Future Of Tungsten In Aerospace Applications

Tungsten Aerospace Evolution and Objectives

Tungsten has played a crucial role in aerospace applications since the early days of aviation, with its unique properties making it an indispensable material for high-performance components. The evolution of tungsten in aerospace can be traced back to the mid-20th century when it was first utilized in aircraft engines and rocket nozzles due to its exceptional heat resistance and strength at elevated temperatures.

As aerospace technology advanced, the demand for materials capable of withstanding extreme conditions grew exponentially. Tungsten's high melting point, excellent thermal conductivity, and low thermal expansion coefficient made it an ideal candidate for various critical applications. The material's journey in aerospace has been marked by continuous improvements in processing techniques, alloy development, and innovative applications.

In recent decades, the focus has shifted towards developing advanced tungsten-based composites and alloys to enhance its performance further. These developments have led to the creation of materials with improved ductility, reduced brittleness, and enhanced radiation resistance, addressing some of the inherent limitations of pure tungsten.

The current objectives for tungsten in aerospace applications are multifaceted and ambitious. One primary goal is to optimize tungsten-based materials for next-generation hypersonic vehicles, where extreme temperatures and aerodynamic stresses pose significant challenges. Researchers are working on developing tungsten alloys that can maintain structural integrity at temperatures exceeding 2000°C while resisting oxidation and erosion.

Another critical objective is to enhance the manufacturability of tungsten components, particularly through additive manufacturing techniques. This would allow for the creation of complex geometries and internal structures that were previously impossible or impractical to produce, opening up new design possibilities for aerospace engineers.

Furthermore, there is a growing emphasis on improving the sustainability and recyclability of tungsten in aerospace applications. This includes developing more efficient extraction and processing methods, as well as exploring ways to recycle and reuse tungsten from decommissioned aircraft and spacecraft components.

Looking ahead, the future of tungsten in aerospace is closely tied to the industry's push towards more efficient, lighter, and more durable aircraft and spacecraft. The material is expected to play a pivotal role in enabling technologies such as reusable launch vehicles, advanced propulsion systems, and thermal protection systems for planetary exploration missions.

Aerospace Market Demand Analysis

The aerospace industry's demand for tungsten is experiencing a significant upward trend, driven by the material's unique properties that make it indispensable in various critical applications. Tungsten's high melting point, excellent strength-to-weight ratio, and superior wear resistance make it an ideal choice for components subjected to extreme conditions in aerospace environments.

In the commercial aviation sector, the growing demand for more fuel-efficient and environmentally friendly aircraft is propelling the use of tungsten in engine components. Tungsten-based alloys are increasingly being utilized in turbine blades, combustion chambers, and nozzle guide vanes, contributing to improved engine performance and longevity. The market for these components is expected to grow steadily as airlines continue to upgrade their fleets with newer, more efficient aircraft models.

The space exploration sector is another key driver of tungsten demand in aerospace applications. As space agencies and private companies intensify their efforts to explore deep space and establish a presence on other celestial bodies, the need for materials that can withstand extreme temperatures and radiation becomes paramount. Tungsten's properties make it an excellent candidate for radiation shielding, heat shields, and propulsion system components in spacecraft and satellites.

Defense aerospace applications also contribute significantly to the market demand for tungsten. Military aircraft and missile systems rely on tungsten-based materials for armor-piercing projectiles, counterweights, and heat-resistant components. The ongoing modernization of military fleets worldwide and the development of advanced weapon systems are expected to sustain the demand for tungsten in this sector.

Emerging technologies in the aerospace industry, such as hypersonic vehicles and advanced propulsion systems, are opening up new avenues for tungsten applications. These cutting-edge developments require materials that can withstand unprecedented levels of heat and stress, further driving the demand for tungsten and its alloys.

The market for tungsten in aerospace applications is also influenced by global economic factors and geopolitical considerations. As countries invest in their aerospace industries as part of broader economic development strategies, the demand for high-performance materials like tungsten is likely to increase. Additionally, concerns over the security of supply chains and the strategic importance of critical materials may lead to increased efforts to secure stable sources of tungsten for aerospace applications.

Tungsten Tech Status and Challenges

Tungsten's application in aerospace has seen significant advancements in recent years, yet it still faces several challenges. The current status of tungsten technology in aerospace is characterized by its use in high-temperature applications, particularly in rocket nozzles, heat shields, and turbine blades. Its exceptional heat resistance and high melting point make it invaluable for these critical components.

However, the widespread adoption of tungsten in aerospace faces several hurdles. One of the primary challenges is its high density, which can significantly increase the overall weight of aerospace structures. This weight issue is particularly problematic in an industry where every gram matters for fuel efficiency and payload capacity. Engineers are constantly seeking ways to optimize tungsten alloys to reduce weight while maintaining their desirable properties.

Another significant challenge lies in tungsten's inherent brittleness at room temperature. This characteristic limits its application in certain aerospace components that require both heat resistance and impact resistance. Researchers are exploring various alloying techniques and composite materials to enhance tungsten's ductility and toughness without compromising its high-temperature performance.

The manufacturing process of tungsten components for aerospace applications also presents challenges. Traditional machining methods can be difficult and time-consuming due to tungsten's hardness. Advanced manufacturing techniques, such as powder metallurgy and additive manufacturing, are being developed to overcome these limitations, but they are still in the early stages of implementation for aerospace-grade tungsten parts.

Corrosion resistance is another area of concern, particularly in the harsh environments encountered in aerospace applications. While tungsten generally has good corrosion resistance, it can be susceptible to oxidation at high temperatures. Developing effective coatings and surface treatments to protect tungsten components in these extreme conditions remains an ongoing challenge.

From a global perspective, the development and production of aerospace-grade tungsten are concentrated in a few countries, primarily China, the United States, and Russia. This geographical concentration poses potential supply chain risks and has led to efforts to diversify sources and develop alternative materials.

Despite these challenges, ongoing research and development efforts are making strides in addressing these issues. Innovations in nanotechnology, composite materials, and advanced manufacturing processes are opening new possibilities for tungsten in aerospace applications. The future of tungsten in this sector will likely depend on overcoming these technical hurdles while leveraging its unique properties to meet the ever-increasing demands of aerospace technology.

Current Tungsten Aerospace Solutions

01 Tungsten deposition methods

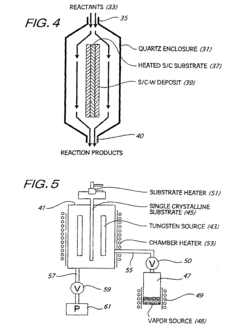

Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.- Tungsten deposition and film formation: Various methods and techniques for depositing tungsten and forming tungsten films on substrates. This includes chemical vapor deposition (CVD), physical vapor deposition (PVD), and atomic layer deposition (ALD) processes. These techniques are used to create thin, uniform tungsten layers for applications in semiconductor manufacturing and other industries.

- Tungsten etching and patterning: Processes for etching and patterning tungsten layers in semiconductor devices. This includes dry etching techniques, wet etching methods, and plasma etching processes. These techniques are used to create precise patterns and structures in tungsten films for various electronic components and integrated circuits.

- Tungsten alloys and composites: Development and production of tungsten alloys and composite materials. This includes combining tungsten with other metals or materials to enhance properties such as strength, hardness, and thermal stability. These alloys and composites find applications in aerospace, defense, and high-temperature industrial settings.

- Tungsten in electronic components: Use of tungsten in various electronic components and devices. This includes applications in transistors, capacitors, and interconnects. Tungsten's properties, such as low resistivity and high melting point, make it valuable for creating reliable and high-performance electronic components.

- Tungsten powder production and processing: Methods for producing and processing tungsten powder for various applications. This includes techniques for creating fine tungsten particles, controlling particle size distribution, and modifying surface properties. These processes are important for applications in powder metallurgy, additive manufacturing, and the production of tungsten-based components.

02 Tungsten-based alloys and composites

Development of tungsten-based alloys and composite materials with enhanced properties, such as improved strength, hardness, and thermal stability. These materials find applications in aerospace, defense, and high-temperature industrial processes.Expand Specific Solutions03 Tungsten etching and patterning

Techniques for etching and patterning tungsten layers in microelectronics fabrication, including plasma etching and chemical mechanical polishing (CMP). These processes are crucial for creating intricate circuit patterns and interconnects in semiconductor devices.Expand Specific Solutions04 Tungsten-based lighting technologies

Innovations in tungsten-based lighting technologies, including improvements in filament design, gas-filling techniques, and envelope materials. These advancements aim to enhance the efficiency and longevity of incandescent and halogen lamps.Expand Specific Solutions05 Tungsten recycling and recovery

Methods for recycling and recovering tungsten from scrap materials and industrial waste. These processes aim to reduce the environmental impact of tungsten production and conserve this valuable resource for future use in various applications.Expand Specific Solutions

Key Aerospace Tungsten Players

The aerospace industry's use of tungsten is evolving rapidly, with the market in a growth phase driven by increasing demand for high-performance materials. The global aerospace tungsten market is expanding, fueled by advancements in aircraft design and space exploration. Technologically, the field is maturing, with companies like The Boeing Co., Aerojet Rocketdyne, Inc., and General Atomics leading innovation. Research institutions such as the University of Science & Technology Beijing and Japan Aerospace Exploration Agency are contributing to technological progress. The competitive landscape is diverse, featuring established aerospace giants, specialized alloy manufacturers like Xiamen Golden Egret Special Alloy Co., Ltd., and materials technology firms such as Applied Materials, Inc., collectively pushing the boundaries of tungsten applications in aerospace.

Applied Materials, Inc.

The Boeing Co.

Innovative Tungsten Alloy Developments

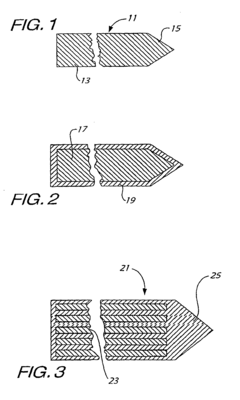

- Development of high creep strength, single crystal tungsten alloys with at least 90% tungsten alloyed with tantalum, rhenium, niobium, or molybdenum, and efficient fabrication methods using chemical vapor deposition (CVD) to create high-density penetrators with enhanced strength and ductility, meeting the U.S. Army's screening criteria.

- Development of tungsten-based alloys with improved high-temperature strength and creep resistance for aerospace applications.

- Integration of tungsten components in advanced thermal protection systems for hypersonic vehicles.

- Utilization of tungsten's high density in radiation shielding applications for space exploration missions.

Environmental Impact of Tungsten Use

The use of tungsten in aerospace applications has significant environmental implications that must be carefully considered. Tungsten mining and processing can lead to soil and water contamination, particularly due to the release of heavy metals and toxic compounds. The extraction process often involves large-scale land disturbance, potentially causing habitat destruction and biodiversity loss in mining areas.

During the manufacturing of aerospace components, tungsten processing generates hazardous waste materials that require proper disposal to prevent environmental contamination. The high energy requirements for tungsten production contribute to increased carbon emissions, impacting climate change. Additionally, the use of tungsten in aerospace applications may result in the release of fine particulates during operation, potentially affecting air quality and human health.

However, the aerospace industry is actively working to mitigate these environmental concerns. Recycling initiatives for tungsten-containing components are becoming more prevalent, reducing the need for new raw material extraction. Advanced manufacturing techniques are being developed to minimize waste and improve energy efficiency in tungsten processing.

The long lifespan and high performance of tungsten-based aerospace components contribute to improved fuel efficiency and reduced emissions over the operational life of aircraft and spacecraft. This long-term benefit may partially offset the environmental impact of initial production.

Research is ongoing into more environmentally friendly alternatives to tungsten in certain aerospace applications. However, the unique properties of tungsten make it challenging to replace entirely. As a result, efforts are focused on improving the sustainability of tungsten production and use.

The aerospace industry is also exploring ways to reduce the environmental footprint of tungsten through the development of more efficient extraction methods and cleaner production processes. These efforts include the use of renewable energy sources in manufacturing and the implementation of closed-loop systems to minimize waste and maximize resource recovery.

As environmental regulations become more stringent globally, the aerospace sector is likely to face increased pressure to address the environmental impact of tungsten use. This may drive further innovation in sustainable practices and technologies related to tungsten production and application in aerospace.

Supply Chain Resilience Strategies

In the aerospace industry, where reliability and performance are paramount, ensuring a resilient supply chain for critical materials like tungsten is essential. To address potential disruptions and maintain a steady supply of tungsten for aerospace applications, several strategies can be implemented.

Diversification of suppliers is a key approach to mitigate risks associated with geopolitical tensions, natural disasters, or economic fluctuations. By sourcing tungsten from multiple geographical locations and suppliers, aerospace companies can reduce their dependence on a single source and improve overall supply chain stability.

Vertical integration is another strategy that some aerospace manufacturers may consider. By acquiring or partnering with tungsten mining and processing companies, they can gain more control over the supply chain and ensure a consistent supply of high-quality tungsten materials.

Stockpiling is a common practice in the aerospace industry to buffer against short-term supply disruptions. Maintaining strategic reserves of tungsten and its alloys can provide a cushion during periods of supply uncertainty or sudden demand spikes.

Developing alternative materials or technologies that can partially or fully replace tungsten in certain applications is a long-term strategy to reduce dependence on this critical material. This approach requires significant investment in research and development but can lead to innovative solutions and improved supply chain resilience.

Implementing advanced supply chain management systems and leveraging data analytics can help aerospace companies better predict demand, optimize inventory levels, and identify potential supply chain risks before they materialize. This proactive approach enables more efficient resource allocation and faster response to disruptions.

Collaboration within the industry, including partnerships with suppliers, customers, and even competitors, can lead to more robust supply chain networks. Sharing best practices, coordinating procurement strategies, and jointly developing contingency plans can enhance the overall resilience of the tungsten supply chain for aerospace applications.

Lastly, engaging with policymakers to address trade barriers, promote sustainable mining practices, and support research into new tungsten sources can contribute to a more stable and resilient supply chain in the long term. This approach recognizes the strategic importance of tungsten in aerospace and aims to create a more favorable regulatory environment for its production and distribution.