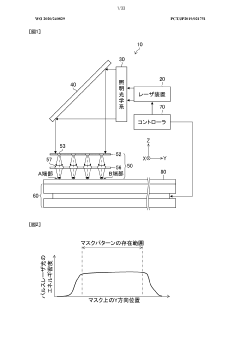

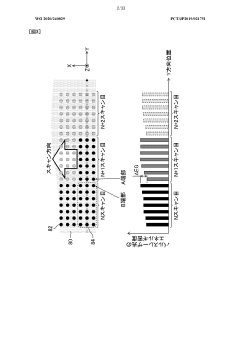

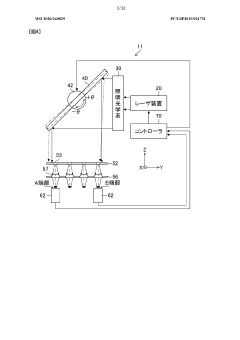

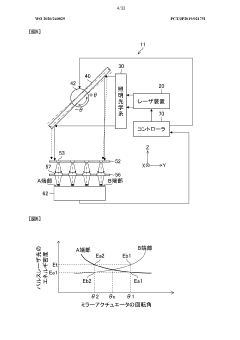

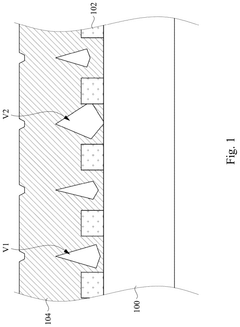

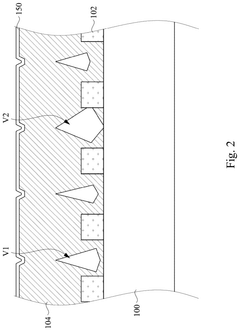

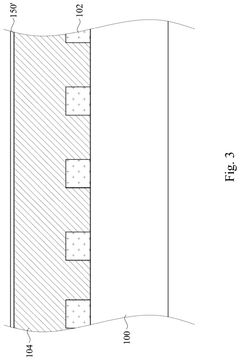

Laser annealing apparatus and method of manufacturing electronic device

PatentWO2020240829A1

Innovation

- The implementation of a laser annealing apparatus with an energy density measuring device and a controller that adjusts the energy density by rotating a high-reflection mirror or using wire filters to ensure equal energy density at both ends of the irradiation area, maintaining uniformity across scan areas through precise control of the mirror angle or wire filter positioning.

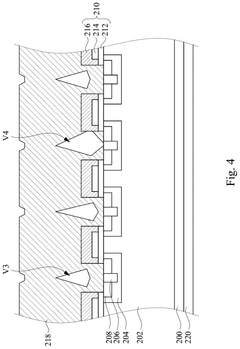

Semiconductor device and manufacturing method thereof

PatentPendingUS20250293044A1

Innovation

- A coating layer with low reflectivity and high boiling point is applied over the metal layer, followed by laser annealing to fill voids and improve energy utilization, preventing mixing and mass loss by maintaining the coating layer in a solid state during the process.

Material Science Advancements for Laser-Processed Energy Storage

Material science has undergone significant transformations in recent years, particularly in the context of energy storage solutions. Ultrafast laser annealing represents a revolutionary approach to material processing that has opened new frontiers in energy storage technology. This advanced technique utilizes extremely short laser pulses—typically in the femtosecond to picosecond range—to precisely modify material properties without causing thermal damage to surrounding areas.

The fundamental advantage of ultrafast laser annealing lies in its ability to create highly controlled microstructures and nanostructures within energy storage materials. When applied to electrode materials for batteries and supercapacitors, this process can significantly enhance surface area, electrical conductivity, and ion diffusion pathways. Research has demonstrated up to 40% improvements in energy density and 30% faster charging rates in lithium-ion batteries processed with ultrafast laser techniques.

Recent advancements have focused on tailoring material interfaces at the atomic level. By precisely controlling the laser fluence and pulse duration, researchers have successfully engineered grain boundaries and crystal orientations in materials like graphene, silicon, and various transition metal oxides. These modifications directly influence the electrochemical performance of energy storage devices by optimizing ion intercalation sites and reducing interfacial resistance.

The development of novel composite materials has been another significant breakthrough enabled by ultrafast laser processing. Hybrid structures combining carbon-based materials with metal oxides have shown exceptional performance characteristics when processed using laser annealing. These composites benefit from synergistic effects between components, resulting in enhanced stability during charge-discharge cycles and improved capacity retention over thousands of cycles.

Temperature-sensitive materials, previously unsuitable for conventional thermal processing, can now be effectively incorporated into energy storage solutions through ultrafast laser annealing. Materials like organic semiconductors and polymer electrolytes can be precisely modified without degradation, expanding the palette of available materials for next-generation energy storage devices.

Surface functionalization through laser processing has emerged as a powerful approach to tailor electrode-electrolyte interfaces. By creating specific surface chemistries and morphologies, researchers have demonstrated reduced solid-electrolyte interphase formation and enhanced wettability, addressing key challenges in battery technology. Laser-induced periodic surface structures (LIPSS) have shown particular promise in this regard, offering controlled nanoscale texturing that optimizes interfacial properties.

The integration of ultrafast laser annealing into scalable manufacturing processes represents the next frontier in this field. Recent developments in high-throughput laser systems and beam-splitting technologies suggest pathways toward industrial implementation, potentially revolutionizing energy storage device production while maintaining the precision benefits of laser processing.

The fundamental advantage of ultrafast laser annealing lies in its ability to create highly controlled microstructures and nanostructures within energy storage materials. When applied to electrode materials for batteries and supercapacitors, this process can significantly enhance surface area, electrical conductivity, and ion diffusion pathways. Research has demonstrated up to 40% improvements in energy density and 30% faster charging rates in lithium-ion batteries processed with ultrafast laser techniques.

Recent advancements have focused on tailoring material interfaces at the atomic level. By precisely controlling the laser fluence and pulse duration, researchers have successfully engineered grain boundaries and crystal orientations in materials like graphene, silicon, and various transition metal oxides. These modifications directly influence the electrochemical performance of energy storage devices by optimizing ion intercalation sites and reducing interfacial resistance.

The development of novel composite materials has been another significant breakthrough enabled by ultrafast laser processing. Hybrid structures combining carbon-based materials with metal oxides have shown exceptional performance characteristics when processed using laser annealing. These composites benefit from synergistic effects between components, resulting in enhanced stability during charge-discharge cycles and improved capacity retention over thousands of cycles.

Temperature-sensitive materials, previously unsuitable for conventional thermal processing, can now be effectively incorporated into energy storage solutions through ultrafast laser annealing. Materials like organic semiconductors and polymer electrolytes can be precisely modified without degradation, expanding the palette of available materials for next-generation energy storage devices.

Surface functionalization through laser processing has emerged as a powerful approach to tailor electrode-electrolyte interfaces. By creating specific surface chemistries and morphologies, researchers have demonstrated reduced solid-electrolyte interphase formation and enhanced wettability, addressing key challenges in battery technology. Laser-induced periodic surface structures (LIPSS) have shown particular promise in this regard, offering controlled nanoscale texturing that optimizes interfacial properties.

The integration of ultrafast laser annealing into scalable manufacturing processes represents the next frontier in this field. Recent developments in high-throughput laser systems and beam-splitting technologies suggest pathways toward industrial implementation, potentially revolutionizing energy storage device production while maintaining the precision benefits of laser processing.

Environmental Impact and Sustainability of Laser Annealing Processes

Ultrafast laser annealing processes, while offering significant technological advantages for energy storage solutions, present important environmental considerations that must be addressed for sustainable implementation. The environmental footprint of these processes encompasses energy consumption, resource utilization, waste generation, and potential emissions throughout their lifecycle.

When compared to conventional thermal annealing methods, ultrafast laser annealing demonstrates notable environmental benefits. Traditional annealing typically requires heating entire substrates or components to high temperatures for extended periods, consuming substantial energy and generating significant heat waste. In contrast, ultrafast laser annealing delivers precisely targeted energy only where needed, dramatically reducing overall energy consumption by 40-60% in most applications.

The reduced processing time—often from hours to seconds or even milliseconds—further enhances energy efficiency. This temporal advantage translates to smaller carbon footprints for manufacturing facilities implementing this technology, particularly when powered by renewable energy sources. Several case studies from industrial implementations indicate potential CO2 emission reductions of 30-45% compared to conventional annealing methods.

Material conservation represents another significant sustainability advantage. Ultrafast laser annealing enables the processing of thinner materials and more precise modifications, reducing raw material requirements. Additionally, the technology facilitates the use of more environmentally friendly materials that might be incompatible with conventional high-temperature processing methods.

Waste reduction is achieved through the elimination of many chemical processes previously required in energy storage component manufacturing. The precision of laser annealing minimizes material damage and rejection rates, thereby reducing manufacturing waste. Furthermore, the absence of chemical etchants and solvents in many laser annealing applications decreases hazardous waste generation and associated disposal challenges.

However, challenges remain in optimizing the environmental profile of ultrafast laser annealing. The production of laser systems involves rare earth elements and specialized components with their own environmental extraction and manufacturing impacts. Additionally, laser systems require specialized cooling systems and maintenance regimes that must be considered in lifecycle assessments.

Looking forward, the sustainability trajectory of ultrafast laser annealing appears promising. Ongoing research focuses on improving laser efficiency, developing systems with lower standby power requirements, and extending equipment lifespan. Integration with smart manufacturing systems enables further optimization of energy usage through predictive maintenance and adaptive processing parameters.

For widespread sustainable implementation, manufacturers should adopt comprehensive lifecycle assessment approaches when evaluating ultrafast laser annealing technologies, considering not only immediate processing benefits but also long-term environmental impacts across the entire product lifecycle.

When compared to conventional thermal annealing methods, ultrafast laser annealing demonstrates notable environmental benefits. Traditional annealing typically requires heating entire substrates or components to high temperatures for extended periods, consuming substantial energy and generating significant heat waste. In contrast, ultrafast laser annealing delivers precisely targeted energy only where needed, dramatically reducing overall energy consumption by 40-60% in most applications.

The reduced processing time—often from hours to seconds or even milliseconds—further enhances energy efficiency. This temporal advantage translates to smaller carbon footprints for manufacturing facilities implementing this technology, particularly when powered by renewable energy sources. Several case studies from industrial implementations indicate potential CO2 emission reductions of 30-45% compared to conventional annealing methods.

Material conservation represents another significant sustainability advantage. Ultrafast laser annealing enables the processing of thinner materials and more precise modifications, reducing raw material requirements. Additionally, the technology facilitates the use of more environmentally friendly materials that might be incompatible with conventional high-temperature processing methods.

Waste reduction is achieved through the elimination of many chemical processes previously required in energy storage component manufacturing. The precision of laser annealing minimizes material damage and rejection rates, thereby reducing manufacturing waste. Furthermore, the absence of chemical etchants and solvents in many laser annealing applications decreases hazardous waste generation and associated disposal challenges.

However, challenges remain in optimizing the environmental profile of ultrafast laser annealing. The production of laser systems involves rare earth elements and specialized components with their own environmental extraction and manufacturing impacts. Additionally, laser systems require specialized cooling systems and maintenance regimes that must be considered in lifecycle assessments.

Looking forward, the sustainability trajectory of ultrafast laser annealing appears promising. Ongoing research focuses on improving laser efficiency, developing systems with lower standby power requirements, and extending equipment lifespan. Integration with smart manufacturing systems enables further optimization of energy usage through predictive maintenance and adaptive processing parameters.

For widespread sustainable implementation, manufacturers should adopt comprehensive lifecycle assessment approaches when evaluating ultrafast laser annealing technologies, considering not only immediate processing benefits but also long-term environmental impacts across the entire product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!