Tungsten-Based Solutions For Corrosive Environments

Tungsten Corrosion Resistance Evolution

The evolution of tungsten's corrosion resistance has been a significant journey in materials science, driven by the increasing demand for materials capable of withstanding harsh, corrosive environments. Initially, tungsten was primarily valued for its high melting point and mechanical strength, but its potential for corrosion resistance was not fully realized.

In the early stages of tungsten's development, researchers focused on understanding its basic properties and behavior in various environments. The metal's inherent resistance to many acids and its stability at high temperatures were recognized, but its susceptibility to oxidation at elevated temperatures was a limiting factor.

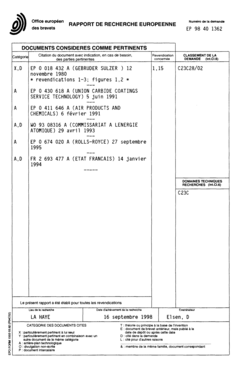

The 1950s and 1960s saw a surge in research aimed at improving tungsten's corrosion resistance. Scientists began experimenting with alloying elements and surface treatments to enhance its performance. One significant breakthrough came with the development of tungsten carbide coatings, which dramatically improved the metal's resistance to wear and corrosion in industrial applications.

The 1970s and 1980s marked a period of rapid advancement in tungsten-based corrosion-resistant materials. Researchers developed more sophisticated alloying techniques, incorporating elements like rhenium, molybdenum, and tantalum to create tungsten alloys with superior corrosion resistance. These alloys found applications in chemical processing equipment, aerospace components, and nuclear reactors.

In the 1990s, nanotechnology began to play a crucial role in enhancing tungsten's corrosion resistance. Nanostructured tungsten coatings and composites were developed, offering unprecedented levels of protection against corrosive environments. These innovations opened up new possibilities for tungsten in extreme conditions, such as in plasma-facing components for fusion reactors.

The turn of the millennium saw a shift towards more environmentally friendly and sustainable solutions. Researchers began exploring ways to improve tungsten's corrosion resistance while minimizing the use of rare or toxic alloying elements. This led to the development of advanced surface modification techniques, such as ion implantation and plasma spraying, which could enhance corrosion resistance without significantly altering the bulk properties of the material.

In recent years, computational materials science has accelerated the evolution of tungsten-based corrosion-resistant solutions. Machine learning algorithms and high-throughput screening methods have enabled researchers to predict and design novel tungsten alloys and composites with optimized corrosion resistance properties. This data-driven approach has significantly reduced the time and cost associated with developing new materials.

Today, the focus is on creating multi-functional tungsten-based materials that not only offer superior corrosion resistance but also excel in other areas such as thermal management, radiation shielding, and self-healing capabilities. These advanced materials are pushing the boundaries of what is possible in extreme environments, from deep-sea exploration to space technology.

Market Demand Analysis

The market demand for tungsten-based solutions in corrosive environments has been steadily increasing across various industries. This growth is primarily driven by the exceptional properties of tungsten, particularly its high melting point, excellent corrosion resistance, and superior mechanical strength. These characteristics make tungsten-based materials ideal for applications in harsh and corrosive settings.

In the chemical processing industry, there is a significant demand for tungsten-based equipment and components. Reactors, heat exchangers, and piping systems in chemical plants often require materials that can withstand aggressive chemicals and high temperatures. Tungsten alloys offer a reliable solution, leading to increased adoption and market growth in this sector.

The oil and gas industry represents another major market for tungsten-based solutions. Offshore drilling operations and deep-sea exploration face extreme corrosive conditions due to saltwater exposure and high pressures. Tungsten-based coatings and components are increasingly used in drilling equipment, valves, and subsea structures to enhance durability and extend operational lifespans.

In the power generation sector, particularly in nuclear and fossil fuel plants, there is a growing need for corrosion-resistant materials. Tungsten-based alloys are being employed in turbine components, heat exchangers, and other critical parts exposed to high-temperature steam and corrosive gases. This trend is expected to continue as the industry focuses on improving efficiency and reducing maintenance costs.

The aerospace and defense sectors also contribute significantly to the market demand for tungsten-based solutions. Aircraft engines, rocket nozzles, and military equipment often operate in extreme environments, necessitating materials with superior corrosion resistance and high-temperature stability. Tungsten alloys and coatings are increasingly specified for these applications, driving market growth.

Environmental regulations and sustainability concerns are further propelling the demand for tungsten-based solutions. As industries seek to reduce emissions and improve process efficiency, there is a growing interest in materials that can withstand more aggressive operating conditions. Tungsten-based materials enable the design of more efficient and durable equipment, aligning with these environmental goals.

The global market for corrosion-resistant materials, including tungsten-based solutions, is projected to experience substantial growth in the coming years. Factors such as increasing industrialization in developing countries, ongoing technological advancements, and the need for materials capable of withstanding extreme conditions are expected to drive this expansion. As research and development efforts continue to improve the properties and applications of tungsten-based materials, their market penetration is likely to increase across a wider range of industries.

Current Challenges

Tungsten-based solutions for corrosive environments face several significant challenges that hinder their widespread adoption and effectiveness. One of the primary obstacles is the high cost associated with tungsten and its alloys. The expense of raw materials, processing, and manufacturing limits the economic viability of tungsten-based solutions, particularly for large-scale applications or in industries with tight budget constraints.

Another critical challenge is the limited formability and machinability of tungsten. Its high melting point and hardness, while beneficial for corrosion resistance, make it difficult to shape and fabricate into complex components. This limitation restricts the design flexibility and potential applications of tungsten-based solutions in various corrosive environments.

The brittleness of tungsten at room temperature poses a significant challenge, especially in dynamic or high-stress environments. This inherent property increases the risk of cracking or failure under certain operating conditions, potentially compromising the integrity of the protective layer in corrosive settings.

Oxidation resistance remains a concern for tungsten-based solutions, particularly at elevated temperatures. While tungsten exhibits excellent corrosion resistance in many environments, it can form volatile oxides in high-temperature oxidizing atmospheres, leading to material loss and degradation of protective properties.

The development of effective coating techniques for tungsten-based solutions presents another challenge. Ensuring uniform, adherent, and defect-free coatings on various substrate materials is crucial for optimal corrosion protection. Current coating technologies often struggle to achieve the desired level of consistency and durability, especially for complex geometries or large surfaces.

Compatibility issues between tungsten-based materials and other components in corrosive systems can also pose challenges. The potential for galvanic corrosion when tungsten is in contact with dissimilar metals must be carefully considered and mitigated in design and implementation.

Long-term stability and performance of tungsten-based solutions in diverse corrosive environments remain areas of ongoing research. Understanding the degradation mechanisms, predicting service life, and developing strategies to enhance longevity are critical challenges that require further investigation and technological advancements.

Lastly, the environmental impact and sustainability of tungsten-based solutions present growing concerns. The mining and processing of tungsten have significant environmental footprints, and the recyclability and end-of-life management of tungsten-containing products need to be addressed to ensure long-term sustainability and regulatory compliance.

Existing Tungsten Solutions

01 Alloying elements for improved corrosion resistance

Adding specific alloying elements to tungsten-based materials can significantly enhance their corrosion resistance. These elements form protective layers or alter the material's microstructure, making it more resistant to various corrosive environments. Common alloying elements include chromium, nickel, and molybdenum, which can create passive films or increase the overall stability of the material.- Alloying elements for improved corrosion resistance: Adding specific alloying elements to tungsten-based materials can significantly enhance their corrosion resistance. These elements form protective oxide layers or alter the material's microstructure, making it more resistant to various corrosive environments. Common alloying elements include chromium, molybdenum, and rhenium.

- Surface treatments and coatings: Applying surface treatments or protective coatings to tungsten-based materials can greatly improve their corrosion resistance. These treatments may include nitriding, carburizing, or depositing thin films of corrosion-resistant materials such as ceramics or noble metals. The coatings act as a barrier between the tungsten material and the corrosive environment.

- Microstructure optimization: Optimizing the microstructure of tungsten-based materials through heat treatments, mechanical processing, or advanced manufacturing techniques can enhance their corrosion resistance. This may involve controlling grain size, reducing porosity, or creating specific phase distributions that are more resistant to corrosive attack.

- Composite materials and reinforcements: Developing tungsten-based composite materials or incorporating reinforcements can improve corrosion resistance. This may involve adding ceramic particles, fibers, or creating layered structures that combine the strength of tungsten with the corrosion resistance of other materials.

- Environmental control and inhibitors: Implementing environmental control measures or using corrosion inhibitors can enhance the corrosion resistance of tungsten-based materials in specific applications. This may include controlling pH levels, removing aggressive species from the environment, or adding chemical inhibitors that form protective films on the material surface.

02 Surface treatments and coatings

Applying surface treatments or protective coatings to tungsten-based materials can greatly improve their corrosion resistance. These treatments may include nitriding, carburizing, or the application of ceramic or metallic coatings. Such processes create a barrier between the base material and the corrosive environment, effectively prolonging the lifespan of the tungsten-based components.Expand Specific Solutions03 Microstructure optimization

Optimizing the microstructure of tungsten-based materials through heat treatments, mechanical processing, or advanced manufacturing techniques can enhance their corrosion resistance. This may involve controlling grain size, reducing porosity, or creating specific phase distributions that are more resistant to corrosive attack. Improved microstructures can lead to better overall material performance in corrosive environments.Expand Specific Solutions04 Composite materials and reinforcements

Developing tungsten-based composite materials or incorporating reinforcements can improve corrosion resistance. This may involve adding ceramic particles, fibers, or creating layered structures that combine the beneficial properties of multiple materials. Such composites can provide enhanced corrosion resistance while maintaining other desirable properties of tungsten-based materials.Expand Specific Solutions05 Environmental control and inhibitors

Implementing environmental control measures or using corrosion inhibitors can help protect tungsten-based materials from corrosive attack. This may involve controlling pH levels, removing aggressive species from the environment, or adding specific inhibitors that form protective films on the material surface. These approaches can significantly extend the service life of tungsten-based components in corrosive applications.Expand Specific Solutions

Key Industry Players

The market for tungsten-based solutions in corrosive environments is in a growth phase, driven by increasing demand across various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like NIPPON STEEL CORP., Henkel AG & Co. KGaA, and Ecolab USA, Inc. leading innovation. These firms, along with others such as Resonac Corp. and Plansee SE, are developing sophisticated tungsten-based materials and coatings to enhance corrosion resistance. The technology's maturity varies across applications, with some solutions already commercialized while others are still in research stages, as evidenced by involvement from academic institutions like Central South University and Jilin University.

NIPPON STEEL CORP.

Gesellschaft für Wolfram-Industrie mbH

Innovative Tungsten Alloys

- The use of a tungstate-based corrosion inhibitor, combined with an iron stabilizer such as a dispersant polymer, effectively inhibits corrosion in ferrous metal surfaces by maintaining soluble ferrous ions and preventing particulate formation, while being non-foaming and non-sludging, using alkali metal tungstates like sodium tungstate at effective concentrations.

- A multilayer material with a tungsten-based deposit and an underlayer of intermediate mechanical and thermomechanical properties, composed of materials like chromium, molybdenum, niobium, titanium, and their nitrides or carbides, is used, which enhances adhesion by creating a chemical bond and reducing thermal stress.

Environmental Impact Assessment

The environmental impact of tungsten-based solutions for corrosive environments is a critical consideration in their development and implementation. These solutions, while offering significant advantages in terms of corrosion resistance, can potentially have both positive and negative effects on the environment.

One of the primary environmental benefits of tungsten-based solutions is their ability to extend the lifespan of equipment and infrastructure in corrosive environments. This longevity reduces the frequency of replacements, thereby minimizing waste generation and the associated environmental impacts of manufacturing and disposal. Additionally, the improved durability of tungsten-coated surfaces can lead to reduced material consumption over time, contributing to resource conservation.

However, the production and processing of tungsten can have environmental implications. Mining operations for tungsten ore can lead to habitat disruption, soil erosion, and potential water pollution if not managed properly. The refining process of tungsten is energy-intensive, contributing to greenhouse gas emissions. Proper management of waste products from tungsten processing is crucial to prevent contamination of soil and water resources.

In corrosive environments, the use of tungsten-based solutions can help prevent leaks and spills of hazardous materials, thereby protecting surrounding ecosystems. This is particularly important in industries such as chemical processing, where containment of corrosive substances is critical for environmental safety.

The potential for tungsten to leach into the environment must be carefully assessed. While tungsten is generally considered to have low toxicity compared to many other metals, its long-term environmental effects are still being studied. In aquatic environments, there is concern about the potential bioaccumulation of tungsten in organisms, which could have implications for the food chain.

Recycling and end-of-life management of tungsten-based products are important considerations. Tungsten's high value and recyclability offer opportunities for closed-loop systems, reducing the need for primary resource extraction. However, effective recycling processes must be developed and implemented to fully realize these benefits.

In conclusion, while tungsten-based solutions offer significant environmental advantages in terms of durability and corrosion resistance, their overall environmental impact must be carefully managed throughout the product lifecycle. This includes responsible mining practices, efficient production processes, proper application and maintenance, and effective recycling strategies. Ongoing research into the long-term environmental effects of tungsten is essential to ensure the sustainable use of these solutions in corrosive environments.

Cost-Benefit Analysis

The implementation of tungsten-based solutions for corrosive environments requires a comprehensive cost-benefit analysis to determine their economic viability and long-term value. Initial investment costs for tungsten-based materials and coatings are typically higher than traditional alternatives due to the rarity and processing complexity of tungsten. However, these upfront expenses must be weighed against the potential long-term savings and operational benefits.

One of the primary advantages of tungsten-based solutions is their exceptional durability in harsh environments. This translates to reduced maintenance frequency and extended equipment lifespans, potentially offsetting the higher initial costs over time. For instance, in chemical processing plants, tungsten-coated components may require replacement far less often than standard materials, minimizing production downtime and associated losses.

The corrosion resistance of tungsten-based solutions also contributes to improved safety and reduced environmental risks. By preventing material degradation and potential failures, these solutions can help avoid costly accidents, environmental cleanup efforts, and regulatory fines. This aspect of risk mitigation should be factored into the overall cost-benefit equation.

Energy efficiency is another consideration in the analysis. Tungsten's thermal properties can lead to improved heat management in certain applications, potentially reducing energy consumption and associated costs over the long term. This is particularly relevant in high-temperature industrial processes where energy expenses form a significant portion of operational costs.

The recyclability of tungsten presents an additional economic benefit. Unlike some corrosion-resistant materials, tungsten can be reclaimed and reprocessed at the end of a component's lifecycle, potentially recovering some of the initial material costs and aligning with circular economy principles.

However, the cost-benefit analysis must also account for potential drawbacks. The limited availability of tungsten may lead to supply chain vulnerabilities and price fluctuations, which could impact long-term cost projections. Additionally, the specialized nature of tungsten processing and application may require investment in new equipment or staff training, further increasing initial costs.

When conducting a thorough cost-benefit analysis, it is crucial to consider industry-specific factors and operational contexts. For example, in aerospace applications, the weight savings offered by tungsten alloys may translate to fuel efficiency gains, providing a unique economic advantage. Conversely, in less demanding environments, the benefits of tungsten-based solutions may not justify the higher costs.

In conclusion, while tungsten-based solutions for corrosive environments often come with higher upfront costs, their potential to deliver long-term savings through increased durability, reduced maintenance, and improved operational efficiency can make them economically attractive. A comprehensive cost-benefit analysis, tailored to specific industry needs and operational conditions, is essential for making informed decisions about the adoption of these advanced materials.