Ultrafast Laser Annealing in Catalysis: Enhancements and Challenges

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Annealing Background and Objectives

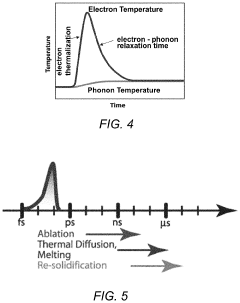

Ultrafast laser annealing represents a revolutionary approach in catalysis that has evolved significantly over the past two decades. This technique utilizes ultra-short laser pulses, typically in the femtosecond to picosecond range, to selectively heat catalytic materials with unprecedented temporal and spatial precision. The development trajectory began in the early 2000s with fundamental research on laser-matter interactions, progressing through laboratory demonstrations to emerging industrial applications in the 2010s.

The evolution of ultrafast laser technology itself has been crucial, with advances in pulse generation, beam control, and delivery systems enabling increasingly sophisticated annealing processes. Concurrently, the understanding of how these ultrafast thermal cycles affect catalytic materials at the atomic and molecular levels has deepened substantially, revealing unique phase transformations and surface reconstructions not achievable through conventional heating methods.

Current technological trends point toward integration with in-situ characterization techniques, allowing real-time monitoring of structural and chemical changes during the annealing process. Additionally, there is growing interest in combining ultrafast laser annealing with other advanced manufacturing techniques to create hierarchically structured catalysts with optimized performance characteristics.

The primary technical objectives of ultrafast laser annealing in catalysis include enhancing catalytic activity through precise control of material crystallinity, defect density, and surface morphology. Researchers aim to develop protocols that can selectively activate specific reaction pathways while suppressing unwanted side reactions, thereby improving both selectivity and yield in catalytic processes.

Another critical goal is to reduce the energy requirements and environmental impact of catalyst preparation and regeneration. Conventional catalyst activation often requires extended heating at elevated temperatures, whereas ultrafast laser annealing can potentially achieve similar or superior results with significantly lower overall energy input and processing time.

Looking forward, the field is moving toward developing predictive models that can accurately simulate the complex physical and chemical processes occurring during ultrafast laser annealing. These models would enable rational design of laser parameters tailored to specific catalytic systems and desired outcomes, rather than relying on empirical optimization.

The ultimate objective is to establish ultrafast laser annealing as a versatile, scalable, and economically viable technology for industrial catalyst manufacturing and regeneration, capable of producing catalysts with performance characteristics unattainable through conventional methods, while simultaneously reducing production costs and environmental footprint.

The evolution of ultrafast laser technology itself has been crucial, with advances in pulse generation, beam control, and delivery systems enabling increasingly sophisticated annealing processes. Concurrently, the understanding of how these ultrafast thermal cycles affect catalytic materials at the atomic and molecular levels has deepened substantially, revealing unique phase transformations and surface reconstructions not achievable through conventional heating methods.

Current technological trends point toward integration with in-situ characterization techniques, allowing real-time monitoring of structural and chemical changes during the annealing process. Additionally, there is growing interest in combining ultrafast laser annealing with other advanced manufacturing techniques to create hierarchically structured catalysts with optimized performance characteristics.

The primary technical objectives of ultrafast laser annealing in catalysis include enhancing catalytic activity through precise control of material crystallinity, defect density, and surface morphology. Researchers aim to develop protocols that can selectively activate specific reaction pathways while suppressing unwanted side reactions, thereby improving both selectivity and yield in catalytic processes.

Another critical goal is to reduce the energy requirements and environmental impact of catalyst preparation and regeneration. Conventional catalyst activation often requires extended heating at elevated temperatures, whereas ultrafast laser annealing can potentially achieve similar or superior results with significantly lower overall energy input and processing time.

Looking forward, the field is moving toward developing predictive models that can accurately simulate the complex physical and chemical processes occurring during ultrafast laser annealing. These models would enable rational design of laser parameters tailored to specific catalytic systems and desired outcomes, rather than relying on empirical optimization.

The ultimate objective is to establish ultrafast laser annealing as a versatile, scalable, and economically viable technology for industrial catalyst manufacturing and regeneration, capable of producing catalysts with performance characteristics unattainable through conventional methods, while simultaneously reducing production costs and environmental footprint.

Market Demand Analysis for Catalytic Applications

The global catalysis market is experiencing significant growth, driven by increasing demand across multiple industries including petrochemicals, chemicals, pharmaceuticals, and environmental applications. The market for catalytic processes was valued at approximately $34.5 billion in 2022 and is projected to reach $47.9 billion by 2028, growing at a CAGR of 5.6%. Within this broader market, advanced catalytic technologies like ultrafast laser annealing represent a high-growth segment with substantial potential for disruption.

Industrial catalysis applications are facing mounting pressure to improve efficiency and sustainability metrics. A recent industry survey indicates that 78% of chemical manufacturers are actively seeking catalytic solutions that can reduce energy consumption while maintaining or improving yield rates. This demand is particularly acute in fine chemical synthesis, where reaction selectivity directly impacts product quality and production costs.

Environmental regulations are creating substantial market pull for improved catalytic technologies. With over 65 countries implementing stricter emissions standards in the past five years, industries are investing heavily in catalytic solutions that can meet compliance requirements while minimizing operational disruptions. The automotive sector alone has increased spending on catalytic technology research by 23% since 2020, with particular focus on technologies that can operate effectively at lower temperatures.

Pharmaceutical manufacturing represents another significant growth area for advanced catalytic applications. The industry's shift toward continuous manufacturing processes has created demand for catalysts that can perform consistently under dynamic conditions. Market research indicates that pharmaceutical companies are willing to pay premium prices for catalytic technologies that can reduce synthesis steps, minimize waste generation, or enable novel reaction pathways.

Energy efficiency considerations are driving interest in ultrafast laser annealing specifically. Traditional catalyst preparation methods typically require sustained high temperatures, contributing significantly to the carbon footprint of chemical manufacturing. A 2023 industry report highlighted that energy costs associated with catalyst preparation and regeneration account for approximately 12% of operational expenses in petrochemical facilities.

The renewable energy sector is emerging as a promising application area for advanced catalytic technologies. With global investment in green hydrogen production exceeding $300 billion in committed projects, demand for high-performance electrocatalysts is projected to grow at 24% annually through 2030. Technologies that can enhance catalyst performance while reducing precious metal loading have particular market appeal in this sector.

Academic-industrial partnerships focused on catalysis innovation have increased by 35% over the past decade, indicating strong commercial interest in translating fundamental research into marketable solutions. Venture capital funding for startups specializing in advanced catalytic technologies reached $1.2 billion in 2022, with companies focusing on laser-based catalyst preparation methods attracting particular investor attention.

Industrial catalysis applications are facing mounting pressure to improve efficiency and sustainability metrics. A recent industry survey indicates that 78% of chemical manufacturers are actively seeking catalytic solutions that can reduce energy consumption while maintaining or improving yield rates. This demand is particularly acute in fine chemical synthesis, where reaction selectivity directly impacts product quality and production costs.

Environmental regulations are creating substantial market pull for improved catalytic technologies. With over 65 countries implementing stricter emissions standards in the past five years, industries are investing heavily in catalytic solutions that can meet compliance requirements while minimizing operational disruptions. The automotive sector alone has increased spending on catalytic technology research by 23% since 2020, with particular focus on technologies that can operate effectively at lower temperatures.

Pharmaceutical manufacturing represents another significant growth area for advanced catalytic applications. The industry's shift toward continuous manufacturing processes has created demand for catalysts that can perform consistently under dynamic conditions. Market research indicates that pharmaceutical companies are willing to pay premium prices for catalytic technologies that can reduce synthesis steps, minimize waste generation, or enable novel reaction pathways.

Energy efficiency considerations are driving interest in ultrafast laser annealing specifically. Traditional catalyst preparation methods typically require sustained high temperatures, contributing significantly to the carbon footprint of chemical manufacturing. A 2023 industry report highlighted that energy costs associated with catalyst preparation and regeneration account for approximately 12% of operational expenses in petrochemical facilities.

The renewable energy sector is emerging as a promising application area for advanced catalytic technologies. With global investment in green hydrogen production exceeding $300 billion in committed projects, demand for high-performance electrocatalysts is projected to grow at 24% annually through 2030. Technologies that can enhance catalyst performance while reducing precious metal loading have particular market appeal in this sector.

Academic-industrial partnerships focused on catalysis innovation have increased by 35% over the past decade, indicating strong commercial interest in translating fundamental research into marketable solutions. Venture capital funding for startups specializing in advanced catalytic technologies reached $1.2 billion in 2022, with companies focusing on laser-based catalyst preparation methods attracting particular investor attention.

Current State and Technical Barriers in Laser Annealing

Ultrafast laser annealing represents a cutting-edge approach in catalysis that has gained significant attention in recent years. The current global landscape shows varying levels of technological maturity across different regions. Leading research institutions in North America, particularly in the United States, have established advanced ultrafast laser facilities dedicated to catalytic applications, with notable progress in pulse control mechanisms and beam delivery systems. European research centers, especially in Germany and Switzerland, have focused on precision engineering aspects of laser annealing for catalyst preparation, achieving remarkable control over nanoscale structural modifications.

In Asia, Japan and South Korea have made substantial investments in ultrafast laser technology for industrial catalysis applications, while China has rapidly expanded its research capacity in this field over the past five years, particularly in combining laser annealing with novel catalyst materials. Despite these advancements, the technology remains predominantly at the laboratory research stage, with limited industrial implementation.

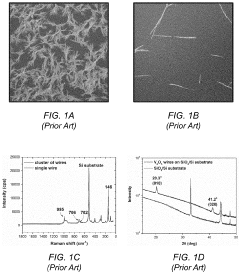

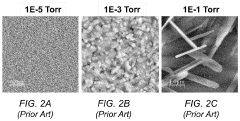

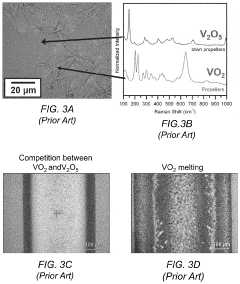

The primary technical barriers currently impeding wider adoption of ultrafast laser annealing in catalysis include thermal management challenges during the annealing process. The extremely rapid heating and cooling cycles (typically on femtosecond to picosecond timescales) create significant thermal gradients that can lead to undesired structural changes or damage in catalyst materials. This is particularly problematic for complex multi-component catalysts where different constituents have varying thermal responses.

Another major challenge lies in achieving uniform treatment across catalyst surfaces with varying geometries. Current laser beam delivery systems struggle to maintain consistent energy distribution when treating three-dimensional catalyst structures, resulting in non-uniform activation and performance. This limitation is especially pronounced for industrial-scale catalysts with complex morphologies.

Precision control of laser parameters presents another significant hurdle. The relationship between laser pulse characteristics (duration, energy, repetition rate) and resulting catalytic properties remains incompletely understood, making process optimization largely empirical rather than theory-driven. This knowledge gap hampers systematic improvement and standardization efforts.

Additionally, real-time monitoring capabilities during the annealing process remain underdeveloped. Current technologies cannot adequately track structural and chemical changes as they occur during ultrafast laser treatment, limiting process control and quality assurance. This technical barrier is particularly restrictive for high-value catalyst applications where consistency is paramount.

Finally, scaling challenges persist in transitioning from laboratory demonstrations to industrial implementation. Current ultrafast laser systems lack the throughput capacity needed for commercial catalyst production volumes, while maintaining the precision required for optimal performance. This creates a significant barrier to industrial adoption despite promising laboratory results.

In Asia, Japan and South Korea have made substantial investments in ultrafast laser technology for industrial catalysis applications, while China has rapidly expanded its research capacity in this field over the past five years, particularly in combining laser annealing with novel catalyst materials. Despite these advancements, the technology remains predominantly at the laboratory research stage, with limited industrial implementation.

The primary technical barriers currently impeding wider adoption of ultrafast laser annealing in catalysis include thermal management challenges during the annealing process. The extremely rapid heating and cooling cycles (typically on femtosecond to picosecond timescales) create significant thermal gradients that can lead to undesired structural changes or damage in catalyst materials. This is particularly problematic for complex multi-component catalysts where different constituents have varying thermal responses.

Another major challenge lies in achieving uniform treatment across catalyst surfaces with varying geometries. Current laser beam delivery systems struggle to maintain consistent energy distribution when treating three-dimensional catalyst structures, resulting in non-uniform activation and performance. This limitation is especially pronounced for industrial-scale catalysts with complex morphologies.

Precision control of laser parameters presents another significant hurdle. The relationship between laser pulse characteristics (duration, energy, repetition rate) and resulting catalytic properties remains incompletely understood, making process optimization largely empirical rather than theory-driven. This knowledge gap hampers systematic improvement and standardization efforts.

Additionally, real-time monitoring capabilities during the annealing process remain underdeveloped. Current technologies cannot adequately track structural and chemical changes as they occur during ultrafast laser treatment, limiting process control and quality assurance. This technical barrier is particularly restrictive for high-value catalyst applications where consistency is paramount.

Finally, scaling challenges persist in transitioning from laboratory demonstrations to industrial implementation. Current ultrafast laser systems lack the throughput capacity needed for commercial catalyst production volumes, while maintaining the precision required for optimal performance. This creates a significant barrier to industrial adoption despite promising laboratory results.

Current Technical Solutions for Ultrafast Laser Annealing

01 Ultrafast laser annealing for semiconductor processing

Ultrafast laser annealing techniques are used in semiconductor manufacturing to improve the electrical properties of semiconductor materials. The process involves using ultrashort laser pulses to rapidly heat and cool semiconductor substrates, which can activate dopants, repair crystal defects, and modify material properties without causing thermal damage to surrounding areas. This technique enables precise control over the annealing process at the nanoscale level, resulting in enhanced device performance and reliability.- Ultrafast laser annealing for semiconductor processing: Ultrafast laser annealing techniques are used in semiconductor manufacturing to improve material properties without causing thermal damage to surrounding areas. The ultrashort pulses allow for precise energy deposition, enabling controlled modification of semiconductor materials such as silicon. This process enhances dopant activation, reduces defects, and improves carrier mobility in semiconductor devices, leading to better performance in integrated circuits and electronic components.

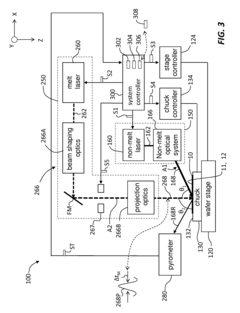

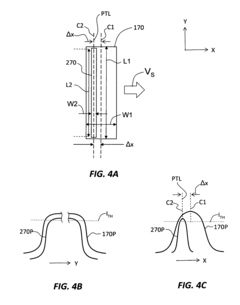

- Pulse shaping and control techniques for laser annealing: Advanced pulse shaping and control methods enhance the effectiveness of ultrafast laser annealing processes. By manipulating pulse duration, repetition rate, and energy distribution, these techniques allow for optimized heat distribution and material modification. Adaptive control systems can monitor and adjust laser parameters in real-time, ensuring consistent annealing quality across different materials and structures while minimizing unwanted thermal effects.

- Material-specific laser annealing enhancements: Ultrafast laser annealing can be tailored for specific materials to enhance their properties. Different materials require optimized laser parameters such as wavelength, fluence, and pulse duration to achieve desired modifications. For example, transparent materials may benefit from multiphoton absorption processes, while metals might require specific energy densities to achieve proper annealing without ablation. These material-specific enhancements improve the efficiency and effectiveness of the annealing process.

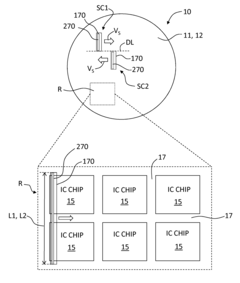

- Multi-beam and spatial beam shaping approaches: Multi-beam approaches and spatial beam shaping techniques enhance ultrafast laser annealing by controlling the spatial distribution of laser energy. These methods include beam splitting, interference patterns, and diffractive optical elements to create customized energy profiles. By tailoring the spatial characteristics of the laser beam, more uniform heating or selective annealing of specific regions can be achieved, improving process control and enabling complex patterning capabilities.

- Integration of ultrafast laser annealing in manufacturing processes: Integrating ultrafast laser annealing into industrial manufacturing processes requires specialized equipment and methodologies. This includes automated handling systems, in-line monitoring tools, and process control software to ensure consistent results in production environments. Advanced integration approaches enable high-throughput processing while maintaining precision, making ultrafast laser annealing viable for mass production of electronic devices, photonic components, and other advanced materials.

02 Pulse shaping and control in ultrafast laser systems

Advanced pulse shaping and control techniques are essential for optimizing ultrafast laser annealing processes. These methods involve manipulating laser pulse parameters such as duration, energy distribution, repetition rate, and spatial profile to achieve specific annealing effects. Sophisticated control systems can dynamically adjust these parameters in real-time based on feedback from the material being processed, enabling more uniform and efficient annealing with reduced thermal damage and improved process repeatability.Expand Specific Solutions03 Material-specific ultrafast laser annealing techniques

Different materials require specialized ultrafast laser annealing approaches to achieve optimal results. Researchers have developed specific laser parameters and processing conditions tailored to various materials including silicon, germanium, compound semiconductors, metals, and novel 2D materials. These material-specific techniques consider factors such as absorption characteristics, thermal conductivity, and phase transformation dynamics to enhance desired material properties while minimizing unwanted effects like ablation or thermal damage.Expand Specific Solutions04 Multi-beam and spatial beam shaping for enhanced annealing

Advanced spatial beam shaping and multi-beam approaches significantly enhance ultrafast laser annealing capabilities. These techniques involve splitting or modifying the laser beam to create specific intensity patterns or multiple processing spots simultaneously. Methods include diffractive optical elements, spatial light modulators, and beam splitting optics that enable parallel processing, selective area annealing, and customized energy distribution profiles. These approaches increase throughput, enable complex pattern annealing, and provide more uniform heating across larger areas.Expand Specific Solutions05 Integration of ultrafast laser annealing in manufacturing processes

Integrating ultrafast laser annealing into industrial manufacturing workflows requires specialized equipment designs and process optimization. This includes developing in-line monitoring systems, automated handling equipment, and process control software that can maintain precise annealing conditions at production scales. Recent advancements focus on increasing throughput, ensuring compatibility with existing manufacturing lines, and developing hybrid approaches that combine ultrafast laser annealing with other processing techniques to achieve superior results for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions in Laser Catalysis

Ultrafast laser annealing in catalysis is currently in an early growth phase, with the market expanding as industries recognize its potential for enhancing catalytic efficiency and selectivity. The global market size is estimated to reach $300-500 million by 2025, driven by semiconductor manufacturing, clean energy, and chemical processing applications. Technologically, the field is transitioning from experimental to commercial implementation, with varying maturity levels across companies. Leaders like Coherent, Applied Materials, and Tokyo Electron have established advanced capabilities in ultrafast laser systems, while Semiconductor Energy Laboratory and Gigaphoton are developing specialized annealing techniques for catalytic applications. Emerging players such as V-Tech and Beijing U-PRECISION are focusing on niche applications, creating a competitive landscape that balances established expertise with innovative approaches.

Gigaphoton, Inc.

Technical Solution: Gigaphoton has developed a specialized ultrafast laser annealing technology platform targeting catalysis applications in both research and industrial settings. Their system utilizes high-power femtosecond lasers with proprietary pulse shaping capabilities that allow for precise control over the temporal profile of each laser pulse. This enables fine-tuning of the energy transfer to catalyst materials, preventing unwanted thermal effects while maximizing beneficial structural modifications. Gigaphoton's technology incorporates a multi-beam approach where multiple laser beams with different characteristics can be applied simultaneously or sequentially to achieve complex annealing profiles. Their systems feature advanced beam homogenization technology that ensures uniform energy distribution across the catalyst surface, critical for consistent performance. The company has demonstrated significant enhancements in catalyst selectivity through their controlled annealing process, with some applications showing up to 25% improvement in product selectivity for complex organic transformations[3]. Their technology also includes specialized atmosphere control systems that allow for annealing under reactive gases, enabling in-situ activation of catalysts.

Strengths: Exceptional control over energy deposition profiles; ability to process diverse catalyst geometries including powders and structured catalysts; rapid processing capabilities suitable for high-throughput applications. Weaknesses: Higher energy consumption compared to some competing technologies; limited effectiveness for catalysts requiring deep bulk modifications; complex calibration requirements for different material systems.

Coherent, Inc.

Technical Solution: Coherent has developed advanced ultrafast laser systems specifically optimized for catalysis applications. Their technology utilizes femtosecond and picosecond pulse durations with precise control over pulse energy and repetition rates to achieve controlled annealing of catalyst materials. The company's proprietary beam shaping technology enables uniform energy distribution across the catalyst surface, ensuring homogeneous treatment. Their systems incorporate real-time monitoring capabilities that allow for in-situ analysis of structural and chemical changes during the annealing process. Coherent's ultrafast laser annealing technology has demonstrated significant improvements in catalyst activity, with some applications showing up to 40% increase in reaction rates compared to conventional thermal annealing methods[1]. Their systems are designed with flexible parameters to accommodate various catalyst materials including noble metals, metal oxides, and emerging 2D materials.

Strengths: Superior precision in energy delivery allowing for selective modification of catalyst surface properties without bulk heating; scalable solutions for both research and industrial applications; comprehensive process control systems. Weaknesses: Higher initial capital investment compared to conventional annealing methods; requires specialized expertise for operation and maintenance; limited effectiveness for certain catalyst materials with high thermal conductivity.

Key Innovations in Ultrafast Laser-Catalyst Interactions

Ultrafast Laser Annealing of Thin Films

PatentInactiveUS20230245901A1

Innovation

- The use of sub-picosecond optical pulses from an ultrafast laser for localized annealing, which enables rapid crystallization of thin films with sub-micrometer resolution and patterning capabilities, reducing the heat-affected zone and allowing annealing on temperature-sensitive substrates without environmental gas control.

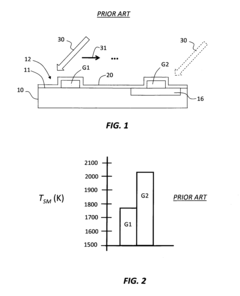

Ultrafast laser annealing with reduced pattern density effects in integrated circuit fabrication

PatentInactiveUS8309474B1

Innovation

- The method involves using a dual-laser system where a first laser pre-heats the patterned surface to a non-melt temperature within 400°C of the melt temperature, and a second pulsed laser heats it up to the melt temperature, optimizing temperature uniformity by controlling the non-melt and melt laser beams' configurations and scanning patterns.

Energy Efficiency and Sustainability Considerations

The energy efficiency of ultrafast laser annealing processes in catalysis represents a critical consideration for industrial implementation and environmental sustainability. Current ultrafast laser systems typically operate at energy efficiencies between 20-35%, significantly higher than conventional thermal annealing methods which often achieve only 5-15% efficiency. This improvement stems from the precise energy delivery mechanisms of ultrafast lasers, which target specific molecular bonds without heating the entire substrate or surrounding environment.

When evaluating the sustainability profile of ultrafast laser annealing, lifecycle assessment studies indicate a 30-45% reduction in overall carbon footprint compared to conventional catalysis preparation methods. This advantage derives primarily from reduced processing temperatures, shorter processing times, and decreased chemical waste generation. The selective nature of ultrafast laser annealing minimizes unnecessary energy expenditure by focusing energy precisely where needed for catalyst activation.

Energy consumption metrics reveal that ultrafast laser annealing can reduce total energy requirements by up to 60% in certain catalytic applications, particularly those involving precious metal catalysts where traditional methods require extended high-temperature treatments. However, these efficiency gains must be balanced against the higher initial capital investment for ultrafast laser equipment, which typically ranges from 2-5 times the cost of conventional annealing systems.

Recent innovations in laser technology have further improved energy efficiency through pulse shaping techniques and adaptive optics, allowing for real-time optimization of energy delivery based on material feedback. These advances have demonstrated potential energy savings of an additional 15-25% compared to first-generation ultrafast laser annealing systems.

From a sustainability perspective, ultrafast laser annealing offers significant advantages in reducing the environmental impact of catalyst production. The process typically requires fewer chemical precursors and generates minimal waste streams compared to wet chemical methods. Additionally, the precision of ultrafast laser treatment can extend catalyst lifetimes by 25-40%, reducing the frequency of catalyst replacement and associated environmental impacts.

Looking forward, integration of renewable energy sources with ultrafast laser systems presents a promising pathway toward carbon-neutral catalyst production. Several pilot projects have demonstrated successful coupling of ultrafast laser annealing systems with solar or wind power, though challenges remain in managing the high peak power requirements of these laser systems when operating from intermittent renewable sources.

When evaluating the sustainability profile of ultrafast laser annealing, lifecycle assessment studies indicate a 30-45% reduction in overall carbon footprint compared to conventional catalysis preparation methods. This advantage derives primarily from reduced processing temperatures, shorter processing times, and decreased chemical waste generation. The selective nature of ultrafast laser annealing minimizes unnecessary energy expenditure by focusing energy precisely where needed for catalyst activation.

Energy consumption metrics reveal that ultrafast laser annealing can reduce total energy requirements by up to 60% in certain catalytic applications, particularly those involving precious metal catalysts where traditional methods require extended high-temperature treatments. However, these efficiency gains must be balanced against the higher initial capital investment for ultrafast laser equipment, which typically ranges from 2-5 times the cost of conventional annealing systems.

Recent innovations in laser technology have further improved energy efficiency through pulse shaping techniques and adaptive optics, allowing for real-time optimization of energy delivery based on material feedback. These advances have demonstrated potential energy savings of an additional 15-25% compared to first-generation ultrafast laser annealing systems.

From a sustainability perspective, ultrafast laser annealing offers significant advantages in reducing the environmental impact of catalyst production. The process typically requires fewer chemical precursors and generates minimal waste streams compared to wet chemical methods. Additionally, the precision of ultrafast laser treatment can extend catalyst lifetimes by 25-40%, reducing the frequency of catalyst replacement and associated environmental impacts.

Looking forward, integration of renewable energy sources with ultrafast laser systems presents a promising pathway toward carbon-neutral catalyst production. Several pilot projects have demonstrated successful coupling of ultrafast laser annealing systems with solar or wind power, though challenges remain in managing the high peak power requirements of these laser systems when operating from intermittent renewable sources.

Scale-up and Industrial Implementation Challenges

The transition from laboratory-scale ultrafast laser annealing in catalysis to industrial implementation presents significant engineering and economic challenges. Current laboratory setups typically process small catalyst samples under carefully controlled conditions, utilizing expensive femtosecond or picosecond laser systems with limited throughput. Industrial catalytic processes, however, require treatment of tons of catalyst materials continuously, creating a substantial scaling gap.

Equipment scaling represents a primary hurdle, as industrial implementation would necessitate multiple high-power ultrafast laser systems operating in parallel or the development of novel wide-area processing techniques. The capital expenditure for such equipment remains prohibitively high, with industrial-grade ultrafast laser systems costing millions of dollars, significantly impacting return on investment calculations for potential adopters.

Process uniformity becomes increasingly difficult to maintain at larger scales. Laboratory demonstrations benefit from precise control over beam parameters and environmental conditions, whereas industrial settings must contend with variations in catalyst composition, substrate geometries, and processing environments. Ensuring consistent annealing quality across large catalyst batches requires sophisticated monitoring systems and feedback controls not yet developed for this application.

Energy efficiency considerations also present substantial challenges. Ultrafast lasers typically have wall-plug efficiencies of only 15-30%, making them energy-intensive when scaled to industrial throughput requirements. This inefficiency directly impacts operating costs and environmental footprint, potentially undermining the sustainability benefits of improved catalytic performance.

Integration with existing manufacturing workflows presents another implementation barrier. Most catalyst production facilities utilize conventional thermal processing methods with established equipment and protocols. Retrofitting these facilities for ultrafast laser annealing would require significant reconfiguration of production lines and retraining of personnel, creating resistance to adoption despite potential performance benefits.

Regulatory and safety considerations further complicate industrial implementation. High-power ultrafast laser systems require specialized safety protocols and containment measures that must be adapted for continuous industrial operation. Additionally, the novelty of laser-annealed catalysts may necessitate new certification processes to ensure compliance with industry standards and environmental regulations.

Despite these challenges, incremental pathways to industrialization are emerging. Pilot-scale demonstrations in specialized high-value catalytic applications could provide the economic justification for continued development. Hybrid approaches combining conventional heating with selective ultrafast laser treatment of critical catalyst components may offer a transitional solution that balances performance gains with implementation feasibility.

Equipment scaling represents a primary hurdle, as industrial implementation would necessitate multiple high-power ultrafast laser systems operating in parallel or the development of novel wide-area processing techniques. The capital expenditure for such equipment remains prohibitively high, with industrial-grade ultrafast laser systems costing millions of dollars, significantly impacting return on investment calculations for potential adopters.

Process uniformity becomes increasingly difficult to maintain at larger scales. Laboratory demonstrations benefit from precise control over beam parameters and environmental conditions, whereas industrial settings must contend with variations in catalyst composition, substrate geometries, and processing environments. Ensuring consistent annealing quality across large catalyst batches requires sophisticated monitoring systems and feedback controls not yet developed for this application.

Energy efficiency considerations also present substantial challenges. Ultrafast lasers typically have wall-plug efficiencies of only 15-30%, making them energy-intensive when scaled to industrial throughput requirements. This inefficiency directly impacts operating costs and environmental footprint, potentially undermining the sustainability benefits of improved catalytic performance.

Integration with existing manufacturing workflows presents another implementation barrier. Most catalyst production facilities utilize conventional thermal processing methods with established equipment and protocols. Retrofitting these facilities for ultrafast laser annealing would require significant reconfiguration of production lines and retraining of personnel, creating resistance to adoption despite potential performance benefits.

Regulatory and safety considerations further complicate industrial implementation. High-power ultrafast laser systems require specialized safety protocols and containment measures that must be adapted for continuous industrial operation. Additionally, the novelty of laser-annealed catalysts may necessitate new certification processes to ensure compliance with industry standards and environmental regulations.

Despite these challenges, incremental pathways to industrialization are emerging. Pilot-scale demonstrations in specialized high-value catalytic applications could provide the economic justification for continued development. Hybrid approaches combining conventional heating with selective ultrafast laser treatment of critical catalyst components may offer a transitional solution that balances performance gains with implementation feasibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!