How To Optimize Tungsten Alloys For Durability?

Tungsten Alloy Evolution and Objectives

Tungsten alloys have been a cornerstone of industrial applications for decades, prized for their exceptional strength, high melting point, and resistance to wear. The evolution of these alloys has been driven by the continuous demand for materials that can withstand extreme conditions in various sectors, including aerospace, defense, and energy production.

The journey of tungsten alloy development began in the early 20th century with simple binary compositions. As technology advanced, so did the complexity and performance of these alloys. The 1950s and 1960s saw significant breakthroughs in powder metallurgy techniques, enabling the creation of more sophisticated tungsten-based materials with enhanced properties.

In recent years, the focus has shifted towards optimizing tungsten alloys for durability, a critical factor in extending the lifespan of components and reducing maintenance costs. This optimization process involves a multifaceted approach, considering factors such as composition, microstructure, and processing methods.

The primary objective in tungsten alloy optimization is to enhance their resistance to various forms of degradation, including wear, corrosion, and fatigue. This involves improving the alloy's mechanical properties, such as hardness and toughness, while maintaining its high-temperature stability. Additionally, there is a growing emphasis on developing alloys that can withstand extreme environments, such as those encountered in nuclear reactors or hypersonic aircraft.

Another key goal is to address the inherent brittleness of tungsten, which has long been a limiting factor in its applications. Researchers are exploring novel alloying elements and nanostructuring techniques to impart ductility and improve fracture toughness without compromising the alloy's strength.

Environmental considerations have also become increasingly important in tungsten alloy development. Efforts are being made to create more sustainable production processes and to develop alloys that are easier to recycle or reprocess at the end of their lifecycle.

The future objectives for tungsten alloy optimization include the development of smart alloys with self-healing properties, the integration of computational modeling for predictive design, and the exploration of additive manufacturing techniques to create complex geometries with tailored properties. These advancements aim to push the boundaries of what is possible with tungsten alloys, opening up new applications and improving performance in existing ones.

Market Demand Analysis for Durable Tungsten Alloys

The market demand for durable tungsten alloys has been steadily increasing across various industries due to their exceptional properties and performance characteristics. The aerospace and defense sectors are primary drivers of this demand, with a growing need for high-strength, heat-resistant materials in aircraft engines, rocket nozzles, and armor-piercing ammunition. The global aerospace market, valued at $298 billion in 2020, is projected to reach $430 billion by 2025, indicating a significant potential for durable tungsten alloys in this sector.

In the automotive industry, the push for more efficient and lightweight vehicles has led to increased interest in tungsten alloys for components such as crankshafts, piston rings, and turbocharger rotors. The global automotive market, expected to reach $3.8 trillion by 2030, presents a substantial opportunity for optimized tungsten alloys that can withstand high temperatures and mechanical stress.

The energy sector, particularly in oil and gas exploration, has shown a growing demand for durable tungsten alloys in drilling equipment and downhole tools. As deep-sea and unconventional oil extraction methods become more prevalent, the need for materials that can withstand extreme conditions continues to rise. The global oilfield equipment market is anticipated to grow at a CAGR of 3.7% from 2021 to 2026, further driving the demand for high-performance tungsten alloys.

In the medical field, tungsten alloys are increasingly used in radiation shielding applications and surgical instruments. The global medical devices market, valued at $456 billion in 2019, is expected to reach $603 billion by 2023, indicating a growing potential for durable tungsten alloys in this sector.

The electronics industry also contributes to the market demand, with tungsten alloys being used in heat sinks, electrical contacts, and vibration damping components. As the global semiconductor market continues to expand, reaching $452 billion in 2021, the need for heat-resistant and durable materials like tungsten alloys is expected to grow proportionally.

Market analysis indicates that the Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth in demand for durable tungsten alloys. This is attributed to rapid industrialization, increased defense spending, and the expansion of high-tech manufacturing in these countries. North America and Europe remain significant markets, driven by aerospace and automotive industries.

The global tungsten market size was valued at $3.4 billion in 2020 and is projected to reach $5.7 billion by 2027, growing at a CAGR of 8.7%. This growth is largely attributed to the increasing demand for durable tungsten alloys across various industries. As manufacturers and end-users continue to seek materials with superior durability, heat resistance, and strength-to-weight ratios, the market for optimized tungsten alloys is expected to expand further in the coming years.

Current Challenges in Tungsten Alloy Durability

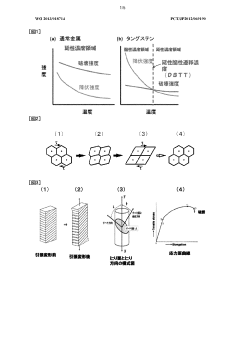

Tungsten alloys, renowned for their exceptional strength and high-temperature resistance, face several critical challenges in achieving optimal durability. One of the primary issues is the inherent brittleness of tungsten, which limits its application in environments requiring both strength and ductility. This brittleness becomes particularly problematic at lower temperatures, where the material's tendency to fracture increases significantly.

Another major challenge lies in the susceptibility of tungsten alloys to oxidation at elevated temperatures. When exposed to oxygen-rich environments above 400°C, tungsten rapidly forms volatile oxides, leading to material loss and degradation of mechanical properties. This oxidation resistance limitation severely restricts the use of tungsten alloys in high-temperature applications without protective coatings or controlled atmospheres.

The recrystallization behavior of tungsten alloys presents an additional hurdle. At high temperatures, the microstructure of these alloys can undergo significant changes, leading to grain growth and a consequent reduction in strength and toughness. This phenomenon is particularly challenging in applications where the material is subjected to prolonged exposure to high temperatures, such as in nuclear fusion reactors or aerospace components.

Radiation-induced embrittlement is another critical issue, especially in nuclear applications. Exposure to high-energy neutrons can cause significant damage to the crystal structure of tungsten alloys, leading to increased brittleness and reduced overall durability. This challenge is compounded by the formation of transmutation products, which can further alter the material's properties and performance.

The manufacturing and processing of tungsten alloys also present significant challenges. Due to tungsten's high melting point, conventional casting techniques are often impractical, necessitating complex powder metallurgy processes. These processes can introduce defects and inhomogeneities in the material, which can act as stress concentrators and reduce overall durability.

Lastly, the development of tungsten alloys with improved ductility and toughness without compromising their high-temperature strength remains a significant challenge. While alloying elements can enhance certain properties, they often come at the cost of others, necessitating careful balancing and optimization of composition and microstructure.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative processing techniques, and a deep understanding of the underlying mechanisms affecting tungsten alloy durability. Future research directions may include the development of nanostructured tungsten alloys, exploration of novel alloying elements, and the implementation of advanced surface treatment techniques to enhance oxidation resistance and overall durability.

Existing Durability Enhancement Techniques

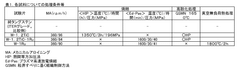

01 Composition optimization for improved durability

Tungsten alloys can be optimized for durability by carefully adjusting their composition. This includes adding specific alloying elements or adjusting the ratios of existing components to enhance properties such as hardness, wear resistance, and corrosion resistance. The optimized composition can lead to improved overall durability and longevity of the alloy in various applications.- Composition optimization for improved durability: Tungsten alloys can be engineered for enhanced durability by carefully adjusting their composition. This involves incorporating specific elements or adjusting the ratios of existing components to improve properties such as hardness, wear resistance, and corrosion resistance. The optimized composition can lead to alloys with superior performance in demanding applications.

- Heat treatment processes for durability enhancement: Various heat treatment processes can be applied to tungsten alloys to enhance their durability. These may include annealing, quenching, and tempering, which can alter the microstructure of the alloy, leading to improved mechanical properties and increased resistance to wear and fatigue. Proper heat treatment can significantly extend the lifespan of tungsten alloy components.

- Surface modification techniques: Surface modification techniques can be employed to enhance the durability of tungsten alloys. These may include coating, nitriding, or carburizing processes that create a protective layer on the alloy surface. Such treatments can improve wear resistance, corrosion resistance, and overall durability without altering the bulk properties of the alloy.

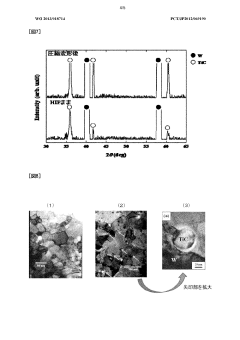

- Nanostructured tungsten alloys for improved durability: Developing nanostructured tungsten alloys can lead to significant improvements in durability. By controlling the grain size and distribution at the nanoscale, these alloys can exhibit enhanced strength, toughness, and resistance to radiation damage. This approach is particularly promising for applications in extreme environments.

- Reinforcement with other materials: Tungsten alloys can be reinforced with other materials to enhance their durability. This may involve creating composite materials by incorporating ceramic particles, fibers, or other reinforcing agents. The resulting composites can offer improved wear resistance, thermal stability, and overall durability compared to conventional tungsten alloys.

02 Heat treatment processes for enhanced durability

Various heat treatment processes can be applied to tungsten alloys to enhance their durability. These processes may include annealing, quenching, and tempering, which can alter the microstructure of the alloy, leading to improved mechanical properties such as strength, toughness, and wear resistance. Proper heat treatment can significantly extend the lifespan of tungsten alloy components.Expand Specific Solutions03 Surface treatment techniques for durability enhancement

Surface treatment techniques can be applied to tungsten alloys to improve their durability. These may include coatings, surface hardening processes, or surface modification techniques that enhance wear resistance, corrosion resistance, and overall durability of the alloy surface. Such treatments can significantly extend the service life of tungsten alloy components in demanding environments.Expand Specific Solutions04 Nanostructured tungsten alloys for improved durability

Developing nanostructured tungsten alloys can lead to significant improvements in durability. By controlling the grain size and structure at the nanoscale, these alloys can exhibit enhanced mechanical properties, including improved strength, toughness, and wear resistance. Nanostructured tungsten alloys may offer superior durability compared to their conventional counterparts in various applications.Expand Specific Solutions05 Composite tungsten alloys for enhanced durability

Developing composite tungsten alloys by incorporating reinforcing phases or particles can significantly enhance durability. These composites may combine the high-temperature strength of tungsten with the toughness or other desirable properties of the reinforcing materials. The resulting composite alloys can offer improved wear resistance, thermal stability, and overall durability in demanding applications.Expand Specific Solutions

Key Players in Tungsten Alloy Industry

The optimization of tungsten alloys for durability is a critical area of research in the advanced materials industry. This field is currently in a mature development stage, with ongoing innovations driven by increasing demand in various sectors such as aerospace, defense, and energy. The global tungsten alloy market is experiencing steady growth, with a projected market size reaching several billion dollars by 2025. Technologically, the field is well-established but continues to evolve, with companies like Plansee SE, A.L.M.T. Corp., and voestalpine BÖHLER Edelstahl GmbH & Co. KG leading in research and development. Academic institutions such as Central South University and Tohoku University are also contributing significantly to advancements in tungsten alloy durability, focusing on novel compositions and processing techniques to enhance performance characteristics.

A.L.M.T. Corp.

Guangzhou Huasite Alloy Products Co., Ltd.

Innovative Approaches to Tungsten Alloy Optimization

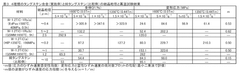

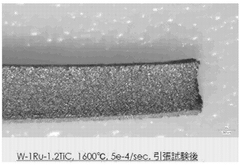

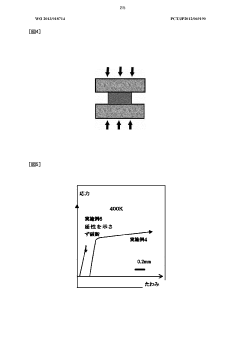

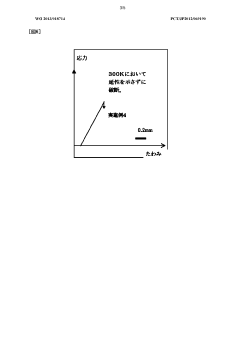

- A superplastic alloy containing tungsten, transition metals, and transition metal carbides is developed by dissolving and grain boundary segregating different metal elements in a tungsten matrix phase, and finely precipitating transition metal carbides at grain boundaries or within grains, achieving a high elongation rate of 50% to 1000% and improved embrittlement resistance.

- A method involving mechanical alloying and hot isostatic pressing, followed by superplastic deformation to strengthen recrystallized grain boundaries through grain boundary sliding, incorporating transition metal carbides to enhance grain boundary strength and ductility, particularly in tungsten alloys.

Environmental Impact of Tungsten Alloy Production

The production of tungsten alloys, while crucial for various industrial applications, carries significant environmental implications that warrant careful consideration. The extraction and processing of tungsten ore, primarily wolframite and scheelite, involve energy-intensive operations that contribute to greenhouse gas emissions. Mining activities can lead to habitat disruption, soil erosion, and potential contamination of water sources with heavy metals and other pollutants.

Refining tungsten ore typically requires the use of strong acids and bases, which can result in the generation of hazardous waste streams. The disposal of these chemical byproducts poses challenges for environmental management and may lead to soil and groundwater contamination if not properly handled. Additionally, the high temperatures required for tungsten alloy production consume substantial amounts of energy, often derived from fossil fuels, further contributing to the carbon footprint of the manufacturing process.

The production of tungsten alloys also involves the use of other metals such as nickel, iron, or cobalt, each with its own environmental impact profile. The mining and processing of these additional materials compound the overall environmental burden of tungsten alloy production. Furthermore, the fine particulate matter generated during the powder metallurgy processes used in alloy production can pose air quality concerns and potential health risks for workers and surrounding communities if not adequately controlled.

Water usage is another significant environmental factor in tungsten alloy production. Large volumes of water are required for ore processing, cooling, and cleaning operations, potentially straining local water resources, especially in water-scarce regions. The recycling and treatment of process water present both a challenge and an opportunity for reducing the environmental impact of production.

As the demand for durable tungsten alloys increases, particularly in sectors such as aerospace, automotive, and energy production, the cumulative environmental impact of their production is likely to grow. This underscores the importance of developing and implementing more sustainable production methods, such as improving energy efficiency, increasing the use of recycled tungsten, and adopting cleaner technologies for ore processing and alloy manufacturing.

Efforts to mitigate the environmental impact of tungsten alloy production are ongoing. These include research into more environmentally friendly extraction methods, the development of closed-loop production systems to minimize waste and emissions, and the exploration of alternative materials that could potentially replace tungsten in certain applications. As environmental regulations become more stringent globally, the tungsten alloy industry faces the challenge of balancing the demand for high-performance materials with the imperative of environmental stewardship.

Tungsten Alloy Testing and Certification Standards

Tungsten alloy testing and certification standards play a crucial role in ensuring the quality, reliability, and durability of tungsten alloys used in various applications. These standards provide a framework for evaluating the performance characteristics and properties of tungsten alloys, enabling manufacturers and end-users to make informed decisions about material selection and optimization.

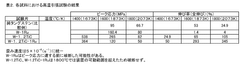

The testing standards for tungsten alloys typically cover a wide range of properties, including mechanical strength, hardness, density, thermal conductivity, and corrosion resistance. ASTM International, one of the leading organizations in materials testing, has developed several standards specifically for tungsten and its alloys. For instance, ASTM B777 outlines the standard specification for tungsten base, high-density metal, while ASTM B760 covers the standard specification for sintered tungsten alloys.

Mechanical testing is a critical aspect of tungsten alloy evaluation. Tensile strength, yield strength, and elongation are commonly assessed using methods described in ASTM E8/E8M. Hardness testing, often performed using the Rockwell or Vickers scales, follows procedures outlined in ASTM E18 and ASTM E92, respectively. These tests provide valuable data on the alloy's ability to withstand stress and resist deformation, which are essential factors in optimizing durability.

Microstructural analysis is another key component of tungsten alloy testing. ASTM E3 provides guidelines for the preparation of metallographic specimens, while ASTM E112 outlines methods for determining average grain size. These analyses help in understanding the alloy's internal structure and its influence on overall performance and durability.

Certification standards for tungsten alloys often involve a combination of material composition verification and property testing. X-ray fluorescence (XRF) spectroscopy, following ASTM E1621, is commonly used to determine elemental composition. Additionally, certification may require compliance with specific industry standards, such as those set by aerospace or defense sectors, which often have more stringent requirements for material properties and performance.

Environmental testing is becoming increasingly important in tungsten alloy certification, particularly for applications in extreme conditions. Standards like ASTM G31 for immersion corrosion testing and ASTM G48 for pitting and crevice corrosion resistance provide methods to evaluate the alloy's behavior in corrosive environments. These tests are crucial for optimizing tungsten alloys for durability in challenging operational settings.

As the demand for high-performance materials continues to grow, the development and refinement of testing and certification standards for tungsten alloys remain ongoing processes. Organizations like ASTM, ISO, and industry-specific bodies regularly review and update these standards to keep pace with technological advancements and evolving application requirements. This continuous improvement in testing methodologies and certification criteria plays a vital role in driving innovation and enhancing the durability of tungsten alloys across various industries.