Tungsten's Role In Enhancing Renewable Energy Systems

Tungsten in Renewables: Background and Objectives

Tungsten, a rare metal with exceptional properties, has emerged as a crucial element in the advancement of renewable energy systems. The evolution of tungsten's role in this field can be traced back to the early 2000s when researchers began exploring its potential applications in solar cells and wind turbines. As the global focus on sustainable energy intensified, tungsten's unique characteristics, such as high melting point, excellent thermal conductivity, and remarkable strength-to-weight ratio, became increasingly valuable in addressing the challenges faced by renewable energy technologies.

The primary objective of incorporating tungsten into renewable energy systems is to enhance their efficiency, durability, and overall performance. In solar energy applications, tungsten-based materials have shown promise in improving the conversion efficiency of photovoltaic cells by enhancing light absorption and electron transport. For wind energy, tungsten alloys are being investigated for their potential to create stronger, lighter turbine blades that can withstand harsh environmental conditions and operate at higher speeds.

The technological trajectory of tungsten in renewable energy has been marked by significant milestones. Early research focused on tungsten's use in thin-film solar cells, where it served as a back contact material. Subsequently, innovations in nanotechnology led to the development of tungsten nanoparticles and nanowires, opening up new possibilities for energy harvesting and storage. More recently, tungsten-based composites have gained attention for their potential in improving the efficiency of thermoelectric generators, which could play a crucial role in waste heat recovery systems.

As the renewable energy sector continues to grow, the demand for advanced materials that can withstand extreme conditions while maintaining high performance has intensified. Tungsten's unique properties position it as a key player in meeting these demands. The metal's resistance to corrosion and wear makes it particularly suitable for components in offshore wind turbines and concentrated solar power systems, where exposure to harsh environments is a significant concern.

Looking ahead, the integration of tungsten into renewable energy systems is expected to drive further technological advancements. Research is ongoing to explore novel tungsten-based materials and alloys that could revolutionize energy storage, improve the lifespan of renewable energy infrastructure, and enable the development of more efficient and cost-effective clean energy solutions. As global efforts to combat climate change accelerate, the role of tungsten in enhancing renewable energy systems is likely to become increasingly pivotal, contributing to the transition towards a more sustainable energy future.

Market Analysis for Tungsten in Green Energy

The global market for tungsten in renewable energy systems is experiencing significant growth, driven by the increasing adoption of clean energy technologies. Tungsten's unique properties, including its high melting point, excellent thermal and electrical conductivity, and exceptional wear resistance, make it a crucial material in various green energy applications.

In the solar energy sector, tungsten is utilized in the production of thin-film photovoltaic cells, where it serves as a barrier layer to prevent the diffusion of impurities. The global solar PV market is projected to reach $200 billion by 2026, with an annual growth rate of 20.5% from 2021 to 2026. This rapid expansion is expected to drive the demand for tungsten in solar cell manufacturing.

Wind energy is another key area where tungsten plays a vital role. Tungsten carbide is used in the production of wear-resistant components for wind turbines, such as bearings and gears, which are subjected to high stress and require exceptional durability. The global wind energy market is forecasted to grow at a CAGR of 14.2% from 2021 to 2026, reaching a value of $127 billion by the end of the forecast period.

In the emerging field of hydrogen fuel cells, tungsten is employed as a catalyst support material, enhancing the efficiency and longevity of fuel cell systems. The global hydrogen fuel cell market is anticipated to expand at a CAGR of 21.4% from 2021 to 2028, presenting a significant opportunity for tungsten suppliers in this sector.

The electric vehicle (EV) industry, which is closely linked to renewable energy systems, is also driving demand for tungsten. Tungsten is used in EV batteries, motors, and other components to improve performance and efficiency. The global EV market is expected to grow at a CAGR of 29% from 2021 to 2026, reaching a market value of $1.3 trillion by 2028.

Geographically, Asia-Pacific is the largest market for tungsten in green energy applications, followed by Europe and North America. China, in particular, dominates both the production and consumption of tungsten, accounting for over 80% of global tungsten supply. However, concerns over supply chain vulnerabilities have led to increased efforts to diversify tungsten sources, with new mining projects being developed in countries such as Australia, Canada, and the United States.

The market for tungsten in renewable energy systems faces some challenges, including price volatility and environmental concerns associated with tungsten mining and processing. However, ongoing research into more sustainable extraction methods and the development of recycling technologies for tungsten-containing products are expected to address these issues and support long-term market growth.

Current Challenges in Tungsten-Enhanced Renewables

Despite the promising potential of tungsten in enhancing renewable energy systems, several significant challenges currently hinder its widespread adoption and optimal utilization. These challenges span across technical, economic, and environmental domains, requiring comprehensive solutions to unlock the full potential of tungsten-enhanced renewables.

One of the primary technical challenges is the integration of tungsten-based components into existing renewable energy infrastructures. While tungsten offers superior properties, such as high melting point and excellent thermal conductivity, incorporating it into solar panels, wind turbines, and other renewable energy systems often requires redesigning and re-engineering existing technologies. This process is time-consuming and resource-intensive, potentially slowing down the adoption rate of tungsten-enhanced renewables.

The high cost of tungsten remains a significant economic barrier. Although tungsten's unique properties make it an attractive material for renewable energy applications, its relatively high price compared to conventional materials can lead to increased overall system costs. This cost factor can deter manufacturers and energy providers from investing in tungsten-enhanced technologies, particularly in price-sensitive markets or regions with limited financial resources for renewable energy development.

Another challenge lies in the limited availability and geopolitical considerations surrounding tungsten resources. The concentration of tungsten deposits in a few countries, primarily China, raises concerns about supply chain stability and potential geopolitical tensions. This situation could lead to price volatility and supply disruptions, affecting the long-term viability of tungsten-enhanced renewable energy projects.

Environmental concerns also pose challenges to the widespread use of tungsten in renewable energy systems. While tungsten itself is not considered highly toxic, the mining and processing of tungsten ores can have significant environmental impacts, including habitat destruction, water pollution, and energy-intensive extraction processes. Balancing the environmental benefits of enhanced renewable energy systems with the ecological footprint of tungsten production remains a complex issue.

The durability and longevity of tungsten-enhanced components in renewable energy systems present both opportunities and challenges. While tungsten's resistance to wear and corrosion can potentially extend the lifespan of renewable energy equipment, it also raises questions about end-of-life management and recycling. Developing efficient recycling processes for tungsten-containing renewable energy components is crucial to ensure the sustainability of these technologies and minimize waste.

Lastly, there is a need for more extensive research and development to fully understand and optimize the performance of tungsten in various renewable energy applications. While initial studies show promising results, long-term performance data and comprehensive lifecycle analyses are still limited. This knowledge gap can create uncertainty among stakeholders and slow down the adoption of tungsten-enhanced renewable technologies.

Existing Tungsten Solutions for Renewable Energy

01 Tungsten deposition methods

Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.- Tungsten deposition methods: Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.

- Tungsten alloys and composites: Development of tungsten alloys and composites with improved properties, such as increased strength, hardness, and heat resistance. These materials are used in various applications, including aerospace, defense, and high-temperature industrial processes.

- Tungsten in semiconductor devices: Use of tungsten in semiconductor devices, particularly for interconnects, gate electrodes, and contact plugs. Tungsten's low resistivity and high melting point make it suitable for these applications in advanced integrated circuits.

- Tungsten processing and manufacturing: Techniques for processing and manufacturing tungsten products, including powder metallurgy, sintering, and machining. These processes are used to create various tungsten components for industrial and scientific applications.

- Tungsten in lighting and electronics: Applications of tungsten in lighting and electronics, such as filaments for incandescent lamps and cathodes for electron tubes. Tungsten's high melting point and low vapor pressure make it ideal for these high-temperature applications.

02 Tungsten-based alloys and composites

Development of tungsten-based alloys and composite materials with enhanced properties, such as improved strength, hardness, and thermal stability. These materials find applications in aerospace, defense, and high-temperature industrial processes.Expand Specific Solutions03 Tungsten in electronic components

Utilization of tungsten in various electronic components, including interconnects, vias, and electrodes. Tungsten's high melting point and good electrical conductivity make it suitable for use in advanced semiconductor devices and integrated circuits.Expand Specific Solutions04 Tungsten processing and recycling

Methods for processing tungsten ores, refining tungsten, and recycling tungsten-containing materials. These processes aim to improve the efficiency of tungsten production and reduce environmental impact through sustainable practices.Expand Specific Solutions05 Surface treatment of tungsten

Techniques for modifying the surface properties of tungsten and tungsten-based materials, including etching, polishing, and coating. These treatments enhance the performance and durability of tungsten components in various applications.Expand Specific Solutions

Key Players in Tungsten-Renewable Integration

The tungsten market for renewable energy systems is in a growth phase, driven by increasing demand for clean energy solutions. The market size is expanding, with applications in wind turbines, solar panels, and energy storage systems. Technologically, tungsten's role in renewable energy is evolving, with varying levels of maturity across different applications. Companies like Chongyi Zhangyuan Tungsten Co., Ltd. and Orchard Material Technology LLC are at the forefront of tungsten material development. Research institutions such as Central South University and Beijing University of Technology are contributing to technological advancements. Multinational corporations like Panasonic Holdings Corp., Toshiba Corp., and General Electric Company are integrating tungsten-based solutions into their renewable energy products, indicating a competitive and diverse market landscape.

Panasonic Holdings Corp.

Chongyi Zhangyuan Tungsten Co., Ltd.

Innovative Tungsten Applications in Green Tech

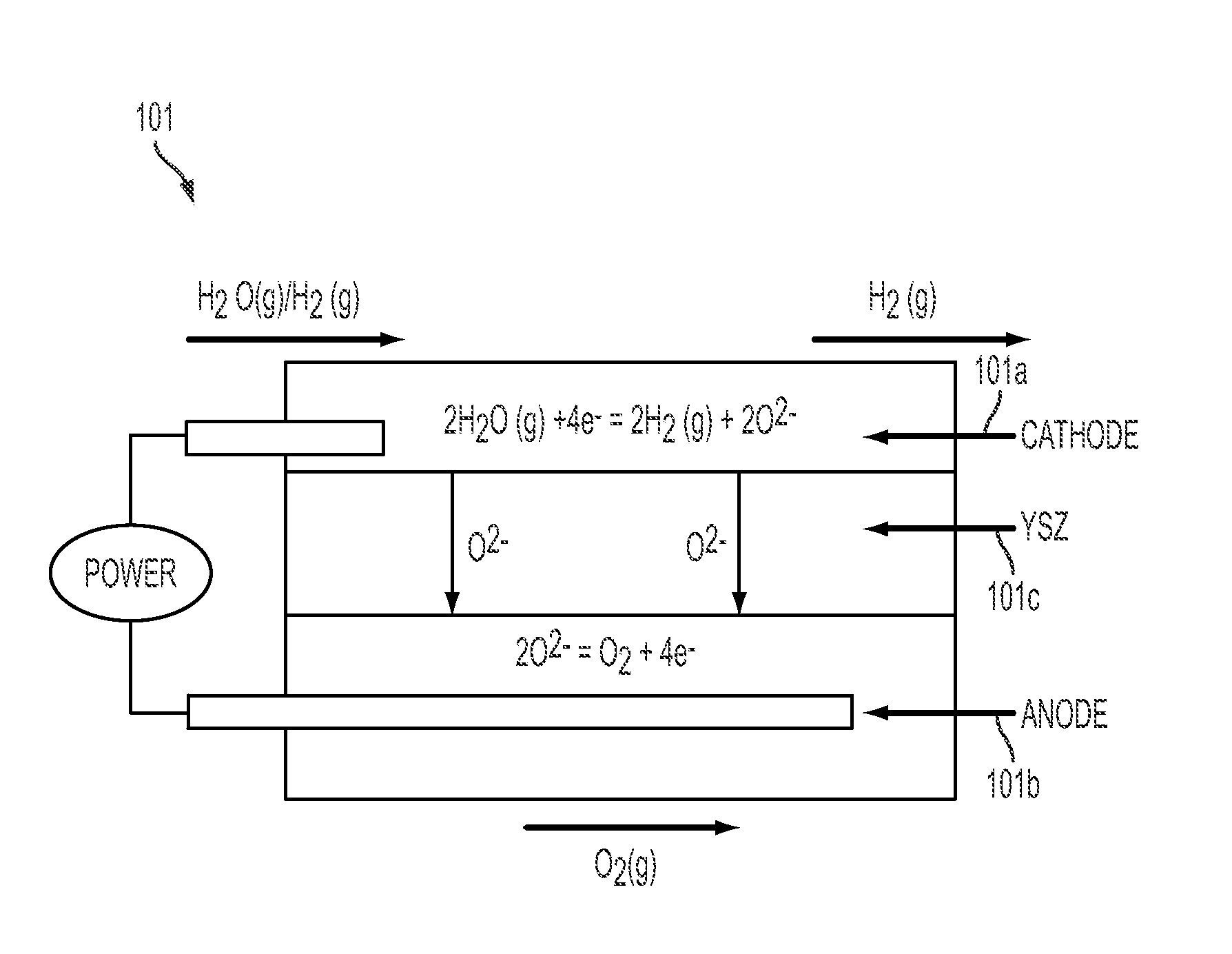

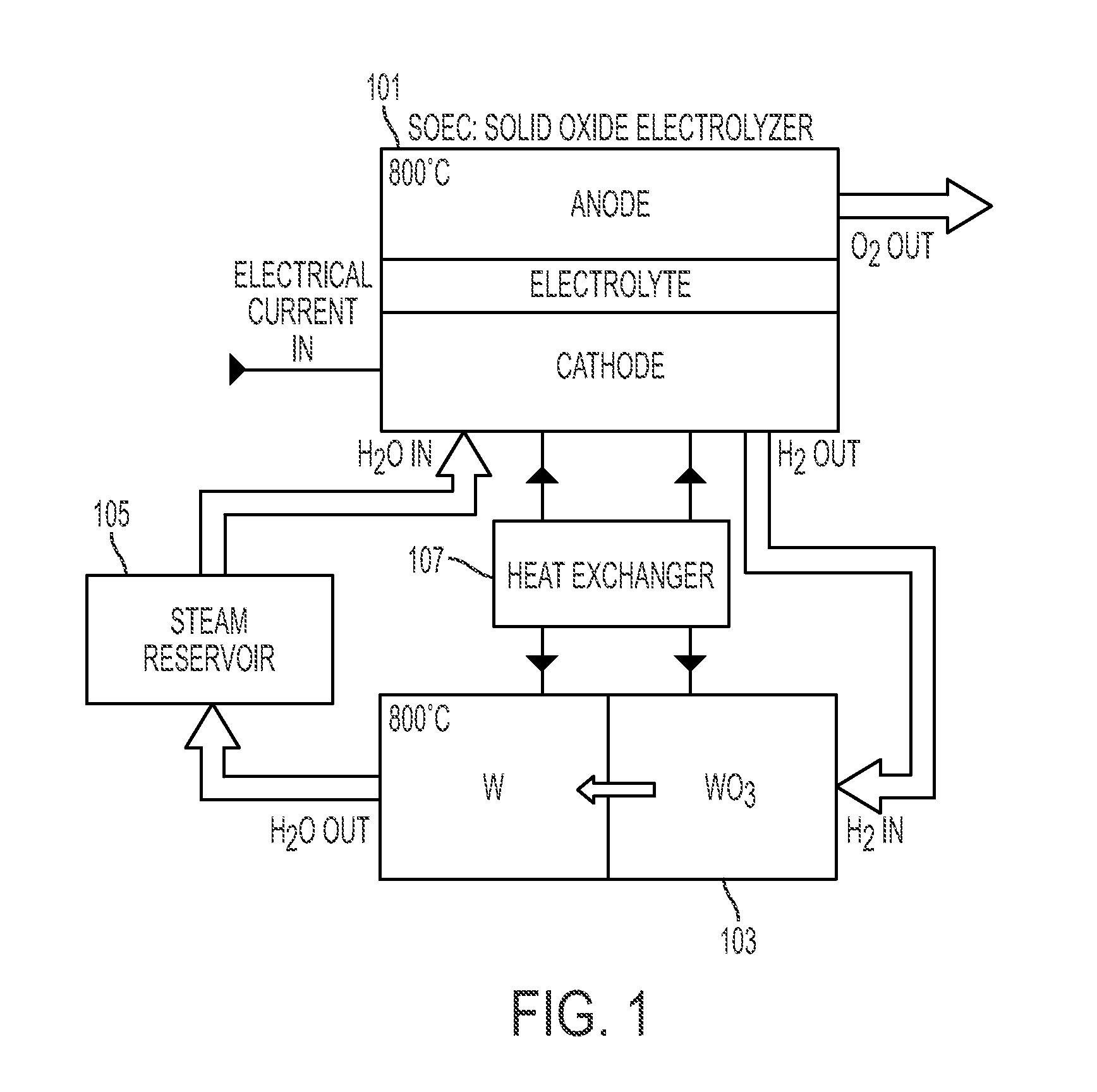

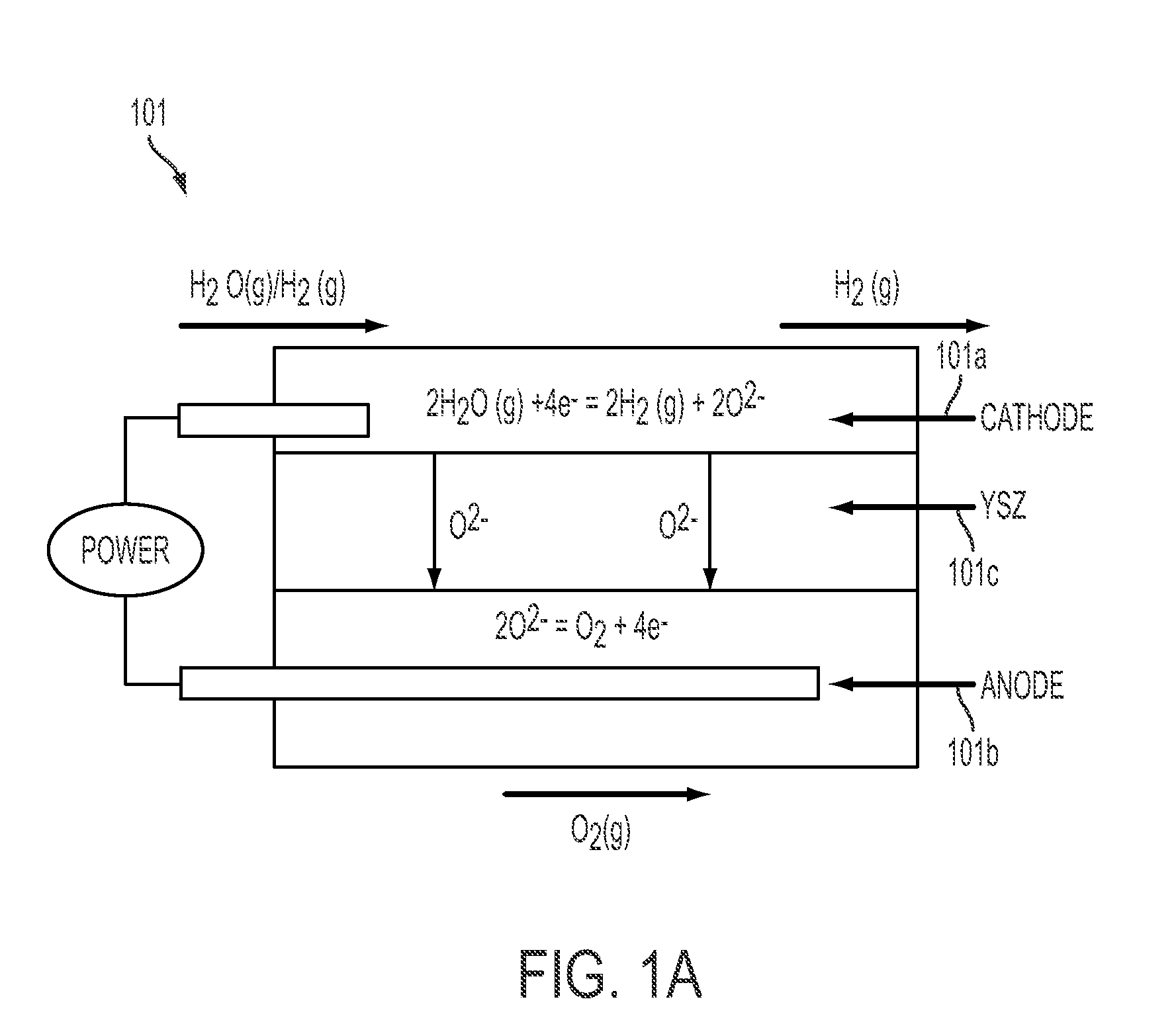

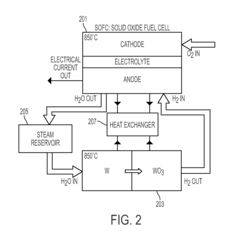

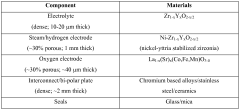

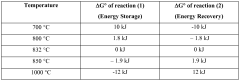

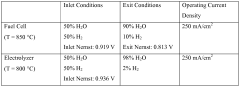

- A reversible solid oxide electrochemical cell (RSOEC) system using a porous cathode, anode, and electrolyte with a reactor containing tungsten or tungsten oxide, capable of electrolyzing water to store energy and converting back to electricity, operating between 600°C to 1000°C, with a heat exchanger for efficient energy transfer.

- A system utilizing reversible solid oxide electrochemical cells (RSOEC) and reactors with tungsten or tungsten oxide to store and recover energy through electrolysis and oxidation reactions, allowing for efficient electrical energy conversion and storage in the form of chemical potential energy.

Environmental Impact of Tungsten in Renewables

The environmental impact of tungsten in renewable energy systems is a critical consideration as the world transitions towards cleaner energy sources. Tungsten, known for its high melting point and durability, plays a significant role in various renewable technologies, particularly in wind turbines and solar panels. However, its extraction and processing can have substantial environmental consequences.

In wind energy, tungsten carbide is used in the bearings and gears of turbines, enhancing their longevity and efficiency. This application reduces the need for frequent replacements, thereby minimizing waste generation and the environmental footprint associated with manufacturing and transportation of replacement parts. Additionally, the use of tungsten in wind turbines contributes to increased energy output, indirectly reducing the reliance on fossil fuels and associated greenhouse gas emissions.

For solar energy systems, tungsten is utilized in thin-film solar cells, improving their efficiency and durability. The enhanced performance of these solar panels leads to greater energy production over their lifetime, potentially offsetting the environmental costs of tungsten extraction and processing. Moreover, the longevity of tungsten-enhanced solar panels reduces the frequency of replacements, further minimizing waste and resource consumption.

However, the mining and processing of tungsten ore can have significant environmental impacts. Open-pit mining, often used for tungsten extraction, can lead to habitat destruction, soil erosion, and water pollution. The processing of tungsten ore involves energy-intensive methods and the use of chemicals, which can result in air and water pollution if not properly managed. Additionally, tungsten mining often occurs in ecologically sensitive areas, potentially threatening biodiversity and local ecosystems.

The recycling of tungsten from renewable energy components presents an opportunity to mitigate some of these environmental concerns. Effective recycling processes can reduce the demand for primary tungsten extraction, thereby lessening the environmental impact associated with mining activities. However, the current recycling rates for tungsten in renewable energy systems remain relatively low, presenting a challenge for the industry.

As the renewable energy sector continues to grow, it is crucial to balance the benefits of tungsten use with its environmental costs. Developing more sustainable mining practices, improving recycling technologies, and exploring alternative materials could help mitigate the negative environmental impacts while maintaining the performance advantages that tungsten brings to renewable energy systems. Future research and development efforts should focus on optimizing tungsten use in renewables to maximize energy efficiency while minimizing environmental harm.

Supply Chain Considerations for Tungsten

The supply chain for tungsten plays a crucial role in its application to renewable energy systems. Tungsten's unique properties make it valuable for various components in renewable energy technologies, but its supply chain faces several challenges and considerations.

Tungsten is primarily sourced from a limited number of countries, with China being the dominant producer, accounting for over 80% of global production. This concentration of supply raises concerns about potential disruptions and geopolitical risks. Other significant producers include Vietnam, Russia, and Bolivia, but their output is considerably smaller compared to China's.

The extraction and processing of tungsten ore involve complex and energy-intensive processes. The primary ore, wolframite, requires extensive beneficiation and chemical treatment to produce tungsten concentrates. This process can have environmental impacts, including water pollution and energy consumption, which need to be carefully managed to align with sustainability goals in renewable energy applications.

Recycling plays an increasingly important role in the tungsten supply chain. The high value of tungsten and its ability to be recycled without loss of properties make it an attractive material for circular economy initiatives. However, the collection and processing of tungsten-containing scrap present logistical challenges that need to be addressed to maximize recycling rates.

The demand for tungsten in renewable energy applications is expected to grow significantly in the coming years. This increased demand may put pressure on existing supply chains and potentially lead to price volatility. Diversification of supply sources and development of new mining projects outside of China are being explored to mitigate these risks.

Transportation and logistics are critical aspects of the tungsten supply chain. The concentrated nature of production means that long-distance transportation is often required to bring tungsten to manufacturing centers. This can increase costs and carbon footprints, which must be factored into the overall environmental impact assessment of renewable energy technologies using tungsten.

Quality control and traceability are essential considerations in the tungsten supply chain, particularly for high-tech applications in renewable energy systems. Ensuring consistent quality and purity of tungsten materials is crucial for the performance and reliability of components such as wind turbine bearings or solar panel electrodes.

In conclusion, the tungsten supply chain for renewable energy applications requires careful management and strategic planning. Addressing issues of supply concentration, environmental impacts, recycling, and quality control will be crucial for ensuring a stable and sustainable supply of this critical material for the renewable energy sector.