Exploring Tungsten's Potential In Fusion Reactors

Fusion Reactor Materials Evolution and Objectives

The evolution of fusion reactor materials has been a critical aspect of nuclear fusion research since its inception. Initially, the focus was on developing materials that could withstand the extreme conditions within a fusion reactor, including high temperatures, intense radiation, and strong magnetic fields. Early experiments primarily utilized stainless steel and other conventional alloys, which quickly proved inadequate for long-term fusion operations.

As research progressed, scientists recognized the need for more advanced materials capable of enduring the harsh fusion environment while maintaining structural integrity and minimizing radioactive waste. This led to the development of low-activation materials, such as reduced-activation ferritic/martensitic (RAFM) steels, which became a significant milestone in fusion material science.

The discovery of plasma-facing materials marked another crucial step in the evolution of fusion reactor components. Carbon-based materials, particularly graphite, were initially favored due to their excellent thermal properties and low atomic number. However, their tendency to erode and trap tritium prompted researchers to explore alternatives.

Tungsten emerged as a promising candidate for plasma-facing components due to its high melting point, low sputtering yield, and good thermal conductivity. The transition to tungsten-based materials represented a paradigm shift in fusion reactor design, addressing many of the limitations associated with carbon-based materials.

The objectives of current fusion reactor material research are multifaceted. Primarily, scientists aim to develop materials that can withstand neutron fluxes exceeding 10^14 neutrons/cm^2/s and heat fluxes of up to 10 MW/m^2. Additionally, there is a strong focus on creating materials with low activation properties to minimize long-term radioactive waste.

Another key objective is to improve the overall efficiency and economic viability of fusion reactors. This involves developing materials that not only withstand the extreme conditions but also contribute to enhanced energy conversion and reduced maintenance requirements. Researchers are exploring advanced manufacturing techniques, such as additive manufacturing, to create complex geometries and functionally graded materials that optimize performance.

Looking ahead, the fusion community is setting ambitious goals for material development. These include creating self-healing materials that can repair radiation damage in situ, as well as nanostructured materials that exhibit superior radiation resistance. The ultimate objective is to develop a suite of materials that will enable the construction of commercially viable fusion power plants, capable of providing clean, safe, and virtually limitless energy for future generations.

Tungsten Demand in Nuclear Fusion Industry

The demand for tungsten in the nuclear fusion industry has been steadily increasing as research and development in fusion technology progress. Tungsten plays a crucial role in fusion reactors due to its unique properties, making it an essential material for various components. The primary driver of tungsten demand in this sector is its use in plasma-facing components, particularly the divertor and first wall of fusion reactors.

As fusion research advances, the need for high-performance materials capable of withstanding extreme conditions has become more pronounced. Tungsten's high melting point, excellent thermal conductivity, and low sputtering yield make it an ideal candidate for these applications. The International Thermonuclear Experimental Reactor (ITER) project, the world's largest fusion experiment, has significantly contributed to the increased demand for tungsten in recent years.

The global tungsten market has responded to this growing demand from the fusion industry. Major tungsten producers have been expanding their production capacities and developing specialized grades of tungsten tailored for fusion applications. This has led to the emergence of a niche market segment within the broader tungsten industry, focused on meeting the specific requirements of fusion reactor components.

However, the demand for tungsten in the fusion industry is not without challenges. The high purity requirements and specific material properties needed for fusion applications often result in higher production costs compared to conventional tungsten products. Additionally, the limited number of fusion research facilities and the long development cycles of fusion projects can lead to fluctuations in demand, creating uncertainties for suppliers.

Despite these challenges, the long-term outlook for tungsten demand in the fusion industry remains positive. As fusion technology continues to advance and move closer to commercial viability, the demand for tungsten is expected to grow further. This trend is likely to be reinforced by the increasing global focus on clean energy solutions and the potential of fusion as a sustainable power source.

The fusion industry's demand for tungsten has also spurred innovation in material science and manufacturing processes. Researchers and manufacturers are exploring new ways to enhance tungsten's properties, such as improving its ductility and radiation resistance, to better meet the demanding requirements of fusion reactors. These developments not only benefit the fusion sector but also have potential applications in other high-tech industries, further driving the overall demand for advanced tungsten materials.

Tungsten Properties and Fusion Reactor Challenges

Tungsten possesses unique properties that make it a promising candidate for fusion reactor applications, particularly in the plasma-facing components. Its high melting point of 3422°C, the highest among all metals, enables it to withstand the extreme temperatures encountered in fusion reactors. This thermal stability is crucial for maintaining structural integrity under intense heat loads.

The exceptional density of tungsten, at 19.3 g/cm³, contributes to its ability to resist erosion and sputtering caused by high-energy plasma particles. This resistance is vital for prolonging the lifespan of reactor components and minimizing contamination of the plasma. Additionally, tungsten's low tritium retention characteristics help mitigate fuel loss and reduce safety concerns associated with radioactive tritium accumulation.

However, the use of tungsten in fusion reactors presents several challenges. Its high ductile-to-brittle transition temperature makes it susceptible to embrittlement under neutron irradiation, potentially leading to cracking and failure of components. This issue is particularly pronounced at lower temperatures, necessitating careful thermal management strategies.

The recrystallization of tungsten at high temperatures can result in grain growth and degradation of mechanical properties. This phenomenon may compromise the structural integrity of reactor components over time, requiring innovative solutions to maintain material performance throughout the reactor's operational lifetime.

Tungsten's high atomic number also poses challenges related to plasma contamination. Even small amounts of tungsten entering the plasma can lead to significant radiation losses, potentially disrupting the fusion process. Developing methods to minimize tungsten erosion and control its interaction with the plasma is crucial for maintaining optimal reactor performance.

The manufacturing and fabrication of tungsten components for fusion reactors present additional hurdles. The metal's high hardness and brittleness make it difficult to machine and form into complex shapes required for reactor designs. Advanced manufacturing techniques, such as powder metallurgy and additive manufacturing, are being explored to overcome these limitations and produce tungsten components with desired geometries and properties.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, plasma physics, and engineering. Ongoing studies focus on developing tungsten alloys and composites with improved ductility and radiation resistance, as well as exploring surface modification techniques to enhance tungsten's performance in fusion environments.

Current Tungsten Solutions for Fusion Reactors

01 Tungsten deposition methods

Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.- Tungsten deposition methods: Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.

- Tungsten etching processes: Techniques for selectively removing tungsten from surfaces, often used in semiconductor fabrication. These processes may involve chemical etching, plasma etching, or other methods to pattern tungsten layers or remove unwanted tungsten deposits.

- Tungsten-based alloys and composites: Development of materials that combine tungsten with other elements or compounds to enhance specific properties. These alloys and composites may offer improved strength, conductivity, or other characteristics for various applications.

- Tungsten in electronic components: Use of tungsten in the manufacture of electronic devices, including interconnects, electrodes, and other conductive elements. Tungsten's high melting point and good electrical conductivity make it valuable in this field.

- Tungsten powder production and processing: Methods for producing and processing tungsten powder, including techniques for controlling particle size, shape, and purity. These processes are important for applications in powder metallurgy and the production of tungsten-based components.

02 Tungsten etching processes

Techniques for selectively removing tungsten from surfaces, often used in semiconductor fabrication. These processes may involve chemical etching, plasma etching, or other methods to pattern tungsten layers or remove unwanted tungsten deposits.Expand Specific Solutions03 Tungsten-based alloys and composites

Development of materials that incorporate tungsten with other elements to create alloys or composites with enhanced properties. These materials may offer improved strength, heat resistance, or other desirable characteristics for specific applications.Expand Specific Solutions04 Tungsten in electronic components

Use of tungsten in various electronic components and devices, such as interconnects, electrodes, and heat sinks. Tungsten's high melting point and good electrical conductivity make it valuable in these applications.Expand Specific Solutions05 Tungsten processing and recycling

Methods for processing raw tungsten ore, refining tungsten, and recycling tungsten-containing materials. These processes aim to efficiently extract and reuse tungsten, which is a valuable and relatively rare metal.Expand Specific Solutions

Key Players in Tungsten-based Fusion Research

The exploration of tungsten's potential in fusion reactors is in an early developmental stage, with significant research ongoing but limited commercial applications. The market size is currently small, primarily driven by research funding and government initiatives. Technologically, the field is still maturing, with various institutions and companies contributing to advancements. Key players like Hefei University of Technology, Hefei Institutes of Physical Science, and the University of Science & Technology Beijing are leading academic research. Companies such as Plansee SE and Xiamen Tungsten Co., Ltd. are developing specialized tungsten materials. International collaboration is evident, with involvement from the Centre National de la Recherche Scientifique and Korea Atomic Energy Research Institute, indicating a global effort to harness tungsten's potential in fusion technology.

Plansee SE

Korea Atomic Energy Research Institute

Innovative Tungsten Alloys for Fusion Environment

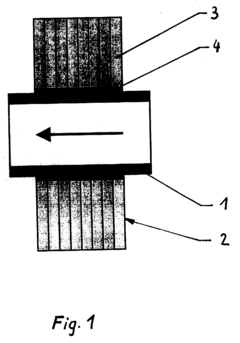

- Designing tungsten or tungsten alloy sections as laminated packages with individual sheet metal sections of 0.1 to 2 mm thickness, and incorporating a particle-hardened alloy with 0.3-5% lanthanum oxide, which reduces crack formation and propagation, and integrating these laminated parts with a copper alloy coolant-carrying tube for enhanced thermal shock resistance.

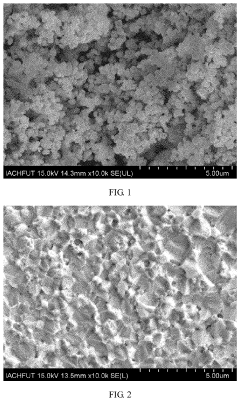

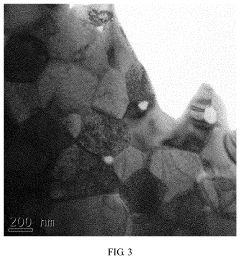

- A high-hardness composite oxide dispersion-strengthened tungsten alloy is developed by incorporating nano-scale Y2O3 and ZrO2 particles, refined through a wet chemical method and spark plasma sintering, creating a Y—Zr—O ternary phase structure that enhances interface strength and mechanical properties.

Safety and Radiation Considerations

Safety and radiation considerations are paramount when exploring tungsten's potential in fusion reactors. Tungsten's high melting point and excellent thermal conductivity make it an attractive material for plasma-facing components, but its use also presents unique challenges in terms of safety and radiation management.

One of the primary concerns is the activation of tungsten under neutron bombardment. When exposed to the high-energy neutrons produced in fusion reactions, tungsten can become radioactive, forming various isotopes with different half-lives. This activation not only affects the material properties but also poses long-term waste management issues. Careful analysis of the activation products and their decay chains is essential for developing appropriate handling and disposal strategies.

Radiation shielding is another critical aspect when using tungsten in fusion reactors. While tungsten's high density provides excellent shielding properties against gamma radiation, it is less effective against neutrons. This necessitates the development of composite shielding solutions that combine tungsten with other materials to provide comprehensive protection for both reactor personnel and the surrounding environment.

The potential for dust formation is a significant safety concern in tungsten-based fusion reactor components. Tungsten dust can be highly reactive and potentially explosive, posing risks to both operational safety and maintenance procedures. Implementing robust dust management systems and developing specialized cleaning protocols are crucial to mitigate these risks.

Tritium retention in tungsten is another important consideration. Tritium, a radioactive isotope of hydrogen used in fusion fuel, can be trapped within the tungsten structure. This retention can lead to increased radioactive inventory and potential release hazards. Developing effective methods for tritium removal and monitoring is essential for maintaining safe reactor operations and minimizing environmental impact.

The mechanical integrity of tungsten components under extreme conditions is also a key safety factor. The intense heat and radiation environment in a fusion reactor can cause material degradation, potentially leading to structural failures. Comprehensive testing and modeling of tungsten's behavior under these conditions are necessary to ensure the long-term reliability and safety of reactor components.

Lastly, the development of advanced diagnostic tools and monitoring systems is crucial for ensuring the safe operation of tungsten-based components in fusion reactors. Real-time monitoring of material conditions, radiation levels, and potential failure modes will be essential for maintaining optimal safety standards and enabling rapid response to any emerging issues.

Economic Feasibility of Tungsten in Fusion Energy

The economic feasibility of tungsten in fusion energy is a critical consideration for the development and implementation of fusion reactors. Tungsten's unique properties make it a promising material for fusion reactor components, particularly in the divertor region where it must withstand extreme heat and particle bombardment. However, the economic viability of using tungsten in large-scale fusion projects depends on several factors.

Firstly, the cost of tungsten itself is a significant consideration. While tungsten is not a rare element, its extraction and processing can be expensive. The current market price of tungsten fluctuates, but it remains relatively high compared to other structural materials. This cost must be weighed against the potential long-term benefits of using tungsten in fusion reactors, such as increased durability and reduced maintenance requirements.

The manufacturing processes for tungsten components also contribute to the overall economic picture. Tungsten's high melting point and hardness make it challenging to work with, often requiring specialized and costly fabrication techniques. These include powder metallurgy, additive manufacturing, and advanced machining processes. The development of more efficient and cost-effective manufacturing methods for tungsten components is crucial for improving the economic feasibility of its use in fusion reactors.

Another economic consideration is the potential for recycling and reuse of tungsten components. Given the high initial cost of tungsten, the ability to recycle and reprocess used components could significantly improve the long-term economic viability of tungsten in fusion energy. Research into efficient recycling methods and the potential for reusing tungsten from decommissioned reactors is an important area of study.

The economic feasibility also depends on the performance and longevity of tungsten components in operational fusion reactors. If tungsten components can significantly extend the operational life of reactor parts and reduce downtime for maintenance, this could offset the higher initial costs. Studies on the behavior of tungsten under fusion conditions, including its resistance to neutron damage and retention of tritium, are crucial for accurately assessing its long-term economic benefits.

Lastly, the scale of fusion reactor projects and the potential for mass production of tungsten components play a role in economic feasibility. As fusion technology advances and more reactors are built, economies of scale could reduce the cost of tungsten components. Additionally, increased demand for tungsten in the fusion industry could drive innovation in extraction and processing technologies, potentially lowering costs over time.