How To Integrate Tungsten In Biocompatible Applications?

Tungsten Biocompatibility Background and Objectives

Tungsten, a metal with exceptional properties, has garnered significant attention in the field of biomedical engineering due to its potential for biocompatible applications. The integration of tungsten in biocompatible applications represents a promising frontier in materials science and medical technology. This technological domain has evolved rapidly over the past few decades, driven by the increasing demand for advanced materials in medical devices, implants, and diagnostic tools.

The historical development of tungsten in biomedical applications can be traced back to its initial use in X-ray tubes and radiation shielding. As research progressed, scientists and engineers began to explore tungsten's unique characteristics, such as its high density, excellent mechanical strength, and corrosion resistance, for broader biomedical applications. This exploration has led to a growing interest in leveraging tungsten's properties to enhance the performance and longevity of medical implants and devices.

The primary objective of integrating tungsten in biocompatible applications is to harness its superior physical and chemical properties while ensuring compatibility with biological systems. This goal encompasses several key aspects, including improving the durability and functionality of medical implants, enhancing the precision and effectiveness of surgical instruments, and developing novel diagnostic and therapeutic tools. Researchers aim to overcome the challenges associated with tungsten's potential toxicity and optimize its surface properties to promote better integration with living tissues.

Current technological trends in this field focus on developing innovative tungsten-based alloys and composites that combine biocompatibility with the metal's inherent strengths. These efforts are driven by the need for materials that can withstand the harsh biological environment while maintaining their structural integrity and functionality over extended periods. Additionally, there is a growing emphasis on surface modification techniques to enhance the biocompatibility of tungsten-based materials, such as coating technologies and nanostructuring approaches.

The integration of tungsten in biocompatible applications intersects with several emerging technologies, including 3D printing of medical devices, nanoparticle-based drug delivery systems, and advanced imaging techniques. These synergies are expected to drive further innovation and expand the potential applications of tungsten in the biomedical field. As research continues to advance, the goal is to develop a new generation of tungsten-based biomaterials that can revolutionize various aspects of medical treatment and diagnostics.

In conclusion, the background and objectives of tungsten biocompatibility research reflect a dynamic and rapidly evolving technological landscape. The pursuit of integrating tungsten in biocompatible applications holds great promise for addressing critical challenges in healthcare and medical technology. As this field progresses, it is poised to make significant contributions to improving patient outcomes and advancing the capabilities of medical devices and treatments.

Market Analysis for Biocompatible Tungsten Applications

The market for biocompatible tungsten applications is experiencing significant growth, driven by advancements in medical technology and the increasing demand for innovative materials in healthcare. Tungsten's unique properties, including high density, excellent mechanical strength, and corrosion resistance, make it an attractive option for various biomedical applications.

In the medical device sector, tungsten is gaining traction in the production of radiation shielding components, surgical instruments, and implantable devices. The global medical device market, valued at $432.23 billion in 2020, is projected to reach $612.72 billion by 2025, with a compound annual growth rate (CAGR) of 5.4%. This growth presents substantial opportunities for biocompatible tungsten applications.

The orthopedic implant market, a key area for tungsten integration, is expected to reach $64.0 billion by 2026, growing at a CAGR of 4.3%. Tungsten's biocompatibility and mechanical properties make it an excellent candidate for bone implants and prosthetics, potentially capturing a significant portion of this market.

In the field of medical imaging, tungsten is increasingly used in X-ray equipment and computed tomography (CT) scanners. The global medical imaging market, valued at $39.94 billion in 2020, is forecasted to reach $51.43 billion by 2025, with a CAGR of 5.2%. Tungsten's role in enhancing image quality and reducing radiation exposure positions it well to benefit from this market growth.

The dental industry also presents opportunities for biocompatible tungsten applications. The global dental implants market, valued at $3.6 billion in 2020, is expected to reach $5.9 billion by 2026, growing at a CAGR of 8.5%. Tungsten's potential use in dental implants and tools could capture a portion of this expanding market.

Geographically, North America and Europe currently dominate the market for biocompatible materials, including tungsten applications. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing healthcare expenditure and growing awareness of advanced medical technologies.

Challenges in the market include the high cost of tungsten compared to alternative materials and the need for extensive clinical trials to ensure long-term biocompatibility. However, ongoing research and development efforts are addressing these issues, potentially expanding the market for biocompatible tungsten applications.

In conclusion, the market for biocompatible tungsten applications shows promising growth potential across various medical sectors. As research continues to unlock new applications and improve existing ones, tungsten is poised to play an increasingly important role in the biomedical field, offering significant opportunities for innovation and market expansion.

Current Challenges in Tungsten Biointegration

The integration of tungsten in biocompatible applications faces several significant challenges that hinder its widespread adoption in medical and biological fields. One of the primary obstacles is the potential toxicity of tungsten and its compounds when introduced into biological systems. While tungsten is generally considered inert in its metallic form, certain tungsten compounds can be harmful to living organisms, raising concerns about long-term biocompatibility and safety.

Another major challenge lies in the mechanical properties of tungsten. Although it possesses excellent strength and durability, its high density and brittleness can make it difficult to process and shape into the intricate forms often required for biomedical applications. This limitation restricts its use in certain implantable devices or tissue engineering scaffolds where flexibility and precise geometries are crucial.

The corrosion resistance of tungsten in biological environments presents another hurdle. While tungsten exhibits good corrosion resistance in many settings, the complex and dynamic nature of biological fluids can lead to gradual degradation over time. This degradation not only compromises the structural integrity of tungsten-based implants but also raises concerns about the release of potentially harmful tungsten ions or particles into the surrounding tissues.

Surface modification and functionalization of tungsten for enhanced biocompatibility remain challenging. Creating stable, bioactive coatings that adhere well to tungsten surfaces while promoting cell adhesion, proliferation, and tissue integration is an ongoing area of research. The development of such coatings must also consider the potential impact on the underlying tungsten substrate's properties and performance.

The biological response to tungsten-based materials is not fully understood, presenting a significant challenge in predicting long-term outcomes. Variations in immune responses, potential inflammatory reactions, and the material's interaction with different tissue types need extensive investigation to ensure safe and effective integration in diverse biomedical applications.

Regulatory hurdles and stringent approval processes for new biomaterials add another layer of complexity to tungsten integration. Demonstrating the safety and efficacy of tungsten-based biomedical devices or implants requires comprehensive preclinical and clinical studies, which can be time-consuming and costly.

Lastly, the limited availability of standardized testing protocols specifically designed for evaluating the biocompatibility of tungsten-based materials poses a challenge. Developing and validating appropriate in vitro and in vivo models that accurately predict the material's behavior in biological systems is crucial for advancing its integration in biocompatible applications.

Existing Tungsten Biocompatibility Solutions

01 Tungsten deposition methods

Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.- Tungsten deposition methods: Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.

- Tungsten-based alloys and composites: Development of tungsten-based alloys and composite materials with enhanced properties. These materials combine tungsten with other elements or compounds to improve characteristics such as strength, hardness, and thermal stability for use in high-performance applications.

- Tungsten in semiconductor devices: Utilization of tungsten in semiconductor devices, particularly in the fabrication of interconnects, contacts, and vias. Tungsten's low resistivity and high melting point make it suitable for these applications in integrated circuits.

- Tungsten processing and recycling: Methods for processing tungsten ores, refining tungsten, and recycling tungsten-containing materials. These processes aim to efficiently extract and reuse tungsten, which is a valuable and relatively scarce metal.

- Tungsten in lighting and electronics: Applications of tungsten in lighting and electronic components, such as filaments in incandescent bulbs and electrodes in various devices. Tungsten's high melting point and good electrical conductivity make it suitable for these uses.

02 Tungsten etching processes

Techniques for selectively removing tungsten from surfaces, often used in semiconductor fabrication. These processes may involve chemical etching, plasma etching, or other methods to pattern tungsten layers or remove unwanted tungsten deposits.Expand Specific Solutions03 Tungsten alloys and composites

Development of tungsten-based alloys and composite materials for various applications. These materials combine tungsten with other elements or compounds to enhance specific properties such as strength, conductivity, or thermal resistance.Expand Specific Solutions04 Tungsten in electronic components

Use of tungsten in the manufacture of electronic components, including interconnects, vias, and electrodes. Tungsten's properties make it suitable for high-performance and miniaturized electronic devices.Expand Specific Solutions05 Tungsten processing and recycling

Methods for processing raw tungsten ore, refining tungsten, and recycling tungsten-containing materials. These processes aim to improve the efficiency of tungsten production and reduce waste in industrial applications.Expand Specific Solutions

Key Players in Biocompatible Tungsten Research

The integration of tungsten in biocompatible applications is an emerging field with significant potential. The market is in its early growth stage, driven by increasing demand for advanced medical devices and implants. While the global market size is still relatively small, it is expected to expand rapidly due to tungsten's unique properties. Technologically, the field is progressing, with companies like Biotronik AG and Cordis Corp. leading in medical device applications. Academic institutions such as Central South University and Beijing University of Technology are advancing fundamental research. The involvement of diverse players, from specialized firms like Orchard Material Technology to large corporations such as FUJIFILM Business Innovation Corp., indicates a growing interest in developing tungsten-based biocompatible solutions across various sectors.

Biotronik AG

KIST Corp. (South Korea)

Innovative Approaches in Tungsten Biointegration

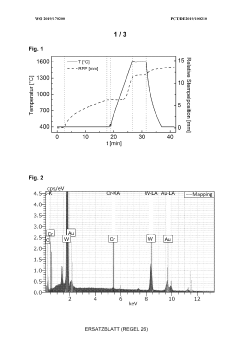

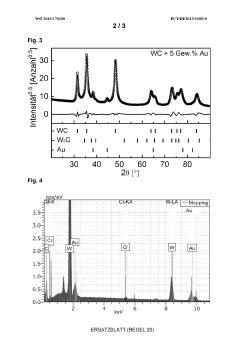

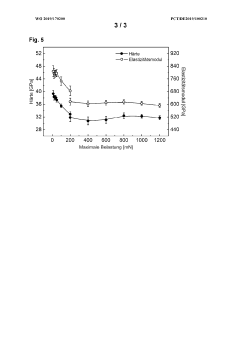

- Development of tungsten carbide composite materials with gold, palladium, or platinum as binders, produced using field-assisted sintering (FAST) process, which maintains high hardness and biocompatibility while minimizing W2C impurities and avoiding cobalt and nickel, allowing resistance to acidic and oxidizing agents.

- Incorporating tungsten or other metals like rhenium, osmium, and molybdenum as main alloy components with pH-dependent corrosion behavior, allowing for controlled degradation by altering the pH in the biological environment, and using secondary elements and inclusions to enhance corrosion rates, along with tubular base bodies and sintered metal inclusions for targeted corrosion.

Regulatory Framework for Biomedical Tungsten Use

The regulatory framework for biomedical tungsten use is a critical aspect of integrating this material into biocompatible applications. Regulatory bodies, such as the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in Europe, play pivotal roles in establishing guidelines and standards for the use of tungsten in medical devices and implants.

These regulatory agencies typically require extensive pre-clinical and clinical testing to ensure the safety and efficacy of tungsten-based biomedical products. This includes rigorous evaluation of the material's biocompatibility, toxicity profiles, and long-term effects on biological systems. Manufacturers must demonstrate compliance with Good Manufacturing Practices (GMP) and adhere to quality control measures throughout the production process.

The ISO 10993 series of standards is particularly relevant for assessing the biocompatibility of tungsten-containing medical devices. These standards outline specific tests for evaluating cytotoxicity, sensitization, irritation, and systemic toxicity. Additionally, the ISO 13485 standard provides a comprehensive framework for quality management systems in the medical device industry, which is applicable to tungsten-based products.

Regulatory requirements often extend beyond initial approval, encompassing post-market surveillance and reporting of adverse events. This ongoing monitoring helps identify any long-term effects or unforeseen complications associated with tungsten use in biomedical applications.

Environmental regulations also play a role in the biomedical use of tungsten. Manufacturers must consider the entire lifecycle of tungsten-containing products, including disposal and potential environmental impact. This may involve adherence to regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous substances in electrical and electronic equipment.

As research progresses and new applications for tungsten in biomedicine emerge, regulatory frameworks are likely to evolve. Regulatory agencies may update their guidelines to address novel tungsten-based technologies or refine existing standards based on accumulated data and experience. This dynamic regulatory landscape necessitates ongoing engagement between researchers, manufacturers, and regulatory bodies to ensure the safe and effective integration of tungsten in biocompatible applications.

Environmental Impact of Tungsten in Biomedicine

The integration of tungsten in biomedical applications has raised concerns about its potential environmental impact. As tungsten-based materials gain traction in various biocompatible applications, it is crucial to assess their ecological footprint throughout their lifecycle.

Tungsten's environmental impact begins with its extraction and processing. Mining operations can lead to habitat disruption and soil contamination. The refining process requires significant energy input, contributing to carbon emissions. However, tungsten's durability and recyclability partially offset these initial environmental costs by reducing the need for frequent replacements.

In biomedical applications, tungsten's inertness generally limits its direct environmental impact during use. Its corrosion resistance prevents leaching of harmful substances into the body or surrounding ecosystems. Nevertheless, the disposal of tungsten-containing medical devices presents challenges. While tungsten itself is not considered toxic to most organisms, improper disposal can lead to accumulation in soil and water systems.

Recent studies have investigated the potential ecological effects of tungsten in aquatic environments. Some research suggests that elevated tungsten concentrations may affect certain aquatic organisms, although the long-term consequences remain unclear. The bioaccumulation of tungsten in the food chain is another area of ongoing investigation, with preliminary data indicating limited biomagnification.

The environmental fate of tungsten nanoparticles, increasingly used in biomedical applications, is of particular interest. These nanoparticles may exhibit different behavior compared to bulk tungsten, potentially leading to unforeseen environmental interactions. Research is ongoing to understand their mobility in soil and water, as well as their potential impacts on microbial communities and plant life.

Efforts to mitigate the environmental impact of tungsten in biomedicine focus on several areas. Improved mining and processing techniques aim to reduce the initial ecological footprint. In device design, emphasis is placed on creating easily recyclable products to minimize waste. Additionally, advanced water treatment methods are being developed to remove tungsten from effluents, preventing its release into natural water bodies.

As the use of tungsten in biocompatible applications expands, ongoing environmental monitoring and risk assessment are essential. Future research should focus on long-term ecological studies, refining our understanding of tungsten's environmental behavior, and developing sustainable practices for its use and disposal in biomedical contexts.