How To Boost Tungsten Recycling Processes?

Tungsten Recycling Background and Objectives

Tungsten, a rare and valuable metal, has become increasingly important in various industries due to its unique properties. The recycling of tungsten has gained significant attention in recent years as a means to ensure a sustainable supply chain and reduce environmental impact. The evolution of tungsten recycling technologies has been driven by the growing demand for this metal in applications such as cutting tools, mining equipment, and electronics.

The primary objective of enhancing tungsten recycling processes is to improve the efficiency and cost-effectiveness of recovering tungsten from end-of-life products and industrial waste. This goal aligns with the broader trend of circular economy principles, which aim to minimize waste and maximize resource utilization. By developing more advanced recycling techniques, the industry seeks to reduce reliance on primary tungsten mining, which can be both environmentally damaging and geopolitically sensitive.

Historically, tungsten recycling has been limited by technological constraints and economic factors. Early recycling efforts focused primarily on the recovery of tungsten carbide from cutting tools and wear-resistant parts. However, as the applications of tungsten have expanded, so too has the need for more sophisticated recycling methods capable of handling diverse tungsten-containing materials.

The technological trajectory of tungsten recycling has seen significant advancements in recent decades. Initial processes relied heavily on pyrometallurgical methods, which were energy-intensive and often resulted in the loss of valuable alloying elements. Subsequent developments in hydrometallurgical techniques have allowed for more selective recovery of tungsten and associated metals, improving both the efficiency and economics of recycling operations.

Current trends in tungsten recycling technology are focused on developing more environmentally friendly processes, increasing the recovery rates of tungsten from complex waste streams, and exploring novel applications for recycled tungsten materials. These efforts are driven by a combination of regulatory pressures, market demands for sustainable materials, and the potential for cost savings through improved resource efficiency.

Looking ahead, the future of tungsten recycling is likely to be shaped by emerging technologies such as advanced sorting systems, precision chemical processes, and innovative material design that facilitates easier end-of-life recycling. The integration of digital technologies and artificial intelligence is expected to play a crucial role in optimizing recycling processes and improving the traceability of tungsten throughout its lifecycle.

As the global demand for tungsten continues to grow, particularly in emerging sectors such as renewable energy and advanced manufacturing, the importance of efficient recycling processes cannot be overstated. The ongoing research and development in this field aim not only to address current challenges but also to anticipate future needs and opportunities in the tungsten recycling industry.

Market Analysis for Recycled Tungsten

The global market for recycled tungsten has been experiencing significant growth in recent years, driven by increasing environmental concerns, resource scarcity, and the push for sustainable manufacturing practices. Tungsten, a critical raw material with unique properties, finds extensive applications in various industries, including aerospace, automotive, electronics, and mining. The recycling of tungsten not only addresses environmental issues but also offers economic benefits and ensures a stable supply chain.

The demand for recycled tungsten is primarily fueled by the growing awareness of the finite nature of primary tungsten resources and the environmental impact of mining activities. Industries are increasingly recognizing the value of tungsten recycling as a means to reduce their carbon footprint and comply with stringent environmental regulations. This shift in perspective has led to a surge in the adoption of recycled tungsten across different sectors.

In terms of market size, the recycled tungsten industry has shown robust growth. The market value is expected to continue its upward trajectory in the coming years, with a compound annual growth rate (CAGR) projected to be substantial. This growth is attributed to the increasing use of tungsten in emerging technologies, such as additive manufacturing and renewable energy systems, coupled with the rising emphasis on circular economy principles.

Geographically, the market for recycled tungsten is well-established in regions with strong industrial bases and advanced recycling infrastructure. North America and Europe currently lead the market, owing to their stringent environmental regulations and well-developed recycling ecosystems. However, the Asia-Pacific region is emerging as a significant player, driven by rapid industrialization and growing environmental consciousness in countries like China and Japan.

The recycled tungsten market is characterized by a diverse range of end-use industries. The automotive sector remains a major consumer, utilizing recycled tungsten in various components to enhance durability and performance. The aerospace industry also represents a substantial market share, incorporating recycled tungsten in critical applications such as turbine blades and heat shields. Additionally, the electronics sector is increasingly turning to recycled tungsten for use in semiconductors and other high-tech applications.

Market trends indicate a growing preference for recycled tungsten over virgin materials among manufacturers. This shift is driven by cost considerations, as recycled tungsten often proves more economical in the long run, especially in light of fluctuating raw material prices. Furthermore, the push for sustainable and responsible sourcing practices by major corporations is creating additional demand for recycled tungsten, as it aligns with their environmental, social, and governance (ESG) goals.

Current Challenges in Tungsten Recycling

Tungsten recycling faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the complex nature of tungsten-containing products, which often consist of multiple materials and components. This complexity makes it difficult to separate and isolate tungsten from other materials, requiring sophisticated and costly processing techniques.

The high energy consumption associated with tungsten recycling processes presents another major challenge. Traditional recycling methods, such as pyrometallurgical and hydrometallurgical processes, demand substantial energy inputs, leading to increased operational costs and environmental concerns. This energy-intensive nature of tungsten recycling often makes it less economically viable compared to primary production from ores.

Contamination of tungsten scrap with other metals and impurities poses a significant hurdle in the recycling process. The presence of contaminants can compromise the quality of the recycled tungsten, making it unsuitable for high-end applications that require high purity levels. Developing effective purification techniques that can remove these impurities without significantly increasing costs remains a challenge for the industry.

The variability in the composition of tungsten scrap sources further complicates the recycling process. Different tungsten-containing products may have varying alloy compositions, coatings, or treatments, necessitating tailored recycling approaches. This variability makes it challenging to establish standardized recycling processes and increases the complexity of recycling operations.

Limited collection and sorting infrastructure for tungsten-containing products also hinder the recycling efforts. Many tungsten-containing items, particularly those in consumer products, end up in general waste streams due to a lack of dedicated collection systems. Improving the collection and sorting of tungsten scrap requires significant investment in infrastructure and public awareness campaigns.

The economic viability of tungsten recycling is often challenged by fluctuating market prices for tungsten. When the price of primary tungsten is low, it can make recycling less attractive from a financial perspective. This volatility in market conditions creates uncertainty for recycling businesses and can discourage long-term investments in recycling technologies and infrastructure.

Regulatory challenges and inconsistent policies across different regions also impact tungsten recycling efforts. The lack of harmonized regulations and standards for tungsten recycling can create barriers to the development of efficient, large-scale recycling operations. Additionally, varying environmental regulations and waste classification systems across countries can complicate the international trade of tungsten scrap and recycled materials.

Existing Tungsten Recycling Processes

01 Chemical dissolution and precipitation methods

This process involves dissolving tungsten-containing materials in chemical solutions, followed by selective precipitation of tungsten compounds. The method can be optimized for efficiency by controlling factors such as pH, temperature, and reagent concentrations. It allows for high purity recovery of tungsten from various sources, including scrap and industrial waste.- Chemical leaching and recovery: This process involves using chemical solutions to dissolve tungsten-containing materials, followed by selective precipitation or extraction to recover tungsten compounds. The method can be applied to various tungsten-containing wastes, including scrap metal and spent catalysts. The efficiency of this process can be improved by optimizing leaching conditions, such as temperature, pH, and reagent concentrations.

- Thermal treatment and oxidation: This approach utilizes high-temperature treatment to convert tungsten-containing materials into more easily recoverable forms. The process may involve oxidation of tungsten to form tungsten oxides, which can then be reduced to metallic tungsten or further processed. The efficiency of this method can be enhanced by controlling the atmosphere, temperature, and duration of the thermal treatment.

- Electrochemical recycling methods: Electrochemical processes can be used to recover tungsten from various sources, including industrial waste and spent catalysts. These methods involve the use of electrolysis to selectively dissolve and deposit tungsten. The efficiency of electrochemical recycling can be improved by optimizing electrode materials, electrolyte composition, and applied current density.

- Mechanical separation and concentration: This approach involves physical methods such as crushing, grinding, and separation techniques to concentrate tungsten-containing materials. It can be applied to various sources, including ore tailings and scrap metal. The efficiency of mechanical separation can be enhanced by optimizing particle size distribution, using advanced sorting technologies, and implementing multi-stage separation processes.

- Biological recovery methods: Bioleaching and biosorption techniques utilize microorganisms to extract and concentrate tungsten from low-grade ores or waste materials. These environmentally friendly methods can be particularly effective for treating complex or dilute tungsten-containing sources. The efficiency of biological recovery can be improved by selecting and optimizing microbial strains, controlling growth conditions, and enhancing metal uptake mechanisms.

02 Hydrometallurgical processes for tungsten recovery

Hydrometallurgical techniques are employed to extract tungsten from ores, concentrates, and secondary sources. These processes typically involve leaching, solvent extraction, and electrowinning steps. The efficiency can be improved by optimizing leaching conditions, selecting appropriate extractants, and enhancing electrodeposition parameters.Expand Specific Solutions03 Pyrometallurgical methods for tungsten recycling

High-temperature processes are used to recover tungsten from scrap and waste materials. These methods include oxidation-reduction reactions, carbothermic reduction, and plasma processing. The efficiency of these processes can be enhanced by optimizing furnace design, controlling atmosphere composition, and improving heat transfer mechanisms.Expand Specific Solutions04 Mechanical and physical separation techniques

These processes involve the use of mechanical and physical methods to separate tungsten from other materials. Techniques such as crushing, grinding, magnetic separation, and density-based separation are employed. The efficiency can be improved by optimizing particle size distribution, enhancing magnetic field strength, and refining separation equipment design.Expand Specific Solutions05 Advanced recycling technologies for tungsten recovery

Innovative approaches are being developed to improve the efficiency of tungsten recycling. These include the use of supercritical fluids, microwave-assisted extraction, bioleaching, and electrochemical processes. These advanced technologies aim to reduce energy consumption, minimize environmental impact, and increase the recovery rate of tungsten from complex materials.Expand Specific Solutions

Key Players in Tungsten Recycling Industry

The tungsten recycling industry is in a growth phase, driven by increasing demand for sustainable practices and resource conservation. The market size is expanding, with a projected CAGR of 5.2% from 2021 to 2028. Technological maturity varies across companies, with leaders like Xiamen Tungsten Co., Ltd. and Mitsubishi Materials Corp. demonstrating advanced recycling processes. Research institutions such as Central South University and Korea Institute of Geoscience & Mineral Resources are contributing to innovation in the field. Companies like Jingmen Dewei Green Tungsten Resource Recycling Co. Ltd. and Chongyi Zhangyuan Tungsten Co., Ltd. are focusing on specialized recycling technologies, while global players such as Sumitomo Chemical Co., Ltd. and Kyocera Corp. are integrating recycling into their broader materials management strategies.

Xiamen Tungsten Co., Ltd.

Mitsubishi Materials Corp.

Innovative Tungsten Recovery Techniques

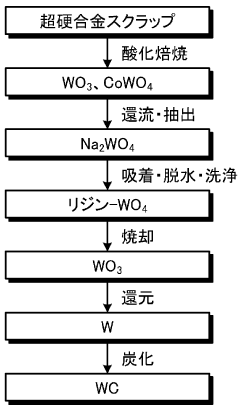

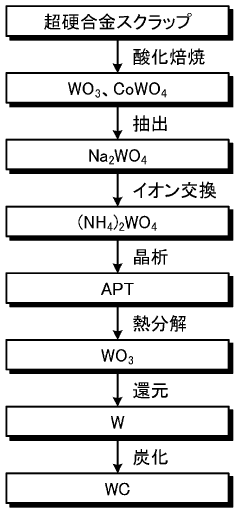

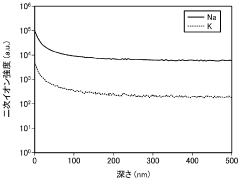

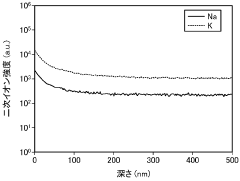

- The development of a tungsten oxide powder with a higher sodium concentration than potassium throughout its depth direction, which enhances the reaction promoting effect in hydrogen reduction treatment, allowing for efficient production of metallic tungsten and subsequently tungsten carbide by maintaining sodium in a molten state and suppressing potassium volatilization, thereby facilitating grain growth at lower energy levels.

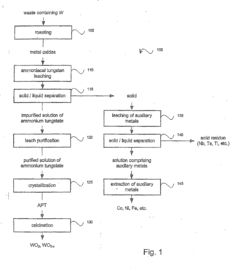

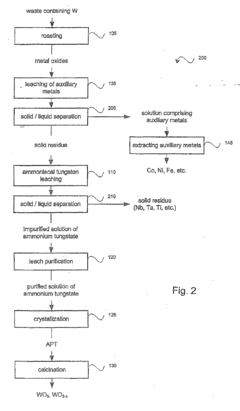

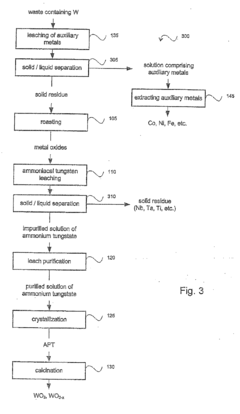

- A continuous oxidative roasting process followed by selective leaching in an alkaline ammonia solution to convert tungsten compounds into tungsten oxide, bypassing the need for intermediate steps and solvent extraction, allowing for direct separation and recycling of tungsten components.

Environmental Impact Assessment

The environmental impact assessment of tungsten recycling processes is a critical aspect of evaluating the sustainability and viability of these methods. Tungsten recycling offers significant environmental benefits compared to primary production, primarily due to reduced energy consumption and decreased greenhouse gas emissions. The recycling process typically requires only 30-40% of the energy needed for primary production, resulting in a substantial reduction in carbon footprint.

One of the key environmental advantages of tungsten recycling is the conservation of natural resources. By reclaiming tungsten from scrap and waste materials, the demand for raw ore extraction is reduced, leading to less habitat disruption and ecosystem damage associated with mining activities. This also helps preserve biodiversity in tungsten-rich regions and minimizes the environmental impact of ore processing and transportation.

Water usage is another important factor to consider in the environmental assessment of tungsten recycling. While recycling processes do require water, the overall consumption is generally lower than that of primary production. However, it is crucial to implement proper water treatment and recycling systems to minimize the discharge of potentially harmful substances into local water bodies.

The recycling of tungsten-containing materials also contributes to waste reduction. By diverting tungsten-bearing scrap from landfills, the recycling process helps mitigate soil and groundwater contamination risks associated with improper disposal. This is particularly important given the potential toxicity of some tungsten compounds and their long-term persistence in the environment.

Air quality is another aspect that must be evaluated in the environmental impact assessment. While tungsten recycling processes generally produce fewer air pollutants than primary production, it is essential to implement effective emission control systems to minimize the release of particulate matter and volatile organic compounds. This is particularly important in urban areas where recycling facilities may be located closer to population centers.

The life cycle assessment (LCA) of tungsten recycling processes reveals that the environmental benefits extend beyond the immediate recycling phase. By reducing the need for primary production, recycling indirectly contributes to lower environmental impacts throughout the entire supply chain, including reduced transportation emissions and decreased reliance on energy-intensive mining and ore processing operations.

However, it is important to note that the environmental impact of tungsten recycling can vary depending on the specific processes and technologies employed. Advanced recycling methods, such as hydrometallurgical processes, may offer improved environmental performance compared to traditional pyrometallurgical techniques. Continuous research and development in this field aim to further enhance the environmental sustainability of tungsten recycling processes.

Economic Viability of Recycling Processes

The economic viability of tungsten recycling processes is a critical factor in determining the feasibility and sustainability of these operations. As global demand for tungsten continues to rise, particularly in industries such as electronics, aerospace, and automotive, the importance of efficient recycling processes becomes increasingly apparent. The economic considerations of tungsten recycling encompass various aspects, including the cost of collection, processing, and refining, as well as the market value of recycled tungsten products.

One of the primary drivers of economic viability in tungsten recycling is the price of raw tungsten ore. When the price of primary tungsten is high, recycling becomes more attractive as a cost-effective alternative. However, the volatility of tungsten prices in the global market can impact the long-term stability of recycling operations. To mitigate this risk, many recycling facilities have implemented flexible processing systems that can adapt to market fluctuations.

The efficiency of recycling processes plays a crucial role in determining economic viability. Advanced technologies, such as hydrometallurgical and pyrometallurgical methods, have significantly improved the recovery rates of tungsten from scrap materials. These improvements have led to higher yields and reduced processing costs, enhancing the overall profitability of recycling operations. Additionally, the development of automated sorting systems has increased the efficiency of scrap collection and pre-processing, further contributing to cost reduction.

Energy consumption is another significant factor affecting the economic viability of tungsten recycling. Traditional recycling methods often require high energy inputs, which can substantially impact operational costs. However, recent advancements in energy-efficient technologies and the integration of renewable energy sources have helped to mitigate these expenses. Some recycling facilities have reported energy savings of up to 30% by implementing these innovative approaches.

The market demand for recycled tungsten products also plays a crucial role in determining economic viability. As more industries prioritize sustainability and seek to reduce their environmental footprint, the demand for recycled tungsten has grown. This trend has created new opportunities for recycling operations to expand their customer base and increase their market share. Furthermore, government regulations and incentives promoting the use of recycled materials have provided additional economic benefits for tungsten recycling facilities.

The scale of recycling operations is another important consideration. Larger-scale facilities often benefit from economies of scale, allowing them to process higher volumes of scrap material more efficiently. This can lead to lower per-unit costs and increased profitability. However, smaller, specialized recycling operations can also be economically viable by focusing on niche markets or high-value tungsten products.

In conclusion, the economic viability of tungsten recycling processes depends on a complex interplay of factors, including raw material prices, technological efficiency, energy costs, market demand, and operational scale. As the industry continues to innovate and adapt to changing market conditions, the economic prospects for tungsten recycling remain promising, with potential for further growth and optimization in the future.