Tungsten And The Progress In Inertial Confinement Fusion

ICF Tungsten Background

Inertial Confinement Fusion (ICF) represents a groundbreaking approach to harnessing fusion energy, with tungsten playing a crucial role in its development. The journey of ICF began in the 1960s, driven by the quest for clean and abundant energy sources. Initially, ICF experiments utilized glass or plastic capsules to contain the fusion fuel. However, as research progressed, scientists recognized the need for materials capable of withstanding extreme conditions.

Tungsten emerged as a promising candidate due to its exceptional properties. With the highest melting point of any metal and remarkable strength at high temperatures, tungsten became an ideal material for ICF components. Its high density and ability to resist erosion under intense plasma conditions made it particularly suitable for the inner walls of fusion chambers and other critical components.

The evolution of tungsten's role in ICF has been marked by continuous refinement and innovation. Early applications focused on using tungsten as a coating material for fusion targets. As technology advanced, researchers began exploring more sophisticated tungsten-based structures, such as foams and nanoengineered surfaces, to enhance fusion performance.

A significant milestone in tungsten's ICF journey was the development of tungsten wire arrays for z-pinch experiments. These arrays, consisting of hundreds of fine tungsten wires, allowed for the generation of powerful x-ray sources, crucial for driving fusion reactions. This technique opened new avenues for studying high-energy-density physics and fusion processes.

The integration of tungsten in ICF has not been without challenges. Scientists have had to address issues such as tungsten's potential to introduce impurities into the fusion plasma and its behavior under extreme radiation conditions. Overcoming these obstacles has led to advancements in material science and fusion engineering, pushing the boundaries of our understanding of high-temperature physics.

Recent years have seen a surge in research focusing on tungsten's role in mitigating plasma-material interactions within fusion reactors. This includes the development of tungsten divertors and first-wall components designed to handle the intense heat and particle fluxes generated during fusion experiments. These innovations are crucial for extending the operational lifetime of fusion devices and improving overall system efficiency.

As ICF technology continues to evolve, tungsten remains at the forefront of materials research in this field. Its unique properties continue to drive innovation, from advanced alloy development to novel fabrication techniques. The ongoing exploration of tungsten's potential in ICF not only contributes to fusion science but also has far-reaching implications for other high-temperature applications across various industries.

Market Demand Analysis

The market demand for inertial confinement fusion (ICF) technology, particularly involving tungsten, is driven by the global pursuit of clean and sustainable energy sources. As concerns over climate change and energy security intensify, fusion energy presents a promising solution, attracting significant investment from both public and private sectors.

In the energy sector, ICF research has garnered substantial funding, with governments and research institutions allocating billions of dollars towards fusion projects. The potential for tungsten in ICF applications, especially as a material for target fabrication and hohlraum design, has sparked interest among materials scientists and fusion researchers.

The defense industry also shows keen interest in ICF technology, particularly for its applications in stockpile stewardship programs. Tungsten's high melting point and density make it an attractive material for simulating nuclear weapons tests without actual detonations, driving demand in this sector.

Additionally, the medical field has identified potential applications for ICF-related technologies. Tungsten's properties make it valuable in developing advanced radiotherapy techniques and medical imaging technologies, further expanding the market demand.

The semiconductor industry, a significant consumer of tungsten, is closely monitoring ICF progress. Advancements in ICF could lead to new manufacturing processes and materials, potentially revolutionizing chip production and driving demand for specialized tungsten components.

Market analysis indicates a growing interest from private investors and venture capital firms in fusion startups. This trend is expected to accelerate as ICF technology progresses, with tungsten playing a crucial role in various aspects of fusion research and development.

The space exploration sector also presents a potential market for ICF technology and tungsten applications. As space agencies and private companies plan long-duration missions, compact fusion reactors using tungsten components could provide efficient power sources for spacecraft and extraterrestrial bases.

However, the market faces challenges due to the long-term nature of fusion research and the technical complexities involved. The high costs associated with ICF experiments and the uncertainty of commercial viability in the near term may limit immediate market growth.

Despite these challenges, the potential for breakthrough discoveries and the increasing urgency of finding alternative energy sources continue to drive market demand. As ICF technology advances, the role of tungsten in fusion research is expected to expand, potentially creating new market opportunities across multiple industries.

Tungsten ICF Challenges

Tungsten's role in inertial confinement fusion (ICF) presents several significant challenges that researchers and engineers must overcome to advance the technology. One of the primary obstacles is the high melting point of tungsten, which, while beneficial for withstanding extreme temperatures, complicates manufacturing processes and limits design flexibility for ICF components.

The intense radiation environment in ICF experiments poses another challenge for tungsten materials. Exposure to high-energy neutrons and gamma rays can lead to radiation damage, altering the material's properties and potentially compromising its performance over time. This necessitates the development of radiation-resistant tungsten alloys or protective coatings to maintain structural integrity under prolonged exposure.

Tungsten's high density, while advantageous for certain ICF applications, can also be problematic. The material's weight may limit its use in certain components where lighter alternatives are preferred, particularly in mobile or space-based ICF systems. Balancing the benefits of tungsten's density with the need for overall system efficiency remains a ongoing challenge.

The interaction between tungsten and the fusion plasma presents another set of challenges. Surface erosion and material migration can occur due to plasma-wall interactions, potentially contaminating the fusion fuel and reducing overall system performance. Developing surface treatments or alternative geometries to mitigate these effects is crucial for optimizing tungsten's use in ICF.

Thermal management is a critical issue when using tungsten in ICF systems. While the material's high thermal conductivity is generally beneficial, managing heat dissipation and preventing localized hot spots in complex geometries can be challenging. This requires advanced cooling systems and careful thermal design to maintain optimal operating conditions.

The brittleness of tungsten at lower temperatures poses challenges for the fabrication and handling of ICF components. Developing ductile tungsten alloys or composite materials that retain the desired properties while improving toughness and workability is an active area of research.

Lastly, the cost and availability of high-purity tungsten suitable for ICF applications can be limiting factors. Developing cost-effective production methods and exploring alternative materials or composites that can match or exceed tungsten's performance in specific applications are ongoing challenges in the field of ICF research and development.

Current Tungsten ICF Solutions

01 Tungsten deposition methods

Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.- Tungsten deposition methods: Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.

- Tungsten etching processes: Techniques for selectively etching tungsten layers in microelectronic fabrication. These processes are crucial for creating precise patterns and structures in tungsten-based components, often using specialized etchants and plasma-based methods.

- Tungsten-based alloys and composites: Development of tungsten alloys and composite materials that combine tungsten with other elements to enhance properties such as strength, hardness, and thermal stability. These materials find applications in aerospace, defense, and high-temperature industrial settings.

- Tungsten in electronic components: Use of tungsten in various electronic components, including interconnects, vias, and electrodes. Tungsten's low resistivity and high melting point make it valuable for creating reliable and high-performance electronic devices.

- Tungsten powder production and processing: Methods for producing and processing tungsten powder, including techniques for controlling particle size, shape, and purity. These processes are important for creating high-quality tungsten materials for various industrial applications.

02 Tungsten etching processes

Techniques for selectively etching tungsten layers in semiconductor fabrication. These processes are crucial for creating precise patterns and structures in integrated circuits and other microelectronic devices.Expand Specific Solutions03 Tungsten-based alloys and composites

Development of tungsten alloys and composite materials with enhanced properties for various applications. These materials combine tungsten with other elements to improve characteristics such as strength, hardness, and thermal stability.Expand Specific Solutions04 Tungsten in electronic components

Use of tungsten in the manufacture of electronic components, including interconnects, vias, and electrodes. Tungsten's high melting point and good electrical conductivity make it suitable for these applications in advanced semiconductor devices.Expand Specific Solutions05 Tungsten surface treatment and modification

Methods for treating and modifying tungsten surfaces to enhance their properties or compatibility with other materials. These techniques can improve adhesion, reduce oxidation, or alter the surface characteristics of tungsten components.Expand Specific Solutions

Key ICF Industry Players

The competitive landscape for tungsten in inertial confinement fusion (ICF) is evolving rapidly as the technology progresses towards commercialization. The market is in its early growth stage, with significant potential for expansion as fusion energy becomes more viable. Key players like Lawrence Livermore National Security LLC and UK Atomic Energy Authority are at the forefront of ICF research, while companies such as General Fusion, Inc. and Blue Laser Fusion, Inc. are developing innovative approaches. The technology's maturity varies, with national laboratories and research institutions like Commissariat à l'énergie atomique et aux énergies Alternatives leading in scientific advancements, while private companies focus on scaling and commercialization efforts. The involvement of diverse players, from academic institutions to specialized materials suppliers like Plansee SE, indicates a complex and dynamic ecosystem.

Commissariat à l´énergie atomique et aux énergies Alternatives

Lawrence Livermore National Security LLC

Tungsten ICF Innovations

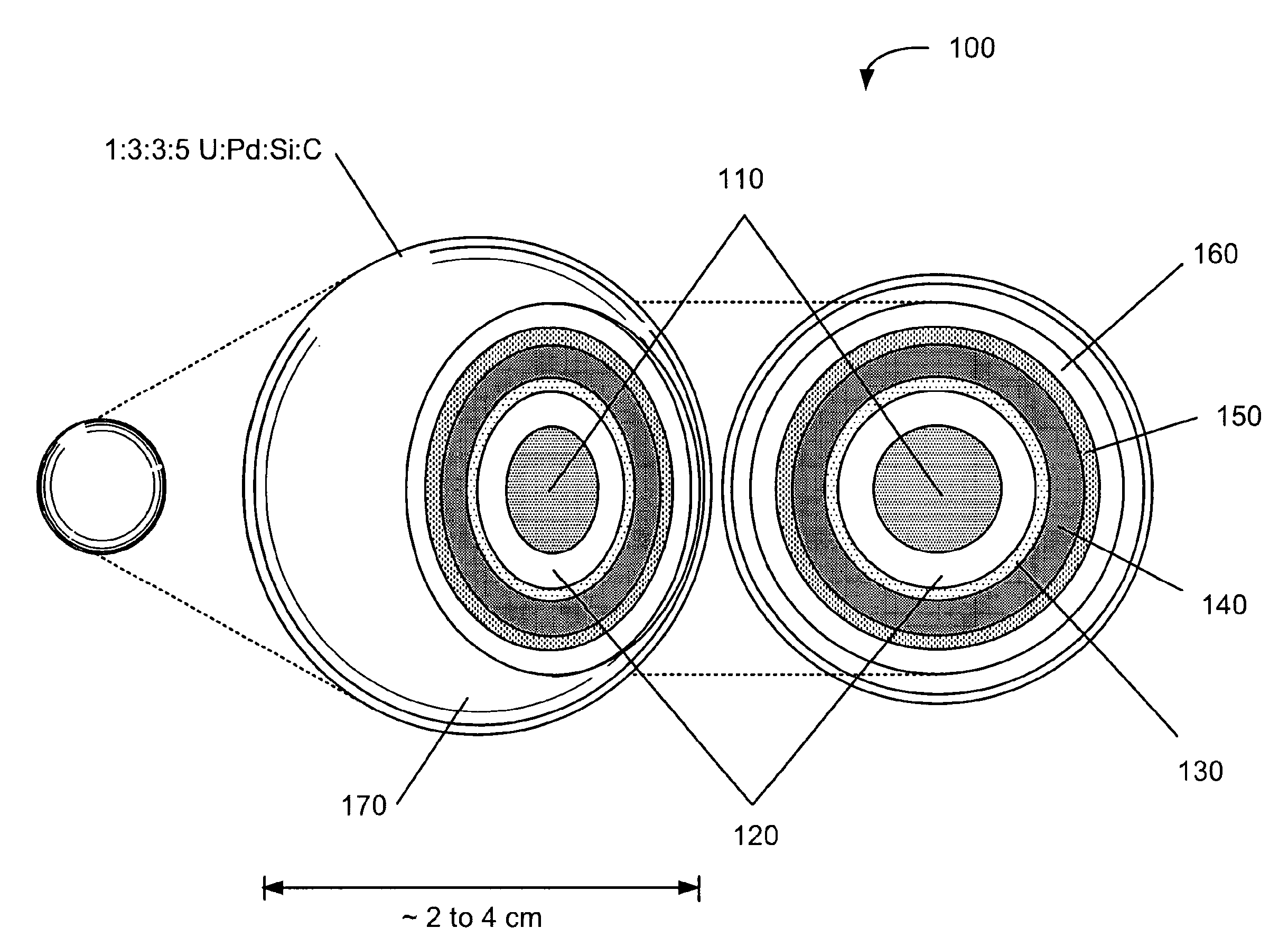

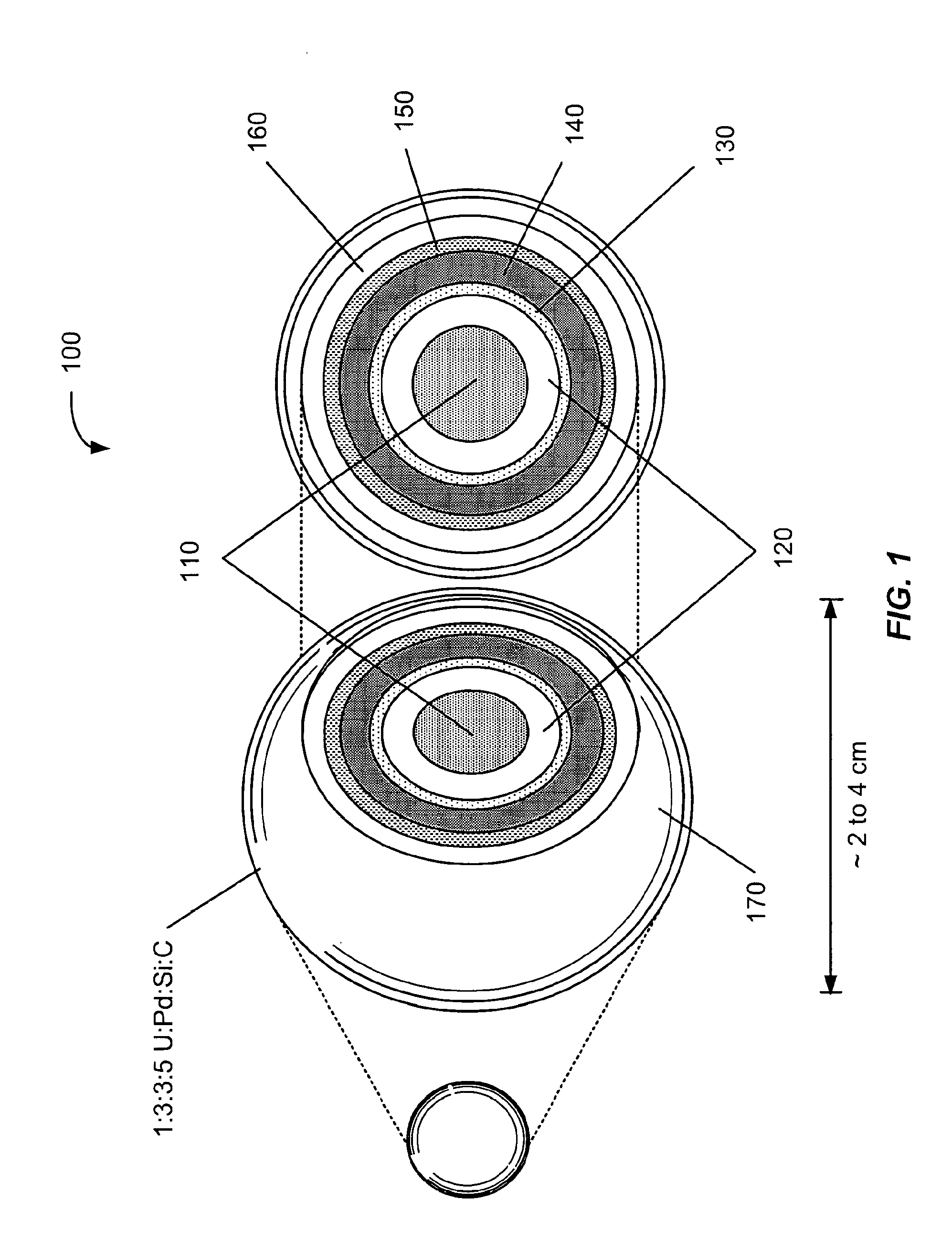

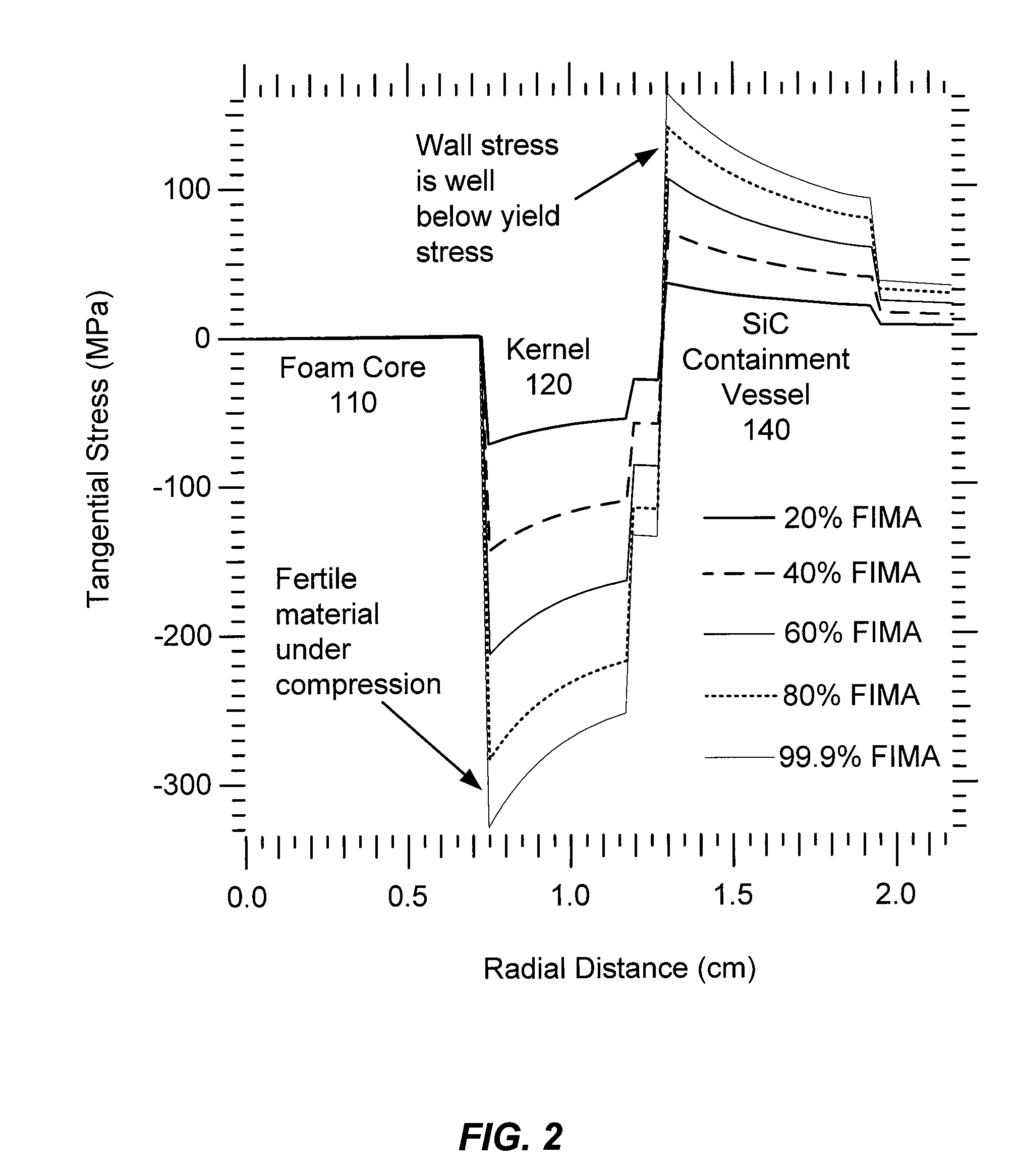

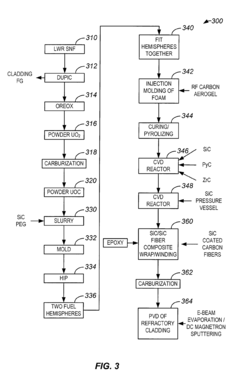

- Development of a robust solid hollow core fuel pebble for laser inertial confinement fusion-fission power plants, featuring a porous carbon aerogel buffer, uranium oxy-carbide fissile shell, silicon carbide containment, and high-strength carbon fiber composite layers for enhanced burn-up and heat transfer.

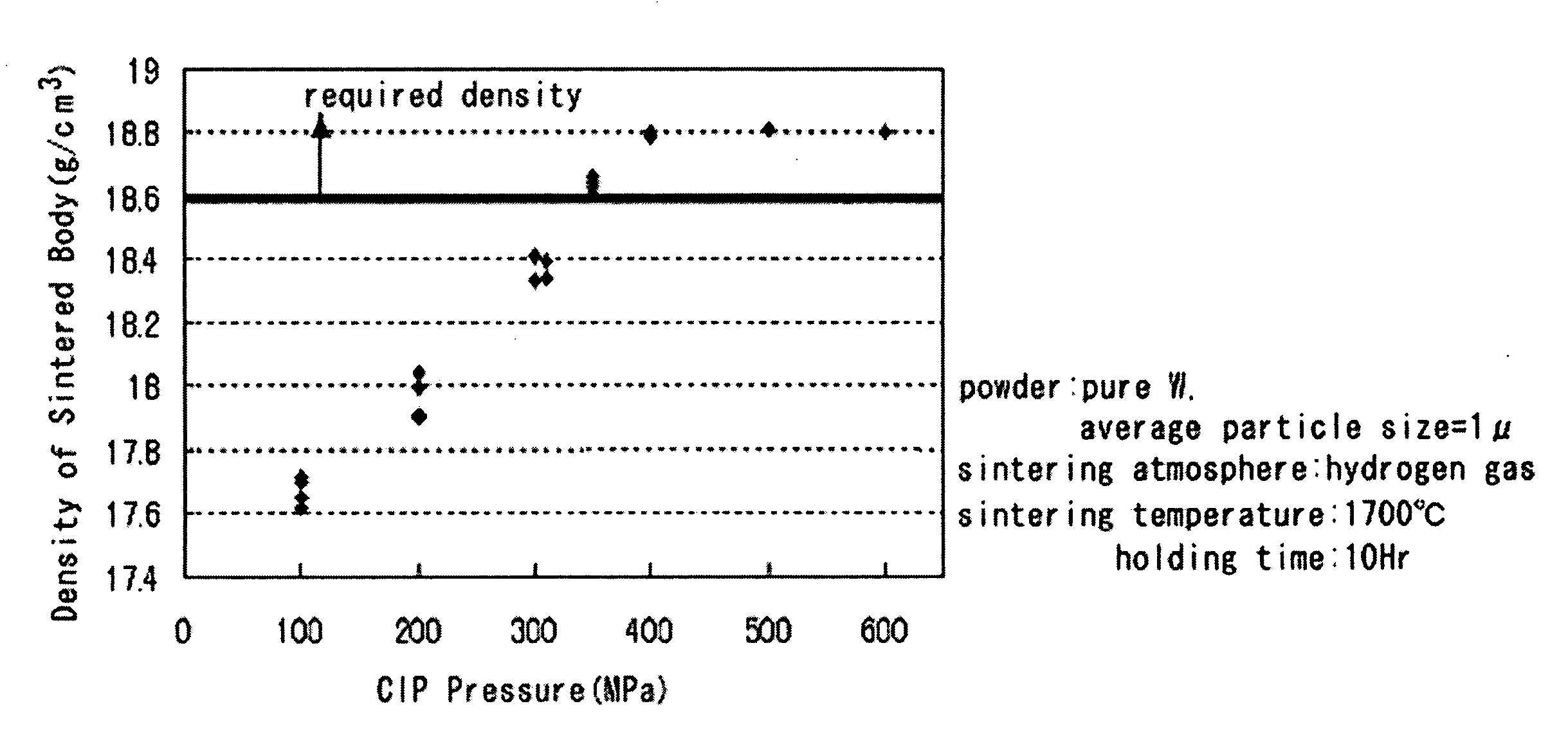

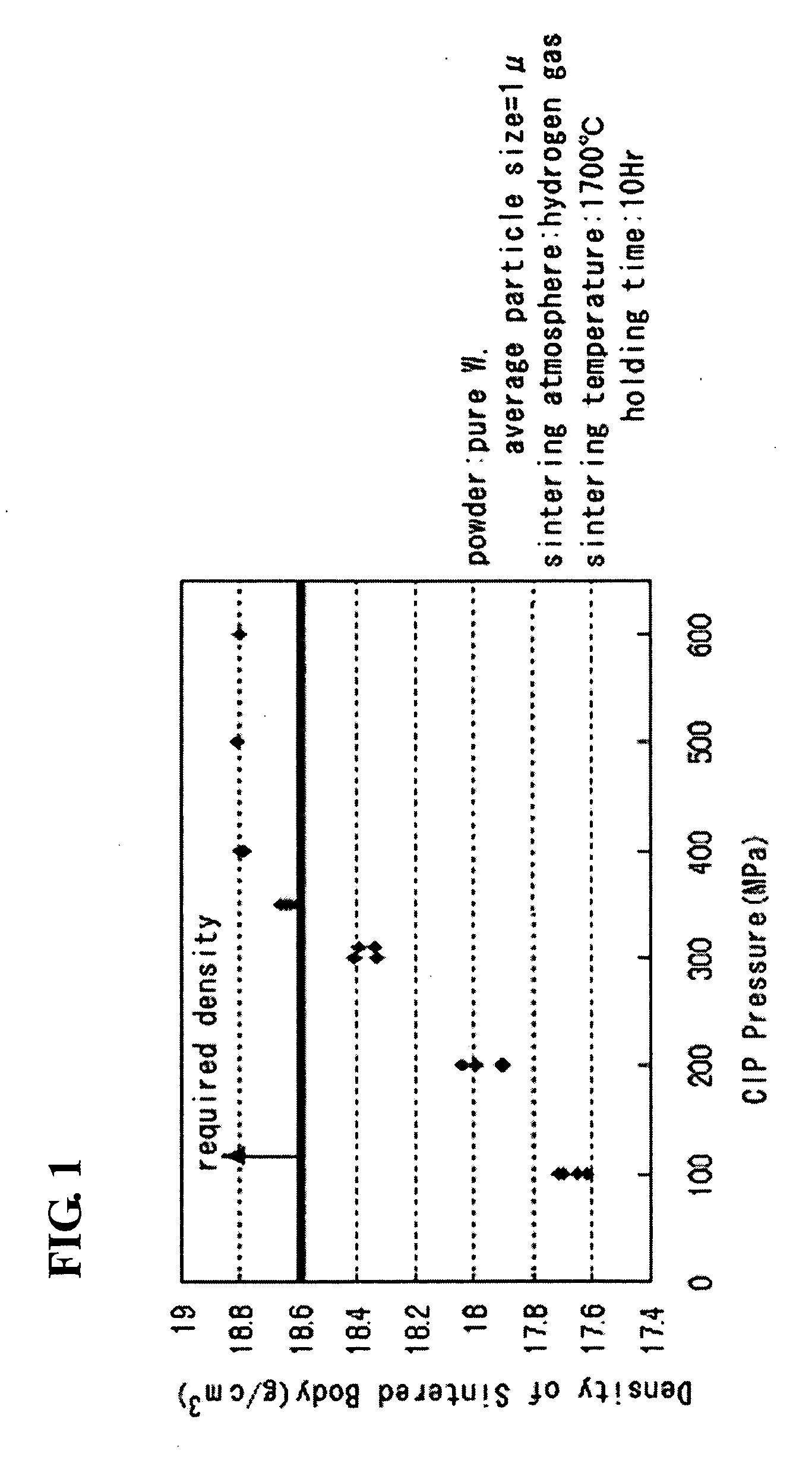

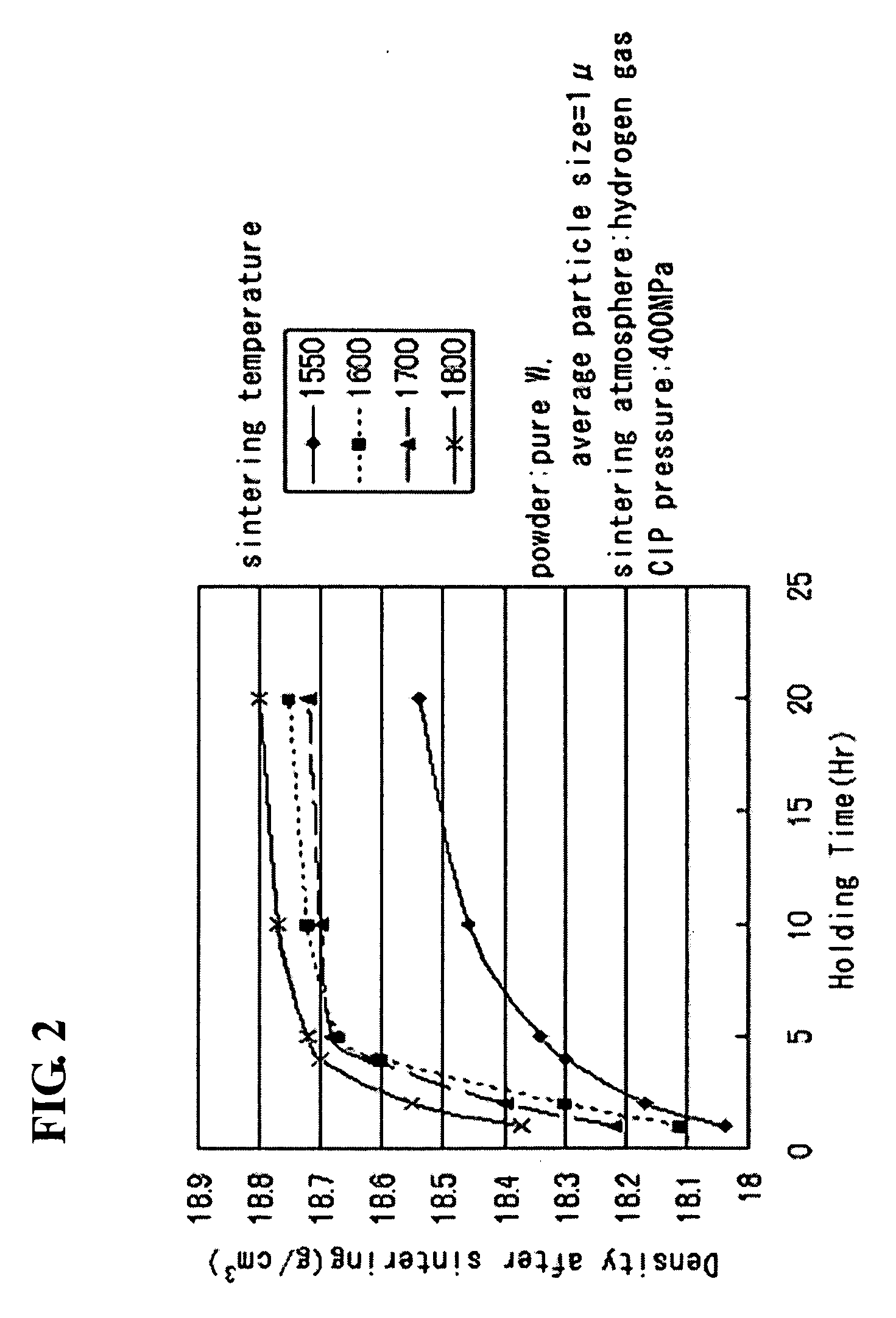

- A tungsten-based sintered body with a relative density of 99.5% or more, isotropic structure, and average crystal grain size of 30 μm or less, produced using a method involving CIP and HIP processes in specific pressure and temperature conditions, with additives like oxides and molybdenum to achieve uniform properties and minimize pores.

Energy Policy Implications

The progress in inertial confinement fusion (ICF) using tungsten as a material for fusion targets has significant implications for energy policy. As ICF research advances, policymakers must consider the potential impact on future energy landscapes and adjust strategies accordingly.

Tungsten's role in ICF experiments has shown promise in improving fusion yields and efficiency. This development could accelerate the timeline for achieving practical fusion energy, necessitating a reevaluation of long-term energy policies. Governments and energy agencies may need to allocate more resources to fusion research and development, potentially redirecting funds from other energy sectors.

The success of tungsten in ICF experiments also highlights the importance of materials science in energy innovation. Policymakers should consider increasing support for interdisciplinary research that combines materials science with energy technologies. This could lead to breakthroughs not only in fusion but also in other clean energy solutions.

As ICF technology progresses, it may become necessary to develop new regulatory frameworks for fusion energy. Policymakers must begin preparing for the potential commercialization of fusion power, addressing safety concerns, licensing procedures, and integration into existing power grids. This proactive approach can ensure a smooth transition if and when fusion becomes a viable energy source.

The potential of fusion energy, bolstered by advancements in tungsten-based ICF, may influence international energy cooperation. Countries may need to reassess their energy diplomacy strategies, focusing on collaborative efforts in fusion research and development. This could lead to new international agreements and partnerships centered around fusion technology.

Furthermore, the progress in ICF using tungsten may impact investment strategies in the energy sector. Policymakers may need to create incentives for private sector involvement in fusion research and development, potentially through public-private partnerships or targeted funding programs. This could accelerate the commercialization of fusion technology and its integration into the energy mix.

Lastly, as fusion technology advances, policymakers must consider the potential socioeconomic impacts. This includes workforce development strategies to prepare for the skills needed in a fusion-powered future, as well as plans to manage the transition for communities currently dependent on traditional energy sources. By addressing these aspects early, policymakers can ensure a just and equitable transition to a potential fusion energy future.

Environmental Considerations

The environmental considerations surrounding tungsten use in inertial confinement fusion (ICF) research and potential future applications are multifaceted and require careful examination. Tungsten, while offering significant advantages in ICF experiments due to its high melting point and density, also presents environmental challenges that must be addressed.

One primary concern is the potential for tungsten contamination in the environment. Although tungsten is naturally occurring, increased concentrations resulting from industrial processes or ICF experiments could lead to soil and water pollution. Studies have shown that elevated tungsten levels in soil can affect plant growth and microbial communities, potentially disrupting local ecosystems.

The mining and processing of tungsten also have environmental implications. Extraction methods can lead to habitat destruction, soil erosion, and water pollution if not properly managed. Additionally, the energy-intensive nature of tungsten production contributes to greenhouse gas emissions, further emphasizing the need for sustainable practices in its procurement and use.

Radiation safety is another critical environmental consideration in ICF research involving tungsten. While tungsten itself is not radioactive, its use in fusion experiments can lead to the production of radioactive isotopes through neutron activation. Proper containment, handling, and disposal protocols are essential to prevent environmental contamination and protect public health.

Recycling and waste management of tungsten materials used in ICF experiments present both challenges and opportunities. Developing efficient recycling processes can reduce the need for new tungsten extraction, minimizing environmental impact. However, the potential radioactivity of used materials complicates disposal and recycling efforts, necessitating specialized handling and storage solutions.

The long-term environmental effects of tungsten accumulation in the biosphere are not fully understood and require ongoing research. Some studies suggest that tungsten and its compounds may have toxic effects on certain organisms, highlighting the importance of continued environmental monitoring and risk assessment as ICF research progresses.

As ICF technology advances towards potential commercial applications, the scale of tungsten use may increase significantly. This prospect underscores the need for proactive environmental management strategies, including the development of cleaner production methods, improved recycling technologies, and comprehensive life cycle assessments of tungsten use in fusion energy systems.