Exploring the viability of V16 engines in vertical take-off and landing (VTOL) aircraft

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine VTOL Background

The concept of utilizing V16 engines in vertical take-off and landing (VTOL) aircraft represents a fascinating intersection of automotive engineering and aerospace innovation. This exploration stems from the ongoing quest for more powerful, efficient, and versatile propulsion systems in the aviation industry, particularly for VTOL applications.

V16 engines, traditionally associated with high-performance automobiles and marine vessels, have a rich history dating back to the early 20th century. These engines are characterized by their 16 cylinders arranged in a V configuration, typically in two banks of eight cylinders each. This design allows for increased power output while maintaining a relatively compact form factor compared to inline configurations of similar displacement.

The aviation industry's interest in V16 engines for VTOL aircraft is driven by several factors. VTOL aircraft require significant power for vertical lift, especially during takeoff and landing phases. The power-to-weight ratio of V16 engines, coupled with their potential for high torque output, makes them an intriguing option for these demanding applications.

Historically, VTOL aircraft have relied on various propulsion systems, including turboshaft engines, ducted fans, and tiltrotors. The consideration of V16 engines represents a departure from conventional thinking, potentially offering advantages in terms of power delivery, fuel efficiency, and operational flexibility.

The evolution of materials science and manufacturing techniques has also played a crucial role in making this exploration viable. Advanced lightweight materials and precision engineering methods have the potential to address traditional concerns about the weight and complexity of V16 engines in aerospace applications.

Moreover, the push towards more sustainable aviation solutions has sparked interest in alternative engine configurations. V16 engines, with their potential for adaptation to various fuel types, including biofuels and synthetic fuels, align with the industry's long-term sustainability goals.

The exploration of V16 engines in VTOL aircraft is not without challenges. Issues such as weight management, vibration control, and integration with aircraft systems need to be carefully addressed. Additionally, the regulatory landscape for such novel propulsion systems in aviation presents a complex hurdle that must be navigated.

As the aviation industry continues to evolve, the investigation into V16 engines for VTOL aircraft represents a bold step towards reimagining aircraft propulsion. This exploration not only pushes the boundaries of current technology but also opens up new possibilities for the future of vertical flight.

V16 engines, traditionally associated with high-performance automobiles and marine vessels, have a rich history dating back to the early 20th century. These engines are characterized by their 16 cylinders arranged in a V configuration, typically in two banks of eight cylinders each. This design allows for increased power output while maintaining a relatively compact form factor compared to inline configurations of similar displacement.

The aviation industry's interest in V16 engines for VTOL aircraft is driven by several factors. VTOL aircraft require significant power for vertical lift, especially during takeoff and landing phases. The power-to-weight ratio of V16 engines, coupled with their potential for high torque output, makes them an intriguing option for these demanding applications.

Historically, VTOL aircraft have relied on various propulsion systems, including turboshaft engines, ducted fans, and tiltrotors. The consideration of V16 engines represents a departure from conventional thinking, potentially offering advantages in terms of power delivery, fuel efficiency, and operational flexibility.

The evolution of materials science and manufacturing techniques has also played a crucial role in making this exploration viable. Advanced lightweight materials and precision engineering methods have the potential to address traditional concerns about the weight and complexity of V16 engines in aerospace applications.

Moreover, the push towards more sustainable aviation solutions has sparked interest in alternative engine configurations. V16 engines, with their potential for adaptation to various fuel types, including biofuels and synthetic fuels, align with the industry's long-term sustainability goals.

The exploration of V16 engines in VTOL aircraft is not without challenges. Issues such as weight management, vibration control, and integration with aircraft systems need to be carefully addressed. Additionally, the regulatory landscape for such novel propulsion systems in aviation presents a complex hurdle that must be navigated.

As the aviation industry continues to evolve, the investigation into V16 engines for VTOL aircraft represents a bold step towards reimagining aircraft propulsion. This exploration not only pushes the boundaries of current technology but also opens up new possibilities for the future of vertical flight.

VTOL Aircraft Market Analysis

The VTOL aircraft market has experienced significant growth in recent years, driven by increasing demand for efficient and versatile transportation solutions. This market segment encompasses a wide range of applications, including urban air mobility, military operations, emergency services, and cargo delivery. The global VTOL aircraft market was valued at approximately $4.5 billion in 2020 and is projected to reach $13.6 billion by 2025, growing at a CAGR of 24.7% during the forecast period.

One of the key factors driving market growth is the rising interest in urban air mobility solutions. As cities become more congested and traditional transportation infrastructure struggles to keep pace with population growth, VTOL aircraft offer a promising alternative for short-distance travel and commuting. Several major companies, including Uber, Airbus, and Boeing, have invested heavily in developing electric VTOL (eVTOL) aircraft for urban air taxi services.

The military sector also plays a crucial role in the VTOL aircraft market. Armed forces worldwide are increasingly adopting VTOL platforms for various missions, including reconnaissance, search and rescue, and troop transport. The ability of VTOL aircraft to operate in austere environments and confined spaces makes them particularly valuable for military applications.

In terms of regional distribution, North America currently dominates the VTOL aircraft market, accounting for approximately 40% of the global market share. This is primarily due to the presence of major aerospace companies and significant investments in research and development. Europe follows closely behind, with a market share of around 30%, driven by advancements in eVTOL technology and supportive regulatory frameworks.

The Asia-Pacific region is expected to witness the highest growth rate in the coming years, with a projected CAGR of 28.5% from 2020 to 2025. This growth is attributed to increasing urbanization, rising disposable incomes, and government initiatives to promote advanced air mobility solutions in countries like China, Japan, and South Korea.

When considering the potential integration of V16 engines in VTOL aircraft, it is essential to analyze market trends and customer requirements. While the majority of current VTOL development focuses on electric propulsion systems, there may be niche applications where high-power, internal combustion engines like V16s could offer advantages. These applications might include long-range cargo transport or specialized military operations that require extended flight times and high payload capacities.

However, it is important to note that the market is increasingly prioritizing environmentally friendly and low-noise solutions, particularly for urban air mobility applications. This trend may pose challenges for the adoption of V16 engines in VTOL aircraft, as they typically have higher emissions and noise levels compared to electric propulsion systems.

One of the key factors driving market growth is the rising interest in urban air mobility solutions. As cities become more congested and traditional transportation infrastructure struggles to keep pace with population growth, VTOL aircraft offer a promising alternative for short-distance travel and commuting. Several major companies, including Uber, Airbus, and Boeing, have invested heavily in developing electric VTOL (eVTOL) aircraft for urban air taxi services.

The military sector also plays a crucial role in the VTOL aircraft market. Armed forces worldwide are increasingly adopting VTOL platforms for various missions, including reconnaissance, search and rescue, and troop transport. The ability of VTOL aircraft to operate in austere environments and confined spaces makes them particularly valuable for military applications.

In terms of regional distribution, North America currently dominates the VTOL aircraft market, accounting for approximately 40% of the global market share. This is primarily due to the presence of major aerospace companies and significant investments in research and development. Europe follows closely behind, with a market share of around 30%, driven by advancements in eVTOL technology and supportive regulatory frameworks.

The Asia-Pacific region is expected to witness the highest growth rate in the coming years, with a projected CAGR of 28.5% from 2020 to 2025. This growth is attributed to increasing urbanization, rising disposable incomes, and government initiatives to promote advanced air mobility solutions in countries like China, Japan, and South Korea.

When considering the potential integration of V16 engines in VTOL aircraft, it is essential to analyze market trends and customer requirements. While the majority of current VTOL development focuses on electric propulsion systems, there may be niche applications where high-power, internal combustion engines like V16s could offer advantages. These applications might include long-range cargo transport or specialized military operations that require extended flight times and high payload capacities.

However, it is important to note that the market is increasingly prioritizing environmentally friendly and low-noise solutions, particularly for urban air mobility applications. This trend may pose challenges for the adoption of V16 engines in VTOL aircraft, as they typically have higher emissions and noise levels compared to electric propulsion systems.

V16 Engine Challenges in VTOL

The integration of V16 engines into vertical take-off and landing (VTOL) aircraft presents a unique set of challenges that must be addressed to ensure the viability and efficiency of such systems. One of the primary obstacles is the weight-to-power ratio of V16 engines, which are typically heavier than traditional aircraft engines. This increased weight can significantly impact the VTOL capabilities, requiring more powerful lift systems to compensate for the additional mass.

Another critical challenge lies in the complexity of the V16 engine design. With 16 cylinders arranged in a V-configuration, these engines require intricate cooling systems and lubrication networks to maintain optimal performance. In a VTOL aircraft, where space is at a premium and weight distribution is crucial, accommodating these complex systems becomes a significant engineering hurdle.

The fuel consumption of V16 engines is also a concern in VTOL applications. These engines are known for their high power output but often at the cost of increased fuel usage. For VTOL aircraft, which require substantial power during takeoff and landing phases, this could lead to reduced range and operational flexibility, potentially limiting the aircraft's practical applications.

Vibration and noise management present additional challenges. V16 engines, due to their size and power output, generate considerable vibrations and noise. In a VTOL aircraft, where stability during hover and transition phases is critical, mitigating these effects becomes essential to ensure safe and comfortable operation.

The integration of V16 engines with VTOL propulsion systems poses another significant challenge. Coordinating the power delivery from the engine to both vertical lift systems and forward propulsion mechanisms requires sophisticated control systems and power distribution networks. This integration must be seamless to allow for smooth transitions between vertical and horizontal flight modes.

Maintenance and reliability are also key considerations. V16 engines, with their increased number of components, may require more frequent maintenance and have a higher likelihood of mechanical issues. In VTOL aircraft, where reliability is paramount, ensuring the longevity and dependability of these complex engines becomes a critical engineering task.

Lastly, the environmental impact of V16 engines in VTOL aircraft cannot be overlooked. With increasing focus on reducing aviation emissions, the higher fuel consumption and emissions of V16 engines may pose regulatory and market acceptance challenges. Developing cleaner, more efficient versions of these engines or exploring hybrid solutions may be necessary to address these concerns.

Another critical challenge lies in the complexity of the V16 engine design. With 16 cylinders arranged in a V-configuration, these engines require intricate cooling systems and lubrication networks to maintain optimal performance. In a VTOL aircraft, where space is at a premium and weight distribution is crucial, accommodating these complex systems becomes a significant engineering hurdle.

The fuel consumption of V16 engines is also a concern in VTOL applications. These engines are known for their high power output but often at the cost of increased fuel usage. For VTOL aircraft, which require substantial power during takeoff and landing phases, this could lead to reduced range and operational flexibility, potentially limiting the aircraft's practical applications.

Vibration and noise management present additional challenges. V16 engines, due to their size and power output, generate considerable vibrations and noise. In a VTOL aircraft, where stability during hover and transition phases is critical, mitigating these effects becomes essential to ensure safe and comfortable operation.

The integration of V16 engines with VTOL propulsion systems poses another significant challenge. Coordinating the power delivery from the engine to both vertical lift systems and forward propulsion mechanisms requires sophisticated control systems and power distribution networks. This integration must be seamless to allow for smooth transitions between vertical and horizontal flight modes.

Maintenance and reliability are also key considerations. V16 engines, with their increased number of components, may require more frequent maintenance and have a higher likelihood of mechanical issues. In VTOL aircraft, where reliability is paramount, ensuring the longevity and dependability of these complex engines becomes a critical engineering task.

Lastly, the environmental impact of V16 engines in VTOL aircraft cannot be overlooked. With increasing focus on reducing aviation emissions, the higher fuel consumption and emissions of V16 engines may pose regulatory and market acceptance challenges. Developing cleaner, more efficient versions of these engines or exploring hybrid solutions may be necessary to address these concerns.

Current V16 VTOL Solutions

01 V16 engine design and configuration

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines with the same number of cylinders, while still providing significant power output.- V16 engine design and configuration: V16 engines are characterized by their unique configuration of 16 cylinders arranged in a V-shape. This design allows for high power output while maintaining a relatively compact size. The V-arrangement helps in balancing the engine and reducing vibrations. These engines are often used in high-performance vehicles, marine applications, and industrial machinery.

- V16 engine applications in vehicles: V16 engines find applications in various types of vehicles, particularly in luxury and high-performance automobiles. These engines provide exceptional power and torque, making them suitable for large sedans, sports cars, and even some specialized racing vehicles. The use of V16 engines in vehicles often requires advanced cooling systems and specialized transmission designs to handle the high power output.

- V16 engine control systems: Modern V16 engines incorporate sophisticated control systems to optimize performance, fuel efficiency, and emissions. These systems may include advanced engine management units, variable valve timing, and electronic fuel injection. The control systems also help in managing the complex interactions between the engine's multiple cylinders and ensure smooth operation across various speed ranges.

- V16 engine manufacturing and assembly: The manufacturing and assembly of V16 engines require specialized processes due to their complexity and size. This includes precision machining of engine blocks, crankshafts, and cylinder heads. Advanced assembly techniques are employed to ensure proper alignment and balancing of the engine components. Quality control measures are crucial throughout the manufacturing process to maintain the high performance and reliability expected from V16 engines.

- V16 engine cooling and lubrication systems: V16 engines generate significant heat and require advanced cooling and lubrication systems. These systems often include high-capacity oil pumps, multiple radiators, and sophisticated coolant circulation designs. The cooling system must efficiently manage heat across all 16 cylinders, while the lubrication system ensures proper oil distribution to all moving parts, including the crankshaft, camshafts, and valve train components.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized racing vehicles. These engines provide exceptional power and torque, making them suitable for large, heavy vehicles that require significant propulsion. The use of V16 engines in vehicles often results in distinctive designs to accommodate the large powerplant.Expand Specific Solutions03 Historical development of V16 engines

The development of V16 engines dates back to the early 20th century, with various designs and configurations emerging over time. These engines have been used in a range of applications, from aircraft to automobiles and marine vessels. The historical progression of V16 engines showcases advancements in engineering and manufacturing techniques.Expand Specific Solutions04 V16 engine control systems and optimization

Modern V16 engines incorporate advanced control systems and optimization techniques to improve performance, efficiency, and emissions. These may include electronic fuel injection, variable valve timing, and sophisticated engine management systems. Optimization strategies focus on balancing power output with fuel economy and environmental considerations.Expand Specific Solutions05 V16 engine components and manufacturing

The production of V16 engines involves specialized components and manufacturing processes. This includes the design and fabrication of engine blocks, crankshafts, pistons, and valve trains specific to the V16 configuration. Advanced materials and precision engineering techniques are often employed to ensure reliability and performance in these complex powerplants.Expand Specific Solutions

Key VTOL Engine Manufacturers

The development of V16 engines for VTOL aircraft is in its early stages, with the market still emerging and relatively small. The technology is not yet mature, with companies like Aurora Flight Sciences, Sikorsky Aircraft, and Boeing leading research efforts. Other players such as Archer Aviation and Lilium are focusing on electric VTOL designs, indicating a shift towards more sustainable propulsion systems. The competition is intensifying as both established aerospace firms and innovative startups vie for dominance in this nascent field, driving rapid advancements in VTOL technology and expanding potential applications beyond traditional aviation sectors.

Sikorsky Aircraft Corp.

Technical Solution: Sikorsky's approach to V16 engines in VTOL aircraft leverages their extensive experience in helicopter design. Their solution integrates a hybrid powertrain system, combining V16 engines with electric motors for optimal performance during different flight phases[2]. The V16 engines are used primarily for high-power demands during takeoff and landing, while electric motors provide efficient cruise power. Sikorsky has developed a proprietary engine management system that dynamically adjusts power output based on flight conditions, optimizing fuel efficiency and performance[4]. Additionally, they have implemented advanced noise reduction technologies to mitigate the acoustic signature of the V16 engines, addressing a key concern for urban air mobility applications[6].

Strengths: Versatile power delivery, efficient energy management, and reduced noise emissions. Weaknesses: System complexity, potential reliability issues due to multiple power sources, and increased maintenance requirements.

The Boeing Co.

Technical Solution: Boeing's approach to V16 engines in VTOL aircraft focuses on integrating high-power density propulsion systems with advanced flight control technologies. Their design incorporates a distributed electric propulsion (DEP) architecture, utilizing multiple smaller V16 engines strategically placed around the aircraft[1]. This configuration allows for enhanced maneuverability and redundancy. Boeing's V16 engines are optimized for power-to-weight ratio, featuring advanced materials like titanium alloys and carbon fiber composites to reduce overall weight[3]. The company has also developed a sophisticated thermal management system to address the heat generation issues associated with V16 engines in VTOL applications[5].

Strengths: Exceptional power output, improved redundancy, and enhanced maneuverability. Weaknesses: Increased complexity, potential weight challenges, and higher fuel consumption compared to smaller engine configurations.

V16 VTOL Core Technologies

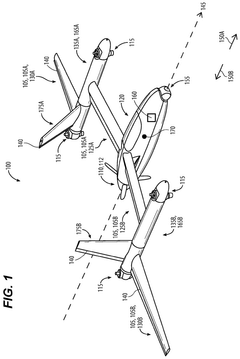

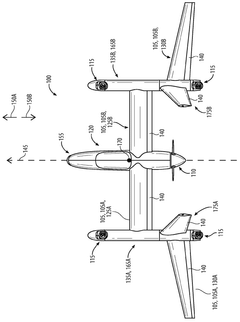

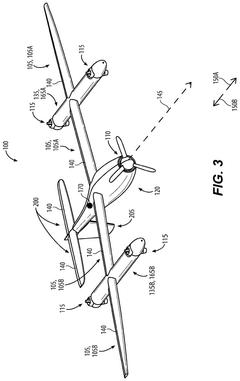

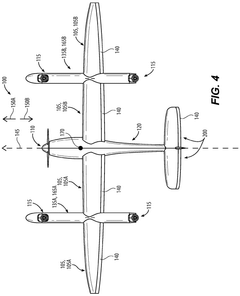

Vertical take-off and landing aircraft

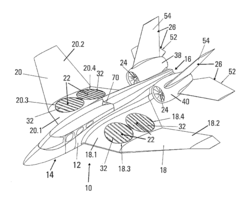

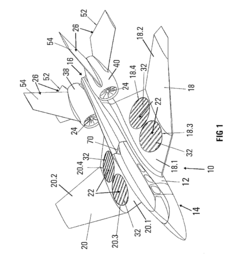

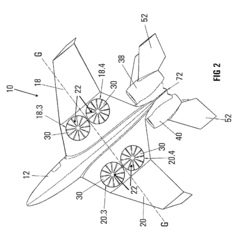

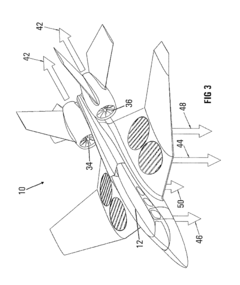

PatentWO2024263593A2

Innovation

- The design incorporates a wing with a first engine providing axial thrust and a plurality of second engines that rotate from a perpendicular to an axial direction, allowing for efficient transition between vertical and horizontal flight, reducing drag by stowing the second engines within the fuselage profile during cruise.

Vertical take-off and landing aircraft

PatentActiveUS20170158321A1

Innovation

- A VTOL aircraft design featuring a fuselage with lift fan drive systems in each wing, a forward thrust fan drive system, and a stabiliser arrangement, including variable pitch blades and louvers, powered by multiple turbine engines with a planetary gearbox for redundancy, and a computer-controlled stability system for automated control.

Aerospace Regulations Impact

The integration of V16 engines in vertical take-off and landing (VTOL) aircraft is subject to a complex web of aerospace regulations that significantly impact their development and deployment. These regulations, established by aviation authorities worldwide, aim to ensure the safety, reliability, and environmental compatibility of aircraft systems.

One of the primary regulatory challenges for V16-powered VTOL aircraft lies in noise reduction requirements. Aviation authorities have stringent noise emission standards, particularly for urban air mobility applications. The powerful V16 engine, while offering high performance, must be engineered to meet these acoustic regulations through advanced noise suppression technologies and innovative exhaust system designs.

Emissions regulations pose another significant hurdle for V16 engines in VTOL aircraft. With increasing focus on environmental sustainability, aviation authorities are implementing stricter emissions standards. Manufacturers must demonstrate that V16 engines can comply with these regulations, potentially necessitating the development of cleaner combustion technologies or the integration of hybrid-electric systems to offset emissions.

Certification processes for novel propulsion systems in VTOL aircraft are rigorous and time-consuming. Regulatory bodies require extensive testing and validation to ensure the safety and reliability of V16 engines in this application. This includes demonstrating the engine's ability to perform under various flight conditions, its durability over extended operational periods, and its integration with the aircraft's control systems.

Weight and size regulations also play a crucial role in the viability of V16 engines for VTOL aircraft. Aviation authorities impose strict limits on aircraft weight and dimensions, particularly for urban air mobility vehicles. Engineers must optimize the V16 engine's design to meet these constraints while maintaining the necessary power output for vertical lift and forward flight.

Fuel efficiency standards are becoming increasingly important in aerospace regulations. While V16 engines are known for their power, they must also demonstrate competitive fuel efficiency to meet regulatory requirements and operational cost targets. This may drive innovations in engine management systems and materials technology to enhance efficiency without compromising performance.

Lastly, the regulatory landscape for VTOL aircraft is evolving rapidly, particularly in response to the emerging urban air mobility sector. Manufacturers pursuing V16-powered VTOL designs must stay abreast of these changes and engage proactively with aviation authorities to shape regulations that accommodate innovative propulsion solutions while maintaining the highest safety standards.

One of the primary regulatory challenges for V16-powered VTOL aircraft lies in noise reduction requirements. Aviation authorities have stringent noise emission standards, particularly for urban air mobility applications. The powerful V16 engine, while offering high performance, must be engineered to meet these acoustic regulations through advanced noise suppression technologies and innovative exhaust system designs.

Emissions regulations pose another significant hurdle for V16 engines in VTOL aircraft. With increasing focus on environmental sustainability, aviation authorities are implementing stricter emissions standards. Manufacturers must demonstrate that V16 engines can comply with these regulations, potentially necessitating the development of cleaner combustion technologies or the integration of hybrid-electric systems to offset emissions.

Certification processes for novel propulsion systems in VTOL aircraft are rigorous and time-consuming. Regulatory bodies require extensive testing and validation to ensure the safety and reliability of V16 engines in this application. This includes demonstrating the engine's ability to perform under various flight conditions, its durability over extended operational periods, and its integration with the aircraft's control systems.

Weight and size regulations also play a crucial role in the viability of V16 engines for VTOL aircraft. Aviation authorities impose strict limits on aircraft weight and dimensions, particularly for urban air mobility vehicles. Engineers must optimize the V16 engine's design to meet these constraints while maintaining the necessary power output for vertical lift and forward flight.

Fuel efficiency standards are becoming increasingly important in aerospace regulations. While V16 engines are known for their power, they must also demonstrate competitive fuel efficiency to meet regulatory requirements and operational cost targets. This may drive innovations in engine management systems and materials technology to enhance efficiency without compromising performance.

Lastly, the regulatory landscape for VTOL aircraft is evolving rapidly, particularly in response to the emerging urban air mobility sector. Manufacturers pursuing V16-powered VTOL designs must stay abreast of these changes and engage proactively with aviation authorities to shape regulations that accommodate innovative propulsion solutions while maintaining the highest safety standards.

Environmental Considerations

The integration of V16 engines in vertical take-off and landing (VTOL) aircraft presents significant environmental considerations that must be carefully evaluated. These powerful engines, while offering potential performance benefits, also pose challenges in terms of emissions, noise pollution, and overall ecological impact.

Emissions from V16 engines in VTOL aircraft are a primary concern. These large displacement engines typically consume substantial amounts of fuel, leading to increased carbon dioxide and other greenhouse gas emissions. The environmental impact is particularly pronounced during the vertical take-off and landing phases, where fuel consumption is at its peak. Addressing these emissions will require innovative solutions, such as the development of more efficient combustion processes or the exploration of alternative fuels.

Noise pollution is another critical environmental factor to consider. V16 engines are known for their distinctive sound profile, which can be particularly disruptive in urban or residential areas where VTOL aircraft might operate. The high-frequency noise generated during take-off and landing could potentially exceed acceptable limits set by environmental regulations. Mitigating this issue may involve advanced sound dampening technologies or redesigning engine components to reduce noise output.

The ecological impact of V16-powered VTOL aircraft extends beyond emissions and noise. The increased power and weight of these engines may necessitate larger aircraft designs, potentially leading to greater habitat disruption in areas where these vehicles operate or are stationed. Additionally, the manufacturing and maintenance of V16 engines involve the use of various materials and chemicals, some of which may have environmental implications if not properly managed.

Water and soil contamination risks associated with fuel leaks or improper disposal of engine fluids must also be addressed. The complexity of V16 engines may increase the likelihood of such incidents, requiring robust containment systems and stringent maintenance protocols to prevent environmental damage.

Energy efficiency is another crucial aspect to consider. While V16 engines can deliver high power output, their fuel efficiency may be lower compared to smaller engines or electric propulsion systems. This inefficiency not only impacts operational costs but also increases the overall environmental footprint of VTOL aircraft utilizing these engines.

To mitigate these environmental concerns, research and development efforts should focus on enhancing the efficiency of V16 engines, exploring hybrid propulsion systems, and investigating the use of sustainable aviation fuels. Additionally, the implementation of advanced engine management systems and noise reduction technologies will be crucial in minimizing the environmental impact of V16-powered VTOL aircraft.

Emissions from V16 engines in VTOL aircraft are a primary concern. These large displacement engines typically consume substantial amounts of fuel, leading to increased carbon dioxide and other greenhouse gas emissions. The environmental impact is particularly pronounced during the vertical take-off and landing phases, where fuel consumption is at its peak. Addressing these emissions will require innovative solutions, such as the development of more efficient combustion processes or the exploration of alternative fuels.

Noise pollution is another critical environmental factor to consider. V16 engines are known for their distinctive sound profile, which can be particularly disruptive in urban or residential areas where VTOL aircraft might operate. The high-frequency noise generated during take-off and landing could potentially exceed acceptable limits set by environmental regulations. Mitigating this issue may involve advanced sound dampening technologies or redesigning engine components to reduce noise output.

The ecological impact of V16-powered VTOL aircraft extends beyond emissions and noise. The increased power and weight of these engines may necessitate larger aircraft designs, potentially leading to greater habitat disruption in areas where these vehicles operate or are stationed. Additionally, the manufacturing and maintenance of V16 engines involve the use of various materials and chemicals, some of which may have environmental implications if not properly managed.

Water and soil contamination risks associated with fuel leaks or improper disposal of engine fluids must also be addressed. The complexity of V16 engines may increase the likelihood of such incidents, requiring robust containment systems and stringent maintenance protocols to prevent environmental damage.

Energy efficiency is another crucial aspect to consider. While V16 engines can deliver high power output, their fuel efficiency may be lower compared to smaller engines or electric propulsion systems. This inefficiency not only impacts operational costs but also increases the overall environmental footprint of VTOL aircraft utilizing these engines.

To mitigate these environmental concerns, research and development efforts should focus on enhancing the efficiency of V16 engines, exploring hybrid propulsion systems, and investigating the use of sustainable aviation fuels. Additionally, the implementation of advanced engine management systems and noise reduction technologies will be crucial in minimizing the environmental impact of V16-powered VTOL aircraft.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!