How To Drive Business Value With Tungsten Innovation?

Tungsten Innovation Landscape and Objectives

Tungsten innovation has emerged as a critical area of focus in the materials science and engineering sectors, driven by the unique properties of this versatile metal. The landscape of tungsten innovation spans across multiple industries, including aerospace, electronics, energy, and advanced manufacturing. As global demand for high-performance materials continues to grow, tungsten's exceptional characteristics, such as its high melting point, excellent thermal and electrical conductivity, and superior strength, position it as a key player in driving technological advancements.

The objectives of tungsten innovation are multifaceted, aiming to address both current industrial needs and future challenges. One primary goal is to enhance the efficiency and durability of existing tungsten-based products, such as cutting tools, mining equipment, and radiation shielding materials. This involves developing new alloys and composites that leverage tungsten's inherent properties while mitigating its limitations, such as its relatively high density and potential for brittleness.

Another crucial objective is to explore novel applications for tungsten in emerging technologies. This includes its potential use in advanced nuclear reactors, where tungsten's heat resistance and radiation shielding capabilities make it an attractive material for reactor components. In the field of electronics, researchers are investigating tungsten's role in next-generation semiconductors and high-frequency devices, capitalizing on its excellent electrical properties and thermal management capabilities.

Sustainability is also a key focus in the tungsten innovation landscape. Efforts are underway to develop more efficient recycling processes for tungsten-containing products, addressing the metal's limited global supply and reducing environmental impact. Additionally, researchers are exploring ways to minimize tungsten's energy-intensive production processes, aligning with global efforts to reduce carbon emissions in industrial manufacturing.

The tungsten innovation landscape is further shaped by geopolitical factors, as the metal's strategic importance has led to increased focus on securing stable supply chains and developing alternative sources. This has spurred research into urban mining and the recovery of tungsten from secondary sources, as well as the exploration of new extraction technologies for low-grade ores.

As we look to drive business value through tungsten innovation, the objectives extend beyond purely technical advancements. There is a growing emphasis on creating value-added products and services that leverage tungsten's unique properties to solve complex industrial challenges. This includes developing customized tungsten-based solutions for specific industry applications, as well as creating new business models around tungsten recycling and resource management.

Market Demand for Advanced Tungsten Solutions

The market demand for advanced tungsten solutions has been steadily growing across various industries, driven by the unique properties of tungsten and its alloys. Tungsten's exceptional hardness, high melting point, and excellent thermal and electrical conductivity make it indispensable in numerous applications, from aerospace and automotive to electronics and energy sectors.

In the aerospace industry, there is a significant demand for tungsten-based materials in aircraft engines and rocket nozzles due to their ability to withstand extreme temperatures and pressures. The automotive sector is increasingly adopting tungsten alloys for wear-resistant components, such as valve seats and turbocharger rotors, to enhance engine performance and durability.

The electronics industry relies heavily on tungsten for its use in integrated circuits, heat sinks, and electrical contacts. As electronic devices become more compact and powerful, the demand for tungsten's thermal management properties continues to rise. Additionally, the growing trend of miniaturization in consumer electronics has led to increased use of tungsten in microelectronic applications.

In the energy sector, tungsten plays a crucial role in both traditional and renewable energy technologies. Nuclear power plants utilize tungsten alloys for radiation shielding, while the wind energy industry employs tungsten in wear-resistant components for wind turbines. The oil and gas sector also demands tungsten-based materials for drilling equipment and wear-resistant coatings.

The medical field has seen a surge in demand for tungsten solutions, particularly in radiation shielding for diagnostic imaging equipment and cancer treatment technologies. Tungsten's high density makes it an ideal material for X-ray collimators and radiation therapy equipment.

As global industrialization continues, the demand for cutting tools and mining equipment made from tungsten carbide remains strong. These tools offer superior hardness and wear resistance, essential for increasing productivity in manufacturing and resource extraction industries.

The market for advanced tungsten solutions is also being driven by emerging technologies such as additive manufacturing and 3D printing. Tungsten powders are being developed for use in these processes, opening up new possibilities for creating complex, high-performance components across various industries.

Environmental concerns and sustainability initiatives are shaping the demand for tungsten recycling and more efficient use of tungsten resources. This has led to increased interest in developing innovative recycling technologies and exploring alternative sources of tungsten to ensure a stable supply chain.

Current Challenges in Tungsten Technology

Despite its long history and widespread use, tungsten technology faces several significant challenges that hinder its full potential in driving business value. One of the primary issues is the limited availability and high cost of raw materials. Tungsten is a rare metal, and its extraction and processing are complex and expensive, leading to supply chain vulnerabilities and price volatility.

Another major challenge is the environmental impact of tungsten mining and processing. Traditional methods often involve harmful chemicals and generate substantial waste, raising concerns about sustainability and regulatory compliance. This has led to increased pressure on companies to develop more eco-friendly extraction and production techniques.

The high melting point of tungsten, while advantageous in many applications, also presents difficulties in manufacturing and processing. Specialized equipment and expertise are required to work with tungsten, which can increase production costs and limit innovation in certain areas.

Tungsten's brittleness is another technical challenge, particularly in applications requiring high impact resistance. This property limits its use in certain industries and necessitates the development of composite materials or alternative alloys to overcome this limitation.

In the realm of advanced technologies, there is a growing need for tungsten materials with enhanced properties. For instance, the semiconductor industry demands ultra-high purity tungsten for use in chip manufacturing. Achieving and maintaining such purity levels at scale remains a significant technical hurdle.

The recycling of tungsten products is another area facing challenges. While tungsten is highly recyclable, the processes for recovering and reprocessing tungsten from end-of-life products are not yet optimized for efficiency and cost-effectiveness. This gap in the circular economy of tungsten represents both a challenge and an opportunity for innovation.

Lastly, the development of alternatives to tungsten in certain applications poses a competitive threat. As industries seek to reduce dependence on rare and costly materials, research into substitutes for tungsten is ongoing. This trend necessitates continuous innovation in tungsten technology to maintain its relevance and competitive edge in various markets.

Addressing these challenges requires a multifaceted approach, combining technological innovation, sustainable practices, and strategic business planning. Overcoming these hurdles will be crucial for companies looking to drive business value through tungsten innovation in the coming years.

Existing Tungsten Innovation Strategies

01 Business value assessment and optimization

Tungsten's business value can be assessed and optimized through various methods, including data analysis, performance metrics, and strategic planning. This involves evaluating the company's assets, market position, and potential for growth to maximize its overall value and competitiveness in the industry.- Business value assessment and optimization: Methods and systems for assessing and optimizing business value in various industries, including those involving tungsten. This includes techniques for evaluating financial performance, market positioning, and strategic decision-making to maximize the value of tungsten-related businesses.

- Supply chain management for tungsten: Strategies and technologies for managing the supply chain of tungsten, from mining to end-use products. This involves optimizing logistics, inventory management, and distribution processes to enhance the overall business value of tungsten-related operations.

- Tungsten processing and manufacturing innovations: Advancements in tungsten processing and manufacturing techniques that contribute to increased business value. This includes improved methods for refining, shaping, and integrating tungsten into various products, leading to enhanced efficiency and product quality.

- Market analysis and forecasting for tungsten: Tools and methodologies for analyzing the tungsten market and forecasting future trends. This involves assessing supply and demand dynamics, price fluctuations, and emerging applications to inform strategic business decisions and maximize value.

- Intellectual property management in tungsten industry: Strategies for managing intellectual property related to tungsten technologies and applications. This includes patent portfolio management, licensing strategies, and protection of proprietary processes to enhance the overall business value of tungsten-related innovations.

02 Supply chain management and logistics

Efficient supply chain management and logistics are crucial for maximizing the business value of tungsten operations. This includes optimizing procurement, inventory management, and distribution processes to reduce costs and improve overall operational efficiency in the tungsten industry.Expand Specific Solutions03 Technological advancements in tungsten processing

Innovations in tungsten processing technologies can significantly enhance its business value. This includes developing more efficient extraction methods, refining processes, and manufacturing techniques to improve product quality and reduce production costs, thereby increasing the overall value of tungsten-based products and operations.Expand Specific Solutions04 Market analysis and strategic positioning

Conducting thorough market analysis and strategic positioning is essential for maximizing tungsten's business value. This involves identifying market trends, assessing competition, and developing strategies to capitalize on emerging opportunities in various industries that utilize tungsten, such as electronics, aerospace, and automotive sectors.Expand Specific Solutions05 Intellectual property management and innovation

Effective management of intellectual property and continuous innovation are key factors in enhancing tungsten's business value. This includes protecting proprietary technologies, developing new applications for tungsten, and fostering a culture of innovation to maintain a competitive edge in the market and drive long-term growth.Expand Specific Solutions

Key Players in Tungsten Industry

The tungsten innovation market is in a growth phase, driven by increasing demand across various industries. The market size is expanding, with applications in electronics, aerospace, and automotive sectors. Technologically, tungsten innovation is advancing rapidly, with companies like Applied Materials, Inc. and Kennametal, Inc. leading in research and development. The competitive landscape is diverse, featuring established players such as Xiamen Tungsten Co., Ltd. and emerging innovators like Tundra Composites LLC. Universities like Central South University and Hefei University of Technology are contributing to technological advancements, while global corporations like BASF Corp. and Sumitomo Electric Industries Ltd. are integrating tungsten innovations into their product lines, indicating a maturing but still evolving technological field.

Applied Materials, Inc.

Kennametal, Inc.

Breakthrough Tungsten Technologies

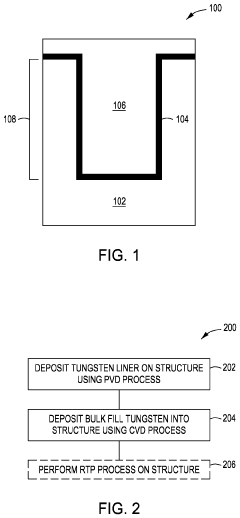

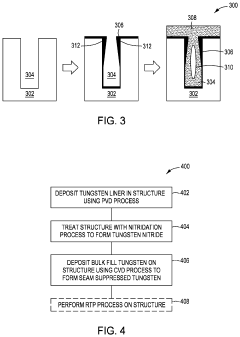

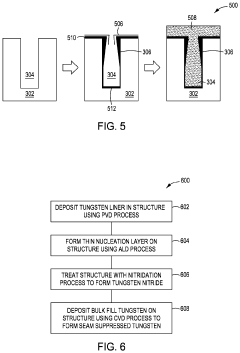

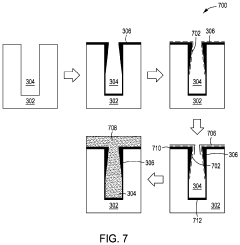

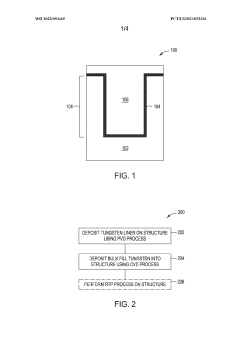

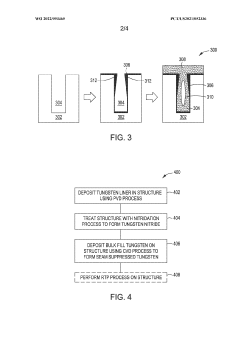

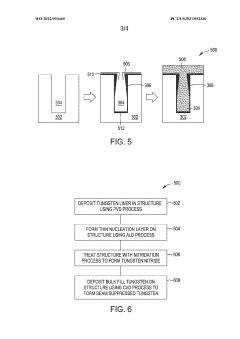

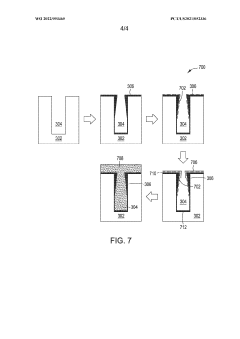

- The proposed method involves a physical vapor deposition of a tungsten liner, followed by an atomic layer deposition nucleation layer and a chemical vapor deposition bulk fill process, with a nitridation step and optional rapid thermal processing to reduce internal stresses and lower resistivity, using argon or krypton as ambient gases and optimizing temperature, pressure, and nitridation conditions.

- The method involves depositing a tungsten liner using physical vapor deposition, followed by a nitridation process and bulk fill tungsten using chemical vapor deposition, with optional rapid thermal processing to reduce internal stresses and lower resistivity, while eliminating boron to prevent adhesion issues.

Economic Impact of Tungsten Innovation

Tungsten innovation has the potential to drive significant economic impact across various industries. The unique properties of tungsten, including its high melting point, density, and strength, make it a valuable material for numerous applications. As industries continue to push the boundaries of technology and performance, tungsten innovations are poised to play a crucial role in driving economic growth and competitiveness.

In the manufacturing sector, tungsten innovations can lead to improved efficiency and productivity. Advanced tungsten-based cutting tools and wear-resistant components can extend the lifespan of machinery and reduce downtime, resulting in substantial cost savings for businesses. This increased productivity can contribute to overall economic growth and competitiveness in global markets.

The energy sector stands to benefit greatly from tungsten innovations. As the world transitions towards cleaner energy sources, tungsten's properties make it an ideal material for various applications in renewable energy technologies. For instance, tungsten-based components in wind turbines can enhance their durability and efficiency, leading to increased energy production and reduced maintenance costs. This can accelerate the adoption of renewable energy and contribute to the growth of the green economy.

In the aerospace and automotive industries, tungsten innovations can drive advancements in lightweight, high-strength materials. This can lead to improved fuel efficiency and performance in vehicles and aircraft, resulting in economic benefits through reduced fuel consumption and increased competitiveness. Additionally, the development of tungsten-based alloys for use in extreme environments can open up new possibilities for space exploration and advanced transportation systems.

The electronics industry can also experience significant economic impact from tungsten innovations. As devices become smaller and more powerful, tungsten's thermal management properties and electrical conductivity make it an attractive material for advanced semiconductor applications. This can lead to the development of more efficient and capable electronic devices, driving economic growth in the technology sector.

Furthermore, tungsten innovations in the medical field can have far-reaching economic implications. The material's biocompatibility and radiopacity make it valuable for medical implants and imaging technologies. Advancements in tungsten-based medical devices can improve patient outcomes, reduce healthcare costs, and drive growth in the medical technology industry.

In conclusion, the economic impact of tungsten innovation extends across multiple sectors, driving efficiency, productivity, and technological advancements. By leveraging the unique properties of tungsten, businesses can create new products, improve existing processes, and gain a competitive edge in the global market. This innovation-driven growth has the potential to stimulate job creation, increase exports, and contribute significantly to overall economic development.

Sustainability in Tungsten Innovation

Sustainability in tungsten innovation is becoming increasingly crucial as businesses seek to balance economic growth with environmental responsibility. The tungsten industry, known for its significant environmental impact, is undergoing a transformation towards more sustainable practices. This shift is driven by regulatory pressures, consumer demands, and the recognition that sustainable operations can lead to long-term business value.

One of the primary areas of focus in sustainable tungsten innovation is the development of more efficient extraction and processing methods. Traditional tungsten mining and refining processes are energy-intensive and often result in significant waste generation. Innovative technologies are being explored to reduce energy consumption and minimize environmental degradation. These include advanced ore sorting techniques, which can significantly reduce the amount of material that needs to be processed, thereby decreasing energy use and waste production.

Recycling and circular economy principles are also gaining traction in the tungsten industry. As tungsten is a finite resource, there is a growing emphasis on recovering and reusing tungsten from end-of-life products. This not only conserves natural resources but also reduces the need for energy-intensive primary production. Companies are investing in advanced recycling technologies that can efficiently extract tungsten from complex waste streams, creating new revenue streams while contributing to sustainability goals.

Water management is another critical aspect of sustainable tungsten innovation. Many tungsten mining and processing operations are water-intensive, often in regions where water scarcity is a concern. Innovations in water recycling, treatment, and conservation are being implemented to reduce freshwater consumption and minimize the discharge of contaminated water. These efforts not only improve environmental performance but also enhance operational efficiency and reduce costs associated with water management.

The development of alternative, more environmentally friendly tungsten compounds is also driving sustainability in the industry. Researchers are exploring new formulations that maintain the desirable properties of tungsten while reducing toxicity and environmental persistence. This innovation not only addresses environmental concerns but also opens up new market opportunities for tungsten-based products in industries with strict environmental regulations.

Sustainable tungsten innovation extends beyond production processes to encompass the entire value chain. Companies are increasingly adopting life cycle assessment approaches to understand and mitigate the environmental impacts of tungsten products from cradle to grave. This holistic view enables businesses to identify opportunities for improvement throughout the product lifecycle, from raw material sourcing to end-of-life management.