Tungsten And Its Impact On Wearable Technology

Tungsten in Wearables: Background and Objectives

Tungsten, a rare metal with exceptional properties, has emerged as a game-changer in the realm of wearable technology. The evolution of this technology can be traced back to the early 2000s when the first commercially viable smartwatches and fitness trackers were introduced. Since then, the wearable tech industry has experienced exponential growth, driven by advancements in miniaturization, sensor technology, and materials science.

The integration of tungsten into wearable devices marks a significant milestone in this technological journey. Known for its high density, extreme hardness, and excellent wear resistance, tungsten has opened up new possibilities for creating more durable, compact, and sophisticated wearable devices. Its unique properties allow for the development of thinner, lighter, and more robust components, addressing many of the challenges faced by earlier generations of wearables.

As the wearable technology market continues to expand, the demand for materials that can withstand the rigors of daily wear while maintaining optimal performance has intensified. Tungsten, with its superior mechanical properties and biocompatibility, has emerged as a prime candidate to meet these demanding requirements. Its ability to be alloyed with other metals further enhances its versatility, allowing for customized solutions tailored to specific wearable applications.

The objectives of incorporating tungsten into wearable technology are multifaceted. Primarily, it aims to enhance the durability and longevity of devices, reducing the need for frequent replacements and improving user satisfaction. Additionally, tungsten's high density allows for the creation of more compact devices without compromising on functionality, enabling the development of sleeker and more aesthetically pleasing designs.

Another key objective is to leverage tungsten's thermal and electrical properties to improve the performance of wearable devices. Its excellent heat dissipation capabilities can help manage the thermal challenges associated with compact, high-performance electronics, potentially leading to improved battery life and overall device efficiency. Furthermore, tungsten's resistance to corrosion and its biocompatibility make it an ideal material for wearables that come into direct contact with the skin, addressing concerns related to allergic reactions and long-term wear.

As we look towards the future, the integration of tungsten in wearable technology is expected to play a crucial role in advancing the field. From enhancing the structural integrity of smartwatches and fitness trackers to enabling new form factors in medical wearables and augmented reality devices, tungsten's impact is set to be far-reaching. The ongoing research and development in this area aim to unlock even more potential applications, pushing the boundaries of what is possible in wearable technology.

Market Analysis for Tungsten-Enhanced Wearables

The wearable technology market has experienced significant growth in recent years, with an increasing demand for advanced, lightweight, and durable materials. Tungsten, known for its exceptional strength-to-weight ratio and high melting point, has emerged as a promising material in this sector. The market for tungsten-enhanced wearables is driven by the growing consumer interest in fitness trackers, smartwatches, and other body-worn devices that require robust and long-lasting components.

Consumer demand for wearables with extended battery life, improved durability, and enhanced functionality is fueling the adoption of tungsten in various applications. The material's properties make it particularly suitable for use in wearable casings, internal components, and even in specialized sensors. As the wearable market continues to expand beyond consumer electronics into medical, industrial, and military applications, the demand for tungsten-enhanced products is expected to grow correspondingly.

The integration of tungsten in wearables aligns with the broader trend of miniaturization in electronics. Its high density allows for the creation of compact yet sturdy components, enabling manufacturers to design slimmer and more aesthetically pleasing devices without compromising on durability. This characteristic is particularly valued in the premium segment of the wearable market, where consumers are willing to pay a premium for devices that offer both style and substance.

Market research indicates that the Asia-Pacific region, particularly countries like China and South Korea, is leading in the adoption of tungsten-enhanced wearables. This is largely due to the presence of major electronics manufacturers and a tech-savvy consumer base. North America and Europe follow closely, with a growing interest in high-end wearables that incorporate advanced materials like tungsten.

The potential applications of tungsten in wearable technology extend beyond traditional consumer devices. In the healthcare sector, tungsten-enhanced wearables are being explored for their potential in creating more accurate and durable medical monitoring devices. The material's biocompatibility and resistance to corrosion make it an attractive option for implantable devices and long-term wearable health monitors.

Despite the promising outlook, the market for tungsten-enhanced wearables faces challenges. The relatively high cost of tungsten compared to more common materials like aluminum or plastic may limit its widespread adoption, particularly in budget-friendly devices. Additionally, concerns about the environmental impact of tungsten mining and processing could influence consumer perception and regulatory policies, potentially affecting market growth.

Current Challenges in Tungsten Integration

The integration of tungsten into wearable technology presents several significant challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is the high density of tungsten, which can make wearable devices incorporating this material relatively heavy and potentially uncomfortable for users. This characteristic limits its application in certain types of wearables where lightweight design is crucial, such as fitness trackers or smart clothing.

Another challenge lies in the processing and manufacturing of tungsten for wearable applications. Tungsten's high melting point, while advantageous in some contexts, makes it difficult to work with using conventional manufacturing techniques. This necessitates the development of specialized processes and equipment, which can increase production costs and complexity.

The biocompatibility of tungsten in prolonged contact with human skin is also a concern that requires further investigation. While tungsten is generally considered to have low toxicity, its long-term effects in wearable applications are not yet fully understood. This uncertainty poses challenges for regulatory approval and consumer acceptance of tungsten-based wearable devices.

Tungsten's electrical properties, while beneficial in many applications, can present challenges in wearable technology. Its relatively high electrical resistance compared to other conductive materials like copper or silver may limit its use in certain electronic components of wearable devices, particularly those requiring high-frequency or low-power operation.

The integration of tungsten with other materials commonly used in wearable technology, such as flexible polymers or textiles, presents another set of challenges. Developing effective bonding and integration techniques that maintain the integrity of both tungsten and the substrate material is crucial for creating durable and functional wearable devices.

Thermal management is an additional concern in tungsten integration for wearables. While tungsten's heat resistance can be advantageous, its thermal conductivity characteristics may require careful design considerations to ensure user comfort and prevent overheating in compact wearable devices.

Lastly, the cost of tungsten and its processing for wearable applications remains a significant challenge. As a relatively rare metal with complex extraction and refinement processes, the economic viability of widespread tungsten use in consumer wearables is a hurdle that needs to be addressed through technological advancements and supply chain optimizations.

Existing Tungsten Applications in Wearables

01 Tungsten deposition methods

Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.- Tungsten deposition and film formation: Various methods and processes for depositing tungsten and forming tungsten films on substrates. This includes techniques such as chemical vapor deposition (CVD), atomic layer deposition (ALD), and physical vapor deposition (PVD) to create thin, uniform tungsten layers for semiconductor applications.

- Tungsten etching and patterning: Techniques for etching and patterning tungsten layers in semiconductor manufacturing. This includes selective etching processes, plasma etching, and methods to create precise tungsten structures for various electronic components and interconnects.

- Tungsten alloys and composites: Development and production of tungsten alloys and composite materials. These materials combine tungsten with other elements or compounds to enhance properties such as strength, conductivity, or thermal resistance for use in various industrial applications.

- Tungsten in semiconductor devices: Applications of tungsten in semiconductor devices, including its use in interconnects, gate electrodes, and contact plugs. This covers the integration of tungsten in various semiconductor manufacturing processes and its role in improving device performance and reliability.

- Tungsten surface treatment and modification: Methods for treating and modifying tungsten surfaces to enhance their properties or compatibility with other materials. This includes cleaning processes, surface activation techniques, and treatments to improve adhesion or electrical characteristics of tungsten layers.

02 Tungsten etching processes

Techniques for selectively removing tungsten from surfaces, often used in semiconductor fabrication. These processes may involve chemical or plasma etching to create precise patterns or structures in tungsten layers.Expand Specific Solutions03 Tungsten-based alloys and composites

Development of materials that combine tungsten with other elements to enhance properties such as strength, heat resistance, or electrical conductivity. These alloys and composites find applications in various industries, including aerospace and electronics.Expand Specific Solutions04 Tungsten in electronic components

Use of tungsten in the manufacture of electronic devices, particularly in the production of interconnects, vias, and other conductive structures in integrated circuits. This includes methods for forming tungsten plugs and lines in semiconductor devices.Expand Specific Solutions05 Tungsten processing and recycling

Methods for processing raw tungsten ore, refining tungsten, and recycling tungsten-containing materials. This includes techniques for extracting tungsten from ores and scrap, as well as purification processes to obtain high-grade tungsten for industrial use.Expand Specific Solutions

Key Players in Tungsten-Based Wearable Tech

The tungsten market for wearable technology is in a growth phase, driven by increasing demand for durable and lightweight materials. The global market size is expanding, with applications in smartwatches, fitness trackers, and medical devices. Technologically, tungsten's use in wearables is advancing, with companies like Applied Materials, Inc. and Toshiba Corp. leading innovation. Universities such as Xi'an Jiaotong University and Central South University are contributing to research and development. The industry is seeing collaborations between academic institutions and corporations like IBM and GlobalFoundries, focusing on improving tungsten's properties for wearable applications. Companies like Stryker Corp. and NSK Ltd. are exploring tungsten's potential in medical wearables, indicating a trend towards specialized applications in this evolving sector.

Applied Materials, Inc.

Xiamen Tungsten Co., Ltd.

Innovative Tungsten-Based Wearable Solutions

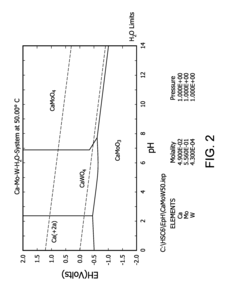

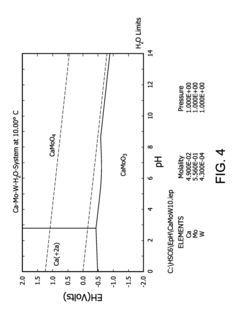

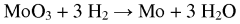

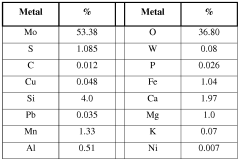

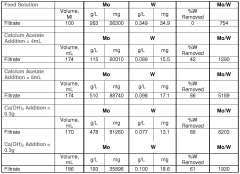

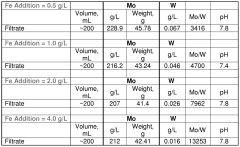

- A process involving the dissolution of technical grade molybdenum trioxide in an aqueous ammonium hydroxide solution, followed by the addition of calcium, iron, or manganese compounds to generate a tungsten-containing precipitate, allowing for selective separation of tungsten from molybdenum.

- A process involving the dissolution of technical grade molybdenum trioxide in aqueous ammonium hydroxide with the addition of metal generating compounds like calcium, iron, and manganese to precipitate tungsten, allowing for selective separation and purification.

Environmental Impact of Tungsten in Wearables

The environmental impact of tungsten in wearable technology is a critical consideration as the industry continues to expand. Tungsten, known for its durability and high melting point, has become increasingly prevalent in wearable devices due to its unique properties. However, its extraction, processing, and disposal pose significant environmental challenges that must be addressed.

Mining tungsten ore often involves open-pit mining, which can lead to habitat destruction, soil erosion, and water pollution. The extraction process requires large amounts of energy and water, contributing to increased carbon emissions and strain on local water resources. Additionally, the use of chemicals in ore processing can result in the release of toxic substances into the environment if not properly managed.

In wearable devices, tungsten is primarily used in components such as vibration motors, microelectromechanical systems (MEMS), and as a heat sink material. While these applications enhance device performance and longevity, they also present end-of-life disposal challenges. As wearable technology becomes more ubiquitous, the volume of electronic waste containing tungsten is expected to rise significantly.

Recycling tungsten from wearable devices is technically feasible but economically challenging. The small quantities present in individual devices make large-scale recovery difficult, leading to potential loss of this valuable resource. Improper disposal of tungsten-containing wearables can result in soil and water contamination, as tungsten compounds can leach into the environment over time.

To mitigate these environmental impacts, the wearable technology industry is exploring several strategies. These include developing more efficient mining and processing techniques to reduce the environmental footprint of tungsten production. Some companies are investing in research to find alternative materials that can replace tungsten in certain applications without compromising device performance.

Efforts are also being made to improve the recyclability of wearable devices. This involves designing products with easier disassembly and material separation in mind, as well as establishing more effective collection and recycling systems for end-of-life devices. Additionally, there is growing interest in developing bio-based or biodegradable materials for wearable technology components, which could potentially reduce the reliance on metals like tungsten.

As consumer awareness of environmental issues increases, there is mounting pressure on manufacturers to address the ecological impact of their products. This has led to the emergence of eco-friendly wearable brands that prioritize sustainability in their material choices and manufacturing processes. While tungsten remains an important material in wearable technology, the industry's focus on sustainability is driving innovation towards more environmentally responsible practices throughout the product lifecycle.

Tungsten Supply Chain for Wearable Industry

The tungsten supply chain for the wearable industry is a complex network that plays a crucial role in the development and production of advanced wearable technologies. Tungsten, known for its exceptional hardness and high melting point, has become an essential material in various components of wearable devices, particularly in miniaturized electronic circuits and sensors.

The supply chain begins with tungsten mining, primarily concentrated in China, which accounts for over 80% of global production. Other significant producers include Vietnam, Russia, and Bolivia. The raw ore undergoes initial processing at or near the mining sites, where it is converted into tungsten concentrates. These concentrates are then shipped to specialized facilities for further refinement into tungsten powders or other intermediate forms.

Tungsten powder manufacturers play a pivotal role in the supply chain, as they produce the high-purity tungsten powders required for wearable technology applications. These powders are used to create tungsten alloys, which are essential for producing durable and miniaturized components. The alloy production process involves precise mixing of tungsten with other metals to achieve specific properties suitable for wearable devices.

Component manufacturers represent the next critical link in the chain. They utilize tungsten alloys to produce various parts for wearable technologies, such as microelectronic components, sensors, and structural elements. These components are designed to meet the stringent requirements of wearable devices, including small size, low weight, and high durability.

The final stage of the supply chain involves wearable device manufacturers who integrate tungsten-based components into their products. These companies rely on a steady supply of high-quality tungsten parts to ensure the performance and reliability of their wearable technologies. The increasing demand for advanced wearables has led to a growing emphasis on securing stable tungsten supplies and developing more efficient production processes.

However, the tungsten supply chain faces several challenges. The concentration of mining in a few countries, particularly China, raises concerns about supply stability and geopolitical risks. Additionally, environmental and ethical considerations in tungsten mining and processing have led to increased scrutiny and efforts to establish more sustainable and responsible sourcing practices.

To address these challenges, the wearable technology industry is exploring alternative sources of tungsten, including recycling and the development of synthetic substitutes. These efforts aim to reduce dependence on primary mining and create a more resilient and sustainable supply chain for the growing wearable technology sector.